2 CFM - Issue 38 - Jun. 2024

4 CFM - Issue 38 - Jun. 2024

CFM - Issue 38 - Jun. 2024 5

CFM - Issue 38 - Jun. 2024 7

8 CFM - Issue 38 - Jun. 2024

CFM - Issue 38 - Jun. 2024 9

10 CFM - Issue 38 - Jun. 2024

12 CFM - Issue 38 - Jun. 2024

CFM - Issue 38 - Jun. 2024 13

CFM - Issue 38 - Jun. 2024 15

16 CFM - Issue 38 - Jun. 2024

18 CFM - Issue 38 - Jun. 2024

20 CFM - Issue 38 - Jun. 2024

CFM - Issue 38 - Jun. 2024 21

Analysis of the Current Status and Market Potential of the Aerospace Fastener Industry

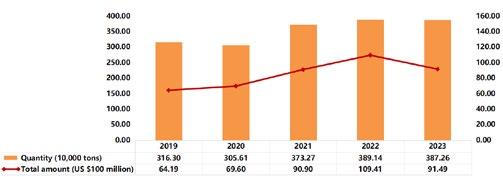

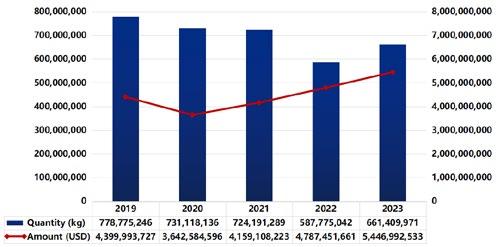

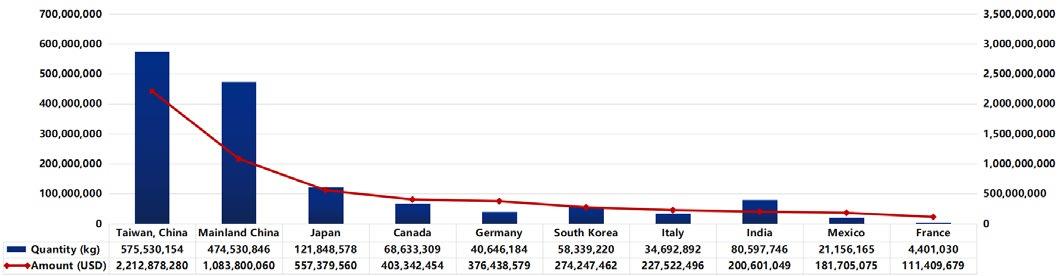

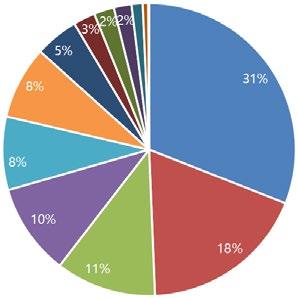

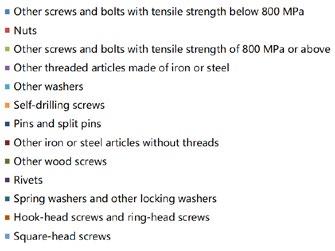

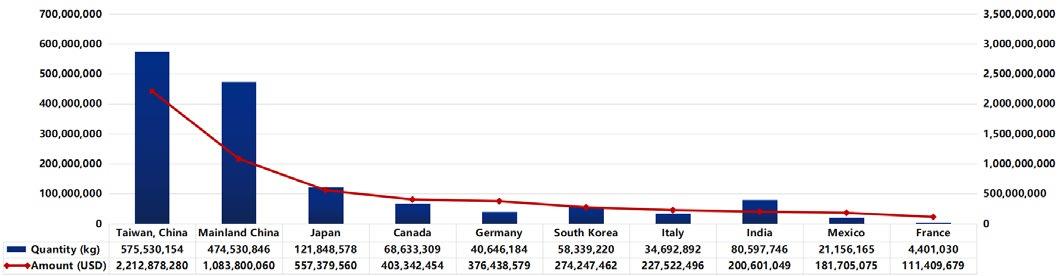

Analysis of China's Fastener Exports in the First Quarter of 2024

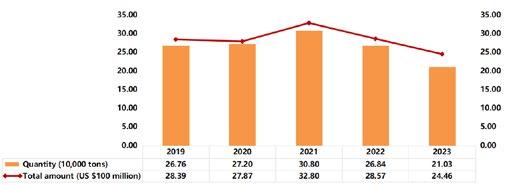

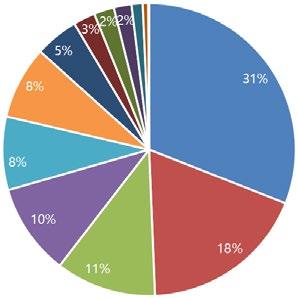

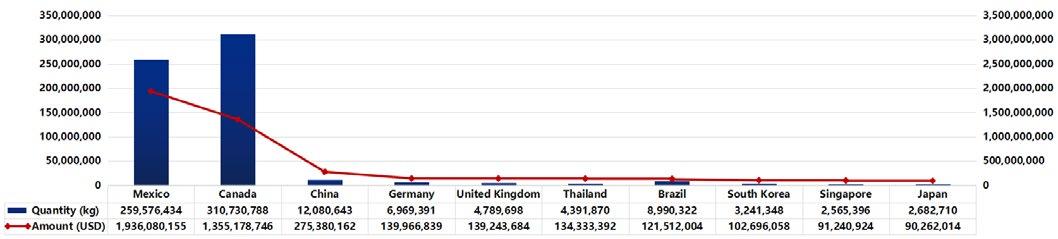

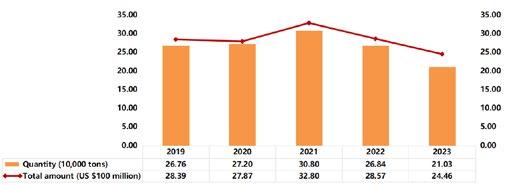

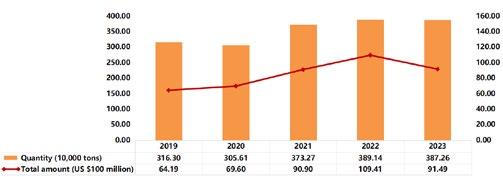

Analysis of Import and Export of China's Fasteners in 2023 Import and Export Situation of Fasteners in the United States in 2023

Jiashan Sanyung Electric Furnace Industry Co., Ltd.: A Premier in the Field of Heat Treatment Equipment

Jiaxing Kinfast Hardware Co., Ltd.: Screw Is Small, Responsibility Is Big

Design, Application, and Specification

The 14th Fastener Expo Shanghai Concluded Successfully Fastener Taiwan 2024: Charting a Sustainable and High-Value Pathway 2024 Fastener Exhibitions

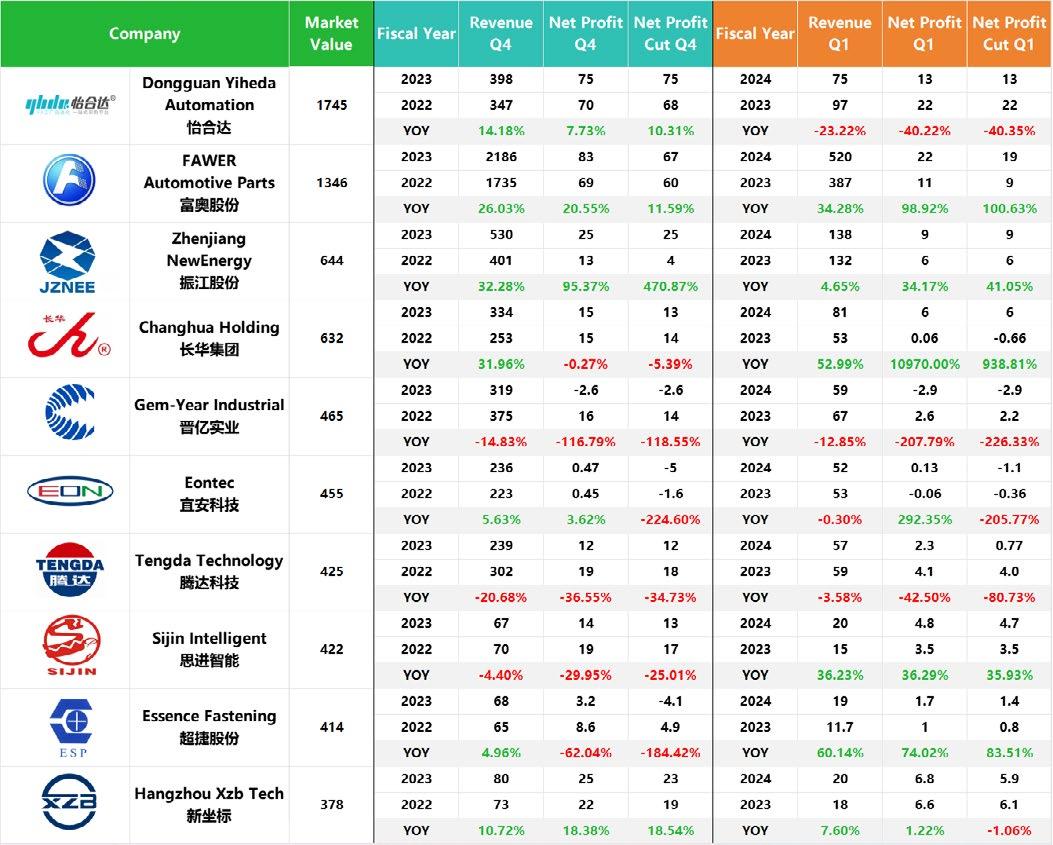

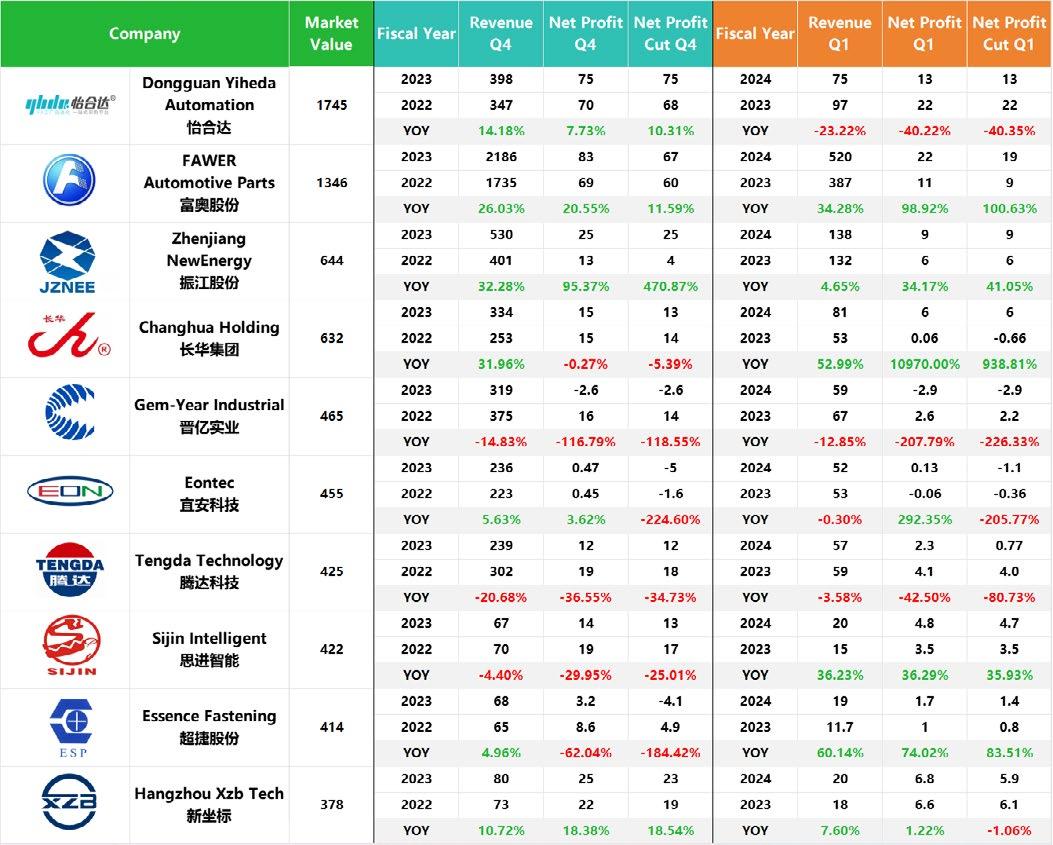

Financial Report P64 Financial Report of Top 10 Fastener Listed Companies Certificated Active Supplier P91-97 P54 P56 P80 P86 P88 P66 P68 P76 P48 P58 Featured Company Exhibition lmport and Export Insight Technology

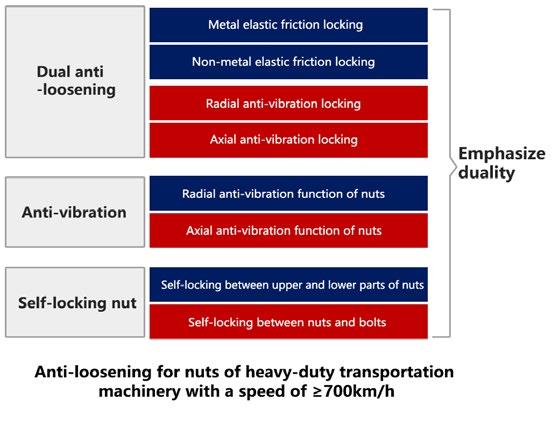

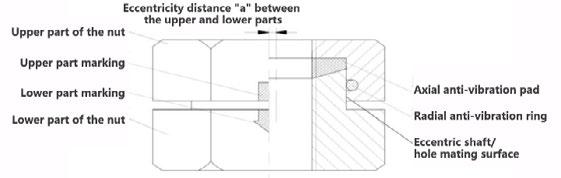

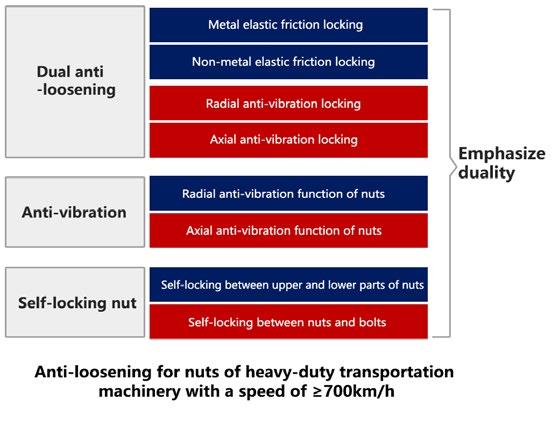

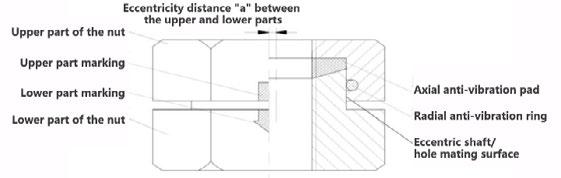

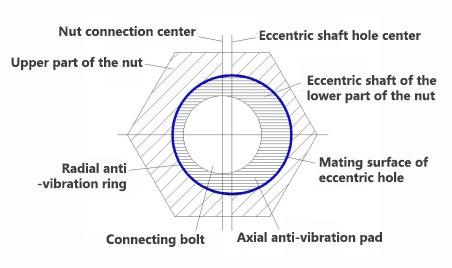

of Dual Anti-loosening

Anti-vibration Self-locking Nut 22 CFM - Issue 38 - Jun. 2024 CONTENTS Cover Story P46-47

P24-45 Industry News

and

Based on Small Packaging Service CHINFAST Expands DIY Fasteners Market in Europe and America

CFM - Issue 38 - Jun. 2024 23

The First Dainan Fastener and Equipment Exhibition Ended Successfully

Dainan, a leading player in China's stainless steel industry, has long been renowned for its fastener industry. With a comprehensive range of products, exceptional processing capabilities, prompt delivery, and dual advantages in technology and pricing, Dainan fasteners have been a hit across the country for years. As the market demand for high-end fasteners continues to grow, Dainan has carved out a unique path for the development of stainless steel fasteners, leveraging its rich heritage.

Currently, over 400 fastener production enterprises are concentrated in Dainan. To further integrate and optimize the regional industry chain, the "First Dainan Fastener and Equipment Exhibition" was organized by the

Dainan Fastener Industry Association and co-organized by Jiangsu Qimei Culture Communication Co., Ltd. and Shanghai Ebseek Exhibition Co., Ltd.

From April 26th to 28th, 2024, this grand event was held at the Modern Logistics Park in Dainan Town, Xinghua City, Jiangsu Province. It gathered over 100 professional fastener manufacturers and upstream and downstream enterprises from across the country, attracting more than 3,000 industry professionals to visit, with a total exhibition area of up to 5,000 square meters.

The exhibition covered a wide range of products, covering multiple segments of the fastener industry. The fastener products mainly included high-end fasteners, standard fasteners, and customized fasteners and non-standard parts for specific industries. The exhibition also showcased dedicated manufacturing and processing equipment and accessories for fasteners. In addition, machine tools,

automation peripherals, CNC systems were also on display. These rich exhibits not only demonstrated the latest products and technologies in the fastener industry but also provided visitors with opportunities to gain a deeper understanding of industry trends.

This exhibition brought together the leading enterprises and equipment manufacturing enterprises in the fastener industry, fully demonstrating their outstanding achievements in technological innovation and industrial strength.

To provide participants with a deeper understanding of industry trends, professional activities such as the "National Stainless Steel Fastener Summit Forum" were also held, providing valuable learning opportunities for industry professionals.

In order to provide participants with a deeper understanding of industry trends, the exhibition also held professional activities such as the "National Stainless Steel Fastener Summit Forum", which provided valuable learning opportunities for industry personnel.

As a significant event in China's stainless steel fastener industry, the First Dainan Fastener and Equipment Exhibition fully demonstrated the strong strength and profound heritage of Dainan Town in the field of fasteners. The successful conclusion of this exhibition not only promoted cooperation and exchange within the fastener industry but also injected new vitality into the future development of the Dainan fastener industry.

24 CFM - Issue 38 - Jun. 2024

INDUSTRY NEWS

CFM - Issue 38 - Jun. 2024 25

The National Stainless Steel Fastener Summit Forum Successfully Held

Stainless steel fasteners, as an important category within the fastener industry, are widely used in construction, communication equipment, medical devices, marine engineering, photovoltaics, and other fields. China, as a leading producer of stainless steel globally, has made stainless steel fasteners an indispensable product in global industrial production.

Dainan town, renowned as the "Famous Town of Stainless Steel Products" in China, boasts a comprehensive and sizable stainless steel industry chain, forming a billion-level industrial cluster. Especially its stainless steel and titanium alloy fasteners, enjoy a national reputation.

On April 26th, the first National Stainless Steel Fastener Summit Forum was successfully held at the Xingda Convention Center in Dainan Town. With stainless steel fasteners as the core topic, the summit delved into discussions on market size, industry applications, technological innovation, and other related issues. Leading enterprises in the fastener industry, professional associations, and upstream and downstream manufacturers gathered to jointly explore and plan the future development blueprint for the stainless steel fastener industry.

Ms. Xu Liyun, Executive Vice President of Aozhan, kicked off the summit with a speech titled "Aozhan's Journey Towards Premium Components through Differentiation". She showcased how Aozhan, with its aviation company as the manufacturing carrier and aviation fastener components as the core, meets market demands for special steel fasteners while continuously

investing in R&D, industry-academia collaboration, and intelligent manufacturing. Subsequently, Mr. Shen Jiayuan, Product Center Director of Zhejiang Tong Ming, provided an insightful analysis of the market prospects for D2-80 stainless steel, demonstrating its application potential across multiple industries. Mr. Chen Kaikai, Co-founder of gpyh.com, proposed how fastener enterprises can innovate in the face of changing market demands and homogenization of services, thereby supporting their own growth. Mr. Yang Naga, Chairman of Shenzhen Guwanji, shared his company's experience of selling 30,000 orders online daily, emphasizing the importance of the e-commerce era for the fastener industry. Mr. Zhou Xin, General Manager of Xinghua Jinchao, focused on the diversification of market demands, introducing a fastener retail platform that meets users' needs for diverse and fragmented samples. Lastly, Mr. Li Zhenhui revealed the opportunities of short videos for fastener industry personnel, sharing his journey from a ordinary user to an internet celebrity in the fastener industry.

The National Stainless Steel Fastener Summit Forum concluded successfully at the Xingda Convention Center in Dainan Town, marking an important step forward in communication, collaboration, and joint progress for the fastener industry. The experiences and insights shared by the participants provided valuable ideas and directions for the future development of the industry. This summit not only established a platform for communication and cooperation within the fastener industry but also promoted innovation and development, contributing to the greater success of China's stainless steel fastener industry in the global market.

26 CFM - Issue 38 - Jun. 2024

INDUSTRY NEWS

The Haiyan County Fastening and Locking Technology Association Was Officially Established

On February 28th, the Haiyan County Association for Science and Technology officially approved the establishment of the Haiyan County Fastening and Locking Technology Association and formed a preparatory group, consisting of Yang Junfeng, Wang Hui, and Sun Yingbing. This marks a new milestone for the region in the field of fastening and locking technology.

The preparatory group of the association will strictly adhere to relevant regulations such as the "Regulations on the Registration and Management of Social Organizations" and establish comprehensive internal management systems including bylaws, financial management regulations, membership management measures, and election procedures to ensure the standardized operation and sustainable development of the association. At the same time, the preparatory group will actively carry out registration work and prepare for the founding conference, laying a solid foundation for the formal operation of the association.

The establishment of the Haiyan County Fastening and Locking Technology Association aims to build a comprehensive platform for academic exchanges, scientific research, and educational training. By gathering industry professionals, sharing knowledge resources, and promoting technological

innovation, the association strives to continuously enhance its influence and cohesion in the field of fastening and locking technology. The association will actively attract more members interested in developing this field to join and jointly promote the innovation and application of fastening and locking technology, contributing wisdom and strength to the technological progress and economic development of Haiyan County.

As an important aspect of the industrial manufacturing field, fastening and locking technology plays a pivotal role in improving product quality and ensuring equipment safety. The establishment of the Haiyan County Fastening and Locking Technology Association not only provides a platform for professionals in this field to exchange and learn from each other, but also helps to promote the innovation and development of fastening and locking technology, enhancing the overall competitiveness of Haiyan County in this field.

With the establishment and operation of the association, it is believed that the Haiyan County Fastening and Locking Technology Association will become an important force in local technology and economic development, making positive contributions to the prosperity and progress of Haiyan County and the fastener industry.

28 CFM - Issue 38 - Jun. 2024

INDUSTRY NEWS

INDUSTRY NEWS

Würth Industry China's Customer Day Came to a Perfect Conclusion

On April 11th, Würth Industry China successfully held a customer day themed "Converging Global Resources, Technology Driving the Future" at the Würth Supply Chain Center in Haiyan, Greater China Region. More than 200 customers from the manufacturing industry and over 30 representatives from 12 countries in Würth Industry's Germany, Americas, Asia-Pacific, and Africa regions participated in this event. They jointly discussed the trends and future of global supply chain development, experienced Würth's products up close, and felt the benefits brought by the company's application technical support and intelligent material management services.

One-stop Service

Würth Industry continues to expand its product range, aiming to help customers achieve lean management of their supply chains through a comprehensive range of products. At the same time, it helps users resist fluctuations in the supply chain caused by external factors and enhances the supply chain's ability to resist risks. As a global leader in the field of installation and connection, the Würth Group has 1 million selectable products, and Würth Industry China's product range has expanded to 150,000 materials, with a standing inventory of 65,000, covering the production needs of customers in different industries.

Technological Innovation

Würth's application technology team can provide product recommendations for specific industries based on industry commonalities, product integration based on common product functions, and technical services based on performance requirements. This not only reduces the number of material categories for users but also Improves the quality management level of materials.

Sharing Global Resources

The Würth Group has over 400 independent companies in more than 80 countries worldwide. As an important component of the Würth Group, the Würth Industry network has nearly 60 independent companies in 40 countries providing services to global industrial customers. It implements unified material inventory management and inventory sharing globally through SAP. The Würth Group's vast global supplier resources and powerful logistics resources worldwide are the foundation for Würth Industry to provide high-quality services to customers globally.

Würth Industry has been deeply rooted in the Chinese market for 30 years. The Haiyan Supply Chain Center, with a building area of 56,000 square meters, is a firm commitment of the Würth Group to serving the Chinese market in the long term.

CFM - Issue 38 - Jun. 2024 29

INDUSTRY NEWS

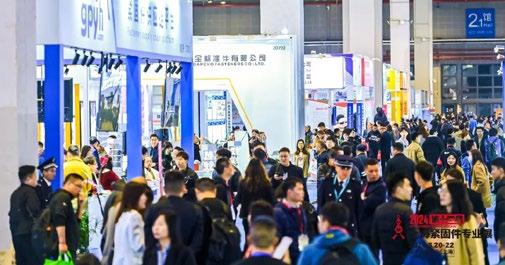

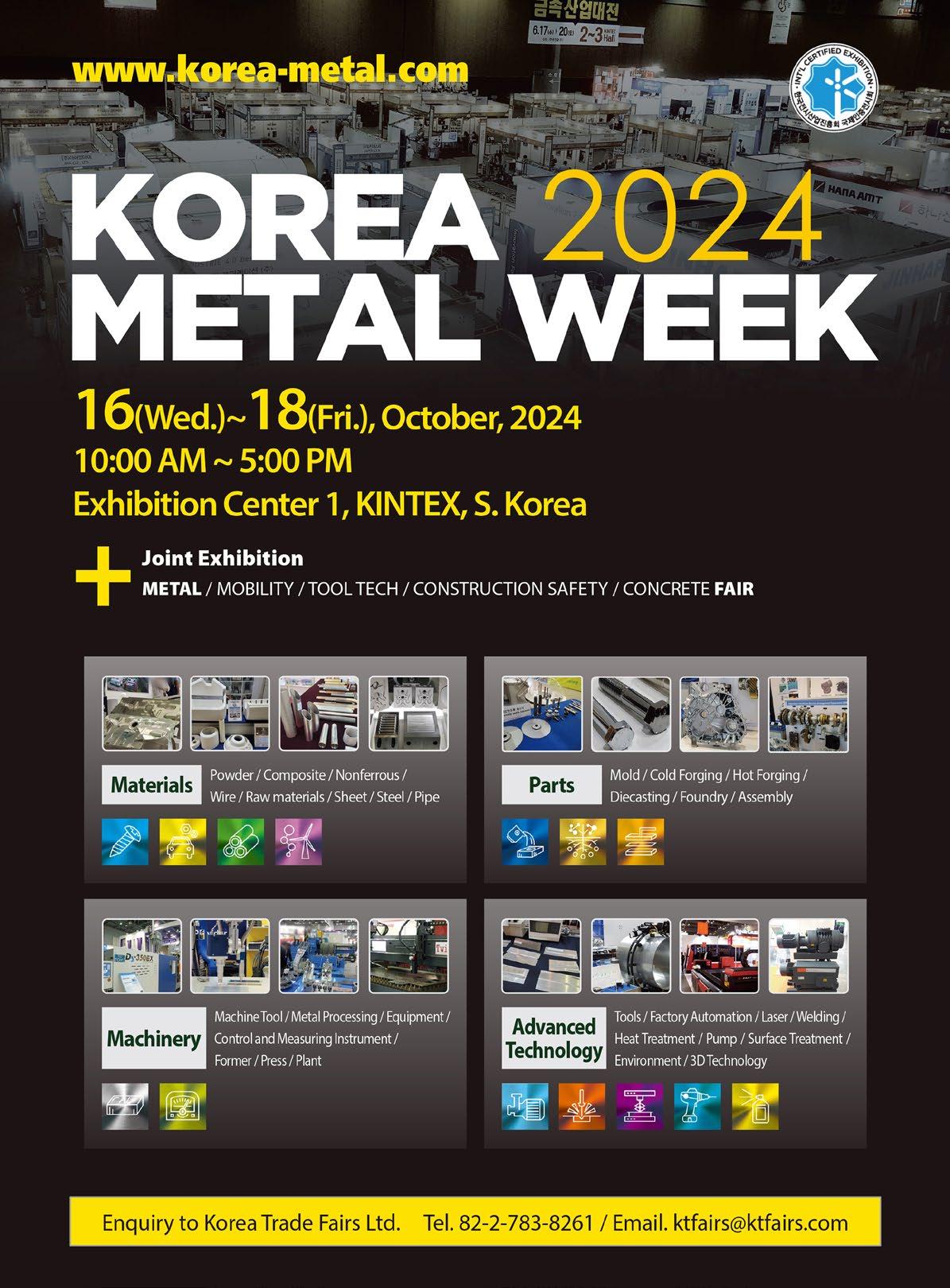

The 14th Fastener Expo Shanghai Came to a Successful Conclusion

The 14th Fastener Expo Shanghai was grandly held from March 20th to 22nd at the National Exhibition and Convention Center in Shanghai, China. With the allnew positioning of a global high-end fastener industry innovation platform, the Fastener Expo Shanghai has crafted a professional and exciting industry event with the spirit of ingenuity. After years of accumulation and development, the exhibition has become one of the top three fastener exhibitions globally, serving as a bellwether leading the development of the fastener industry.

This year's exhibition gathered professionals from the fastener industry worldwide, creating a lively and festive atmosphere on site. Nearly a thousand exhibitors engaged in extensive and profound exchanges with professional visitors from all over the world, jointly discussing industry trends and market prospects. This exhibition not only provided a platform for demonstration and exchange in the industry, but also served as a good opportunity to promote the sustained development of the fastener industry. It is reported that the exhibition attracted the active participation of 18,940 Chinese professional visitors and 987 international professional visitors.

Apart from the rich exhibition content, 10 concurrent events were also held, including the 3rd National Invitational Tournament on Fastener Anti-loosening Performance, Supplier/Buyer Matching Meeting, Special Lecture, and the China Fastener Industry Youth Entrepreneurs' Meeting, covering various aspects of the fastener industry. These activities provided exhibitors and visitors with a rare opportunity for exchange and interaction, further promoting the development of the fastener industry.

The successful conclusion of the 14th Fastener Expo Shanghai has established a vast platform for demonstration and cooperation for the global fastener industry, injecting new vitality and momentum into the industry's development. The successful holding of the exhibition has won unanimous praise from the industry. From June 17th to 19th, 2025, the 15th Fastener Expo Shanghai will be gorgeously upgraded, presenting an even more exciting industry feast with three exhibition halls and a display area of 70,000 square meters. Let's look forward to meeting again and witnessing a more brilliant future for the fastener industry.

INDUSTRY NEWS

30 CFM - Issue 38 - Jun. 2024

The National Center for Quality Inspection and Testing of Special Steel Products (Hubei) Has Been Approved for Establishment

The General Administration of Market Supervision issued the "Notice of the General Administration of Market Supervision on the approval of the establishment of the National Food-related Products and Green Packaging Quality Inspection and Testing Center (Beijing) and other 22 national quality inspection centers", of which the National Center for Quality Inspection and Testing of Special Steel Products (Hubei) is among them.

According to information, the National Center for Quality Inspection and Testing of Special Steel Products, with the Hubei Huangshi Institute of Product Quality Supervision and Inspection as the applicant, is jointly established by the government and enterprises of the Huangshi Institute and Hubei Guoan Special Steel Inspection and Testing Co., Ltd. It is the only national quality inspection center for special steel products in China. The establishment of this center fills the gap in the inspection, testing, and R&D of China's special steel products.

Currently, the center has established five major laboratories, including chemical analysis laboratory, physical property testing laboratory, metallographic analysis laboratory, non-destructive testing laboratory, and failure research laboratory, in accordance with the standard of "leading in the world and first class in China". It has obtained

the national CMA/CNAS dual qualification and possesses the ability to test 37 products and 106 parameters of various metal materials and their products, such as carbon steel, low and medium alloy steel, stainless steel, iron and steel, and alloys, covering nearly 200 standards. It has achieved more than 40 national and provincial scientific research achievements and can provide enterprises and research institutions with "onestop" and "one-chain" services such as physicochemical testing, metallographic analysis, failure research, and new material research and development.

It is reported that the National Center for Quality Inspection and Testing of Special Steel Products (Hubei) will take the approval as a new starting point to actively carry out technological innovation and talent introduction. It will further focus on training consultation, research and development innovation, certification services, standard formulation and revision, and industrial aggregation to support the extension, strengthening, and supplementation of the steel industry chain, as well as the high-quality development of the special steel industry in Huangshi. It aims to radiate its influence to the southeastern Hubei region and even the whole country, striving to become a leader and innovation hub in the field of special steel product inspection and testing in China.

CFM - Issue 38 - Jun. 2024 31 INDUSTRY NEWS

The 16th China Steel Summit Forum Was Grandly Held

The steel industry is an important basic industry of the national economy and an important indicator of the country's economic level and comprehensive national strength. From March 29th to 30th, the 16th China Steel Summit Forum was grandly held in Zhengzhou, Henan, China.

Mr. Liu Shangjin, Vice Governor of the Henan Provincial People's Government, pointed out that since 2023, the Henan Provincial Party Committee and Provincial Government have focused on cultivating and strengthening key industrial chains, accelerating the construction of a modern industrial system, and building seven trillion-level industrial clusters and 28 hundred-billion-level key industrial chains. In the future, Henan will accelerate the reorganization and integration of the steel industry, significantly increase industrial concentration, strengthen and optimize steel groups, and contribute to the modernization of Henan.

Mr. Jiang Wei, Deputy Secretary of the Party Committee, Vice President and Secretary-General of the China Iron

and Steel Association, summarized the operating situation of the steel industry and introduced the key work of the steel industry in 2024. He also introduced the current "1231" work direction adhered to by the Chinese steel industry. Focus on the fundamental task of comprehensively improving the basic capabilities of the industry and the modernization level of the industrial chain; adhere to the two development themes of green and low-carbon development and intelligent manufacturing; focus on addressing the three major pain points in the industry: controlling capacity expansion, promoting industrial concentration, and ensuring resource security; and continuously promoting the internationalization of the Chinese steel industry.

In conclusion, Mr. Jiang Wei called on all steel enterprises and steel-consuming industries to unite, support, and engage in the steel industry's EPD platform and China's low-carbon steel emission standards. At the same time, they should actively address CBAM and low-carbon trade barriers.

32 CFM - Issue 38 - Jun. 2024

INDUSTRY NEWS

The China Hebei (Germany) Key Industry Cooperation Conference Was Held in Berlin

On May 8 (local time), the China Hebei (Germany) key industry cooperation conference was held in Berlin, Germany. Over 70 business association leaders, German entrepreneurs, scholars and experts living in Germany, and other representatives gathered with the delegation from Hebei Province to discuss cooperation intentions and explore development opportunities.

In her speech, Jin Hui, Vice Governor of the Hebei Provincial People's Government, introduced that Hebei is an important coastal province in northern China, surrounded by Beijing and Tianjin. In recent years, economic and trade exchanges between Hebei and Germany have become increasingly close, and both sides have carried out extensive cooperation in areas such as equipment manufacturing, new energy, and food, achieving positive results. She hoped that everyone would seize the opportunity of this conference to further focus on and invest in Hebei, and achieve mutual benefit and win-win development.

Michael Schumann, President of the German Federal Association for Economic Development and Foreign Trade (BWA), pointed out that his association has been committed

to developing German-Chinese relations for more than two decades and firmly believes in the importance of strengthening cooperation between Germany and China. Citing his recent visit to Hebei, he expressed that the openness of the region to German enterprises was impressive. Looking ahead, there are still numerous cooperation opportunities between Germany and China in the field of economic and trade, especially in emerging fields such as artificial intelligence and digital infrastructure construction.

INDUSTRY NEWS

The Industrial Alliance for High-Quality and Collaborative Development of Wind Power Fasteners Was Officially Established

With the booming development of the wind power industry, fasteners, as its key components, are increasingly highlighting their importance in ensuring the safe operation and long-term stability of equipment. Given the urgent need for the development of the current wind power fastener industry, the National Standardization Technical Committee for Fasteners actively initiated an advocacy and successfully facilitated the official establishment of the "Industrial Alliance for High-Quality and Collaborative Development of Wind Power Fasteners."

The establishment of this alliance aims to strengthen the exchange and cooperation across the entire wind power fastener industry chain, jointly promote fastener technology innovation and application, standardize market behavior, and thus lead the wind power fastener industry towards a path of higher quality and more collaborative development. The alliance will focus on the following three core objectives: Firstly, promoting industrial upgrading. By integrating

upstream and downstream resources in the industry and promoting deep integration of production, learning, research, and application, the alliance will assist in elevating the technological level of the wind power fastener industry.

Secondly, establishing an innovative ecosystem. The alliance will strive to build an integrated technological innovation ecosystem encompassing the design and development of wind power fastener products, material and process enhancement, testing and inspection, standard verification, and application promotion. This ecosystem will provide robust support for the innovative development of the industry.

Lastly, advocating quality as a priority. The alliance will actively advocate for enterprises to establish a quality-first mindset, guide healthy and orderly competition within the industry, jointly maintain a good industry image, and provide solid safeguards for the healthy development of the wind power fastener industry.

34 CFM - Issue 38 - Jun. 2024 INDUSTRY NEWS

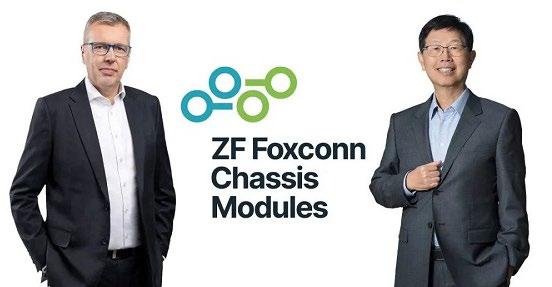

Foxconn Has Established a Joint Venture with ZF Friedrichshafen AG

ZF Friedrichshafen AG, one of the world's largest automotive suppliers, and Foxconn, a global electronics manufacturer, announced on April 30th that they have completed the establishment of a joint venture in the field of passenger car chassis systems.

In this collaboration, Foxconn successfully acquired a 50% stake in ZF Chassis Modules GmbH, establishing an equal 50-50 shareholding relationship between the two parties. This strategic partnership was officially confirmed on July 24th, 2023, and has received approval from relevant regulatory agencies. The newly established joint venture, named ZF Foxconn Chassis Modules, will become a

core component of the future development strategies for both parties.

For ZF Friedrichshafen AG, this collaboration not only helps to achieve profit growth and expand new customer base, but also provides valuable resources for its development in other areas beyond its core markets such as axle system assembly.

For Foxconn, acquiring a 50% stake in ZF Chassis Modules GmbH (with a total enterprise value of approximately 1 billion euros (about 1.1 billion USD)) marks a new chapter in its development in the automotive industry. The joint venture will leverage the core competencies and professional process knowledge of both parties in their respective business areas to jointly explore new market opportunities.

Martin Supply Acquires Trinity Hardware Headquarters

Martin Supply, a premier provider of customized solutions for maintenance, repair, operation, and production supplies across the nation, announced the acquisition of Trinity Hardware Headquarters (THHQ) from Agrisolutions. Agrisolutions is a renowned global manufacturer specializing in wear parts, components, and accessories.

Located in Waukesha, Wisconsin, THHQ excels in supplying both standard and customized components through catalog distribution, tailored inventory management programs, and product delivery services. This acquisition represents a significant milestone in Martin Supply's commitment to strengthening its foothold in the fastening market and expanding its reach within the region.

"We are excited to welcome THHQ to Martin Supply. This acquisition aligns seamlessly with our mission to deliver unparalleled quality and service to our valued customers," said Douglas Ruggles, co-CEO of Martin Supply. "We are

committed to upholding the legacy of excellence that THHQ has established."

Leveraging industry-leading technology, Martin Supply will streamline the flow of products, services, and information across the supply chain, ensuring operational excellence.

36 CFM - Issue 38 - Jun. 2024

INDUSTRY NEWS

Howmet Aerospace Announces Leadership Appointment

Johan (John) Wall joined Howmet Aerospace (NYSE: HWM) as President of Engineered Structures on April 8, 2024. In this position, John has taken charge of all Engineered Structures employees and locations globally. John is located in Cleveland, OH, and reports directly to John Plant, Executive Chairman and Chief Executive Officer.

John holds a bachelor's degree in mathematics from the University of Waterloo, Canada.

About Howmet Aerospace

Howmet Aerospace Inc., headquartered in Pittsburgh, Pennsylvania, is a leading global provider of advanced

engineered solutions for the aerospace and transportation industries. The Company's primary businesses focus on jet engine components, aerospace fastening systems, and airframe structural components necessary for missioncritical performance and efficiency in aerospace and defense applications, as well as forged aluminum wheels for commercial transportation. With approximately 1,150 granted and pending patents, the Company's differentiated technologies enable lighter, more fuel-efficient aircraft and commercial trucks to operate with a lower carbon footprint.

The EU-New Zealand Trade Agreement Enters into Force

The trade agreement between the European Union and New Zealand entered into force on 1 May 2024.John holds a bachelor's degree in mathematics from the University of Waterloo, Canada.

Bilateral trade in goods between the two partners has risen steadily in recent years, reaching almost €9.1 bn in 2022.

The EU is New Zealand's third-biggest trading partner. The implementation of the trade agreement is expected to

further enhance this relationship, fostering increased trade and investment flows between the two regions.

According to an impact assessment on the FTA, trade between New Zealand and the EU is expected to increase by 30%, with removing tariffs alone saving businesses €140 million in duties per year. Moreover, EU investment flows into New Zealand could increase by over 80%.

INDUSTRY NEWS

CFM - Issue 38 - Jun. 2024 37

Global Crude Steel Production Reached 469 Million Tonnes in the First Quarter of 2024

In the first quarter of 2024, global crude steel production reached 469 million tons, a year-on-year increase of 0.5%. In March 2024, the crude steel production of 71 countries and regions included in the statistics of the World Steel Association was 161.2 million tons, a 4.3% decrease compared to March 2023.

Regional crude steel production in March 2024:

Africa's crude steel production was 1.9 million tons, an increase of 1.1% year-on-year.

Asia and Oceania's crude steel production was 118.3 million tons, a decrease of 5.8%.

The EU (27 countries) crude steel production was 11.6 million tons, a decrease of 4.3%.

Other European countries' crude steel production was 3.9 million tons, an increase of 11.0%.

The Middle East's crude steel production was 4.8 million tons, an increase of 4.0%.

North America's crude steel production was 9.5 million tons, a decrease of 1.4%.

Russia and other CIS + Ukraine's crude steel production was 7.8 million tons, an increase of 1.5%.

South America's crude steel production was 3.5 million tons, a decrease of 0.2%.

Top 10 countries in terms of crude steel production in March 2024:

China's crude steel production was 88.27 million tons, a decrease of 7.8% year-on-year.

India's crude steel production was 12.7 million tons, an increase of 7.8%.

Japan's crude steel production was 7.2 million tons, a decrease of 3.9%.

The United States' crude steel production was 6.9 million tons, flat year-on-year.

Russia's estimated crude steel production was 6.6 million tons, an increase of 0.8%.

South Korea's crude steel production was 5.3 million tons, a decrease of 9.5%.

Germany's crude steel production was 3.5 million tons, an increase of 8.4%.

Türkiye's crude steel production was 3.2 million tons, an increase of 18.0%.

Brazil's crude steel production was 2.8 million tons, an increase of 5.6%.

Iran's crude steel production was 2.8 million tons, an increase of 2.0%.

38 CFM - Issue 38 - Jun. 2024

Mar 2024 (Mt) % change Mar 24/23 Jan-Mar 2024 (Mt) % change Jan-Mar 24/23 Africa 1.9 1.1 5.6 8.3 Asia and Oceania 118.3 -5.8 345.9 -0.4 EU (27) 11.6 -4.3 33 -1.4 Europe, Other 3.9 11 11.3 20.5 Middle East 4.8 4 13.7 12.1 North America 9.5 -1.4 27.2 -1.9 Russia & other CIS + Ukraine 7.8 1.5 21.8 1.6 South America 3.5 -0.2 10.6 3.2 Total 71 countries 161.2 -4.3 469.1 0.5 Country Mar 2024 (Mt) % change Mar 24/23 Jan-Mar 2024 (Mt) % change Jan-Mar 24/23 China 88.3 -7.8 256.6 -1.9 India 12.7 7.8 37.3 9.7 Japan 7.2 -3.9 21.5 -0.8 United States 6.9 0 19.9 -1.6 Russia 6.6 e 0.8 18.7 -0.2 South Korea 5.3 -9.5 16.2 -2.5 Germany 3.5 8.4 9.7 6 Türkiye 3.2 18 9.5 28.4 Brazil 2.8 5.6 8.3 6.2 Iran 2.8 2 7.6 16.3 e – estimated. Ranking of top 10 producing countries is based on year-to-date aggregate. INDUSTRY NEWS

CFM - Issue 38 - Jun. 2024 39

Brazil to Levy Import Tax on Solar Panels

The Management and Executive Committee of Brazil's Foreign Trade Council has made an important decision to levy import tax on imported solar panels from January 1, 2024, and will resume the imposition of import duties on 324 categories of related products within 60 days.

Meanwhile, Brazil has enacted a tax reform bill aimed at simplifying its tax system. Additionally, Brazil will also review the common external tariffs of the Mercosur.

It is noteworthy that imported solar panels will be subject

to a 10.8% Mercosur external uniform tariff from January 1, 2024. To facilitate the market's adaptation to the new regulations, GECEX has established a gradually decreasing taxfree quota until 2027.

Specifically, the quota for January to June 2024 is set at 1.13 billion USD; for July 2024 to June 2025, the quota is 1.01 billion USD; for July 2025 to June 2026, the quota is 717 million USD; and for July 2026 to June 2027, the quota is 403 million USD.

Indonesia Relaxes Import Tax Policy for Electric Vehicles

Indonesian President Joko Widodo has issued Presidential Decree No. 79 of 2023, which stipulates that the government will provide financial incentives to importers of battery electric vehicles (BEVs) in the form of exemptions from import duties and luxury sales taxes.

Simultaneously, the government has also adjusted the local component requirement for electric vehicles, known as the TKDN index. The previous regulation required that the TKDN index for electric two-wheeled and four-wheeled vehicles reach at least 40% by 2024, but this deadline has now been extended to 2026.

The specific standards are as follows:

① For electric two-wheeled and three-wheeled vehicles: from 2019 to 2026, the TKDN must reach at least 40%; from 2027 to 2029, the TKDN must reach at least 60%; and after 2030, the TKDN must reach at least 80%.

② For electric vehicles with four wheels or more: from 2019 to 2021, the TKDN must reach at least 35%; from 2022 to 2026, the TKDN must reach at least 40%; from 2027 to 2029, the TKDN must reach at least 60%; and after 2030, the TKDN must reach at least 80%.

Sources: www.luosi.com www.Wuerth-industry.cn www.cqn.com.cn www.chinanews.com China Iron and Steel Association World Steel Association www.howmet.com commission.europa.eu

40 CFM - Issue 38 - Jun. 2024

INDUSTRY NEWS

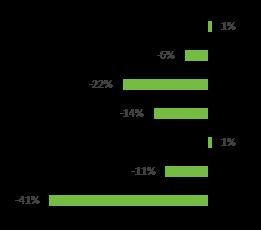

Restrained Demand in a Challenging Market Environment

In the first quarter of 2024, Bossard Group recorded a decline in sales of 15.5% to CHF 257.4 million (prior year: CHF 304.5 million) in a continuously challenging market environment and as a result of the strong Swiss franc.

The decrease in local currency was 11.2%. In a quarter-onquarter comparison, the record high comparative basis of the previous year is noticeable. As expected, demand in Europe continued to decrease, as it has since the second quarter of 2023. Sales declined by 12.2% to CHF 150 million (in local currency: -9.3%). Despite the challenging market environment, the first quarter saw continuing investments in future growth, additional efficiency and productivity improvements, including the successful rollout of the new ERP system in France.

Sales in America declined by 22.9% to CHF 65.8 million (in local currency: -18.4%). Since the record sales in the first quarter of the prior year, a normalisation of demand has been observed.

With a decline in sales by 13.9% (in local currency: -5.2%) to CHF 41.6 million, weaker demand persisted in Asia as well. The appreciation of the Swiss franc was particularly noticeable in this market region. The continued two digit growth rates in India marked a gratifying exception, as Bossard benefited from

nearshoring trends, a dynamic start-up landscape, and the above average growth in the focus industries of electromobility and electronics.

Based on current market observations, Bossard expects the economy to remain restrained in the first half of 2024. However, even this market environment also offers growth opportunities. Thus, the acquisition of new customers as well as the project pipeline make Bossard optimistic for the future. In addition, the continued trend towards nearshoring and the digitalisation of processes, with a focus on efficiency and productivity enhancements, further strengthens the demand for Smart Factory services in the current environment. The Group continues to stand by the communicated medium-term financial goals and the consistent implementation of Strategy 200.

42 CFM - Issue 38 - Jun. 2024

News News provided by Fastener + Fixing Magazine www.fastenerandfixing.com

European

INDUSTRY NEWS

Bulten Group Reports Good Sales

Bulten Group has reported that net sales amounted to SEK 1.533 billion (€131.36 million) for the first quarter of 2024, an increase of 10.5% on the same period the previous year (2023: SEK 1.387 billion). Adjusted operating earnings totalled SEK 116 million, equating to an adjusted operating margin of 7.5%.

Bulten highlights that to achieve the strategic ambitions on the markets where it operates, and further increase innovative power, the organisation was restructured at the beginning of the quarter.

The new interdisciplinary regional structure is divided into three regions – Europe, Asia and North America –which were given responsibility for sales, manufacturing and financial results. There were also adaptations to the company's engineering resources, in order to enhance product development and innovation.

"The year began with good sales and a sequentially improved operating margin. It is clear that efforts following the capacity challenges in Europe and the launch of a new regional organisational structure, combined with closer cost control,

are starting to have an impact on financial results,"

comments Christina Hallin, interim president and CEO.

"I am pleased to see the operating margin has improved on the three previous quarters, and it is satisfying too that our customer mix in automotive, along with sales in new customer groups, is contributing to stable growth. It is also worth noting that we have now had two consecutive quarters with sales in excess of SEK 1.5 billion. Again this quarter, our main priority has been to reduce the production backlog in Europe, which is adding extra costs. We have not yet caught up but have made good progress, and this can also be seen in the improved operating margin," adds Christina.

Scell-it Announces Strategic Double Acquisition

Scell-it (UK) has expanded its presence in the UK by acquiring both Rivco Ltd and Kamtech Fasteners (ARK brand), strengthening its position as one of the leading distributors nationally of construction fixings, rivets, rivnuts and setting tools. This will further enhance the wide Scell-it (UK) Group brand range with names such as ARK, Huck®, FAR, RIVIT and Lobster.

Kidderminster-based Rivco was established in 1994 and is a longstanding player in the UK market, bringing an existing turnover of circa GB£3 million (€3.4 million) and a workforce of ten sales and warehouse staff. This acquisition complements the direction and vision of the Group's growth strategy.

Kamtech Fasteners, based in West Bromwich, was established in 2015 and has a customer base that perfectly aligns with that of Scell-it (UK). This acquisition brings a further GB£1.5 million of turnover and four sales and warehouse staff to the newly formed Group. Steven Auld, the original majority shareholder of both acquired businesses, will continue with the Group in his new role as joint managing director, supporting the Group's staff and customers.

Gary Moseley, joint managing director and one of the founding shareholders of Scell-it (UK), says: "We are thrilled to announce our acquisition of Rivco and Kamtech Fasteners, both businesses have excellent reputations in the UK and align perfectly with the existing Group. From initial discussions it was

clear that this acquisition would fit in perfectly with our existing culture and help strengthen our position in the marketplace."

"These acquisitions reinforce Scell-it (UK) Group's dedication to providing unparalleled supply at competitive prices to meet the precise needs of our customers. We will continue to look for opportunities to grow and Steven and I are excited to embark on this journey with both teams, leveraging our combined expertise to ensure a seamless integration for all involved."

European partners, Scell-it SAS, based at the Group's headquarters in France, echoes this growth vision. With established operations in Poland and Italy, it actively seeks further European acquisitions, propelling the total Group revenue beyond the current €50 million mark.

CFM - Issue 38 - Jun. 2024 43

INDUSTRY NEWS

Daniel Westberg Appointed New CEO for Nord-Lock Group

Nord-Lock Group, a global leader in bolting and engineering solutions, has announced Daniel Westberg as its new Chief Executive Officer. Daniel will assume his responsibilities as CEO on 1st August 2024.

Daniel comments: "I am honoured and excited to take on the role of CEO at Nord-Lock Group, a company with a rich legacy. The Group is on an exciting journey, and I look forward to unlocking new horizons and developing the Group and its four technology brands towards even greater success."

For more than 20 years, Daniel has held various executive level roles within SKF Group and its different subsidiaries, both in Sweden and abroad, most recently Daniel served as president and CEO at Ewellix.

"The appointment of Daniel as CEO marks an exciting chapter for Nord-Lock Group and Latour. Daniel has proven to drive results and has consistently propelled the

businesses he has led forward. With his international industrial background, strong commercial and technical understanding, Daniel brings a fresh perspective and strategic vision to the organisation," says Johan Menckel, chairman of the board for Nord-Lock Group.

Daniel holds a master of science in mechanical engineering, and his strong technical acumen, along with a passion for innovation, has been instrumental throughout his career. Having lived and worked in Canada, Germany, and France, Daniel has an extensive global background. These diverse cultural encounters have brought enriched perspectives and provided valuable insights that Daniel now brings into his role as CEO at Nord-Lock Group.

Stanley Black & Decker Expects Mixed Demand to Persist

First quarter revenues for Stanley Black & Decker reached US$3.9 billion (€3.6 billion), down 2% versus the previous year – as growth in DEWALT and Engineered Fastening was more than offset by lower infrastructure volume and muted consumer and DIY demand.

Donald Allan Jr, Stanley Black & Decker's president and CEO, comments: "Our first quarter performance was the result of consistent, solid execution and continued progress against key operational objectives. We continue to see significant value creation opportunities tied to our strategic business transformation, and we remain focused on disciplined execution of our strategy. Looking forward, we expect mixed demand trends to persist across our businesses in 2024, and we are driving supply chain cost improvements designed to expand margins, deliver earnings growth and generate strong cash flow. At the same time, the long-term growth and market

share gains we are focused on achieving, will be driven by introducing exciting new products within our most powerful brands – designed to deliver enhanced productivity for end users. We are funding growth investments intended to further accelerate innovation and differentiated market activation to capture these compelling long-term opportunities."

He continues: "Stanley Black & Decker continues to become a more streamlined business, built on the strength of our people and culture, with an intensified focus on our core market leadership positions in Tools & Outdoor and Industrial. I am confident that by executing our strategy, we are positioning

44 CFM - Issue 38 - Jun. 2024 INDUSTRY NEWS

the company to deliver higher levels of organic revenue growth, profitability and cash flow to drive strong long-term shareholder returns."

Patrick D. Hallinan, executive vice-president and CFO at Stanley Black & Decker, adds: "The actions we are taking to advance our strategic transformation are progressing successfully, and despite the tepid market backdrop so far in 2024, our profitability remains on an upward trajectory. We will continue our disciplined approach to cost management as we

drive toward our target of 35% adjusted gross margins – while funding additional organic revenue growth investments. The organisation is focused on delivering margin expansion, cash generation and balance sheet strength, while working together to position the company for long-term growth and value creation."

voestalpine Produces 'Green' Wire Rod

voestalpine has melted the first high-quality 'green' wire rod from hydrogen reduced pure iron and scrap at its site in Donawitz, Austria.

The hydrogen reduced pure iron was produced in the Hyfor pilot plant, while the landmark melting was carried out in the Group's own Technikum Metallurgie research facility – a unique, small but complete, steel plant. The CO2 reduced steel was further processed in the wire rod mill to produce roller bearing steel, which is characterised by its particular hardness and wear resistance. The product ion of high-quality, CO2 reduced steel grades is one of the biggest technological challenges in the transition to 'green' steel production.

greentec steel is an ambitious and feasible phased plan with which voestalpine can make a valuable contribution to achieving the climate goals. "We have already made a successful start on our path to 'green' steel production and are advancing quickly with the construction of two arc furnaces powered by 'green' electricity in Linz and Donawitz. Parallel to this, we are researching various breakthrough technologies with partners from industry and science. The first ever melting of hydrogen reduced pure iron and its further processing into high-quality wire rod is a historic milestone," comments Herbert Eibensteiner, CEO at voestalpine AG.

Hyfor is a joint research project of Primetals Technologies, voestalpine, Montanuniversität Leoben and K1-MET, with the goal of researching the use of hydrogen to reduce fine iron ore. In the future, the resulting hot sponge iron could be melted down in an electric arc furnace or used to produce hot briquetted iron (HBI).

"The Technikum Metallurgie provides us with an ideal test environment to quickly adapt our steels to the needs of our

customers and to changed market requirements. I am very pleased that we are now also doing pioneering work in 'green' steel production and would like to thank all the researchers and employees for their commitment," states Franz Kainersdorfer, head of the metal engineering division and member of the management board at voestalpine.

At the Technikum Metallurgie, voestalpine is conducting research into the production of new high performance steels, for subsequent processing into special rails, high-quality wire rod, as well as heavy-duty oil field pipes. The product development involves a CO2 reduced route – the input material is melted using electricity from renewable energy sources.

Austria's largest climate protection programme

In a first step from 2027, voestalpine will reduce its CO2 emissions by up to 30% by partially replacing its current coalbased blast furnace technology with electric arc furnace technology – powered by 'green' electricity.

This represents almost 5% of Austria's entire annual CO2 emissions, making greentec steel the largest cl imate protect ion programme in Austria. The Group is aiming for carbon neutral steel production by 2050 and is researching intensively on several new processes, as well as investing in pilot projects that explore new pathways in steel production.

CFM - Issue 38 - Jun. 2024 45 INDUSTRY NEWS

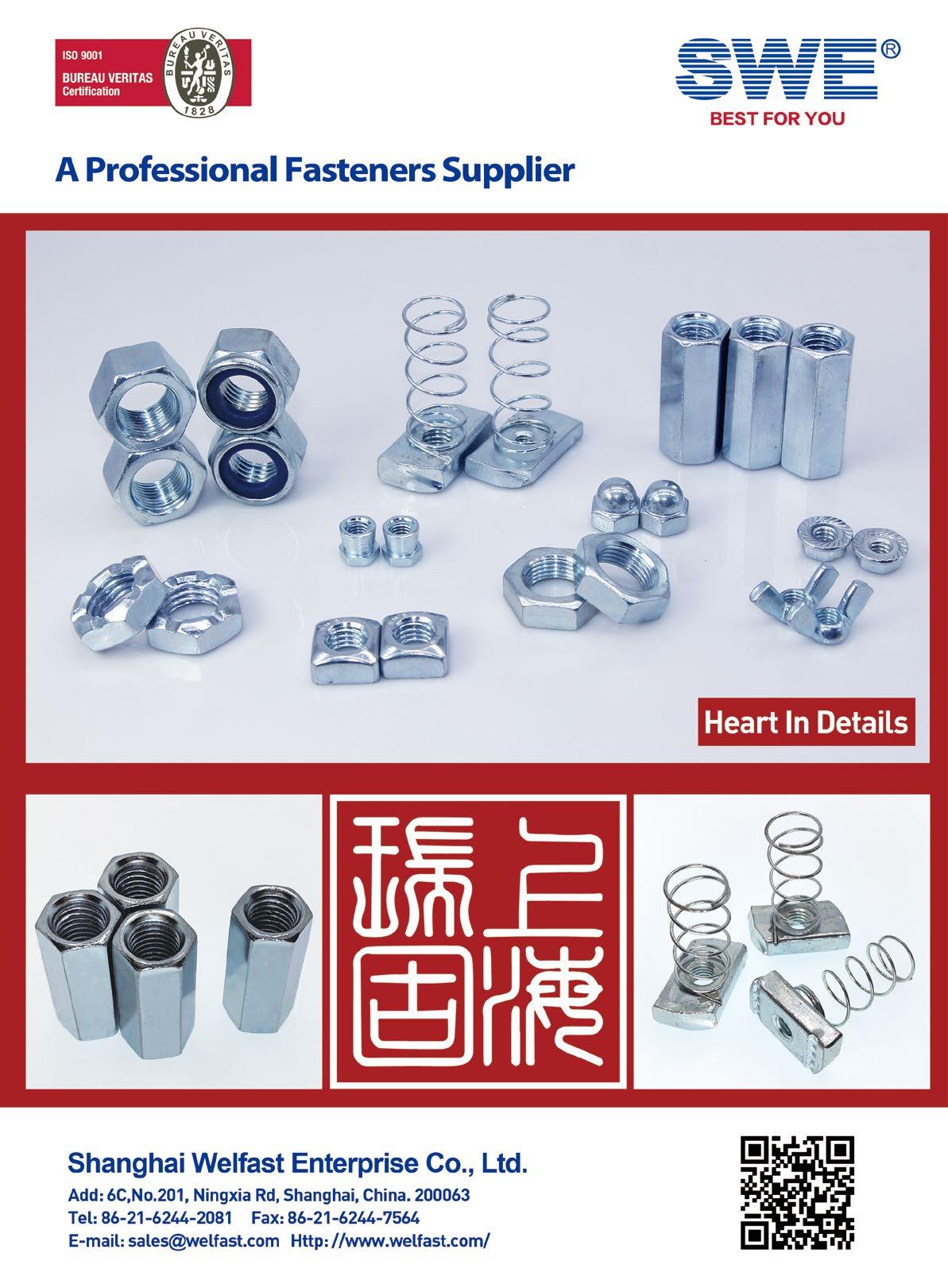

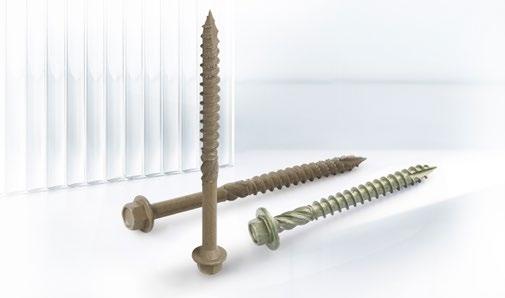

Based on Small Packaging Service

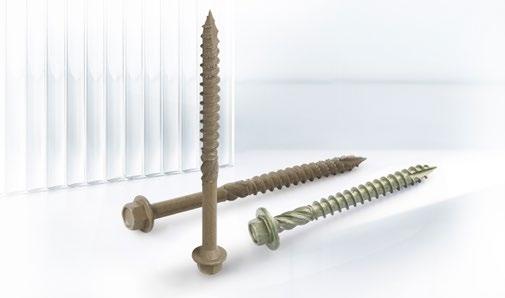

CHINFAST Expands DIY Fasteners Market in Europe and America

In order to further strengthen the link with the demand of first-tier retailers and distributors in Europe and the U.S., CHINFAST, having deeply engaged in the industrial fastener production for nearly 20 years, has been actively expanding its business from the production of advanced multi-purpose screws, timber fixing screws and decking screws made of 10B21 and C1022 to the DIY fasteners packaging service over the past 5 years. In the ever-changing global market, it hopes to create a new milestone for sustainable business development.

Diverse DIY fasteners packaging service intelligent ERP production management

Unlike typical mass production lines, DIY fasteners packaging are characterized by small quantities and diverse categories, which are more time-consuming and labor-intensive, and therefore must be adjusted in a timely manner according to product attributes and quantities. In view of this,

CHINFAST not only provides various tool boxes, plastic boxes/ bins, blisters, blister boxes, cardboards, polybags and various color boxes for customers to choose, but also provides 100% customized service according to customers' requirements.

"Backed by a strong professional team, we have introduced the ERP smart factory management system from production to packaging to ensure the flexibility and traceability. All products are controlled by the automated warehouse, and the automatic

46 CFM - Issue 38 - Jun. 2024

COVER STORY

packaging line with more than 10 semi-automatic packaging machines is also directly connected to the stereoscopic warehouse, and the AGV automatic shuttle vehicles are applied to transport the goods directly to each packaging table, which effectively saves the goods delivery time and enhances the packaging efficiency and flexibility," said CHINFAST.

Professional packaging team and equipment create a smooth one-stop service

CHINFAST has nearly 60 packaging staff with years of experience to assist customers in designing the optimized packaging methods to achieve twice the result with half the effort. At the same time, it has also worked with the automated packaging equipment factory to successfully develop 4 models (totally 12 sets) of packaging equipment which best fit the characteristics of their products, enabling them to significantly

improve the packaging efficiency. From production to packaging, it completely follows the ISO 9001 specification. There are 10 QC employees to conduct strict quality inspection from raw materials to finished products, and all testing data are kept in record to ensure traceability.

"As an emerging DIY fastener factory, although DIY fastener packaging service currently only accounts for 6% of our annual export volume and in 2023 our total sales reached 7,900 containers, we are confident that we can perform better in the next few years," said CHINFAST.

CE certified

ETA certification application in progress

CHINFAST has been active in increasing its competitive edge in recent years. In addition to getting many screws CE certificates, its wholly-owned Haiyan Yousun Enterprise Co., Ltd (Factory code:C788) has also successfully obtained the favorable 39.6% tax rate in Europe. In the future, if it successfully obtains the ETA certification, together with DIY fastener packaging service, it is expected to increase its proportion and competitiveness of screws exported to Europe.

"With the challenges of global economic contraction, customer demand weakening, unstable raw materials prices and exchange rates, we will continue to refine our capability, cherish every order, provide the best service, and be more dedicated to the DIY fasteners' field. " said CHINFAST.

CFM - Issue 38 - Jun. 2024 47

Analysis of the Current Status and Market Potential of the Aerospace Fastener Industry

The aerospace fastener industry serves as an integral part of the aerospace industry chain, providing critical components for the manufacturing and maintenance of aircraft, rockets, and other aerospace vehicles. With the rapid development of the global aerospace industry, the fastener industry has also exhibited robust growth. Moreover, due to the high precision and reliability requirements of aerospace fasteners, their technological content and market value are relatively high.

In recent years, with the continuous advancement of aerospace technology and the sustained growth of market demand, the aerospace fastener industry faces vast development opportunities and tremendous market potential. However, the industry also faces challenges such as rapid technological updates and fierce market competition. Therefore, conducting a thorough analysis of the current status of the aerospace fastener industry and exploring its market potential are crucial for promoting the sustained and healthy development of the industry. This study aims to comprehensively and deeply analyze the current status of the aerospace fastener industry to reveal its development trends and future potential.

Overview

Fasteners, such as bolts, nuts, washers, pins, and others, occupy an irreplaceable position in the aerospace industry. They serve as essential components in aerospace equipment, securely connecting various parts and structures to ensure the stability and safety of the entire system. Under extreme conditions such as high-speed flight, heavy loads, and high vibrations, aerospace fasteners must withstand immense

pressure and tensile forces while maintaining exceptional performance and reliability.

Moreover, the quality of fasteners directly impacts the overall performance and lifespan of aerospace vehicles. High-quality fasteners can ensure the structural strength and stability of aerospace vehicles, reduce failure rates, and enhance safety. Therefore, the aerospace fastener industry plays a crucial role in ensuring the safety and reliability of aerospace vehicles.

With the rapid development of the global aerospace industry, the status of the aerospace fastener industry in the global economy has become increasingly prominent. As an essential link in the aerospace industrial chain, the fastener industry is closely related to the manufacturing and maintenance of aerospace vehicles such as aircraft and rockets, playing a significant role in promoting the development of the aerospace industry.

Currently, the aerospace fastener industry has formed a relatively complete industrial chain and market system. Upstream raw material suppliers provide high-quality titanium alloys, aluminum alloys, stainless steel, and other raw materials. Midstream fastener manufacturers utilize advanced production processes and equipment to produce fasteners that meet the requirements of the aerospace industry. Downstream aerospace equipment manufacturers then incorporate these fasteners into the manufacturing and maintenance of aircraft, rockets, and other aerospace vehicles.

Looking ahead, the aerospace fastener industry has broad development prospects. On the one hand, with the continuous advancement of aerospace technology and the sustained growth of market demand, the aerospace fastener industry will encounter more development opportunities. On the other hand, the emergence and application of new materials and processes will bring new breakthroughs and development spaces to the fastener industry.

Industry Status Analysis

1 Market Size and Growth

The global aerospace fastener industry boasts a vast market size and maintains a continuous growth trajectory. With the constant advancements in aerospace technology

48 CFM - Issue 38 - Jun. 2024 INSIGHT

and the expansion of the global aerospace market, fasteners, as indispensable components in aerospace equipment, are experiencing steady growth in market demand. Additionally, the research and development of new aerospace vehicles are providing new growth points for the fastener industry.

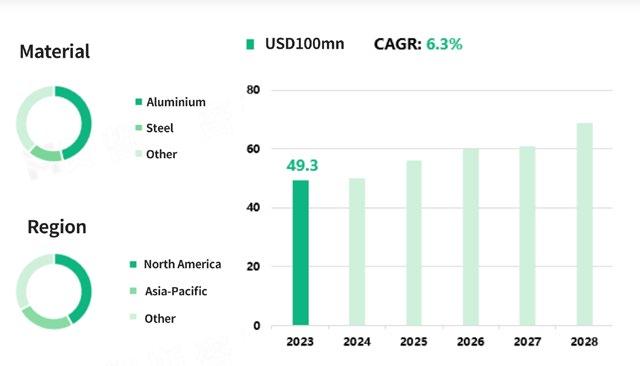

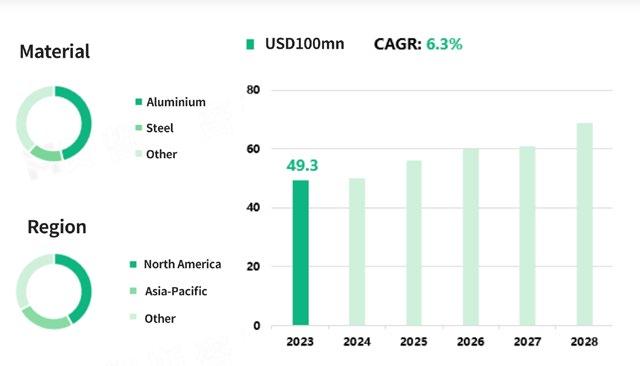

Globally, the market size of aerospace fasteners exhibits a steady growth trend. Based on a report published by Win Market Research, the global aerospace fastener market reached a size of USD 4.93 billion in 2023 and is expected to grow at a compound annual growth rate of 6.3% from 2023 to 2028.

Based on material segmentation, fasteners can be categorized into aluminum, steel, titanium, and other materials. Aluminum dominates the market in 2023 due to its high strength, resistance to extreme temperatures, weight reduction, high versatility, corrosion resistance, and creep resistance. Regionally, North America is a significant production hub for civil and defense aircraft, occupying a leading position in the market in 2023. The Asia-Pacific region, driven by the increasing number of component manufacturers in countries like India, China, and Southeast Asia, is experiencing growing demand for aerospace fasteners, demonstrating significant potential for development.

As one of the largest aerospace markets globally, China's aerospace fastener industry has demonstrated robust growth momentum. In recent years, driven by the rapid development of China's aerospace industry and the country's emphasis on the aerospace sector, the market size of aerospace fasteners in China has continuously expanded, exemplified by fasteners produced by Guangdong STL Fastening System Co., Ltd., which contributed to the commercial maiden flight of the C919 aircraft. Meanwhile, Chinese fastener enterprises are constantly strengthening technological innovation and product upgrading, improving product quality and performance, to meet the demands of the global market.

2 Market Structure

The market structure of the aerospace fastener industry is relatively complex, involving multiple layers and links. From the perspective of the industrial chain, the upstream of the aerospace fastener industry mainly includes raw material suppliers, while the midstream comprises fastener manufacturers, and the downstream consists of aerospace equipment manufacturers.

Globally, the aerospace fastener market exhibits a certain oligopoly competition pattern. Internationally renowned fastener manufacturers such as Precision Castparts Corp, Howmet Aerospace, and LISI Aerospace occupy a dominant position in the market due to their advanced technologies, superior products, and extensive market channels. These companies have consolidated their leading positions in the global aerospace fastener market through continuous technological innovation and market expansion.

50 CFM - Issue 38 - Jun. 2024

Figure 2: Global Aerospace Fastener Market Size and Segmentation Analysis

INSIGHT

Figure 3: Growth Rate of the Aerospace Fastener Market by Region (2022-2027)

Meanwhile, Chinese aerospace fastener enterprises are rapidly growing and strengthening. Some companies with technological strength and market competitiveness have gradually increased their market share by introducing advanced foreign technologies, strengthening independent research and development, and expanding production scale. Additionally, some private enterprises are actively involved in the aerospace fastener sector, gradually gaining a foothold in the market through differentiated competition and specialized services.

Overall, the market structure of the aerospace fastener industry is undergoing positive changes. With the continuous development of global enterprises and intensified market competition, the market landscape will become more diversified and complex.

3 Technical Developments

· Application of New Materials

The aerospace fastener industry has made significant progress in material application in recent years. With the continuous development of new material technologies, the types of materials used in aerospace fasteners are constantly expanding. Traditional materials such as aluminum alloys and titanium alloys still occupy an important position, but new composite materials, including carbon fiber composites and high-temperature alloys, are gradually being utilized. These new materials possess excellent mechanical properties, high temperature resistance, and corrosion resistance, meeting the increasingly demanding requirements for fasteners in the aerospace industry.

Moreover, the application of new materials has also facilitated technological innovation in the aerospace fastener industry. By conducting thorough research on the performance characteristics and application processes of new materials, fastener manufacturers can develop more advanced fastener products.

· Advancements in Manufacturing Processes

With the continuous progress of manufacturing technologies, the aerospace fastener industry has also made significant advancements in manufacturing processes. Traditional manufacturing processes such as casting, forging, and cutting are still widely used, but new manufacturing processes, including additive manufacturing and precision forming, are gradually being adopted. These novel manufacturing processes can significantly improve the production efficiency and precision of fasteners, reduce production costs, and provide strong support for the development of the aerospace fastener industry.

Furthermore, advancements in manufacturing processes are also reflected in the improvement of fastener surface treatment. Through special treatments such as spraying and coating, the wear resistance, corrosion resistance, and hightemperature resistance of fasteners can be enhanced, thereby extending their service life and reliability.

· Intelligence and Automation

With the rapid development of information technology, the aerospace fastener industry is gradually achieving intelligent and automated production. By introducing advanced intelligent equipment and systems, fastener manufacturers can achieve automated control and monitoring of the production process, thereby improving production efficiency and product quality. Simultaneously, intelligent technology can assist manufacturers in collecting and analyzing production data, providing strong support for production decision-making.

Furthermore, intelligent technology can also be applied to the quality inspection and monitoring of aerospace fasteners. Through the introduction of advanced inspection equipment and systems, real-time detection and monitoring of fastener quality can be achieved, allowing for the timely discovery and resolution of potential issues, ensuring the quality and reliability of the products.

4 Policy Environment

· National Policy Support

As an important component of the aerospace industry chain, the aerospace fastener industry has received significant attention and support from the nation. In recent years, the government has issued a series of policies to encourage and support the development of the aerospace fastener industry. These policies cover financial support, research and development assistance, and other aspects, providing strong policy guarantees for the growth of the fastener industry.

Simultaneously, the government has increased its investment and support for the aerospace industry, promoting the coordinated development of the entire industry chain. This effort is conducive to enhancing the overall competitiveness and market position of the aerospace fastener industry, creating a more favorable environment for its development.

· Environmental Requirements

With the global enhancement of environmental awareness and the increasingly stringent environmental regulations, the aerospace fastener industry is facing increasingly high environmental protection requirements. During the production process, fastener manufacturers need to strictly adhere to environmental protection regulations and adopt effective

CFM - Issue 38 - Jun. 2024 51

environmental protection measures to reduce their impact on the environment.

Simultaneously, the increase in environmental protection requirements has also facilitated the green development of the aerospace fastener industry. Manufacturers need to actively research and promote environmentally friendly fastener products, adopt environmentally friendly materials and processes, and improve the environmental performance of their products. This helps enhance the overall image and competitiveness of the fastener industry, laying a solid foundation for the sustainable development of the industry.

In summary, the aerospace fastener industry is exhibiting positive development trends in both technological advancement and policy environment. With the application of new materials, new processes, and intelligent technologies, as well as national policy support and the increase in environmental requirements, the aerospace fastener industry will usher in broader development spaces and opportunities.

Market Potential

With the rapid development of aerospace technology and the continuous expansion of the global market, the aerospace fastener industry faces tremendous market demand and development opportunities. The following is an analysis of the market potential of aerospace fasteners, mainly including technological innovation opportunities and policy opportunities.

1 Technological Innovation Opportunities

Aerospace fasteners serve as the critical components connecting and securing aerospace structures, components, and mechanical systems. Their performance and quality directly impact the safety and reliability of the entire aerospace vehicle. Therefore, as aerospace technology continues to innovate and upgrade, the requirements for fastener performance and quality are also constantly increasing.

In terms of technological innovation, the aerospace fastener industry will continuously emerge with new materials and manufacturing processes. For example, the application of novel materials will further enhance the strength of fasteners. Meanwhile, advanced manufacturing processes and intelligent manufacturing technologies can improve the production efficiency and precision of fasteners, reducing production costs. These technological innovations will drive the aerospace fastener industry towards higher performance, lighter weight, and more environmentally friendly development, opening up immense growth potential for the market.

2 Policy Opportunities

The policy environment plays a crucial role in driving the development of the aerospace fastener industry. In recent years, governments of various countries have introduced policies to support the growth of the aerospace industry, providing a favorable development environment for the fastener industry.

In China, the government has attached great importance to the development of the aerospace industry and issued a series of policies to encourage and support the innovation and development of the aerospace fastener industry. For instance, through financial support and other measures, the government encourages enterprises to increase investment in research and development, thereby improving product quality and technological levels.

Conclusion

The aerospace fastener industry, as a crucial component of the aerospace industry, exhibits a positive development trend with immense potential. Globally, the aerospace fastener market continues to expand, primarily driven by the rapid growth of the aerospace industry and the constant expansion of the global market. Simultaneously, with the emergence of new materials, processes, and technologies, the performance and quality of aerospace fasteners have significantly improved, injecting new vitality into the industry's development. Enterprises should increase their investment in research and development, continuously introducing fastener products with higher performance and quality to meet the increasingly demanding requirements of the aerospace sector. Additionally, businesses can leverage international trade platforms to strengthen cooperation and exchanges with international peers, jointly promoting the development of the aerospace fastener industry.

Sources:

· Market Monitor

· Mordor Intelligence

52 CFM - Issue 38 - Jun. 2024 INSIGHT

CFM - Issue 38 - Jun. 2024 53

Jiashan Sanyung Electric Furnace Industry Co., Ltd.: A Premier in the Field of Heat Treatment Equipment

Overview and Achievements

As an important member of Taiwan's Sanyung Group, Jiashan Sanyung Electric Furnace Industrial Co., Ltd. has inherited and carried forward the group's 53-year-long history and excellent tradition. Since its establishment in Jiashan in 1997, the company has been deeply rooted here for 26 years, gradually establishing its market position with steady steps and unremitting efforts. Jiashan Sanyung Electric Furnace Industrial Co., Ltd. has always adhered to the business philosophy of "steady growth, customer-oriented, and shaping a professional image". It is committed to the research

and development of new products and new technologies, striving to improve the quality superiority of heat treatment and help customers reduce production costs. Therefore, the Sanyung brand is widely supported and trusted by customers around the world. At present, the sales business of Jiashan Sanyung Electric Furnace Industrial Co., Ltd. has spread to many countries and regions around the world, including the United States, Germany, Italy, Brazil, Mexico, Russia, the Czech Republic, Turkey, Iran, South Africa, India, Bangladesh, Dubai, the Philippines, Thailand, Indonesia, Malaysia, Singapore, Vietnam, Japan, mainland China, and Hong Kong, providing quality services to global customers.

Main business: heat treatment equipment

Jiashan Sanyung Electric Furnace Industry Co., Ltd., focuses on the research and development and production of heat treatment equipment. Its products have been deeply applied in many fields such as automobiles, motorcycles, bicycles, aerospace, high-speed rail, wind power generation, construction, bearings, fasteners, hand tools, industrial and household air conditioners, etc., demonstrating its wide market adaptability and high professionalism. The company attaches great importance to the specialization, standardization and humanization of its products, constantly improving its products and services. With excellent quality

54 CFM - Issue 38 - Jun. 2024 FEATURED COMPANY

as its core competitiveness, it has successfully won wide recognition in the market. This pursuit and adherence to quality has enabled Jiashan Sanyung Electric Furnace Industry Co., Ltd. to establish a solid position in the industry. As a brand with a long history, Jiashan Sanyung Electric Furnace Industry Co., Ltd. has always adhered to the spirit of innovation and continuously developed new technologies and products. With multiple national patents and excellent performance, the company has occupied an important position in the market and maintained strong competitiveness in the fiercely competitive market environment. As a brand that keeps pace with the times, Jiashan Sanyung Electric Furnace Industry Co., Ltd. constantly pursues innovation and change, demonstrating strong vitality, and injecting more vitality and momentum into the development of the industry.

Future Development Direction

Jiashan Sanyung Electric Furnace Industry Co., Ltd. is deeply aware of the importance of protecting the environment for both the enterprise and society. The company actively commits to producing energy-saving and environmentfriendly equipment, striving to reduce its impact on the environment during the production process, such as reducing dust emissions. The company adheres to the path of green development, which not only benefits society but also brings long-term benefits to the enterprise. In terms of equipment intelligence, Jiashan Sanyung Electric Furnace Industry Co., Ltd.'s equipment can perfectly adapt to customers' automatic warehousing systems and fully automatic unmanned operating systems, while meeting the CQI-9 standard. This provides effective quality control for high-end product industries. Its products are widely used in military industry, automotive components, fasteners, metal heat treatment and other fields, effectively enhancing market competitiveness.

Research and Development and Innovation

Jiashan Sanyung Electric Furnace Industry Co., Ltd. has always regarded research and development and innovation as the core driving force for the company's development. To meet the constantly changing needs of customers and the market, the company combines the strengths of its business, research and development, and procurement departments to conduct in-depth research and careful planning for equipment improvement, from demand collection, research and development, to component selection. Currently, Jiashan Sanyung Electric Furnace Industry Co., Ltd. has dozens of technical patents, fully demonstrating the company's excellent strength in the field of technical research and development. Looking ahead, the company plans to increase its investment in research and development, as well as innovation, by 5% annually to ensure that the enterprise maintains a rapid update rate, consistently introduces more competitive products, and fulfills the evolving demands of the market.

International Market

Jiashan Sanyung Electric Furnace Industry Co., Ltd. is well aware of the crucial role of brand positioning, integrity, and high-quality products and services in expanding its presence in the international market. With the continuous advancement of globalization, the company actively seeks a precise understanding of its target international markets. To this end, Jiashan Sanyung Electric Furnace Industry Co., Ltd. actively participates in international exhibitions and increases its investment in online marketing, aiming to enhance the brand's exposure, image, and influence on a global scale. Through these efforts, the company has not only consolidated its cooperation with existing customers but has also successfully attracted many potential customers. This strategic direction will be the core of Jiashan Sanyung Electric Furnace Industry Co., Ltd.'s sustained development both now and in the future.

CFM - Issue 38 - Jun. 2024 55

Jiaxing Kinfast Hardware Co., Ltd.: Screw Is Small, Responsibility Is Big

Development History

In 2002, a young and ambitious man, Mr. Qu Hong, was fortunately funded by one of his well-trusted clients. Together, they chose a piece of land in the fields of Haining, Jiaxing, Zhejiang, and started screws production.This is the initial story of KINFAST.Over the past two decades, this land has witnessed the birth of countless screws. These screws, carrying the aspirations, dedication, and passions of the two founders, have traversed vast oceans and reached the hands of people in over 96 countries and regions around the world.

After 24 years of steady development, Jiaxing Kinfast Hardware Co., Ltd. has transformed into a production-oriented enterprise occupying an area of 24,600 square meters. Locally in Jiaxing, the company has constructed three production workshops and two buildings. Currently, Kinfast's monthly production capacity has reached an impressive level: 600 tons of carbon steel products, 100 tons of stainless steel products, 150 tons of nails, and 3,000 thousand pieces of injection molded parts.

At present, Kinfast has a professional team of about 150 employees in the Jiaxing plant, including a R&D team of 10 people. At the same time, Kinfast has also set up offices in Jiaxing city center and Shenzhen, that enlarges the Kinfast group into a well-knit family with 200 employees. Kinfast has always adhered to a people-oriented philosophy, gathering numerous industry professionals to jointly propel the company forward.

Kinfast's Vision

Kinfast's Mission

The mission of Kinfast is to transform customer problems into solutions, and provide clients with the best quality products and services with innovation and passion.

The vision of Kinfast is to truly achieve sustainable social value creation by improving processes, increasing efficiency, investing in employees, and strengthening R&D.

Core Product: Concrete Screw

The first screw born in Jiaxing Kinfast Hardware Co., Ltd. is concrete screw. After 24 years of precipitation, concrete screw has always stood out with its strong competitiveness. Kinfast has always been committed to the manufacture of concrete screws, with a continuous and improving attitude towards product innovation and R&D. Kinfast has invested a lot of effort and time in the development and manufacture of long concrete screws, special concrete screws, and concrete screws made of stainless steel.

With a firm pursuit of innovation and quality, Kinfast has solidified its market position and continuously expanded its product line to meet the changing needs of customers. Its excellent performance in the concrete screw industry demonstrates its commitment to ultimate quality. Kinfast continues to develop new products and strives to achieve the highest standards of performance and durability. Kinfast's continuous investment in R&D has enabled its products to always be at the forefront of technological innovation in the fastener industry, providing customers with reliable and innovative construction and fastening solutions.

Competitive Edge

Kinfast, whose founder initially specialized in international trade, possesses a unique advantage in analyzing and

56 CFM - Issue 38 - Jun. 2024

FEATURED COMPANY

comprehending customer needs. We not only focus on screw manufacturing, but also have a profound affection for the fastener industry and are committed to dedicating ourselves to the overall development and advancement of the fastener industry. Therefore, we are not just manufacturers to our customers, but also development partners who grow and progress alongside them.