Founded in 2005, CHINFAST boasts two wholly-owned factories, namely Joystart Automotive Parts (Zhejiang) Co., Ltd. and Haiyan Yousun Enterprise Co., Ltd., with an export volume of 8,000 containers in 2023. Deeply rooted in the fastener industry, CHINFAST has established business relationships with more than 500 enterprises worldwide. To further strengthen its connection with the demands of first-tier retailers and distributors in Europe and the United States, CHINFAST Co., Ltd., which has been specializing in industrial fastener production for nearly 20 years, has actively expanded its business over the past five years. It has extended its business from the original focus on the manufacturing of multi-purpose wood screws, timber screw and decking screws to DIY fastener packaging services, aiming to create a new milestone for the sustainable development of the enterprise in the everchanging global market.

The main products of CHINFAST are multi-purpose wood screws, trumpet head wood screws, and various window

fastener series. Its patented pointed tail design offers superior speed performance compared to ordinary fasteners. Meeting the 1,200-hour salt spray requirement allows customers with anti-corrosion and rust-proof requirements to use them with greater peace of mind. CHINFAST is currently developing a product with a double-cut tail, which is in the trial production stage. The patented double-cut tail design elevates the product's performance to a new level. This product combines the advantages of wood screws, self-tapping screws, and selfdrilling screws, providing customers with a brand-new and efficient user experience.

The ERP smart factory management system ensures the traceability of all products from production to packaging. CHINFAST is equipped with double first-class laboratories, and the production process strictly follows the ISO9001 system.

With 15 QC personnel, each batch of products must undergo initial inspection, process inspection, warehousing inspection, packaging inspection and final inspection, with records kept online for each step to ensure traceability. The responsibility of CHINFAST's QC personnel is to prevent any defective products from reaching customers. CHINFAST is equipped with advanced cold heading equipment imported from Taiwan, China, which has more stable performance. At the same time, the workshop is equipped with automatic three-dimensional warehouses, automatic packaging lines and AGV robots, which play an important role in the company's production and packaging of high-quality fasteners.

Europe is one of the main markets of CHINFAST. In the future, CHINFAST will continue to develop deeply in Europe and expand into the South American and Australian markets. It is believed that with the expansion of these markets, CHINFAST's export volume will reach a new high.

As the president of Jiaxing Fastener Import and Export Association, General Manager Yu Fengming has spared no effort to develop the fastener export business. CHINFAST is an enterprise with 20 years of experience in fastener exports, holding ETA and CE certifications, as well as SMETA and BSCI reports. The automated production and packaging standards of JOYSTART also provide a guarantee for CHINFAST to explore emerging markets. At the same time, as a factory with an average anti-dumping tax rate in Europe, YOUSUN benefits a larger number of European customers. CHINFAST is familiar with the needs of various markets and can quickly and accurately meet customer requirements, providing customers with high-quality after-sales service. In addition, CHINFAST has an experienced DIY packaging team, which has unparalleled competitiveness in terms of both financial strength and product professionalism.

In the wave of intelligent manufacturing, Kunshan Shengshirenhe Automation Technology Co., Ltd. (hereinafter referred to as "Shengshirenhe") has emerged as a leader in the inspection equipment industry with its outstanding products and profound industry experience. Since officially launching its inspection equipment for sale in 2019, Shengshirenhe has successfully sold nearly 1,500 various types of inspection equipment within just five years, a remarkable achievement that vividly interprets the company's corporate spirit.

The initial journey of Shengshirenhe was not without challenges. Facing the uncertainties and difficulties of the market, the company's founder and his team, despite starting with just ten members, leveraged their collective experience of over a decade in the industry and extensive industry connections to successfully earn the trust and support of customers. The founder reminisced, "During the early stages of our venture, many customers chose to support us without hesitation, even knowing that we were a startup, because they believed in me." This trust served as a solid foundation for Shengshirenhe's sustained development.

In today's increasingly diversified market, Shengshirenhe remains steadfast in its commitment to customer-centricity. To meet customers' expectations for rapid delivery, the company continuously optimizes its production processes, selects professional suppliers, and promotes standardized and modular delivery of components, significantly enhancing production efficiency. Additionally, in response to customers' customized demands, Shengshirenhe deeply analyzes industry trends, transforming customers' individual needs into industrystandard solutions that cater to a broader market. This innovative

model not only elevates customer satisfaction but also helps the company secure a larger market share.

The outbreak of the COVID-19 pandemic brought unprecedented challenges to the global economy but also presented extraordinary development opportunities for Shengshirenhe. During the pandemic, personnel control measures and uncertainties, coupled with the return of international orders, led to a surge in demand for inspection equipment in China. Shengshirenhe swiftly seized this opportunity, emerging as a dark horse in the industry and achieving continuous growth in performance amidst adversity.

Shengshirenhe's products cover a wide range of equipment, including glass disk inspection equipment, indexing disk inspection equipment, eddy current inspection equipment, and go/no-go gauge inspection equipment, each designed to tackle specific inspection challenges in diverse scenarios.

Glass Disk Inspection Equipment: Tailored for screws, nuts, double-ended bolts and other products, this equipment can be equipped with 2-16 industrial cameras to achieve comprehensive product inspection.

Indexing Disk Inspection Equipment: Primarily used for inspecting bolts ranging from 20 to 200mm in size, this equipment can be configured with 3-12 industrial cameras based on customer requirements and features a straightness detection function for long bolts.

Eddy Current Inspection Equipment: Designed to test the hardness, high-frequency properties, and cracks of fasteners such as bolts and nuts, Shengshirenhe collaborates with IBG, a leading manufacturer of eddy current hosts in Germany,

ensuring advanced and stable inspection capabilities.

Go/No-Go Gauge Inspection Equipment:

Focused on the inspection of internal and external threads for go and no-go gauges, this equipment ensures the stability and reliability of products during installation.

Worth mentioning is that all Shengshirenhe's inspection equipment can be integrated with AI deep learning-based intelligent inspection software, enabling the detection of product appearance defects and providing customers with an unprecedented inspection experience.

Shengshirenhe's outstanding performance in customer service is one of the key reasons for its ability to stand out in the fiercely competitive market.

In terms of pre-sales service, Shengshirenhe conducts rigorous pre-shipment testing on each piece of equipment dispatched. This customized testing is strictly based on the unique product characteristics of each customer, ensuring that the equipment fully meets their inspection requirements before shipment. Furthermore, Shengshirenhe emphasizes the traceability of components. Before shipment, all equipment's components are labeled with traceable barcodes to facilitate future maintenance.

In after-sales service, Shengshirenhe demonstrates equal professionalism and efficiency. The company equips each piece of equipment with remote service software and wireless receiver cards, enabling it to provide remote support to customers at any time.

Participating in international exhibitions is a crucial way for understanding industry trends, showcasing corporate strength, and expanding into international markets.

Shengshirenhe regularly attends multiple renowned international exhibitions annually. Currently, the company has established a stable customer base in countries and regions such as Japan, Mexico, Turkey, Vietnam, and South Korea. To better serve the overseas market, Shengshirenhe is actively developing international agents. The company expresses its welcome to international agents interested in collaborating with Shengshirenhe to negotiate and explore cooperative opportunities together.

In the Chinese market, Shengshirenhe has established a network centered around its Kunshan headquarters, with branches and service points extending to regions such as Ningbo, Wenzhou, Dongguan, and Hebei. Looking ahead, Shengshirenhe plans to set up more branches and service points in the clustering areas of the fastener industry, aiming to enhance service quality by providing closer access to customers.

In the international arena, Shengshirenhe has expressed its commitment to successively developing agents in regions including North America, Europe, Japan, South Korea, Russia, and India. Through this channel, the company intends to further expand its international market presence and serve a broader range of international clients.

Regarding product development, Shengshirenhe consistently prioritizes customer needs. It will continue to develop new products that cater to market demands. Simultaneously, the company will further integrate resources to offer a comprehensive solution encompassing product inspection, packaging and palletizing.

In conclusion, by deepening its market layout in China, actively expanding into international markets, and continuously driving product innovation, Shengshirenhe's future development promises to be even brighter and more promising.

On June 18th, the opening ceremony of China Fastener Exporter Association (CFEA) and the High Quality Development Forum of Hardware and Fastener Industry were successfully held in Jiaxing, Zhejiang, China.

So far, CFEA has recruited 42 council members and over 200 members, representing approximately 60% of the China's fastener export share. CFEA plans to expand to around 500 members companies in the next two years, representing over 85% of China's fastener export share. Currently, China's fastener export market scale has broken through 15 billion USD.

Jiang Hui, the President of CCCMC, delivered a speech analyzing the challenges and obstacles faced by the current international trade situation. He elaborated on the original intention of the establishment of CFEA and its future development directions. At the same time, he earnestly hopes that colleagues in the fastener industry will work together to promote the development of China's fastener industry.

Subsequently, the conference reviewed and approved the CFEA's rules of procedure. Mr. Shen Jiahua, the President of the Zhejiang Fastener Industry Association, was elected as the first President of CFEA. Mr. Shen is also the founder and chairman

of Yuxing Fastener (Jiaxing) Co., Ltd. The brand "Yuxing" for nuts is well-known in the Chinese market, and with 60% of its products exported worldwide, Yuxing also enjoys a high reputation in the global market. Mr. Yang Junfeng, the founder of Fastener Expo Shanghai and the Chairman of Shanghai Ebseek Exhibition Co., Ltd., was elected as the Executive President of CFEA. Fastener Expo Shanghai has been an influential exhibition in the industry for 15 years.

Mr. Scott McDaniel, the President of NFDA, sent a congratulatory message expressing his congratulations on the establishment of CFEA and looking forward to long-term cooperation with CFEA. Mr. Andreas Bertaggia, the President of EFDA, expressed his congratulations on the establishment of CFEA and emphasized that the trade relationship between China and Europe is crucial to the fastener industry. However, he also pointed out that the industry is currently facing challenges such as the imposition of anti-dumping duties and the carbon border adjustment mechanism(CBAM). Therefore, he looks forward to cooperating with CFEA to jointly face these challenges.

The High Quality Development Forum of Hardware and Fastener Industry was also held on the same day. The forum conducted professional discussions on global economic and trade situation, CBAM interpretation, digitization of fastener quality management, as well as the import and export situation of fasteners, providing important information for participating enterprises.

CFEA aims to unite its member companies for product quality assurance and international competitiveness enhancement, playing an active role in anti-dumping coordination, international market development, construction of export-base, overseas investment, international relationship and communication mechanisms of government policies and regulations.

In the context of global economic integration, trade ties between China and Russia are continuously strengthening. On July 10th, a business exchange meeting focusing on the Russian market was held at the China Hangzhou International Expo Center. The event was hosted by ITE Group, one of Russia's top exhibition organizers. It aimed to deeply analyze the latest trends in the Russian market and further enhance cooperation between China and Russia in the fields of hardware, welding, and fasteners.

In recent years, trade relations between China and Russia have shown robust growth, with bilateral trade volumes continuously rising and repeatedly breaking historical records. The cooperation between China and Russia is deepening, particularly in industrial sectors such as hardware, welding, and fasteners, bringing more business opportunities and market space for enterprises on both sides.

Exhibitions are an important way to promote communication and cooperation between enterprises of the two countries. Among the participating enterprises, Zhejiang companies are a significant force. Recent data indicates that in 2023, Zhejiang enterprises accounted for 53.8% of Chinese companies participating in the hardware, welding, and

fastener sectors in Russia, fully demonstrating their strong competitiveness and far-reaching influence in the international market.

From October 8th to 11th, 2024, Moscow's Crocus Expo will host three major specialized exhibitions: Weldex, Fastenex, and ToolMash. These exhibitions will comprehensively showcase the latest technologies and products in their respective fields.

"China and Russia have already achieved remarkable success in economic and trade cooperation, and the potential for future cooperation remains enormous. It is foreseeable that more Chinese enterprises will seize this opportunity to actively enter the Russian market and jointly promote the development of the hardware, welding, and fastener industries with Russian enterprises," said a representative from ITE Group.

On August 3, 2024, the 2nd Session of the 1st Member Congress of Suzhou Intelligent Fastener Manufacturers Association was successfully held at Hotel Nikko Suzhou. This grand event brought together numerous professionals from the fastener industry, including leaders from various associations, enterprise representatives, and special guests, who jointly witnessed this important moment in the fastener industry. Jiang Yongfeng, President of Jiangsu Fastener Industry Association, Yao Hui, the Secretary-General, Shi Tianru, the Secretary, and other important guests were invited to attend.

At the beginning of the conference, the organizers invited several industry leaders to participate in a roundtable forum, including Jiang Yongfeng, President of Jiangsu Machinery Industry Association Fastener Branch, Qiu Yongshou, President of Xinghua Dainan Fastener Industry Association, Huang Cheng'an, President of Hangzhou Fastener Industry Chamber of Commerce, Yang Junfeng, Chairman of Shanghai Ebseek Exhibition Co.,Ltd., Wang Yanbo, Chairman of Afastener Exhibition Co., Ltd., Chen Huagen, CEO of Suzhou No.1 Industrial Products Network Co., Ltd., and Ye Junxin, Sales Director of Zhejiang Jiancai Machinery Co., Ltd. The forum delved into

the current status and development prospects of the fastener industry from multiple dimensions such as market, technology, equipment, policy and technological innovation.

Yu Chiqing, President of Suzhou Fastener Intelligent Manufacturing Chamber of Commerce, delivered a summary report on the work. The report elaborated on four aspects: member development, industry

exchange, strengthening party building, and future planning. President Yu stated, "The Fastener Chamber of Commerce must continuously improve its service capabilities, providing policy consultation, market information, technical support, and other services to member enterprises, helping them solve practical problems, and supporting their healthy development."

In addition, Shan Yongmin, Secretary of the Party Branch of the Chamber of Commerce, presented the 2023-2024 Annual Party Building Report, while Zhu Minghua, Chief Supervisor, shared the 2023-2024 Annual Financial Report. Meanwhile, Director Yu Shengdan introduced in detail the Chamber's work plan for the next year (July 2024 to June 2025), charting a clear direction for the Chamber's development.

Another highlight of the conference was the addition of new members to the Chamber. The list of new members, council members, and newly added vice presidents was announced on-site, and a solemn award ceremony was held. The entry of these new members injected new vitality and energy into the Chamber, further strengthening its forces and laying a solid foundation for the common development of the industry.

Desoutter, founded in 1914 with its headquarters in France, is dedicated to the innovative design, research, development, and manufacturing of industrial tools that cater to market demands. It offers "one-stop" solutions to customers in over 170 countries worldwide. On August 2, the signing ceremony of the strategic cooperation for the "Fastening Salon" jointly hosted by Desoutter was successfully held in Shanghai. Representatives from Gusichuang, Ebseek, Guojian Testing, and Desoutter attended the signing ceremony.

After the signing ceremony, the participants engaged in a heated and in-depth discussion about the original intention, development process, and future themes of the "Fastening Salon". The shared vision of the organizing units is to create in-depth and warm topics on fasteners and to continuously serve fastener manufacturers, service providers and young professionals in the industry through public welfare activities.

The "Fastening Salon" is not just a brand of events; it is also a bridge and bond for industry communication, injecting new vitality into the development of the fastener industry.

Recently, Russia's authoritative financial and economic media Kommersant released the latest data, revealing the strong performance of Chinese automotive brands in the Russian market. As stated in the latest findings, sales of auto parts from Chinese automotive brands in the first half of 2024 increased by an astonishing 1.8 times, demonstrating the huge potential of Chinese auto parts in the Russian market.

Although specific figures were not disclosed, Kommersant clearly stated that several well-known Chinese automotive brands, such as Haval, Chery, and the premium sub-brand Exeed, have achieved significant growth. Among them, Haval's auto parts sales increased by 93% year-on-year, Chery's by 78%, and Exeed's by an astonishing 10 times.

Industry experts have expressed that the demand for Chinese auto parts in Russia will continue to grow. This prediction is based on the crucial fact that Chinese manufacturers now account for up to 60% of the new car market share in Russia.

However, it is noteworthy that despite the remarkable progress made by Chinese auto parts in the Russian market, data garnered from Avito, a Russian classified advertisements website, the primary demand in the current Russian auto parts market still focuses on South Korean, Russian, German, and Japanese brands.

Earlier, "Avtostat," a Russian automotive market analysis agency, pointed out that in June 2024, Chinese cars accounted for 61% of total new car sales in Russia. Throughout the first half of the year, the number of Chinese cars in Russia increased by 28.3%, reaching a total of 1.86 million vehicles. Brands such as Chery, Geely, and Haval have been the main driving force behind this growth.

With the continuous deepening of cooperation between China and Russia in the automotive industry chain, the future prospects of Chinese auto parts in the Russian market are promising.

On July 27, 2024, the Fourth Session of the 12th Council Meeting of Chongqing Fastener Industry Association was held.

At the meeting, the Secretary-General of the Association, Mo Taiming, reported on the work achievements of the Association in the first half of 2024. He mentioned that the Association had not only successfully completed the fourth general election, but also actively participated in exchange activities with fastener industry associations in Shenzhen, Foshan, Dainan, etc.

Drawing upon public data from the Chongqing Bureau of Statistics, in the first half of 2024, the GDP of Chongqing reached 1,513.824 billion yuan, with a year-on-year growth of 6.1%. Among them, the added value of the secondary industry was 588.690 billion yuan, an increase of 7%, and the added value of industrial enterprises above the designated size increased by 8.6%. Notably, the automotive industry achieved a significant growth rate of 30.3%. As an indispensable part of the automotive industry chain, the fastener industry performed strongly in this context, with most member units engaged in automotive parts and other related industries, contributing significantly to the development of the regional economy. Secretary-General Mo emphasized that the Association will continue to focus on serving its members and strive to enhance

the influence of the fastener industry in Chongqing and even the entire southwestern region.

In addition, the meeting specially invited the former Secretary-General Yu Yun to give a special presentation. Secretary-General Yu shared his experiences of participating in the International Fastener Show China and elaborated on the current positive progress of the fastener industry in terms of innovation and digitization.

Cao Li, Secretary-General of the Wenzhou Fastener Industry Association, introduced the current situation, achievements, challenges, and future development plans of the Wenzhou fastener industry. Since its establishment in 2005, the Wenzhou Fastener Industry Association has brought together more than 300 member units. Secretary-General Cao expressed that both sides should strengthen cooperation, support each other, jointly explore new development areas, and sincerely invite Chongqing fastener enterprises to participate in the exposition hosted by the Wenzhou Fastener Industry Association.

The successful convening of this meeting not only deepened the communication among members of the Association but also built a more solid bridge for the exchange and cooperation between the Chongqing fastener industry and the outside world.

On July 27, Shanghai Baoye Industrial Engineering Co., Ltd. held open day activities in Shanghai and Gansu simultaneously, showcasing the construction scene of the steel structure of the 4,200mm heavy plate production line workshop of Rolling Plant of Gansu Jiu Steel Group Hongxing Iron & Steel Co., Ltd.

There was no arc light and sparks of traditional welding work at the construction site. Instead, an innovative connection method - full high-strength bolt connection technology was used. Project Manager Shen Hanbing emphasized, "Our entire steel structure plant has abandoned ordinary bolts and welding, and instead used 230,000 high-strength bolts for precision assembly. This move poses an unprecedented challenge to construction accuracy, with a maximum allowable error of only 2 mm, and the technical difficulty is very high."

The chief engineer of the project, Li Dawei, provided an in-depth analysis of the technical support behind the project through video connections. He pointed out that to ensure the accuracy of bolt connections, the project team used advanced three-dimensional application software to control accuracy from the source; and compiled cutting hole programs based on drawings, followed by laser cutting holes to ensure that the hole diameter, hole position, and hole-making accuracy fully meet the design requirements; at the same time, for steel columns, steel beams and their connecting plates, the team implemented a "three-in-one" paired drilling method, which

effectively improved the one-time piercing success rate of highstrength bolts. In addition, all components underwent strict pre-assembly inspections before leaving the factory to ensure efficiency and accuracy at the installation site.

As a key project in Gansu Province, the process equipment upgrade and product structure adjustment project of Rolling Plant of Gansu Jiu Steel Group Hongxing Iron & Steel Co., Ltd. will build a new 4,200mm heavy plate production line with an annual production capacity of 1.2 million tons, with a total construction area of approximately 100,200 square meters.

The Würth Group is a global market leader in the development, production, and sales of assembly and fastening materials. Currently, the Group operates with over 400 companies and more than 2,700 shops. For the first half of 2024, the Group achieved sales of €10.2 billion, a decrease of 3.2% year-on-year and 2.6% after currency adjustments.

Over the past twelve months, the Group has created over 300 new jobs in the digitalization and IT sectors. Currently, Würth Group employs 88,616 employees globally, with 44,437 engaged in sales activities. Approximately 1,200 employees joined the company through acquisitions.

The Würth Group's German companies achieved sales of €4.0 billion, compared to €4.2 billion in the same period last year. Sales of companies outside Germany declined by 1.8% year-on-year. Within the Group's core businesses, the automotive sector saw a positive growth of 4.2%. Among the Group's allied companies, the chemicals sector performed well (+6.6%). With the approval of the European Commission, Würth Group successfully acquired an 80% stake in IDG01 S.p.A., a

leading electrical wholesaler in the Piedmont region of Turin, Italy, on July 1, 2024. This move strengthens the electrical wholesale division's market position in Italy and facilitates further growth in this market. The company employs 580 employees across 41 locations and achieved sales of €285 million in 2023.

As a family business, Würth feels a profound responsibility to support the well-being of others and to assume its social responsibilities as a corporate entity. As part of a worldwide campaign week, the Würth Group supported the UN Children's Fund UNICEF for the seventh time, donating €405,000 to provide safe learning spaces for children in Sudan and secure their futures.

The Würth Group's next annual financial statements press conference will be held on May 7, 2025.

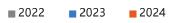

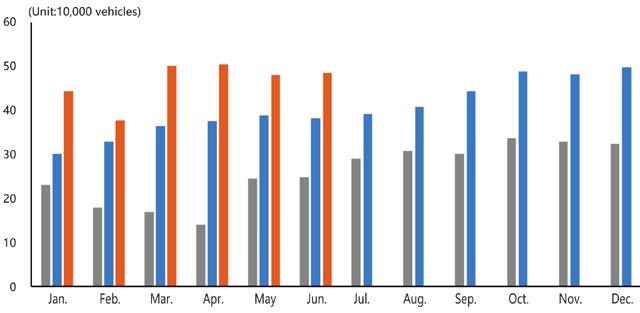

The Korea Automobile Importers & Distributors Association (KAIDA) announced on July 23 that the number of newly registered imported hybrid vehicles in the first half of the year reached 59,522, 86.1% higher than the 31,870 gasoline vehicles.

The data shows that sales of imported hybrid vehicles in the first half of the year increased by 43.5% year-on-year and 18.5% compared to the second half of last year. In contrast, sales of gasoline vehicles decreased by 48.31% year-on-year and 44.6% in comparison to the second half of last year.

On a half-year basis, sales of imported hybrid vehicles surpassed those of gasoline vehicles for the first time. Last year, gasoline vehicles had a monthly average sales of about

10,000, setting an overwhelming sales record, but the situation has completely reversed this year. Since the beginning of last year, sales of hybrid vehicles have gradually increased, and after entering the second quarter of this year, monthly sales have exceeded 10,000.

World crude steel production for the 71 countries reporting to the World Steel Association was 161.4 million tonnes (Mt) in June 2024, a 0.5% increase compared to June 2023.

Africa produced 1.6 Mt in June 2024, down 9.6% on June 2023.

Asia and Oceania produced 120.6 Mt, up 0.3%.

The EU (27) produced 11.1 Mt, up 5.1%.

Europe, Other produced 3.8 Mt, up 2.1%.

The Middle East produced 4.6 Mt, down 2.7%.

North America produced 8.9 Mt, down 1.9%.

Russia & other CIS + Ukraine produced 7.4 Mt, up 1.4%.

South America produced 3.5 Mt, up 4.1%.

China produced 91.6 Mt in June 2024, up 0.2% on June 2023.

India produced 12.3 Mt, up 6.0%.

Japan produced 7.0 Mt, down 4.2%.

The United States produced 6.7 Mt, down 1.5%.

Russia is estimated to have produced 6.0 Mt, down 4.1%.

South Korea produced 5.1 Mt, down 7.2%.

Germany produced 3.2 Mt, down 8.9%.

Türkiye produced 3.1 Mt, up 4.3%.

Iran produced 2.6 Mt, down 8.5%.

Brazil produced 2.9 Mt, up 11.8%.

On July 18, media reported that amid a general decline in European automotive production, renowned automotive parts supplier Valeo would sell its two parts factories and a research and development center in France.

Valeo stated that due to insufficient demand, the parts factories have seen reduced business volumes, while the research and development center also requires significant funds for upgrades, potentially affecting approximately 1,000 employees.

Headquartered in France, Valeo specializes in the design, development, production, and sales of automotive parts, systems, and modules, covering both original equipment and aftermarket segments, providing support to numerous mainstream automakers worldwide.

However, as automakers such as Stellantis shift production and R&D resources to low-cost countries outside Western Europe, coupled with a slowdown in demand for electric vehicles in major markets like Germany and Italy, leading some automakers to adjust their EV plans, these factors have exacerbated the difficulties faced by automotive parts suppliers.

As a whole, the European automotive industry still faces numerous challenges. Other automotive parts suppliers such as Bosch, ZF Friedrichshafen, and Continental are also implementing layoffs to adapt to market changes.

TR Chai Yi Precision Fastenings Manufacturing, now a part of the Trifast plc group of companies, is celebrating the establishment of its Chinese manufacturing facility in Dongguan, Guangdong Province, capitalizing on the continuously growing demand in the region over the years.

Guangdong is a thriving world-class centre of innovation and technology, providing the perfect place for TR to manufacture precision-engineered screws to OEM's and their subcontractors, whilst leveraging its global scale on a local basis.

The new 2,800 square meters of manufacturing space houses 44 cold forging machines and 36 thread rolling machines, which produce micro screws and thread-forming screws ranging from 0.6mm to 4mm in size, made of steel, stainless steel, and titanium, with an annual output of approximately 1 billion pieces.

TR Chai Yi proudly holds the globally recognized ISO 9001 certification, attesting to its adherence to rigorous quality, safety, and efficiency standards. This accreditation underscores the company's unwavering dedication to delivering the highest quality products and services to customers in the region, with a relentless focus on continuous improvement.

Jeremy Scholefield, Asia Pacific Managing Director, commented, "We're delighted to open this new facility and in such a renowned area, it's such a positive move for TR as a

group. Our focus is on producing competitive products and continuing to build a strong capability in China and across the Asia Pacific region to meet market demands."

"Here in Guangdong, one of our key differentiators is our technical engineering knowledge, which enables us to produce very precise and often complex components that are manufactured to exact measurements and mass-produced. This latest investment is crucial for us, as it highlights TR's robust development in the region and our commitment to staying close to our key customers here," added Scholefield.

The new plant in China is the company's seventh global manufacturing facility, with existing factories also located in Italy, Singapore, Taiwan, and Malaysia, further expanding its global footprint.

Bossard Group, a distributor of fastener products based in Switzerland, has announced its intention to acquire Aero Negoce International (ANI), a Béziers-based distributor in France specializing in aerospace fastening solutions and logistics services. The terms of the transaction have not been disclosed.

This underscores Bossard's commitment to expanding its market presence in the aerospace industry, specifically bolstering its position in the Aerospace Valley in France. The company said it wants to enhance its cooperation with Bossard Aerospace Germany, acquired in 2019.

"The intended acquisition of Aero Negoce International SAS is an important step to accelerate our growth strategy in

the aerospace industry and strengthens our strategic presence in the Aerospace Valley in France," Bossard Group CEO Daniel Bossard said in a July 24 news release. "Moreover, we envision immense market potential in collaborating with Bossard Aerospace Germany, which will further consolidate our position in the European aerospace industry."

ANI, which employs 33 individuals in France and anticipates achieving net sales of approximately EUR 25 million for the current fiscal year, also has additional locations in the USA and Malaysia.

BUMAX AB, the Swedish premium fastener manufacturer, has announced the recent appointment of Star Stainless Screw Company, as its new master distribution partner in the United States. This collaboration marks a notable step forward in the BUMAX route to market in the US and is part of the company's ongoing development strategy for the North America region.

Established in 1950, Star Stainless Screw Co. has built an unrivaled reputation throughout the US as an importer and distributor of fastener products in a range of stainless steel and other exotic alloy materials. With a network of distribution centers in strategic locations, Star Stainless is well placed to serve its extensive customer base of fastener and industrial component suppliers nationwide.

"We at Star Stainless Screw Company are so excited to be partnering with BUMAX," exclaimed Tim Roberto, President of Star Stainless Screw Co. "We feel that the quality of products from BUMAX, partnered with Star's reputation for offering

the highest quality of products and service, will be a perfect fit.

We eagerly anticipate this collaboration and thank BUMAX for their trust in Star's excellence in distribution."

Star Stainless will be responsible for stocking and supplying BUMAX's comprehensive range of high-strength stainless steel products to fastener distributors and industrial product suppliers throughout the US. This partnership will significantly enhance the availability, accessibility and speed of supply of BUMAX products to customers in the US.

"After a long road, I am delighted to see our agreement finalized. The geographic size and diversity of the US market have always posed unique challenges. Bringing together the expertise of both companies, we can now begin the important work of raising awareness of the advantages of BUMAX highstrength stainless steel fasteners in the US market and making our products more readily available throughout the region," says Jacob Bergström, BUMAX Segment Manager, Distribution.

On August 13, 2024, the Mexican Secretariat of Economy issued a notice announcing a final affirmative antidumping determination against steel screws originating from China (Spanish: varillas de acero roscadas). It decided to impose anti-dumping taxes ranging from 8.02% to 91.22% on the involved products.

Specifically, Jiaxing Chinafar Standard Parts Co. Ltd. faces a tax rate of 8.02%, while Haiyan Wandefu Precision Hardware Co. Ltd., Lianyungang Xincheng Hardware Co. Ltd., Jiaxing Longyu Machinery Co. Ltd., and Zhejiang Junyue Standard Part Co. Ltd. are subject to a 17% rate. The remaining exporters are taxed at 91.22%.

The involved products are untempered low-carbon, medium-carbon, or alloy steel screws with a diameter of 6.4mm

(1/4 inch) or more but less than 38.1mm (11/2 inch), and a length of 152.4mm (6 inches) or more, classified under TIGIE tariff numbers 7318.15.99 and 7318.19.99. The notice takes effect from the day following its publication.

Previously, on June 9, 2023, Mexico initiated an antidumping investigation on steel screws from China, and on December 22, 2023, the Secretariat of Economy made a preliminary affirmative determination, levying provisional antidumping taxes of 8.02% to 48.08% on the involved products.

Sources:

www.luosi.com www.wuerth.com KAIDA World Steel Association www.trfastenings.com www.fastenernewsdesk.com www.mdm.com China Trade Remedies Information

Peter-Thomas Büsing recently took over the role of CEO Europe at KAMAX, a global technological leader for high strength fasteners and complex cold form parts in the automotive industry.

In his role Peter-Thomas Büsing is in charge of all European plants, the subsidiary GALOL, and the sales, supply chain, technology and tools departments – making him responsible for around 2,500 employees, more than half of KAMAX's workforce.

At KAMAX he will now drive forward the development of processes and the organisational structure. "My goal is to consolidate KAMAX's position in Europe as a strategic partner for our customers that can be relied upon even in times of upheava l and complex challenges. Technologically, we will continue to build on our strengths to offer innovative and individual solutions in the future," states Peter-Thomas Büsing.

Previously, the 55 year old was president of the EMEA region and, since October 2022, a member of the executive committee of Grammer AG. In this role, he had overall operational responsibility for Europe, Middle East, and Africa, which has 18 organisational units.

Peter-Thomas succeeds Dr Reinhard Rupprecht, who has been appointed CEO of the KAMAX Group, with Peter-Thomas reporting directly to Dr Rupprecht.

Bossard Group has expanded its market position within innovative fastening technologies, acquiring Belgian company Dejond Fastening – a manufacturer of blind rivet nuts and specialist in the distribution of high-quality fastening systems.

Dejond Fastening N.V, headquartered in Antwerp, employs 68 people and expects net sales of around €15 million for the current financial year. With its own brand Tubtara®, the company is a pioneer in innovative solutions for sheet metal, profiles, composites and plastic fastening solutions for a wide range of industries.

Dejond's solutions enable engineers to optimise both their product design and manufacturing processes, which fits well with Bossard's 'Proven Productivity' philosophy. With this acquisition, Bossard will further strengthen its market presence in the Benelux region.

"Bossard has been working with Dejond for over 30 years. We have consistently been impressed by the company's reliability and innovations ever since. By combining technical expertise with our global market reach, technical sales

expertise, and trusted access to a wide range of industrial customers, we see great potential to offer even more value to our existing and new customers," reports Daniel Bossard, CEO of Bossard Group.

"Becoming part of the Bossard Group guarantees continuity for our existing customers and it opens up completely new possibilities to expand the global market presence of Tubtara®. It will give us new opportunities to widen our product offering and invest in new technologies and sales capabilities," concludes Jan Maeyens, director R&D and manufacturing at Dejond.

The metal business, including the Metal Service Center, is not part of the acquisition and will continue to operate independently under the name Dejond N.V.

AICHELIN Group and Sistem Teknik have signed an agreement to establish a joint venture in Austria, to produce and distribute industrial vacuum heat treatment technologies and services in Europe.

With this joint agreement, AICHELIN Group is adding a promising segment to its existing product portfolio. Christian Grosspointner, CEO of AICHELIN Group, explains: "As one of the global market leaders in the production of industrial furnaces for industrial heat treatment, we want to become an even stronger partner in the supply of vacuum furnaces for industry. The joint venture combines the best of two worlds, with the products developed by Sistem Teknik and our global aftersales and service network, we create maximum customer focus – a perfect combination to better meet the increasing demand for vacuum solutions in the future."

Mehmet Özde lik, CEO of Sistem Teknik Sanayi Firinlari A.S, adds: "The motivation of our joint venture is to offer the best possible technology that fits our time, which inevitably demands environmental efficiency and sustainability. We have noticed that there is a strong market for megatrends such as carbon footprint, electromobility and Lean production. With our vacuum furnaces, we aim to provide solutions that ensure low carbon emissions and maximum process quality. I am very confident that this collaboration will not only bring innovation, but also benefit our industry."

Novastone Capital Advisors GmbH, a Swiss company renowned for managing the world's largest Entrepreneurship Through Acquisition (ETA) programme, has successfully acquired 100% of Mecavit Srl, through an Italian special purpose vehicle.

With a 40 year history and based in Castel Guelfo di Bologna, Mecavit has established itself as a trusted name in the fastener manufacturing industry, known for its highquality products.

The company's growth and reputation have been carefully nurtured by its partners over the years. The sellers will reinvest in the project, ensuring its continuity and future success.

Nicoletta Nutrito, an engineer and local resident with extensive experience in both national and international industries, will lead the company. Her vision is to maintain the company's high standards of quality while fostering innovation

and growth. "Our goal is to prioritise quality, technical expertise, and reliability, while expanding our offerings to new markets," explains Nicoletta Nutrito.

Former partners Giuseppe Verdoliva and Giorgio Grillini will continue to support the company alongside Mrs Nutrito. "We are pleased to pass the management to a professional from our region who not only possesses the necessary skills but also shares our values and is committed to ensuring growth and continuity," adds Bruno Carafa, director, speaking on behalf of the other partners.

Chinese electric car manufacturer BYD has signed an agreement for a production facility investment in Turkey. According to the agreement, BYD will invest approximately $1 billion in Turkey.

BYD is expected to establish an R&D center for sustainable mobility technologies with an annual capacity of 150,000 vehicles and an electric and rechargeable hybrid car production facility in Turkey with an investment of approximately $1 billion.

The facility, which is targeted to start production by the end of 2026, is planned to provide direct employment for up to 5 thousand people.

Europe will be reached with Turkey's unique advantages

In the statement made regarding the preference of Turkey by BYD, which produces more than 3 million cars annually and is the world leader in electric vehicle sales, "Thanks to Turkey's unique advantages such as its developing technology ecosystem, strong supplier base, exceptional location and qualified workforce, BYD's investment in this new production facility will further improve the brand's local production capabilities and increase logistics efficiency. We aim to reach consumers in Europe by meeting

the growing demand for new energy vehicles in the region."

First foreign investment in automotive after 27 years With BYD's signature, a foreign direct investment has come to the Turkish automotive industry for the first time in 27 years. BYD's investment is expected to have a positive impact on other foreign investors. SWM Motor, which operates under Shineray Group, one of China's leading automotive manufacturers, of other Chinese brands such as Chery and MG, announced that it has applied to produce in Turkey.

Turkey's automotive industry's exports in June decreased by 12.4% to $2.6 billion. The share of the sector, which ranks first in the country's exports, was 14.1 percent.

The sector recorded an increase of 20% in the United Kingdom, 7% in Spain, 23% in Romania and 3% in the United States. In the first six months of the year, exports increased by 2.3% to $17.7 billion."

Exports of passenger cars decreased by 4% to 942 million dollars, exports of Motor Vehicles for the Transport of Goods decreased by 3% to 394 million dollars, Bus-Minibus-Midibus exports decreased by 14% to 177 million dollars and Tow Trucks exports decreased by 83% to 30 million dollars.

While Germany was the country with the most exports in the Supply Industry, exports to this country decreased by 20%. There was a decrease in exports to the USA by 2%, to Russia by 13%, and an increase of 79% in exports to Romania.

While there was a 17% decrease in exports to France, one of the important markets in passenger cars, there was a 29% increase in exports to Spain, 14% to Italy, 83% to the United Kingdom and 2% to Germany.

In Motor Vehicles for the Transport of Goods, there was a 20% increase in exports to the United Kingdom, 15% to Slovenia, 5% to Belgium, a very high increase in exports to the Netherlands, a 13% decrease in exports to Italy, 36% to France, 21% to Spain and 18% to Australia.

In the Bus-Minibus-Midibus product group, there was a 24% decrease in exports to France, a 44% decrease in exports

to Germany, a 59% increase in exports to Spain, a 15% increase in exports to the United Kingdom, and a 66% increase in exports to the USA.

20% increase in exports to the largest market, the United Kingdom

In June, exports to the United Kingdom, the largest market, increased by 20% to $322 million. Germany was the second largest market with $319 million, while exports decreased by 18%. Automotive exports to France decreased by 21% to 315 million dollars. While there was a 7% increase in exports to Spain, 23% to Romania and 3% to the USA, there was a decrease in exports to Italy by 7%, Slovenia by 2%, Poland by 35% and Belgium by 30%.

by 12 percent

Exports to EU Countries, which rank first in the country group with a share of 68 percent, decreased by 12% and reached 1 billion 787 million dollars. While other European countries ranked second among country groups with a share of 14%, exports to this group of countries increased by 14%. There was an 18% decrease in exports to the Commonwealth of Independent States and 28% to African Countries.

Steel Production

In May 2024, Turkey's crude steel production increased by 11.6% compared to the same month last year to 3.2 million tons.

In the first 5 months of the year, production increased by 19.8% to 15.5 million tons.

Steel Consumption

Final product consumption decreased by 16.2% in May to 3.4 million tons, while it decreased by 2.1% to 16.1 million tons in January-May period compared to the same period of 2023.

Export

In May, exports of steel products increased by 45.9% in terms of quantity to 1.1 million tons and by 24.8% in terms of value to 850.9 million dollars.

In the January-May period, compared to the same period of 2023, exports amounted to 5.4 million tons, an increase of 48.6% in quantity, and 4.0 billion dollars, an increase of 26.2% in value.

Import

In May 2024, imports decreased by 29.1% in terms of quantity to 1.5 million tons and decreased by 29.8% in terms of value to 1.3 billion compared to the same month of 2023.

In the January-May period, compared to the same period of 2023, imports decreased by 12.1% in quantity to 7.1 million tons and decreased by 17.5% in value to 5.6 billion dollars.

The ratio of exports to imports, which was 46.5 in the January-May period of 2023, increased to 71% in the JanuaryMay period of 2024.

According to the May 2024 data announced by the World Steel Association (worldsteel), world crude steel production decreased by 1.5% compared to the same month of the previous year, to 165.1 million tons. In the first 5 months of the year, world steel production decreased by 0.1% to 793.2 million tons.

In the first five months of the year, China's crude steel production decreased by 1.4% compared to the same period of 2023 and decreased to 438.6 million tons, while India's crude steel production, which ranked second, increased by 7.7% to 61.9 million tons and Japan's crude steel production decreased by 2.3% to 35.7 million tons.

With the contribution of Turkey's crude steel production increasing by 11.6% to 3.2 million in May, Turkey's crude steel production increased by 19.8% to 15.5 million tons in the first 5 months of 2024. Thus, although Turkey ranks 8th in world steel production, it has reached the position of the 2nd country that has increased its production the most after Vietnam among the 15 countries with the highest production in the world with its performance in the first five months of the year.

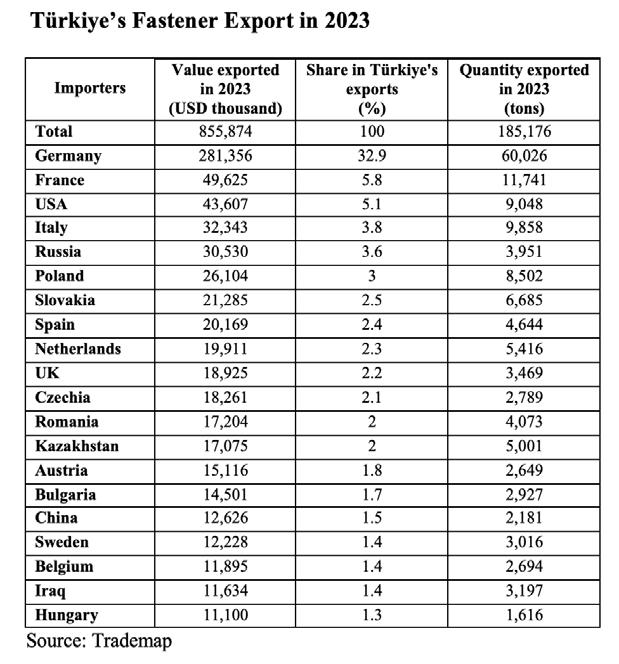

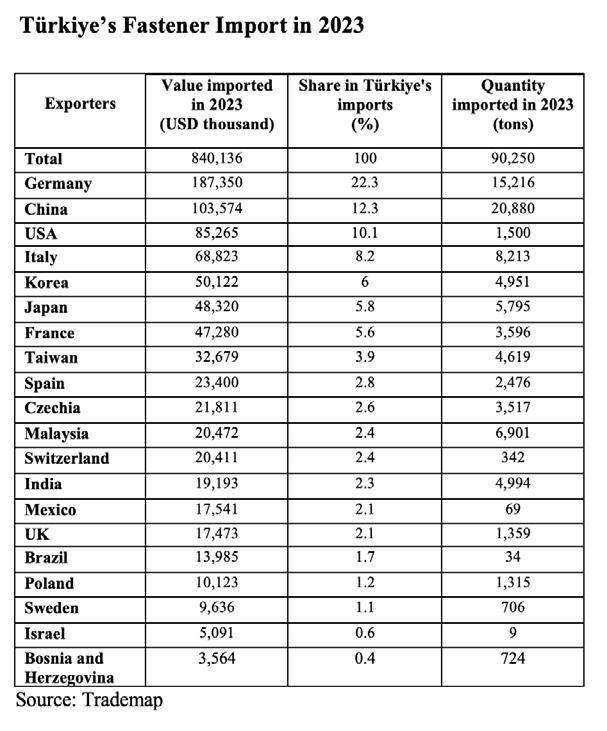

The fastener market in Türkiye is an integral part of the country's industrial sector, playing a significant role in various industries including automotive, construction, machinery, and electronics.

In 2023, Türkiye imported approximately $1 billion worth of fasteners. The majority of these imports came from Germany, China, USA and Italy. Germany is the leading supplier, accounting for over 20% of Türkiye's fastener imports. China and Italy follow with shares of around 15% and 10%, respectively.

During the same period, Türkiye's fastener exports amounted to about $700 million. Türkiye mainly exports these products to European Union countries, the Middle East, and North Africa. Major export destinations include Germany, France, and the USA. Germany account for 25% of Türkiye's fastener exports.

In the fasteners sector, Türkiye has a trade deficit, with imports exceeding exports. However, the increasing trend in exports is a positive sign for reducing this deficit.

Norm Holding is pleased to announce appointments effective Wednesday, January 1, 2025. Vice Chairperson and CEO Nedim Uysal will transition his CEO role to Mahmut Öztürk, Head of Industry Group. Mr. Uysal will continue as Vice Chairperson, ensuring a smooth transition and continuity in our leadership.

Norm Holding is pleased to announce the appointments effective Wednesday, January 1, 2025. Vice Chairperson and CEO Nedim Uysal will transition his CEO role to Mahmut Öztürk, Head of Industry Group. Mr. Uysal will continue as Deputy Chairperson of the Board.

Over the past five years, Nedim Uysal has been instrumental in strengthening Norm Holding's market position. His visionary leadership has led to significant growth, with Norm Holding expanding its operations and revenue to 500 million Euros. Under his guidance, Norm Holding's branding and marketing efforts have advanced domestically and internationally to 24 companies and 20 production facilities. His focus on sustainability and corporate governance has earned Norm Holding several accolades, including the ECOVADIS Silver Medal, TA DER Northern Star Sustainability Award, and Deloitte Best Managed Companies Award.

Chairperson M. Fatih Uysal shared his thoughts on the transition: "Our recent investments have deepened our core activities while enabling growth in new sectors. To meet our evolving needs, we aim for a more agile structure. I extend my heartfelt thanks to Mr. Nedim Uysal for his visionary leadership

and determination, which have greatly enhanced our business. We are deeply appreciative of his contributions and the significant milestones he has achieved for our company. I am confident that under Mr. Mahmut Öztürk's leadership, marked by responsibility, meticulousness, and disciplined dedication, we will make significant strides toward our innovation and sustainable growth goals. I believe that the valuable contributions of both executives will propel our organization further in the coming period. I wish the new appointments all the best and success."

Mahmut Öztürk graduated from Dokuz Eylül University's Faculty of Economics and Administrative Sciences in 1995 and completed the Procade Master program at Dokuz Eylul University Faculty of Business Administration in 1997. He started his career at Norm Fasteners Bolts as an Export Officer in 1997, later holding roles in Production Planning, Domestic Sales, and Automotive Sales. From 2006 to 2017, he served as General Manager at Norm Fasteners Bolts, and since 2017, he has been the Head of Industry Group. In 2024, he graduated from the Harvard Business School Advanced Management Program.

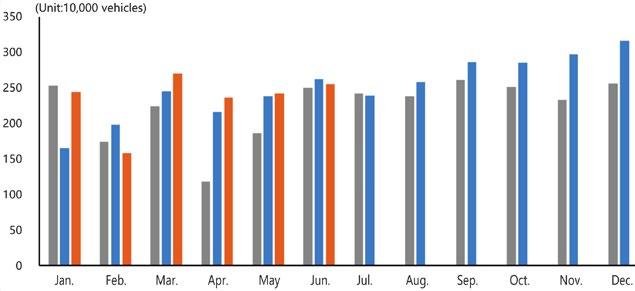

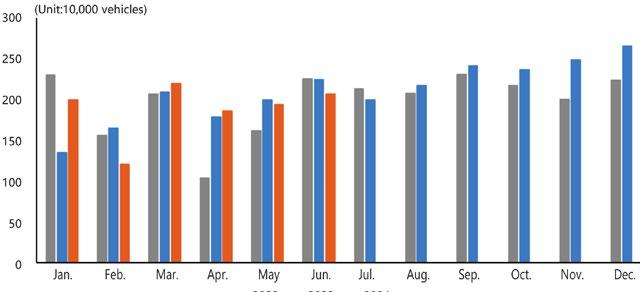

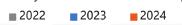

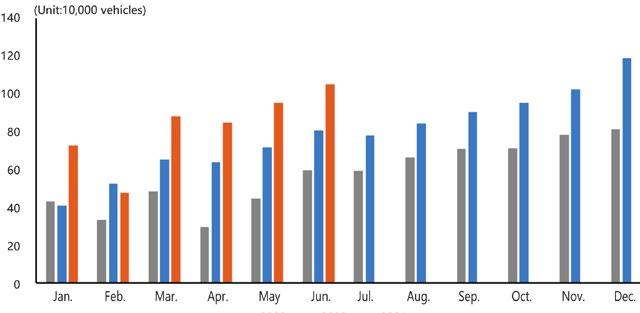

In the first half of 2024, China's automotive industry demonstrated remarkable resilience and innovative vitality amidst a complex and ever-changing market environment. Driven by the global push towards carbon neutrality and the Chinese government's continued support for the new energy vehicle (NEV) industry, the Chinese automotive sector is undergoing an unprecedented transformation and upgrade. This report aims to provide an in-depth analysis of the overall landscape of China's automotive industry during this period, with a particular focus on the sales comparison between NEVs and internal combustion engine vehicles (ICEVs), as well as the rapid rise and increasingly significant role of NEVs in the market.

Statistics provided by the China Association of Automobile Manufacturers (CAAM) reveal that China's automobile production and sales reached 13.891 million and 14.047 million units respectively in the first half of 2024, representing year-on-year growth rates of 4.9% and 6.1% respectively. These figures underscore the resilience and vitality of China's automotive market.

Breaking down the data further by quarters, automobile production and sales in the first quarter of 2024 amounted to 6.606 million and 6.72 million units respectively, laying a solid foundation for growth throughout the year. In the second quarter, production and sales surged to 7.285 million and 7.327 million units respectively, marking notable quarter-onquarter increases that reflect the sustained release of market demand and effective expansion of production capacity.

In terms of sales structure, automobile sales in China totaled 11.255 million units, up 1.4% yearon-year. Notably, automobile exports emerged as a significant driver of market growth, with 2.793 million units exported in the first half of the year, a year-

on-year increase of 30.5%, contributing significantly to the overall market expansion. This data not only underscores the enhanced competitiveness of Chinese automotive brands in the international market but also injects new momentum into the internationalization of China's automotive industry.

In the first half of the year, the rapid growth of new energy vehicles (NEVs) emerged as a notable highlight. With 4.929 million units produced and 4.944 million units sold, NEVs achieved year-on-year growth rates of 30.1% and 32% respectively, steadily increasing their market share. This rapid increase in NEV production and sales not only drove the overall growth of the automotive industry but also accelerated the transformation of China's automotive market towards new energy sources.

NEVs undoubtedly stood out as the biggest bright spot in China's automotive market during the first half of the year. This trend not only reflects the heightened acceptance of NEVs among consumers but also demonstrates the remarkable effectiveness of government policies supporting the NEV industry, coupled with technological advancements.

One of the key factors driving the rapid growth of NEVs is government support. In recent years, the Chinese government has implemented a series of policies aimed at promoting NEV development, including purchase subsidies, exemption from vehicle purchase taxes, and the construction of charging infrastructure. These policies have not only lowered the economic threshold for consumers to purchase NEVs but also enhanced their market competitiveness by optimizing the usage environment. Additionally, the government has attached great importance to R&D investment and

industrial chain integration in the NEV sector, providing a solid foundation for the rapid development of NEV technologies. Technological advancements serve as the internal driving force behind the rapid growth of the NEV market. Continuous innovations in battery technology and optimization of manufacturing processes have significantly improved NEVs' driving range and shortened charging time, effectively alleviating

consumers' "range anxiety." Meanwhile, the overall cost of NEVs has continued to decline, making them more affordable and further stimulating consumer demand. Furthermore, the integration and application of cutting-edge technologies such as intelligence and networking have also injected new vitality into the NEV market, enhancing product attractiveness and competitiveness.

With the growing awareness of environmental protection and the continuous optimization of NEV product experiences, consumer acceptance of NEVs has significantly improved. More and more consumers are paying attention to the environmental performance and energy-saving effects of automobiles, with NEVs receiving widespread attention as representatives of green travel. NEVs also exhibit unique advantages in driving experience and technological configuration, satisfying consumers' pursuit of high-quality life. Moreover, as the NEV market continues to expand and infrastructure improves, consumers' concerns about purchasing NEVs have been effectively addressed.

The explosive growth of NEVs has not only driven the rapid development of key component industries such as batteries, motors, and electric controls but also promoted the improvement of supporting industries like charging infrastructure and intelligent networking. As technology advances and costs decrease, the cost-effectiveness of NEVs continues to improve, further igniting consumer enthusiasm for purchases. Looking ahead, with the continuous advancement of NEV technologies and market expansion, we have reason to believe that China's NEV industry will embrace an even broader development prospect.

During the first half of 2024, China's automotive export market sustained its robust growth momentum, with cumulative exports reaching 2.793 million units, marking a year-on-year growth rate of 30.5%. This figure underscores the competitiveness of China's automotive manufacturing industry in the international market and reflects the high recognition of "Made in China" products by the global automotive market.

ICEVs continue to dominate China's automotive exports, accounting for 2.188 million units exported, up 36.2% yearon-year, significantly outpacing NEVs. This growth is primarily attributed to the maturity and stability of Chinese ICEV technology, their cost-effectiveness, and wide acceptance in multiple global markets.

NEVs exported 605,000 units, with a year-on-year increase of 13.2%. While the export volume of NEVs remains relatively small, their growth rate is noteworthy. As the future direction of the automotive industry, the export growth of NEVs reflects China's gradual accumulation of technological capabilities and brand influence in this field.

However, compared to ICEVs, the export growth rate of NEVs appears slightly lagging, which may be influenced by various factors such as the international market's acceptance of NEVs, the construction of charging infrastructure, and international trade policies.

The high growth of ICEV exports is primarily fueled by

their wide recognition in the global market and the support of mature technologies. The export market for fuel vehicles is likely to become more diversified, covering various countries and regions worldwide.

The growth of NEV exports, on the other hand, is more reliant on technological innovations, brand building, and policy incentives, potentially focusing on developed countries or regions with higher environmental standards and wellestablished charging infrastructure.

As the global automotive industry undergoes transformation and prioritizes sustainable development, the export prospects for NEVs are promising. As one of the leaders in the NEV industry, China is poised to further increase its market share and influence in the international arena. Meanwhile, while ICEVs will continue to occupy a certain market share for some time, their growth rate may gradually decelerate.

In conclusion, China's automotive export market in the first half of 2024 exhibited a parallel development of ICEVs and NEVs. While ICEVs remain the mainstay of exports, the growth potential of NEVs cannot be overlooked.

In the first half of 2024, the production and sales of ICEVs in China's automotive market remained dominant, with a notable year-on-year increase of 36.2% in exports. This indicates that despite the rapid emergence of the NEV market, ICEVs still possess strong competitiveness and market demand globally, particularly in some developing markets.

Opportunities for Fastener Enterprises: For fastener manufacturers, the stable demand in the ICEV market translates into continuous market opportunities. Companies should pay attention to trends such as automotive lightweighting and the application of high-strength materials, developing fastener products that cater to these needs. Additionally, optimizing production processes, enhancing

product quality, and reducing costs are crucial to maintaining a competitive edge.

In the first half of 2024, the production and sales of NEVs experienced significant growth, not only occupying a pivotal position in the Chinese market but also achieving an increase in exports, demonstrating considerable market potential.

Opportunities for Fastener Enterprises: The rapid expansion of the NEV sector has directly fueled the demand for critical components such as battery packs, electric motors, and electric control systems, which rely heavily on fasteners to ensure structural stability and safety during manufacturing. Furthermore, the unique nature of NEVs (e.g., weight and heat dissipation requirements of battery packs) imposes higher standards on fastener materials, strength, and corrosion resistance, presenting new development opportunities for fastener manufacturers.

In summary, China's automotive market performed exceptionally well in the first half of 2024, with the rapid growth of NEVs serving as the highlight, driving overall market expansion and transformation. Meanwhile, substantial increases in automotive exports have introduced new growth points for the Chinese automotive industry. Looking ahead, as NEV technology continues to advance and consumers increasingly prioritize eco-friendly transportation, the NEV market is expected to sustain its high-growth trajectory. Additionally, the competitiveness of Chinese automotive brands in the international market will further escalate, injecting new vitality into the sustainable development of China's automotive industry.

Sources:

Public data reveals that in 2022, Vietnam's fastener imports amounted to approximately $750 million, a 3.0% decrease compared to the previous year. In the same year, Vietnam's fastener exports reached about $700 million, marking a significant 27.0% increase. These figures indicate Vietnam's commitment to developing its fastener industry, with a decreasing dependency on imports and a steadily expanding export volume.

The rapid growth of the fastener industry is driven by the swift development of the engineering machinery, automotive, and motorcycle sectors, along with their respective spare parts industries, leading to strong domestic demand for fasteners. On the export front, amid increasing tariff barriers faced by Chinese companies, the growing presence of Chinese-invested fastener enterprises has become a crucial factor in the growth of Vietnam's fastener exports.

From July 1st to 6th, ChinaFastener.com organized its fifth global business trip, bringing its members to engage with local fastener manufacturers, mold producers, raw material suppliers, and product distributors in Vietnam. During the trip, in-depth exchanges and discussions were conducted with entrepreneurs to further understand Vietnam's local fastener market demand, policy support, and industry prospects. This provided valuable insights for Chinese enterprises exploring overseas markets and making investment decisions.

Xieyi Metal Technology Co., Ltd. was established in Vietnam in 2018 with an investment of $4 million from its parent company, Anji Xieli Hardware Products Co., Ltd. The company specializes in the production and sales of screws, standard fittings, plastic products, hardware accessories, and auxiliary materials for furniture, along with import and export business.

Since 2023, Tinsing Industry (Vietnam) Co., Ltd. has been deeply cultivating the Vietnamese market. Its parent company is Zhejiang Excellent Industries Co., Ltd., which was founded in 1997 in Haiyan, Zhejiang, China. Excellent focuses on the research, development, production, and sales of screws, expansion bolts, stamping parts, and fasteners for automobiles and motorcycles. On July 2, after the grand opening ceremony of Tinsing, the group, led by General Manager He Xinming, toured the production workshops and learned about Tinsing's capabilities. Relevant personnel also briefed the group on employee recruitment.

Director Cheng Zhe stated that as an emerging market and a rapidly growing region for manufacturing, the future prospects for the Vietnamese fastener market are widely regarded with optimism. In 2023, Essence officially entered Vietnam. The superior factory environment, advanced equipment, and strong workforce all underscore Essence's

commitment to the Vietnamese market. Its parent company, Essence Fastener Industries Co., Ltd. (S.E.Z), was established in 1987 and specializes in the manufacturing and design of fasteners. The company recruits industry talents and introduces international production and inspection equipment, dedicated to designing and producing high-tech, high-precision, and highstrength fasteners, specialshaped parts, and various hardware components, and has successively obtained ISO9001, ISO14001, and IATF16949 certifications.

in 2023, Solid Precision Technology (Vietnam) Co., Ltd. is the Vietnamese subsidiary of Solid Precision Technology (Suzhou) Co., Ltd., focusing on the production of high-precision screws ranging from M0.6 to M3, used in smartphones, wearable devices, computers, and other products. Director Xiao Xiao has high expectations for the Vietnamese market, especially given the current trend of industrial transfer from China, where more and more fastener companies are moving to Vietnam.

Since its establishment in 1941, Tokyo Byokane has been committed to products with high-quality requirements related to vehicles, home appliances, and office automation. The company has one factory and 17 business outlets in Japan and over 20 sales and manufacturing bases overseas. With a significant market share, its production of No. 0 and No. 00 screws strictly adheres to JCIS standards, meeting customers' extreme precision requirements. Director Mr. Asano informed the group that the Vietnam factory was established in 2008, mainly producing M2-M6 screws, primarily supplying to automobile manufacturers. In its early days, technical workers were mostly recruited from Japan, while local Vietnamese workers had to undergo training and pass qualifications before entering the production line. As pioneers in manufacturing, the production technology and management experience of Japanese companies are highly valuable for Chinese enterprises to learn from.

Since its establishment in 1985, Jenn Tai (Chen Tai) Machine Enterprise Co., Ltd. has specialized in the production of vibratory feeders. Under the leadership of General Manager Chen Kehong, the group toured the production and assembly workshop.

New Best Wire Vietnam Industrial Co., Ltd. is the Vietnamese subsidiary of New Best Wire Industrial Co., Ltd. Founded in 1993, the parent company employs about 500 people in Taiwan, operates eight production and storage plants in Tainan, and has factories in Mainland China and Vietnam. Serving a global clientele, it supplies high-quality wire materials to the fastener industry. Its product range is extensive, covering carbon steel, alloy steel, and stainless steel, with diameters ranging from 1.0mm to 50.0mm and an annual production capacity of up to 145,000 tons. These high-quality wire materials are widely used in the automotive, electronics, and construction industries.

General Manager Wu Yingzong stated that the Vietnam factory officially began operations in March 2022. Despite being the newest among the subsidiaries, it covers an area of 66,000 square meters and is expected to have a monthly production capacity of over 3,000 tons, mainly supplying highend manufacturing, electronics, and automotive sectors. Mr. Wu also mentioned challenges such as undeveloped land and outdated infrastructure in Vietnam, emphasizing the need for long-term planning in developing the Vietnamese market.

General Manager Louis Tran warmly welcomed the group and provided a detailed introduction to the company's products. ALPHA FASTENER is a leading local manufacturer and distributor of fasteners in Vietnam, specializing in various bonded bolts, chemical bolts, and anchor bolts, complying with ASTM (A193 B7, A325, A490), JIS (S10T, F10T), and ISO standards, offering both metric and imperial systems.

The group observed a microcosm of the fastener industry's development in Vietnam. The local enterprises are continually growing and expanding in scale, with improvements in both technology and production, showing potential to become strong competitors in the industry.

As a newly established industrial supply trading platform in Vietnam, ZKH's General Manager Gu Tianxiang provided unique insights into the market demand and development prospects for fastener products in Vietnam. Founded in 2019, this

comprehensive hardware shopping center boasts over 1,500 square meters of retail space, more than 5,000 square meters of warehouse facilities, and a team of over 100 professional employees, covering sales, after-sales service, and logistics.

Under General Manager Gu's guidance, the group gained an in-depth understanding of ZKH's operational model. Mr. Gu

noted that industries previously relocated to Vietnam mainly focused on assembly and packaging. However, in recent years, manufacturing and raw material supply chains have gradually moved to Vietnam, forming a full industrial chain scale. Nevertheless, Vietnam remains significantly dependent on overseas sources for electricity and raw materials.

In addition to visiting local Vietnamese enterprises, the group also attended the MTA Vietnam 2024 in Ho Chi Minh City, gaining further insights into market demands and industry development trends in Southeast Asia.

During the six-day visit, representatives from over 20 companies explored various fastener manufacturing plants, wire suppliers, and distribution platforms, engaging in in-depth exchanges and learning from their experiences.

Xie Xiaofeng, Chairman of Buddy Automotive Parts (Changzhou) Co., Ltd., remarked that the visit provided a comprehensive view of the entire industry process, akin to witnessing a country's industrialization progress. Deputy General Manager Mao Liya emphasized that for enterprises, quality is paramount. Although striving for high quality might result in losing some initial orders, it ultimately builds a good reputation in the market and attracts more long-term customers.

Mr. Shen Xinguo, General Manager of Ningbo Shengtai Fastener Technology Co., Ltd., was particularly impressed by the visit to the Tokyo Byokane Vietnam Factory. He noted that Japan's manufacturing success is primarily due to their unwavering commitment to quality. Chinese enterprises still need to enhance their pursuit and accumulation of quality, as maintaining superior quality is crucial for long-term development.

Mr. Tan Fei, General Manager of Teerhui Metal Products (Suzhou) Co., Ltd., noted that the cost of land in Vietnam is now comparable to that in China. However, there are still gaps compared to China in terms of energy supply, raw material

procurement, and product transportation, making it less advantageous for setting up factories. He also mentioned that understanding the overseas market environment and policy conditions is crucial for Chinese companies to better expand into foreign markets.

Mr. Yang Junfeng, Founder and Chairman of Ebseek, remarked that the trend of industrial relocation for Chinese enterprises should be viewed with caution. Due to differences in policies, markets, and customs, expanding into international markets presents challenges. However, it is encouraging that young Chinese fastener entrepreneurs possess a global vision and show a strong interest, confidence, and determination in the overseas market. With their pioneering efforts and leadership, he believes a group of international fastener enterprises from China will emerge.

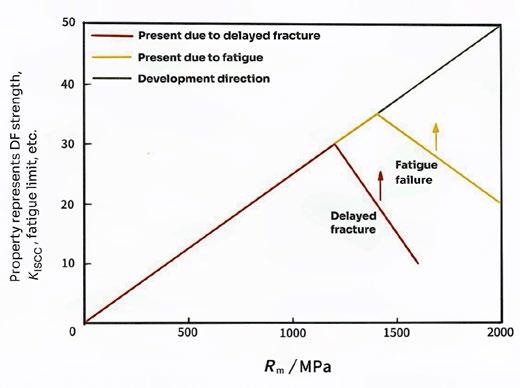

Standardized products formed by fasteners are hailed as the "rice of industry." With the rise of China's machinery and equipment industry, the demand for high-strength fasteners is continually increasing, driven by the trend towards energy efficiency, environmental protection, lightweight design, and miniaturization. High-strength fasteners are predominantly used in critical components such as power systems, chassis, and steering systems. The production of high-strength fasteners demands high standards for raw materials, including fatigue strength, plasticity and toughness, inclusion content, surface quality, metallographic structure, and cold heading performance.

For a long time, China has relied on imports for fasteners used in critical applications, such as steel for 10.9 and 12.9 grade engine fasteners. In recent years, with the continuous advancement of steel production technology in China, the localization of steel production for high-end fasteners has gradually progressed. Currently, several Chinese enterprises possess the capability to produce steel for highstrength fasteners, and some products have obtained certification from host manufacturers and are applied in key parts of high-end equipment. Commonly used steel grades for high-strength fasteners today include SWRCH35K, 45, and ML35 for grade 8.8; 35CrMo and 40Cr for grade 10.9; and 35CrMo, 42CrMo, and SCM435 steel for grade 12.9. This article will explore the application prospects of bolt steel related to high strength and high quality.

Alloy bolt steel, including cold heading alloy steel and alloy structural steel, is a key raw material for fastener manufacturing and is widely used in equipment manufacturing such as machine tools, automobiles, high-speed trains, ships, airplanes, rockets, power stations, etc.

The current standards for alloy bolt steel are GB/T64782015 "Steel for Cold Heading and Cold Extrusion" and GB/ T3077-2015 "Alloy Structural Steel". These standards strictly control the content of impurity elements P and S, with reductions in P and S content across all grades of steel. The former quenched and tempered steel has a maximum content of ≤0.025%, while the latter high-quality steel has a reduced content of 0.005% compared to the previous standard (≤0.030%), reflecting the continuous progress of China's steel metallurgy technology and reducing the risk of quenching cracks during heat treatment.

Enhancing strength has always been a core topic in the development of alloy bolt steel. However, while pursuing high strength, it is necessary to first address the issue of decreased plasticity and toughness, and fully consider the risks of fatigue failure and delayed fracture that may arise from strength enhancement. Therefore, in various stages such as steel production, part processing, and service performance evaluation, the feasibility and comprehensive impact of performance enhancement need to be considered uniformly. Most heat-treated martensitic steels have a tensile strength range of 600 to 1800 MPa. Currently, the highest tensile strength in industrial production of ultra-high-strength steel is close to