ALL

ALL

DEMOLITION DISCUSSION

With Jim Tagg, Redhammer

DESTINATION DEMOLITION

Hub joins the NDA in Phoenix

It’s been a great show season so far.

For the second year, the NDA treated us to a right royal exhibition of demolition, both static and in live motion at its Demolition Phoenix event in February.

Phoenix also allowed me to socialise with the great and good of North American contractors and service providers, as well as time well spent with the EDA’s President Stefano Panseri and Secretary General Jose Blanco.

Our demolition associations run didn’t end there. We have recently become the official media partner to the Indian Demolition Association (IDA), with a duty to promote their Dem Tech event in September, as well as receiving a very kind invitation to the NFDC Awards, which was a well-run event marking out some deserved winners and nominees as well as the changing of the guard at the Federation’s top table.

Summed up, we are ever more recognised as a positive voice for the demolition industry and a true route to promoting it and those working in it.

Having said that, we can’t control the news narrative and it was with unfortunate timing the day before the NFDC’s AGM that the Competition and Markets Authority issued 10 contractors with fines following its long running investigation.

Having been with most of those named last week, it would be wrong of us to pass any judgemental comment. What’s done is done. Things must change and I am a strong believer in positives coming from a negative and that lessons will be learned.

I mentioned in a recent newsletter that we had pulled the plug on a live weekly demolition show. Frankly, there is no market for it and tying me down to commit to a particular time once a week isn’t the easiest thing. This and self-indulgent waffle just isn’t for us. We try things and if they work then great, but we also recognise what works and are able to identify if something is going great guns or is pretty lame.

You can of course watch my previous efforts, but there is much more good stuff on Demolition Hub TV, from our recent appearances in Las Vegas at both the World of Concrete and CONEXPO. Just search Demolition Hub TV on YouTube.

PUBLISHER

Ben Chambers ben@globalnews.media 01903 952 648

EDITOR

Toby Wilsdon toby@globalnews.media 01903 952 645

DEMOLITION EDITOR

Paul Argent paul@globalnews.media 07813 064 590

COLUMNISTS

Richard Dolman Jaqueline O’Donovan

Terry Lloyd

SALES

Luke Chaplin luke@globalnews.media 01903 952 643

DESIGN

Nicki Chambers nic@globalnews.media

Joe Bers joe@globalnews.media

Alex Jarrett

PRODUCED & PUBLISHED BY Global News Media Ltd

Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX ben@chambers.media 01903 952 640

Demolition Hub are proud supporters of the National Demolition Association

Demolition Hub are the media partners for the European Demolition Association & the Indian Demolition Association

Demolition Hub is published six times a year. The subscription rate is £60 per year. Subscription records are maintained at Global News Media Ltd, Suite 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX.

Ben Chambers Publisher, Demolition Hub ben@chambers.mediaArticles and information contained in this publication are the copyright of Global News Media Ltd and may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

6 NEWS

Demolition Hub announces media partnership with Indian trade body

Agg-Pro launches new website

Jacqueline O’Donovan named Business Leader of the Year at Global Irish Diaspora Award

Construction firms fined nearly £60m for bid rigging

NFDC announces change in officers

NFDC winners

Construction plant bodies respond to budget

16

EUROPEAN DEMOLITION ASSOCIATION NEWS

European Demolition Industry Report 2023 on its way

EDA Annual Convention 2023 hosts nuclear decommissioning workshop

Decontamination and demolition and industries reunited in Berlin

RILEM releases 2022 Annual Report

European Commission presents Green Deal Industrial Plan

22 NATIONAL DEMOLITION ASSOCIATION NEWS

Demolishing step by step

Back in the day...

OSHA Citation Liability 2023 – don’t miss the forest for the trees

30 DEMOLITION DISCUSSION

With Jim Tagg of Redhammer

34 FEATURE

AP Air Europe introduces Hebonilube grease pumps

36 CASE STUDY

Space in the city, by Paul Argent

38 HI-REACH EXCAVATORS FEATURE

• SANY SY500HRD

• SANY SY390H

• Cat® 340 UHD

• Sennebogen 830 Demolition

• Develon DX-7 demolition excavators

48 CASE STUDY

Brutal work, by Paul Argent

50 SUPPLIER TALK

With Rebecca Munson of Air Spectrum Environmental

54 CAREERS

Jamie Dial speaks to Demolition Hub for Careers Week

Cawarden hosts employment event with a difference

Supporting the next generation of civil engineers

The Plough Inn: A tale of heritage, demolition and recycling captured by Drone 21

MOTOFOG range from INMALO

BossTek’s duty of care

CONEXPO-CON/AGG

• Exhibitors take industry to the next level

• DEVELON debuts at CONEXPO

• engcon products turn heads in Las Vegas

• Holcim’s ECOPact Low-Carbon Concrete selected as Next Level Awards Contractors’ Choice

• Brokk

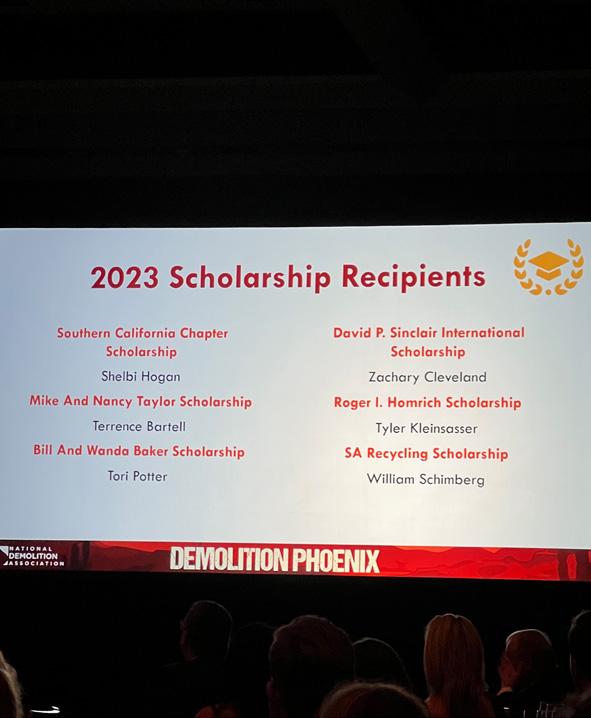

Demolition Hub at Demolition Phoenix by Ben Chambers

Down with school, by Paul Argent

Worsley Plant couples up with OilQuick Liebherr rebrands fully automatic quick coupling system Solidlink

Tele Radio PrimaTEQ: a new name for the T12 compact waist transmitter

10,000th ‘Doosan’ ADT in Norway is Europe’s first in DEVELON colours

MDiG launches online training for Machine Control

Doosan Bobcat announces global brand strategy

SANY launches new range of demolition spec machines

Fuel for thought by Richard Dolman

BIM by Jacqueline O’Donovan

Reasons to be cheerful by Terry Lloyd

Demolition Hub is delighted to announce that it is to become media partner to both the Indian Demolition Association and its DEM TECH event to be held on 28-29 September this year in Bengaluru (Bangalore), India.

Founder of Demolition Hub, Ben Chambers says: “The IDA has agreed an advertising and promotional programme with Demolition Hub recognising our positive stance on demolition, our bimonthly publication that reaches the four corners of the world and our history promoting industry associations.

“I am a big fan of working with associations and being able to spread their good news and that of their members. The Dem Tech event is set to be one of the biggest demolition expos in Asia and we cannot wait to be a part of it and work with the IDA.”

You will be able to read all about the event in the December issue of Demolition Hub magazine.

For more details on Dem Tech 2023 and the IDA please go to: IndianDemolition.org or DemTech.in.

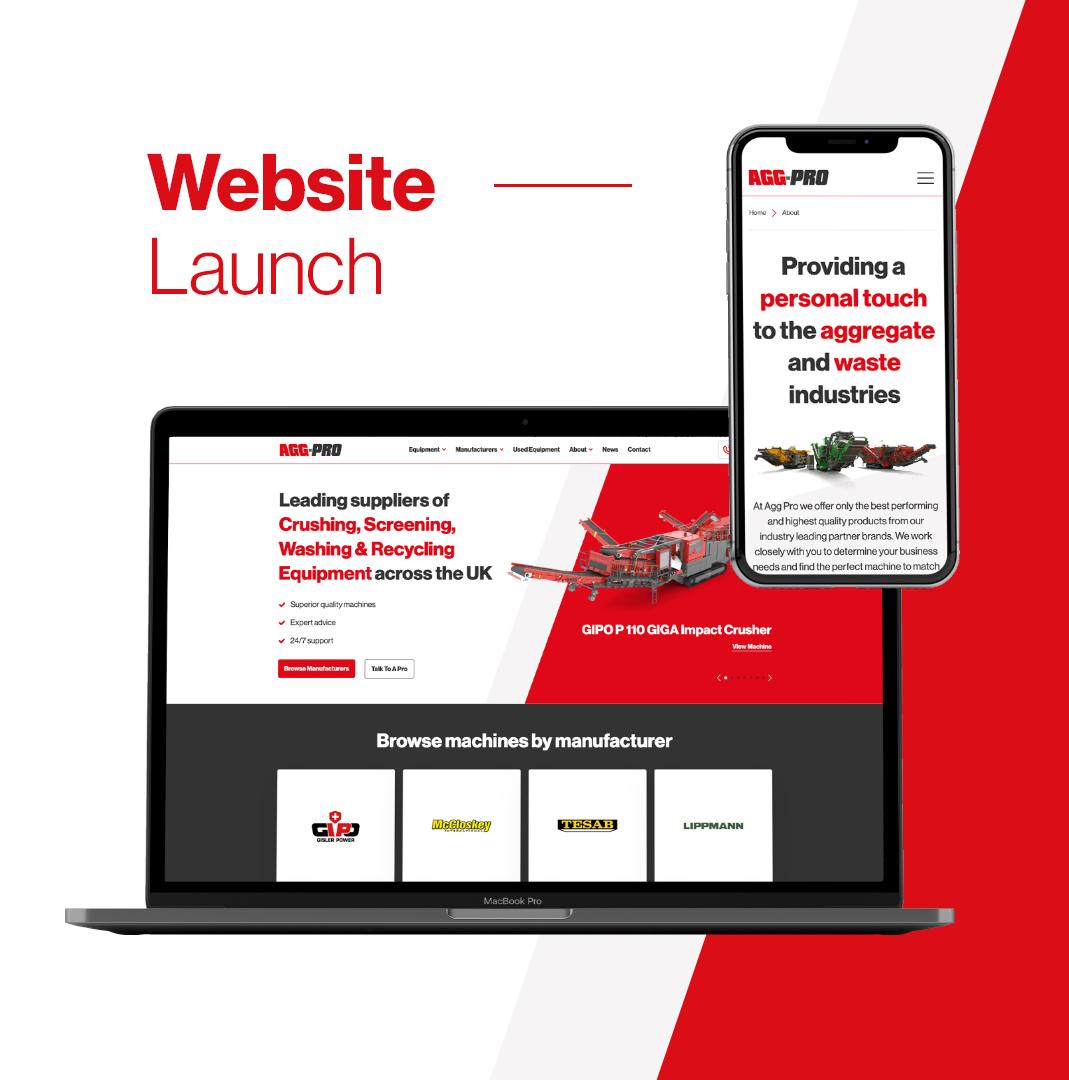

Agg-Pro, one of the UK’s leading suppliers of crushing, screening, washing and recycling equipment, is excited to announce the launch of its new website, www.agg-pro.com.

The new website has been designed with the customer in mind and features include a bespoke product filtering system, WhatsApp integration for easy communication with the team, and a mobile friendly design.

The highly visual website helps to showcase the company’s wide range of superior equipment and has been designed to grow with the business as they continue to add to their product portfolio.

Steve Peterson, Commercial Director at Agg-Pro said: “We are currently experiencing an exciting period of growth and we wanted to develop a new website which showcases our product offering and allows our customers old and new to better understand who we are.

“We are proud of our reputation for excellent customer service and our highly experienced team offer innovative solutions and create

long-standing and collaborative partnerships with our customers, and we wanted our new website to help reflect this.”

Agg-Pro was established in 1996 to provide a personal, customer focussed approach to the supply of equipment for the quarrying and recycling industries. Its head office in Tamworth includes a 3,700 m3 premises incorporating a factory for refurbishments and employs 34 people.

hotel in central London.

Jacqueline, who has strong West Cork roots, is a passionate, driven and successful businesswoman who has not only made the family business a resounding success but has worked hard over the years as a visionary leader and innovator, influencing and improving the industry as a whole.

Jacqueline is also a dedicated supporter of the Irish community in the UK and is involved in a number of projects, most recently funding the launch of an Irish archive at the London Irish Centre. The archive will preserve the history of the stories, letters, tapes and recordings of Irish emigrants who travelled to the UK, known as the men who built Britain, for generations to come.

Jacqueline O’Donovan, the

Managing Director of

has done it again, being honoured at the inaugural Business Post Global Irish Diaspora Awards in London.

Known for being a disrupter and innovator in the construction and waste sector, not only in the UK but in Ireland and the USA, Jacqueline was awarded the Business Leader of the Year title at the glittering event.

With more than 70 million people across the globe having Irish ancestral links, the awards have been established to recognise and celebrate the vast contribution to the world of business that Ireland and its people have made. The first ever Global Diaspora Awards ceremony celebrated the achievements and accomplishments of the Irish diaspora worldwide across 12 nominated categories and was held at the acclaimed Waldorf Hilton

Jacqueline said: “It is a massive privilege to win this esteemed award and it is an honour to be recognised for my skills, commitment and passion to business and doing what I love.”

Jacqueline O’Donovan“It is a massive privilege to win this esteemed award and it is an honour to be recognised for my skills, commitment and passion to business and doing what I love”Demolition Hub columnist trailblazing O’Donovan Waste

of these contracts and not every contractor who submitted a bid for these contracts was involved in the illegal collusion.

Following an investigation by the Competition and Markets Authority (CMA), 10 UK-based construction firms have been fined a total of £59,334,957 for colluding on prices through illegal cartel agreements when submitting bids in competitive tenders for contracts. These bids were rigged, deceiving the customer that they were competitive when that was not the case. Each of the 10 firms was involved in at least one instance of bid rigging between January 2013 and June 2018.

The fines for each are: Brown and Mason (£2,400,000), Cantillon (£1,920,000), Clifford Devlin (£423,615), DSM (£1,400,000), Erith (£17,568,800), JF Hunt (£5,600,000), Keltbray (£16,000,000), McGee (£3,766,278), Scudder (£8,256,264) and Squibb (£2,000,000).

Brown and Mason, Cantillon, Clifford Devlin, DSM, John F Hunt, Keltbray, McGee and Scudder were handed reduced fines as settling parties who had, as announced in June last year, admitted their involvement in the cartel activity.

The CMA has secured the disqualification of three directors of companies involved in the unlawful conduct. These are David Darsey (formerly a director of Erith) for a period of five years and ten months from 2 February 2023, Michael Cantillon (formerly a director of Cantillon) for seven years and six months and Paul Cluskey

(current director of Cantillon) for four years and six months. Each of these directors has benefited from reduced disqualification periods, having voluntarily agreed to the disqualification by way of undertakings to the CMA.

The bids were rigged by one or more of the construction firms agreeing to submit bids that were deliberately priced to lose the tender. This practice, known as cover bidding, can result in customers paying higher prices or receiving lower quality services.

In addition, the CMA found that five of the firms, on at least one occasion each, were involved in arrangements by which the designated “losers” of the contracts were set to be compensated by the winner. The value of this compensation varied but was higher than £500,000 in one instance. Some firms produced false invoices to hide this part of the illegal behaviour.

The CMA found that the instances of illegal collusion took place over a five-year period and affected 19 contracts for demolition work in London, the south-east, and the Midlands.

Public and private sector contracts impacted included the development of Bow Street Magistrates Court and Police station, the Metropolitan Police training centre in Hendon, Selfridges (London), properties belonging to Oxford and Coventry Universities, shopping centres in Reading and Taplow, a large office block on London’s Southbank and other sites in central London. Not all the firms were involved in colluding in each

Michael Grenfell, the CMA’s Executive Director for Enforcement, said: “The construction sector is key to our country’s prosperity, so we want to see a competitive marketplace delivering value, innovation, and quality.

“Today’s significant fines show that the CMA continues to crack down on illegal cartel behaviour. It should serve as a clear warning: the CMA will not tolerate unlawful conduct which weakens competition and keeps prices up at the expense of businesses and taxpayers.

“We have also secured the disqualification of certain company directors involved. Company directors must understand that they have personal responsibility for ensuring that their companies comply with competition law, and that disqualification may follow if they fail to do so.”

The CMA’s decision follows a complex and large-scale investigation, opened in 2019. The CMA conducted unannounced inspections of 15 business premises, interviewed 35 people, served over 120 notices requiring the provision of information or documents and undertook a detailed review of emails, mobile phone communications and financial records relating to the parties.

The CMA’s Cheating or Competing campaign has advice for businesses to help them spot, report and deter illegal anti-competitive practices such as market sharing, fixing prices and bid-rigging. The CMA has also issued a range of guidance to help businesses and directors understand more about how to comply with competition law.

The National Federation of Demolition Contractors [NFDC] announced a change in officers at its AGM on Friday 24 March, having appointed a new CEO, President, and 2nd Vice President.

Having led the Federation for nearly 20 years, Howard Button will be officially stepping down as CEO from June 2023. During his impressive tenure, Howard has played an integral role for the progression of the NFDC, where he has leveraged his own extensive onsite demolition career to spearhead multiple initiatives for the benefit of the entire industry. Howard will be continuing to support the Federation as National Secretary.

Taking over Howard’s role as CEO is Duncan Rudall, previous London and Southern Counties Regional Chairman of the NFDC and President of the Institute of Demolition Engineers (IDE). Boasting extensive experience within the demolition sector, Duncan has made significant contributions to building the image of demolition as a highly skilled, specialist trade, which he will continue to build on as new CEO while driving the Federation forwards.

Joining Duncan in leading the NFDC will be John Lynch, newly appointed President,

with Gary Bishop, remaining Vice President, and Simon Barlow appointed as 2nd Vice President.

With nearly 50 years’ experience in the sector, John Lynch has seen the industry evolve significantly. Having already been integral in a number of important projects for the Federation during his time as 2nd Vice-President, John’s key priority for his presidency is to continue to raise the profile of the NFDC and see its membership grow.

A proven and trusted business leader with extensive experience in the demolition sector, Simon is the Managing Director of Rye Group, a leading provider of demolition, remediation and ground and enabling works. Previously Chair of the London and Southern Counties region for NFDC, Simon now plans to champion the importance of sustainability in his new position as 2nd Vice President of the organisation, while also bringing to the forefront the talent and skills crisis and other key issues that sit across both the demolition and construction industries.

Discussing the new change in officers, incoming President, John Lynch said: “I am honoured to have been appointed President of the NFDC. Having been part of the industry for 50 years, I have seen the Federation

evolve significantly during this timeframe and play a vital role in shaping industry standards and ensuring maximum safety on sites throughout the UK. As the sector continues to evolve, respond to new challenges, and move into a new era, I look forward to working closely with Duncan, Gary, Simon and the rest of the leadership team and in ensuring continued and positive progression for the Federation.

“Finally, I would like to extend my sincere gratitude to Howard. His dedication to both the NFDC and demolition industry as a whole is nothing short of impressive and I am grateful that he will continue to support us as National Secretary in the coming years.”

The NFDC’s AGM concluded with several important announcements including the donation of £100,000 to charitable causes over the last 12 months, together with an update of activity from the NDTG, which included a record intake of Trailblazer Demolition Apprentices.

Held at the Royal Lancaster, the NFDC AGM was extremely well attended by both contractor members and industry service provider [ISP] members and was followed by its annual NFDC awards ceremony.

On Friday 24 March the NFDC announced the winners and highly commended nominees for the 2023 NFDC awards at its annual ceremony – held at the Royal Lancaster Hotel in London

Apprentice, Labourer, or DRO of the Year

Sponsored by CITB

Winner: Jamie Dial – Cawarden

Highly Commended: Tommy Rawlinson – Erith Contractors

Highly Commended: Kamal Radji – Clifford Devlin

Manager of the Year

Sponsored by NDTG

Winner: Rikki Isgar – Brown and Mason Group

Highly Commended: Paul Turbitt – Thompsons of Prudhoe

Highly Commended: Alex Deysell – Clifford Devlin

Highly Commended: Peter Edgerton – Tilley & Barrett

Winner: New Era Fuels

ADO, Chargehand, or Supervisor of the Year

Sponsored by NDTG Scotland

Winner: Mark Davison – MGL Demolition

Highly Commended: Kevin Slegg – Clifford Devlin

Highly Commended: Josh Sandford – Wring Group

Highly Commended: Evaldas Dovydavicius – McGee Group

Plant Operator of the Year

Sponsored by NOCN

Winner: Gabriel Forde – McGee Group

Highly Commended: Dave Welsh – MGL Demolition

Highly Commended: Sean Ellery – R Collard

Highly Commended: SMH Products

Winner: John Lynch – Newline Midlands

National Council awarded John Lynch of Newline Midlands the Outstanding Contribution award in recognition of his pivotal role in the relocation of NFDC and NDTG to a new head office.

John was the driving force in the sourcing of a new property, arranging the sale of the old offices, overseeing the purchasing process, as well as the subsequent fit out of the new office to ensure it was perfectly tailored to the needs of the Federation and Training Group.

by Suneeta Johal, Chief Executive of the CEA

by Suneeta Johal, Chief Executive of the CEA

funding to support a range of interventions including skills, infrastructure, tax relief, and business rates retention, particularly after the delays to HS2 announced last week. Although investment funding is subject to application, where “an area must identify a location where it can offer a bold and imaginative partnership between local government and university or research institutes in a way that catalyses new innovation clusters”, it does offer an excellent opportunity for collaboration and innovation.

Hunt claimed “longterm, sustainable, healthy growth” and said the government would deliver 12 new investment zones, which he labelled “12 potential Canary Wharfs”

Although there were no great surprises from Jeremy Hunt’s Spring Statement – as many of the announcements were leaked earlier this week, there were some positive announcements that will boost productivity within the construction sector.

Hunt claimed that this budget was for “long-term, sustainable, healthy growth” and said the government would deliver 12 new investment zones, which he labelled “12 potential Canary Wharfs”.

The CEA welcomes this announcement and the £80bn

Another positive announcement was the new £9bn policy of “full capital expensing” for the next three years, which is to be saluted. Although currently a welcome shortterm boost for business investment as we see the end of the super deduction this month, we hope to see Hunt follow through on his aim to make it permanent to encourage investment and provide stability in the long term. Hunt says the OBR believes this will boost business tax by 3% a year.

Hunt said: “I can announce we will introduce a new policy of full capital expensing for the next three years with an intention to make it permanent especially can responsibly do so that means that every single pound the company invests in IT equipment plant or machinery can be deducted.”

A new enhanced credit for research-intensive businesses, worth £27 for every £100 it invests is a great incentive for start-up companies investing in R&D. A qualifying small or medium-sized business must spend 40% or more of its total expenditure on R&D.

The extension of the climate change agreement scheme for two years was another welcome move to allow eligible businesses £600m of tax relief for energy efficiency measures, particularly important as

Jeremy Hunt brandishes the iconic red box

Suneeta Johal, Chief Executive of the CEA

Jeremy Hunt brandishes the iconic red box

Suneeta Johal, Chief Executive of the CEA

we head down the road to net zero.

The fuel duty freeze is also well received and will be of great benefit to the construction and infrastructure sectors. Hunt said: “For a further 12 months I’m going to maintain the 5p cut and I’m going to freeze fuel duty too.”

The business tax hike was confirmed, with Hunt keeping the planned increase in corporation tax from 19% to 25% in April despite opposition from some Tory MPs. The Chancellor’s predecessor Kwasi Kwarteng had attempted to scrap the hike at the disastrous minibudget in 2022, but there was a U-turn after financial turmoil.

Hunt set out four pillars of industrial strategy – Enterprise, Employment, Education and Everywhere – saying he had already allocated nearly £4bn in more than 200 projects across the country through the first two rounds of the Levelling Up Fund with a third round to follow, another welcome announcement.

While the CEA welcomes the announcement of more places on “skills boot camps” to encourage over-50s who have left their jobs to return to the workplace, it is not the silver bullet we were hoping to fill the chronic skills gap in our sector. We need more tangible solutions and partnerships to tackle the shortfall.

by Kevin Minton, Chief Executive of the CPA

by Kevin Minton, Chief Executive of the CPA

commitments from government on future infrastructure spending and projects. Proposals in the budget to create Great British Nuclear, while welcome, do not provide immediate comfort to the construction sector, given these plans are medium to long-term goals. However, we hope plans to provide the Carbon Capture Usage and Storage scheme with its £20bn fund, could provide some level of confidence for infrastructure planning.

The construction sector may welcome the Chancellor’s plans to attract over 50s to the workplace to help address the skills shortfall the industry is facing. However, this new scheme must complement existing initiatives already in place.

Steps to boost business investment and maintain the freeze on fuel duty are welcome. However, we are seeking clarification from the Treasury on the details around the successor to the super-deduction allowance (SDA), and whether the plant-hire sector can qualify for this new scheme.

Following the announcements on the delay to HS2 last week, a budget for growth needs firm

Kevin Minton, Chief Executive of the CPA Chancellor of the Exchequer, Jeremy Huntcompanies and entities related to demolition, providing a global vision of the European demolition sector and tools for greater visibility and recognition of demolition.

As the EDA Annual Convention 2023 is getting closer, the Association is finishing up the last details regarding the professional programme of the event. Speakers from all around Europe will be gathering in Amsterdam to share their knowledge and ideas about a variety of topics.

Among the special activities, EDA is very excited to announce that a special workshop will take place during the convention. Titled “Global status of nuclear decommissioning and related HR development and supply chain considerations“, it will take place on the morning of 15 June, right before the professional programme.

The European Demolition Association, EDA, is proud to announce that the online survey for the latest edition of the European Demolition Industry Report is open.

The study collects the latest data about the demolition industry to give a cohesive overview and some forecasts about the sector. It also allows us to track the evolution of the demolition industry on an international level, information that is incredibly valuable to industry professionals.

The survey generates a reference document for

It consists of separate five-minute surveys for contractors and suppliers, with the answers being completely anonymous. Both EDA members and non-members companies can participate in the study.

Answers to the survey can be submitted until 30 April 2023. All companies that take part in the study will have unlimited access to the Industry Report, otherwise restricted to EDA members. The expected release date for the European Demolition Industry Report is June 2023.

Contractors: www.surveymonkey.com/r/ Con_EN

Suppliers: www.surveymonkey.com/r/ SupEN

For the workshop Vladimir Michal, Team leader (D&ER) Waste Technology Section of the International Atomic Energy Agency, and Johan D’Hooghe, CEO of RECYCLING ASSISTANCE BVBA, are the main speakers.

Throughout this activity, various topics related to nuclear decommissioning will be discussed. The speakers will give a global overview of the current state of affairs, followed by the specific conclusions of the IAEA Decommissioning conference on supply chain and technology innovations, which will take place from 15 to 19 May.

Examples of contractual and implementation practices, including those on demolition within nuclear decommissioning projects, will accompany the workshop.

This activity has a limited number of seats and the additional registration is required. The fee includes access to the workshop, as well as the lunch, which will take place afterwards.

Demolition Hub is the media partner for the European Demolition Association

Demolition Hub is the media partner for the European Demolition Association

DAY 1 - 19 TH APRIL @ 8:00AM

Lambourn Business Park, Lambourn Woodlands, Hungerford, RG17 7RY

DAY 2 - 20 TH APRIL @ 8:00AM (TIMED

Contractors Plant Hire, Skates Farm, Pamber Green, Tadley, Hampshire, RG26 3AB

choice

Featuring a selection of excavators, dumpers, telehandlers, rollers & more! View website for full stock list.

Want to know more? Contact David Betts on +44 7834 600 040 or dbetts@euroauctions.com

www.euroauctions.com www.euroauctions.com

2019 Manitou MT1440 Easy - choice

2018 Manitou MT932 Easy

18-21 Kubota U10-3 - choice

13-22 Bomag BW100ADM-5 - choice

2021 Wacker Neuson DW30 - choice

17-22 Kubota KX080-4 - choice

2022 Wacker Neuson DV90 - choice

2012 JCB 520-40 - choice 2013 Bobcat S510

13-21 Bomag BW120AD-5 -

2017 Hitachi ZX130LCN-6 - choice

19-22 Kubota KX016-4 - choice

2022 Kubota U17-3A - choice

17-22 Kubota U27-4 - choice

17-20 Kubota U48-4 - choice

2022 Kubota U50-5 - choice

2019 Manitou MT1440 Easy - choice

2018 Manitou MT932 Easy

18-21 Kubota U10-3 - choice

13-22 Bomag BW100ADM-5 - choice

2021 Wacker Neuson DW30 - choice

17-22 Kubota KX080-4 - choice

2022 Wacker Neuson DV90 - choice

2012 JCB 520-40 - choice 2013 Bobcat S510

13-21 Bomag BW120AD-5 -

2017 Hitachi ZX130LCN-6 - choice

19-22 Kubota KX016-4 - choice

2022 Kubota U17-3A - choice

17-22 Kubota U27-4 - choice

17-20 Kubota U48-4 - choice

2022 Kubota U50-5 - choice

As more and more face-to-face activities take place post-Covid, companies, administrations and national associations are taking the opportunity to get together and enjoy the experience of on-site events.

Welcoming the beginning of spring, the German demolition association, DEUTSCHER ABBRUCHVERBAND (DA), held its annual event: FACHTAGUNG ABBRUCH 2023.

The convention, which took place in Berlin on 3 March, reunited demolition professionals from all around Europe. Attendance was outstanding, with over 1,200 participants and 117

exhibitors travelling to the German capital to discuss the current state of the industry.

This FACHTAGUNG ABBRUCH marked the return of the convention, having last taken place in 2020 right before the Covid-19 pandemic. Hence, when it was finally announced, industry professionals were over the moon with excitement.

Companies such as ACDE, GENESIS, INDECO, Lehnhoff, Lieherr, Rammer and MBI Group had stands at the convention. As for the association itself, the EDA

The International Union of Laboratories and Experts in Construction Materials, Systems, and Structures, RILEM, has just released its 2022 Annual Report.

Among its pages, you can find the 2022 key numbers and many more features of the association

related to last year. It is interesting to read the editorial of the publication by RILEM President Dr Nicolas Roussel about inclusivity.

The EDA and RILEM have an institutional collaboration agreement signed and they usually work together in the promotion of

Yearbook 2022, as well as the EDI Special Publication 2022, made an appearance.

These events are a unique opportunity to get together and meet in person with our members, so we’d like to give our appreciation to the DA for organising the convention and to our associates, for attending.

their projects. The report can be found here:

www.europeandemolition.org/ cms/files/2023161426_rilemar2022-bd.pdf

Demolition Hub is the media partner for the European Demolition Association

Announced by the President of the European Commission, Ursula von der Leyen in her speech at the World Economic Forum in January, this most recent measure aims to bet on clean-tech investment and continue the EU’s path towards climate neutrality.

“We have a once in a generation opportunity to show the way with speed, ambition and a sense of purpose to secure the

EU’s industrial lead in the fastgrowing net-zero technology sector,” von der Leyen explained. “Europe is determined to lead the clean tech revolution.”

The Green Deal Industrial Plan is based upon four pillars. First, it seeks a simplified regulatory framework, allowing for a faster and better promotion of European strategic projects. This will be accompanied by the Critical Raw Material Acts, which ensures sufficient access to the vital materials for these industries.

The plan aims to accelerate investment and funding for clean tech production in Europe. Using competition policy, the Commission seeks to level the playing field in those markets, while making it easier for companies to receive the necessary funding.

Another measure introduced

is the European Year of Skills. Understanding that at least 35% of all jobs will be affected by this transition, the European Commission has a goal of providing education and skill development of workers by establishing Net-Zero Industry Academies.

Finally, global cooperation and making trade work will play a vital part in the Green Deal Industrial Plan. Climate neutrality can only be achieved by fair competition, engagement with EU´s partners and collaboration with World Trade Organization.

To this end, initiatives such as the EU’s network of Free Trade Agreement and Critical Raw Materials Club will take a front seat in its policies moving forward.

The Green Deal Industrial Plan was presented by the Commission in December 2019 and has been in active development ever since. It’s one of many policies whose goal is transforming EU into the first climate-neutral continent by 2050.

The complete version of the Green Deal Industrial Plan is available via the European Commission website:

https://ec.europa.eu/commission/ presscorner/detail/en/ip_23_510

European Commission presents Green Deal Industrial Plan

President of the European Commission, Ursula von der Leyen

European Commission presents Green Deal Industrial Plan

President of the European Commission, Ursula von der Leyen

Our automatic grease pumps are designed to ensure that the right amount of lubricant gets applied throughout the lifetime of your equipment. The automatic distribution of the lubricant is more efficient than manual greasing as it applies grease at a more frequent interval. This will increase your productivity and reduce your downtime significantly.

Reduced repair costs

Increased productivity by reducing vehicle downtime

Works with all standard EP2 grease

Higher residual value of machine

Reduced grease consumption

Improved safety

Pump and pause time fully controllable

We offer a full range of Hebonilube automatic grease pump systems in 12V 2nd 26, available For next day delivery across mainland UK 2nd keep 2kg, 4kg, 6kg and 8kg pumps in stock.

From prep work to teardown to cleanup, demolishing a multistorey building takes a lot of planning and careful execution. Factor in a downtown location, high-traffic roadways and close proximity to a major public transit station and you have quite the task.

For NDA member Adamo Group, the demolition of a sevenstorey office/mixed-use building in downtown Detroit had to be a meticulously planned project. With input from the property’s new owner, Buildtech Ltd, the Adamo team developed an 11-step demolition strategy that would allow for a timely demolition with the least amount of disruptions to businesses and traffic flow around the area.

“Adamo’s approach to the demolition entailed several steps,” says Brian Haller, Adamo Project Manager and Estimator. “This included protection of the surrounding buildings, to the closure of roadway and parking lanes surrounding the site to pedestrian traffic control and actual building demolition.”

Kicking off in June 2022, crews began implementing the first two steps of the strategy, which entailed installing fencing and signage, closing sidewalks, and protecting the roof and siding of the building adjacent to the demolition site. Crews then started hand demolishing block walls and

parapets in close proximity to adjacent active buildings. Shortly after this step was complete, traffic control and barricades were installed and the high reach was brought in so demolition work could begin in early July.

“We used a CAT 385 UHD with a multiprocessor to piece the building down safely from the top down,” Haller says. “Several support machines were also utilised, including CAT 336, CAT 349 and CAT 325 excavators equipped with various tools such as pulverisers, buckets and grapples.”

The demolition took approximately 10 days and, in the following weeks, the Adamo crew saw through the remaining steps, which included site cleanup, material removal and backfill.

While the demolition went seamlessly, there were a few challenges the Adamo crew had to account for that could have delayed multiple steps in their demolition plan. While the building has sat idle on the corner of Michigan Avenue and Washington Boulevard for years, its surroundings continued to experience the hustle and bustle of a major city.

“The height of the building and proximity to high traffic roadways were a challenge,” Haller says. “The building being demolished was less than 18 inches (45 cm) away from a building that is part of the transit

system and houses a major bus depot, as well as the People Mover (Detroit’s elevated railway system) maintenance facility.”

Additionally, the demolition area was located on two major bus routes and a five-lane, major thoroughfare for the city. To address the challenges brought on by the location and keep the project on schedule, the Adamo team worked with city agencies, utility companies and the building owner through all stages of the demolition.

“Addressing the location challenges entailed a large amount of planning, permitting and coordination with city agencies,” Haller says. “We also worked with the owner and utility companies who were performing work on adjacent streets during the demolition.”

Having wrapped up in September 2022, Adamo considers the project a great success. It was completed ahead of schedule, within the project budget and with zero incidents or injuries.

Adamo’s Steps to Demolition Success at 1101 Washington Blvd

• Install site fencing and signage, including required sidewalk closures,

• Protect roof and siding of adjacent building,

• Hand demolish block walls and parapets adjacent to the remaining active building,

• Install traffic control and barricades to close one lane of traffic on two sides of the building,

• Demolish the building down to basement slab,

• Process, sort and load out debris for disposal and recycling,

• Relocate fence back onto site and reopen surrounding driving lanes,

• Backfill the building basement back to grade,

• Demolish site and remove surrounding sidewalks and parking lot,

• Perform final site sweep up and equipment demobilisation,

• Remove fence and barricade and turn the site over to the owner.

Demolition Hub is a proud supporter of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us

In recognition of NDA’s upcoming 50th anniversary in August of this year, we are connecting with past leaders and other important figures in the NDA’s history to hear their perspectives on the industry and association. We caught up with Leonard Cherry, a past member of the NDA board and 2019 NDA Lifetime Achievement Award winner.

QWhat is the history of Cherry Companies, and how did you get involved in NDA?

Our parents started a house moving company that was incorporated in the early 1950s. They had four sons, of which I’m number two, and, for the most part, us four boys were my dad’s crew. My mom did the books. We did hand demolition, tearing down garages and that sort of thing. Sometimes we moved a house or a structure, which was picking up the wood frame house and moving it from point A to point B.

But that was a relatively small industry, and our growth was limited, so we began looking for other things to do. As each of us boys came out of high school, we noticed that only one out of every 20 houses we looked at to move were actually movable; the other 19 got demolished. We said: “Well, tearing them down can’t be that hard compared to moving them,” so we

began estimating demolition.

I was doing this while I had a full-time job at the Houston Fire Department. We lost money on our first two demolition jobs. My dad informed me if we didn’t make money on the third house demolition, we were going to be bankrupt. Thank god we made $100.

We come from a very humble background and beginnings. Our demolition business continued to grow because opportunities by volume were greater in demolition than they were in house moving. We started by sharing assets, manpower and equipment between house moving and demolition. Consequently, our first demo jobs were using winch trucks and cabled-up trailers that don’t even exist anymore. It was shared equipment that we could use in both companies.

As the demolition business grew, we were encouraged by one of the

larger demolition contractors here in Houston to get involved in the then-called NADC because what we had begun doing was subcontracting demolition work from the larger demolition companies. They really didn’t want to fool with tearing down houses and small commercial buildings. They wanted larger projects and we were perfectly fine making a living on those smaller opportunities.

QDo you remember the first NDA convention you attended? How did your involvement evolve?

One of my brothers and I attended the first convention for us, which was in the mid-1980s in New Orleans. We were blown away. We had never seen excavators used in the demolition application before until we went there. We walked out of there and bought our first excavator. Watching that transition

2019 NDA lifetime Achievement Award winner, Leonard Cherryof heavy equipment application, and that technology of attachments — what we saw back in the mid-1980s to what we see now is something completely different.

At that point, we were involved in a state-wide house moving association and we had found real value. We thought, and were correct in our thinking, that NDA would help us grow our business. From that first convention, we continued to attend regularly. I think I went on the board of directors in the late 1980s, probably five or six years later. I went on the executive board in the early 1990s, and then went through committee chairs through 2003.

QWhat can you tell me about your time on the NDA leadership team in those earlier years?

The association was certainly smaller at that time but very close-knit. The majority of the companies then, even more so than now, were family owned and operated by local or regional contractors. There were very few contractors that expanded beyond their own state lines.

This made it very easy for the sharing of information. If you’re never going to compete with each other, than you’re happy to share, so you don’t have to make the same mistakes I do. There’s a curve that goes with that process. You gain information and knowledge, and then you pay it back or pay it forward to the generation that’s coming behind you. We were very fortunate to ride that cycle both ways.

The biggest challenges we initially

had were recognition as the voice of the industry. We focused a lot on both the federal and state level, on gaining credibility as the trade association that represented the demolition industry.

The second biggest challenge was the growth of safety, with environmental and asbestos, etc. The Environmental Protection Agency was in its early stages when we first became involved, but environmental and safety concerns were growing.

QDuring the recession in the early 1990s, did the economy play into how your business or NDA operated?

The economy is cyclical and I’m a firm believer that history does repeat itself. There’s nothing from an economic driver perspective you’ve probably not experienced that I haven’t experienced, I’ve just experienced it more often than you.

You would see as the economies thrived, our membership would increase, our revenue stream would be greater, our attendees for conventions would always be higher. Consequently, we had more revenue to work with for the next year to work on issues within the industry. When the economy was slow, our revenue stream was down.

QWhat is your biggest takeaway from being involved in NDA and this industry?

The recognition that there is truly the ability to be friendly competitors in this industry. I was initially impressed to see family owned businesses that had children working for

competitors, or for other companies in other areas of the country. You’d have family members from California working with companies in Chicago. Even if you didn’t exchange children, for the betterment of the industry as a whole, and the improvement of your individual company, there were always open lines of communication relative to processes and procedures that would make us safer, more efficient or environmentally compliant. That was always the core that held the group together.

QWhat does your involvement look like now?

My wife and I sold our business two and a half years ago to a Fortune 500 company. I’m completely retired from that business. I’ve opened up another business because I’m still under a noncompete.

Much like our family had diversified from house moving and still retains that business line to demolition, we found that same model to be true with the successful demolition companies. The majority were diversified or in the process of diversifying. Whether you were into salvage sales back then, or operating your own landfills, or recycling, or environmental and asbestos abatement, the process from the mid 1980s until the time I left was constantly evolving.

When we sold, we did a fair amount of demolition work, but we were also the largest recycler in the state of Texas. The Fortune 500 company that bought us did so not because of our demolition expertise but because of the fact that we were green and we liked hugging trees.

Demolition Hub is a proud supporter of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us

Frequently, because of the foregoing factors, an employer may receive a citation that:

It is important to have a clear vision of the potential legal and other negative consequences that can arise from receiving an Occupational Safety and Health Administration (OSHA) citation in 2023 and beyond. Most employers are likely unaware that OSHA has emerged from the pandemic with a number of structural changes, not the least of which is a very aggressive campaign to replace significant manpower losses of experienced personnel, many of whom were the baby boomers who formed the original cadre of the agency.

What does this mean in terms of future enforcement and the potential for receiving a citation and whether the employer should challenge it? As these new OSHA compliance officers began to

conduct their initial inspections, employers can expect that many inspections will be conducted in a cursory or incomplete manner because the compliance officer:

• Lacks experience in how to conduct a proper inspection either on-site or virtually,

• Lacks the substantive understanding and knowledge regarding the scope and interpretations of the underlying regulations and recognised industry safe practices,

• Lacks experience with the many elements necessary to establish an OSHA citation and a misguided sense that the mere occurrence of an “accident” or “employee injury” is all the evidence necessary to establish a citation.

• Has no factual foundation – i.e., the citation lacks a credible factual basis for the alleged violation description (AVD) as to how the employer allegedly committed the violation or the underlying incident actually occurred,

• Has no legal foundation – that is, the regulation does not apply to the underlying factual scenario in the AVD; for example, confusing the requirements for machine guarding with lockout/tagout (LOTO),

• Has no factual or legal foundation.

In addition, because of the foregoing factors, the compliance officers (and perhaps their supervisors) frequently may not consider that the employer may have bona fide defences to the issuance of any citation either due to lack of knowledge or experience in assessing the factual information

Adam R Young

Mark

A Lies II

Adam R Young

Mark

A Lies II

that is forthcoming from the inspection, including:

• A citation is time-barred by the statute of limitations – that is, the citation was not issued within six months from when the alleged violation actually occurred, not when OSHA learns about it,

• Unavoidable employee misconduct is the cause of the alleged violation – that is, the employer took all reasonable and feasible actions to avoid the violation from occurring,

• Strict compliance with the regulation is simply not feasible from either existing technology or economically and the employer has developed equally effective alternative means to comply.

Once the employer receives a citation, the clock starts running on the day following actual service of the citation and if the employer does not reach a satisfactory settlement or files a written notice of contest by the close of business on the 15th working day after service, the citation becomes final, the employer can no longer contest and the employer must abate the citations, whether or not there was any violation in the first place. Note: This timeframe may vary in a non-federal (state plan) OSHA jurisdiction. Thus, the employer will have to conduct a timely investigation of the citation to determine:

• Whether the violation occurred,

• Whether the classification of the violation is appropriate (nonserious, serious, repeat, wilful),

• Whether the penalty is based upon consideration of all the facts,

• Whether abatement is feasible.

We often hear this scenario where an employer decides not to contest a citation that may have a monetary penalty that appears nominal, without considering that there are many additional negative liabilities that must be considered and the employer later regrets taking such peremptory action.

Before deciding to accept a citation based on the assessment of the penalty, an employer must consider the following negative consequences in a typical scenario. Your company has just received a set of federal OSHA citations. A typical set of citations may have a total penalty of $15,000 to $30,000. You have 15 working days from the date of receipt to contest or appeal the citations, or they will automatically become final. You are considering attending an informal conference with OSHA and accepting the citations to “put them behind you” because of the rather nominal proposed penalty. Putting citations “behind you” may set the company up for additional highergravity citations, greater penalties, criminal liability and lost business down the road. Employers often fail to appreciate the numerous adverse legal and negative business consequences of accepting a set of OSHA citations. In the long term, an employer often will be better served

by contesting the citations (especially those to which it has strong defences) and reaching a settlement with exculpatory, non-admission language that protects the company in collateral litigation.

OSHA citations are public records and are made publicly available. All OSHA inspections, citations and failure to contest are publicly available on OSHA’s Establishment Search website. As the name suggests, the website is searchable by employer name and location. The Establishment Search identifies the classification, regulation and status of any citation. State plans (23 states where state agencies enforce occupational safety and health for private employers) may choose to upload additional factual information to that listing.

OSHA issues press releases relating to many citations where the agency often alleges unsafe acts and failures by the employer. The Obama and Biden administrations have used this press release tool more often, allegedly to “shame” employers and amplify the effects of the agency’s limited enforcement resources. Press releases can be widely reviewed and result in lost business opportunities, jeopardising existing relationships with business partners and lost confidence from consumers in publicly facing industries.

Bloomberg and other new outlets track OSHA citations and may draft articles about citations issued to and accepted by employers.

Many sophisticated businesses use commercially available third-

Demolition Hub is a proud supporter of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us

party tracking services to run suitability checks on potential business partners. The best services track OSHA citations and can flag the employer as a “yellow” or “red” based on the history of the employer’s acceptance of citations. Serious classifications can result in a “yellow” or “red” rating, as can any citations associated with a fatality.

Conservative business partners may blacklist employers based on their third-party listing, including those who have a “red” rating. If your business works in industries where potential business partners use these third-party tracking services, especially construction, OSHA citations can have a major negative business consequence.

Any citation that the employer accepts goes onto the OSHA Establishment Search database and can serve as the basis for a repeat. During inspections, OSHA reviews that database and can use any accepted citation as a “predicate” for a repeat classification for five years. The repeat must be issued for a substantially similar hazard, normally cited under the same regulation.

Repeats are enhanced classifications that result in five or ten times the penalty, currently up to $145,020. These citations are much more costly to employers

and deleterious to business reputations. OSHA penalties are adjusted and increased annually by the agency based on a number of factors.

Because accepting a citation admits knowledge of an alleged hazardous condition, accepting a citation can also result in a basis for a future wilful citation in the future. Wilful violations have a 10 times enhanced penalty, currently up to $145,020. In the case of a wilful citation relating to a fatality, there is potential criminal liability, prosecution and imprisonment of managers.

OSHA’s Severe Violator Enforcement Program (SVEP) tracks alleged serious offenders of the OSHA standards. The agency maintains a publicly available list and includes employers based solely on the allegations in OSHA citations. A repeat or wilful associated with a fatality results in the employer being placed in the SVEP, as can multiple high gravity citations. The SVEP can result in increased inspections, citations and bad publicity.

The acceptance of OSHA citations may provide evidence for use in tort litigation. When an employee is injured in a typical accident, the workers’ compensation programme usually provides the exclusive

remedy for employee compensation and recovery. In some states like Wisconsin, Ohio and California, following the occurrence of an accident and issuance of citations, an employee can pursue and receive an enhanced workers’ compensation payment (by up to 50%) based on the acceptance of the citation if the injury were due to a violation of a safety regulation.

In certain jurisdictions, a citation depending on the classification can allow an employee to avoid worker’s compensation and pursue direct civil action against the employer.

However, if the injured worker is a non-employee (such as a contractor or staffing agency employee), the worker is not similarly barred from bringing a negligence action. Depending on the state and circumstances, the acceptance of OSHA citations may be admissible in those actions. A plaintiff may use non-compliance with OSHA standards as evidence of negligence.

We regularly advise employers on the defences they may have to OSHA citations and the bases to contest them. We also provide compliance training, including complimentary webinars to employers and associations. If you need additional information, please do not hesitate to contact us.

Interviewee: Jim Tagg

Role: Managing Director

Company: Redhammer

I’m forty-nine years old, married and a father to my eight-year-old son. I enjoy keeping fit, being outside in nature and I love music, particularly when I go back to the old house music days of the early ’90s. I don’t find a great deal of time for hobbies but I do enjoy DIY; I recently built our new home, of which I am extremely proud. I survived a near-fatal head injury a few years ago, but thankfully recovered with most faculties intact.

QHow did you start out in the industry, what attracted you to it?

I originally trained as an engineering surveyor and was working in my first full-time job as a junior surveyor when I was made redundant. In my attempts to find another job, I answered an ad from a local demolition company that was looking for an engineer to work on one of its sites. Upon meeting the MD, he said: “You’ll do”. I started the next day.

QHow has your career developed to where you are now? Has it been a logical progression or were there any tangents?

I suppose you could say it’s been a logical progression. My initial role as an engineer wasn’t just that at all – I was also tasked

with managing the site. Talk about being dropped in at the deep end.

After a crazy few weeks knowing nothing about demo and having to think on my feet, I was brought into the office and began to learn the ropes relating to estimating and project management.

A couple of years later, I teamed up with a two guys who were developing their demolition subcontracting business and preparing to go direct to clients and contractors. Working together we built up a reputable and successful demolition contracting business, of which I became a director and a shareholder. This lasted for 16 years until it became apparent that we were pulling in opposite directions. I formed Redhammer the day after leaving.

It took around six months to get Redhammer going properly. In

the early days, I was using a subbie to carry out relatively small work. I even got my hands dirty on occasion. As Redhammer started to develop, a few of the team from my former company decided to move across, and when the old company went into administration a year or so later, a number more joined me.

We now carry out the full range of demolition disciplines for contractors and as principal contractor across London and the south-east, with annual revenue currently around £5m.

QTell us about your working culture. Is there a fundamental company ethic? What do you bring to this?

I have always based my own conduct on three key fundamentals. And as a result, I believe my reptation to follow the same. These fundamentals

are quality, integrity and reliability. It is not always easy to find people who share those ethical pillars, so finding the right employees with the right skills can be challenging. We resolve this in part by bringing in young talent to be trained up and work alongside the more experienced guys.

QWhat kind of projects do you work on most frequently, and how broad is the range?

We are experienced and equipped to carry out most types of demolition work, including building-based machine work, ground-based work, cut and carve projects – often with significant temporary works schemes, and soft strip works. There is no specific focus, rather a continuing need to retain a broad brush, while keeping our fleet of machinery busy.

QWhat are the standout projects from Redhammer’s history? Why are they special? There are many I could mention here. We tend to often get involved in the trickier projects. This type of work might be a little less competed for, and I like a challenge.

QWhat makes Redhammer different? Why work with you?

We do not seek to spread ourselves too thinly and would rather focus on a select list of clients. We rely heavily on repeat business and by concentrating our efforts on the few we are able to maintain the expected levels of quality and reliability, thus ensuring we are in a good position for the next job. Some may say this is risky because you are only as good as your last job. I am confident that we can take that risk.

QHow do you gain business and spread the word about your services?

For me, marketing my businesses has always been about brand awareness rather than direct selling. I believe Redhammer has an established positive reputation and we are able to back this up with the necessary credentials, training and experience. By keeping people aware of our presence in the market, repeat business and word of mouth appears to keep us busy.

QTell us about any memberships or accreditations the company has

We are members of the NDTG and hold the CHAS Advanced accreditation at Principal Contractor level.

QWhat is your experience of the availability of labour, experienced and inexperienced? What can we do to attract young people into the industry?

The availability of good quality, labour has been a problem for us since early 2021. We saw a huge increase in revenue that year, but also experienced labour shortages and significant increases in rates.

I think many young people still don’t regard demolition as a proper career that can offer the opportunity to develop skills and climb the ladder. I see this as a misguided notion. The training opportunities offered by the industry and the NDTG, I believe, are good and easily available once you know where to look and how to open those doors. Perhaps it continues to be the

image of the industry that it needs modernising further. I know things have come a long way since I started my career and I consider that reputable demolition contractors offer some of the safest and most comprehensive services in construction, despite the hazardous nature of our work. A lot of people may be looking towards the NFDC to see how they might lead the way after recent events and the appointment of the new CEO. Attracting young people into the industry is an issue that should be led from the top.

QDo you undertake any ongoing training or Continuous Professional

At Redhammer we are very keen to have our direct workforce follow a programme of training that is linked to remuneration. We encourage new team members to enrol on the CCDO Apprenticeship Scheme and all training is paid for by the company, under the CITB grant scheme. This has no direct influence on our pricing – it is seen as an essential requirement to achieve the level of service that we wish to offer.

QTell us about any engagement Redhammer has in the community

We have recently begun to fully recognise the importance of social engagement and are in the process of developing a programme to ensure that we remain committed to such responsibilities. Ongoing projects include the sponsorship of our local under eights football team Reeves Rangers, offering free of charge services to schools and community centres and helping with a number of charitable events.

We are currently supporting a fundraising campaign that was set up by my niece, whereby she will be competing in this year’s London Marathon with all proceeds being donated to Horizons, which is a north London based organisation

that strives to create a fairer, more equal start in life for children and young people.

Go to www.justgiving.com and search KellyVinnicombe to donate.

QWhat do you think responsible companies need to be doing in regard to their communities and society in general?

It is important that businesses are seen as a force for good within their local community and within the communities where they undertake their work. I am very much against meaningless virtue signalling; however, I do believe that the creation of a harmonious working relationship with your neighbours can only be a good thing.

QWhat measures is Redhammer taking in regard to the climate crisis and sustainability?

The use of HVO fuels throughout our fleet has been a start. We have now replaced all machinery that was not compatible with this preferred choice of fuel.

Our fleet of management vehicles is now fully electric. Once you get over the range issue, electric cars are a joy to drive. Once you go electric, I think it is hard to go back.

We are also currently looking towards the introduction of electric machinery. The available options at present are fairly limited and we will have to start small, working up the line given the relative cost of this equipment. Hopefully, in time, the demand will rise and therefore cost will fall.

QHow do you see the demolition industry developing over the next few years? Do you foresee different demands on contractors?

I am a little uncertain about the future. I hear a lot of talk about embodied carbon and the potential environmental benefits of refurbishing structures rather than

demolishing them. I am no scientist, but I do know from experience that chopping buildings about can often lead to unexpected problems, delays, and additional costs.

I hope we at Redhammer can continue to offer and succeed in the full range of demolition practices that we currently offer. But we are ready to adapt where necessary, and where opportunities present themselves.

QWhat are the biggest technological developments you have seen in the industry and what do you envisage will be the future game changers?

There are some great pieces of kit on the market nowadays. It is difficult to prophesise, but if you were to ask me what technology may shape the industry in the longterm future, I would have to say robotics.

QDo you have any notable projects in progress or in planning?

At the time of writing, we have an order book that will keep us busy through much of the summer.

QHow do you envisage Redhammer in five to ten years?

We do not strive for growth. Rather, we will continue to focus on quality over quantity. We now have a great team, a young team, and I am comfortable with the £5m annual turnover we appear to have settled at. This seems to be the optimum level, if you like.

QAnd what about you in a few years?

Looking at the longer-term future, it is my hope that some in my team will look to step up so that I might take it a little easier as I get older.

When and where are you happiest?

In the garden, or around the pool somewhere hot.

What’s your tipple of choice?

Kona. What a beer! I found this when out in the States a few years ago. It’s from Hawaii and just tastes magic.

Be or do? Which represents you best? Do

AP Air Europe is pleased to introduce Hebonilube automatic grease pumps into the UK. As a longstanding air-conditioning parts specialist, we have a close relation with plant engineers and when we came across the Hebonilube range we knew these easy-fit auto greasers would be an appealing solution for them and their customers.

Available from stock in two, four, six, and eight kg pumps in 12V and 24V, all pumps and systems are supplied by AP Air with a two-year warranty. Hebonilube pumps are compatible with many other grease pump branded systems.

• Extended equipment life,

• Higher residual machine value,

• Reduced downtime,

• Less maintenance and grease waste,

• Improved fuel efficiency.

In collaboration with Mark from Moonridge Plant Engineers, our installer for the south west we’ve put together a step-by-step guide for fitting a Hebonilube automatic grease pump system on an excavator.

Step 1: Prepare the excavator

Before installing an automatic grease pump system, clean the excavator’s lubrication points and remove any existing grease.

The Hebonilube automatic grease pump system comes with instructions and recommendations for installation. Generally, you should install the pump in a location that is easily accessible and close to the hydraulic system. Most pumps come with brackets that can be attached to the excavator’s frame. Once the pump is securely mounted, connect the power cable to the battery and run the wires to the pump.

Measure and cut hoses to the appropriate length. Attach the fittings to the ends of the hoses, making sure to use the correct fittings for each lubrication point. Once the fittings are attached, connect the hoses to the pump and the lubrication points.

A sound investment for owner operators through to companies running fleets, the Hebonilube system extends equipment life, reduces downtime and labour costs, and keeps value in a machine for when it needs replacing, making it invaluable for any company reliant on its machines.

Fill the pump with a grease gun and your standard EP2 grease and turn on the system. Test each lubrication point to ensure that the proper amount of grease is being delivered. Make sure to check for any leaks or connection issues.

Once installed and working, a system’s grease levels will need to be regularly checked and grease replaced as necessary. Hoses and fittings should also be routinely checked for wear and damage.

Paul Argent

Paul Argent

It’s very rare that inner city demolition works are afforded open space to work in; add in the ability to use freshly soft stripped former office accommodation to site your welfare and anyone would think that Erith had landed a simple project.

“We’ve been very lucky in that respect,” Roberto Timanti, Erith’s Project Manager at their Baker Street demolition project says. The Kent based giants of the UK demolition industry won the tender to demolish a pair of 1960/70s former office and retail accommodation buildings on London’s busy Baker Street.

The parcel of land is being developed by Derwent London, which has consent to bring modern, environmentally friendly living, retail and working spaces to replace two drab 50-year-old structures on site. While the main eight-storey building sits on Baker Street, Erith is demolishing a second, four-storey building to George Street along with the demolition of a three-storey end of terrace structure to Blandford Street.

Roberto looks after the day-today running of the project along with his team consisting of experienced Site Manager Chris Rawlinson and

trainee Project Manager Michal Lisz. “I’ve been with Erith for eight years and have enjoyed every minute,” Roberto says. “I’ve had the opportunity to learn from some very experienced people within the industry and that has taught me so much. You need that practical experience to help you, and this is something Erith are very good at doing, they’ve given me every opportunity to push myself.”

Michal is also very complimentary about the opportunities he has had so far within the Erith team. “The work is very interesting and changes day to day; I would recommend a career in the demolition industry to anyone,” he says.

The project commenced on site

in October 2021 with the client bringing in Erith for early works and to take on additional MOLA survey works to streamline the programme. “It gave us a little bit of a head start, which is very good in this industry,” Roberto explains. “We were even more grateful for our early commencement on site as when we started top-down work on George Street, we found an additional slab within the roof construction, which held us up slightly on programme. We’ve gained that lost time back and are now on programme to complete in June this year.”

The first building to be demolished was the four-storey former retail units and residential accommodation on George Street.

Following a substantial strip out and asbestos removal, Erith was able to deploy several large excavators to the site, including a pair of 50-t-class machines to quickly dispose of the reinforced concrete structure. “Arisings are crushed on site as these will be used in the piling mat,” Roberto explains. “Crushing on site, is estimated to have taken 2,000 truck loads off the already congested city streets. It will also mean a quieter time for the neighbours.”

The two remaining structures on Gloucester Place and Blandford St terrace will remain fully occupied throughout the project. There are residential apartments in the east of the site on Gloucester Place, below which the welfare is situated and a row of 1970s-built town houses sit along Blandford Street. It is the end house on this row that the team are currently demolishing.

Once all the relevant party wall agreements had been signed off, Roberto and the team from

Swanton Consulting designed a temporary works solution to stabilise the property to be retained. “The neighbours have been excellent during our works,” Roberto says. “We undertake constant noise, dust, and vibration monitoring between the property we are demolishing and the remainder of the terrace. Everyone knows what is going on and what is going to happen as we put out regular newsletters to all the residents and businesses surrounding the project.”

With the structural steel installed, a 5-t mini digger was hoisted onto the roof of the building to undertake the safe and steady top down of the structure. Erith is very lucky with the ample access to what was the car park at the rear of the buildings and was able to site an 80-t crane for the handling of skips and machines when they were moved floor to floor.

The former office and retail block on Baker Street was demolished at the same time. The eight-storey

reinforced concrete structure was demolished from the top down with three Caterpillar 308 midi excavators and a range of attachments. The material arising from the demolition process on a top-down is usually disposed of down the lift shafts, but as the one present on this building was deemed too small, Roberto and his team designed an external chute built from tube and fitting scaffold and lined with sacrificial planks. The bespoke chute allows the material to drop safely to the ground, where it was collected and processed.

With demolition work progressing extremely well, Erith’s attention has turned to preparing the ground for the arrival of the piling teams. “The piling and capping beam works are also both part of Erith’s scope,” Roberto says. “To allow for the near 80-t piling rig to safely sit on the cleared ground, Erith and Swanton had to design and install a series of raking supports to keep an existing retaining wall parallel to the rear of Gloucester Place. We are very lucky to have such a wide ranging and comprehensive ability to undertake almost any work inhouse. This is why we are able to undertake complex, time-sensitive projects safely and effectively with total success.”

Once the demolition work is completed, the site will be developed into a mixture of office, retail, and residential properties.

I joined SANY as a mechanical engineer, mainly engaged in the development of adaptability requirements of various regions, such as 21-t (South African machine) stub rod development and 21-t main platform development and maintenance.

I served as the assistant to the director of SANY International Product Institute but mainly served as the project manager of

Name: Jimmy Shu

Job title: R&D Director of Overseas Department

Role: New product development, demolition, marketing including mining excavators

Time at SANY: 15 years

Experience:

Developed the following excavators:

• 2011-2015: SY215/SY235/SY335/SY365/SY500H

• 2018: SY500HRD (Demolition)

• 2022: SY390 Demolition and SY390/SY365 Stage V

the SY335(SY365) Euro IV product (completed development in 2012), assisted the director in team management and provided technical guidance for the team.

I later served as the director of SANY International Product Institute and presided over the development of Euro IV products such as the SY215/SY235/SY335/ SY500H excavators, including drawing design, procurement management, production support, parts atlas and sales data production.

Later I moved to Europe in the position of product

manager, responsible for technical support of front-end products, agent development and global product research.

Since June 2019, I have held the position of Director of the American Office of SANY Mining Company, the most experienced engineer in the international team. I presided over the development of the SY365/SY390/SY500 Euro V products, and completed the development of the SY2000H (200t) mining products. Currently, SY750/ SY980 Euro V products are being developed and the SY4000H (400t) project has been started.

Product name: SY500HRD

Product type: 60-t high reach demolition excavator

Date released: 2018

Brief specifications:

• Operating weight: 64,000 kg,

• Engine power: 298 kW @ 2,100 RPM,

• Maximum operating height: 28.15 m,

• Maximum operating radius: 15.3 m,

• Maximum weight of accessories: 2,400 kg.

The SY500HRD is a 60-t high reach demolition machine specially designed for Europe. It is equipped with a three section ultra-long working arm and the maximum height of the machine is 28 metres. The rotary excavation telescopic chassis is creatively adopted to improve the lateral stability of the machine by 20% and the tilting cab is developed to comprehensively improve the operating comfort and expand the driver’s working vision. All the functions and performance indicators have reached the leading level of the same tonnage products in the world.

At present, it has been exported to the United States, Germany, France, Italy and the United Kingdom and other major European and American markets.

Product name: SY390H

Product type: 40-t demolition excavator

Date released: 2022

Brief specifications:

• Operating weight: 40,000 kg,

• Engine power: 252 kW @ 1,800 RPM,

• Maximum operating height: 9.9 m,

• Maximum operating radius: 10.2 m,

• Maximum weight of accessories: 9,325 kg.