HALIX, THE HEALTHCARE CDMO COMMITTED TO ADVANCING THE DEVELOPMENT AND PRODUCTION OF LIFE-SAVING TREATMENTS FOR PATIENTS WORLDWIDE, IS SET TO EXPAND ITS REACH UNDER NEW MANAGEMENT.

HALIX, THE HEALTHCARE CDMO COMMITTED TO ADVANCING THE DEVELOPMENT AND PRODUCTION OF LIFE-SAVING TREATMENTS FOR PATIENTS WORLDWIDE, IS SET TO EXPAND ITS REACH UNDER NEW MANAGEMENT.

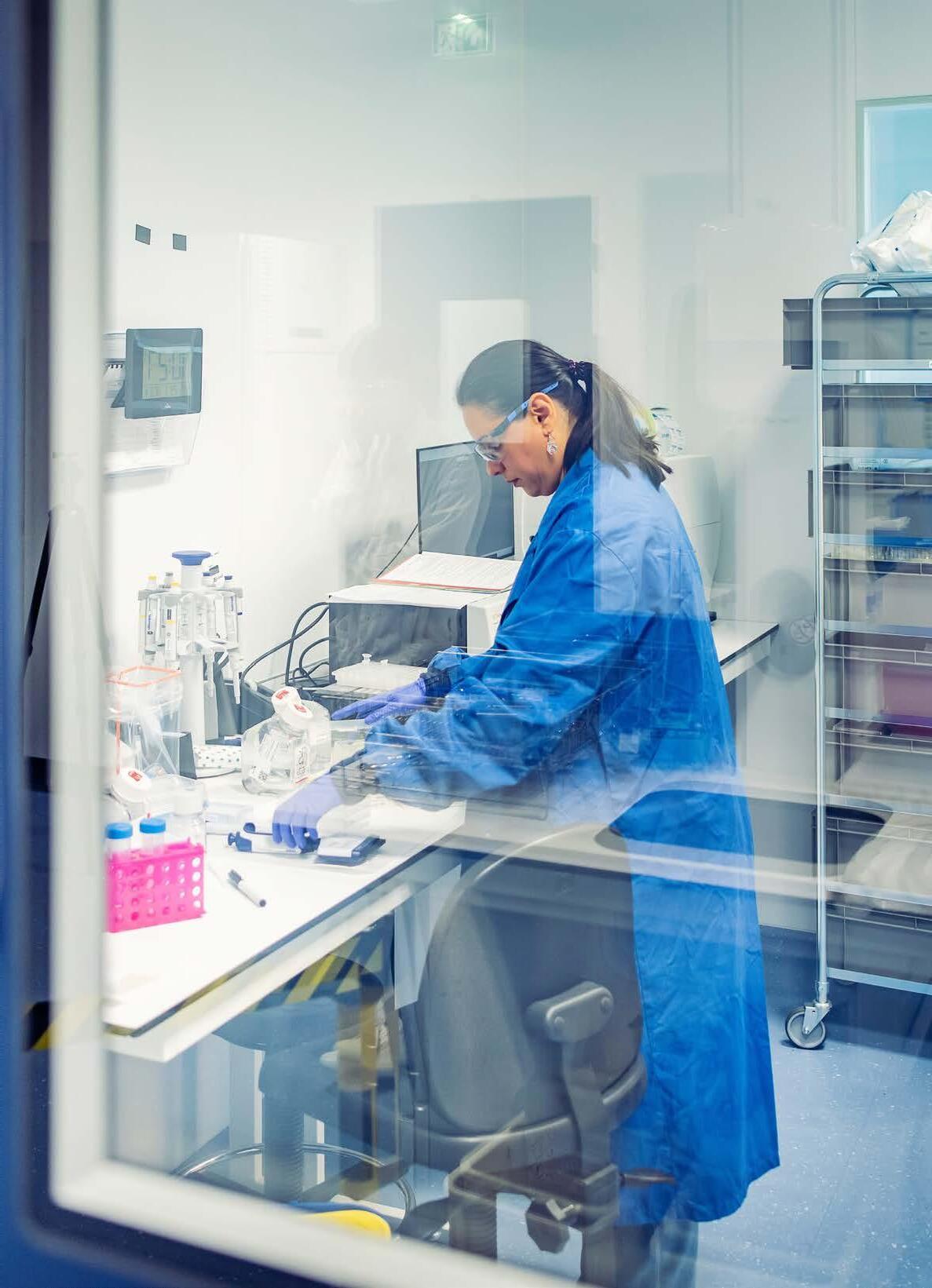

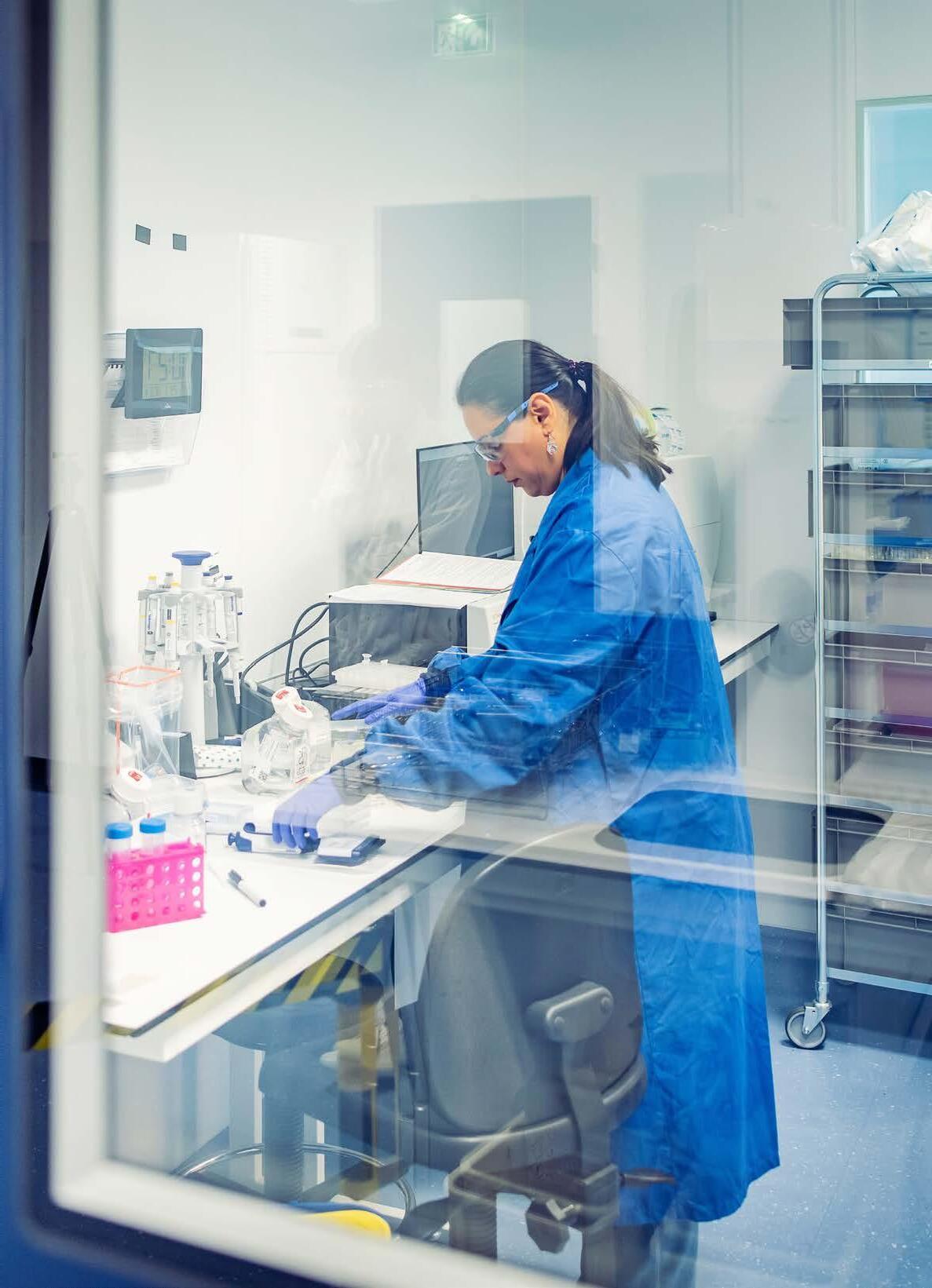

Based in Leiden, the Netherlands, HALIX specializes in the manufacture of biologics, including monoclonal antibodies, viral vectors for gene therapies, and vaccines – all critical tools in addressing some of the world’s most challenging medical conditions.

The company was established in 2012 as a spin-off of HAL Allergy – one of the top European pharma players in the field of allergy immunotherapy — and leveraged initially HAL’s years of industry experience and GMP expertise in the extraction, purification and modification of biologics. As part of the family-owned Droege Group, it benefits from a close corporate structure providing long-term stability.

the journey of innovative therapies from concept to reality, ultimately transforming lives,” says Dr Lutz Hilbrich, the company’s CEO He affirms that what sets HALIX apart is its adaptability and scalability, enabling it to bring pioneering treatments to patients more efficiently. “With a mission rooted in improving human health, HALIX places patients at the centre of its operations.”

Dr Lutz Hilbrich, CEO, HALIX.

“As a healthcare CDMO (Contract Development and Manufacturing Organization), HALIX collaborates closely with biotech and pharmaceutical innovators to ensure treatments are developed and produced to the highest standards of quality and safety. By offering end-toend solutions, we accelerate

Dr Lutz Hilbrich assumed his role as HALIX ‘s Chief Executive Officer in September last year and is going to lead the company into its next stage of growth. With over 20 years in the biotechnology and pharmaceutical sectors, he brings extensive experience in strategic leadership, operational excellence, and innovation in biopharmaceutical development and manufacturing.

Monoclonal antibodies (mAbs), antibody-drug conjugates (ADCs) and recombinant protein are growing in importance as therapeutics for various treatments including cancer, diabetes, and autoimmune diseases like rheumatoid arthritis (RA) and multiple sclerosis (MS).

As the applications for these therapeutics continues to grow, producing these drugs in a format that is administrable subcutaneously offers significant advantages over IV infusion.

*Roots Analysis Report: Subcutaneous Biologics, Technologies and Drug Delivery Systems Market (4th edition)

Development of new drugs or reformulating existing ones for subcutaneous (Sub-C) injection has become an alternative to intravenous (IV) infusion, offering numerous benefits:

• Lifestyle benefits for patients due to convenience of self-administration

• Reduces healthcare costs

Manufacturing challenges

Impact on downstream processes:

• Membrane fouling

• Decrease permeate flux during concentration

• Reduces direct flow filtration flux leading to larger filters

• Increase processing time at unit operations

• Affects recovery of drug substance or drug product

Interested in solutions for high concentration drugs? Let us lend a helping hand to get started.

Growth in the formulation of drugs suitable for delivery by subcutaneous injection highlights manufacturing challenges associated with the higher concentration of active ingredients and formulation components. Manufacturing unit operations that are directly impacted by higher concentration formulations range from ultrafiltration to sterile filtration, filling, mixing, and storage. Good solutions need to maintain quality, maximize process yield and product recovery, and would benefit from being adaptable to existing manufacturing platforms.

OPPORTUNITIES TO ELEVATE YOUR PROCESS FOR HIGH CONCENTRATION DRUG PRODUCTION: ULTRAFILTRATION/DIAFILTRATION

Single-pass tangential flow filtration (SPTFF) may offer real benefits over traditional TFF by reducing shear propensity associated with recirculation. SPTFF systems also offer lower hold-up volume for superior recovery and a higher step yield at higher concentration.

STERILE FILTRATION

The filter choice for high concentration biologics is effectively characterizing membranes that are designed to perform well with viscous fluids but have a lower effective filtration area (EFA). High area and high flow rate sterilizing-grade filters with asymmetric polyethersulfone (PES) membranes overcome the need to oversize filters. The right filter choice can reduce product loss and shorten process time.

Ensuring your bulk drug substance and drug product filling is optimized for higher concentration formulations is important. In addition, the higher protein concentration and higher viscosity mean that filling needles could be prone to dripping and may increase clogging from crystalized protein at the needle tip. This leads to inaccurate dosing, or even interruption of the filling run. Filling needles that are manufactured from hydrophobic materials such as reinforced polyether ether ketone (PEEK) can reduce drip formation. Optimizing filling needle size and your filling flow regime can also guard against drips and clogging and safeguard valuable product at a critical point in the process

Mixing systems with impellers designed for high power input but low shear can maintain product homogeneity in high viscosity environments. Optimal blade design when mixing highly viscous biologics could make a significant difference with product yield. Powerful mixers need the ability to efficiently transfer torque into a fluid at reduced speeds. Combining this with levitation technology, based on non-contact magnetic coupling, can create an ideal mixing environment for sensitive applications.

When highly concentrated/highly valuable fluid samples are scarce, process validation services for filters and single-use components can ensure a minimum volume of drug substance is consumed.

Interested in solutions for high concentration drugs? Let us lend a helping hand to get started. Download the white paper and fill out the form to contact us.

Cytiva is a global provider of the technologies, services, and expertise that researchers and biopharma companies need to bring transformative medicines from discovery to delivery. Visit cytiva.com to learn more.

Cytiva.com/contact

A medical doctor by training, he has spent much of his career in big pharma, focusing on clinical development. In addition to his medical qualifications, he also holds business and leadership qualifications as an alumnus of NYU and Harvard Business School. He has worked across multiple regions, including the US, China, Europe, and Africa, successfully leading organisations through significant growth and transformation.

“Before joining HALIX, I served as CEO for two companies in Germany, which provided invaluable experience in leading organizations through complex challenges,” he says.

“This unique combination of expertise and leadership led me to HALIX, where I aim to drive transformative growth and innovation. As a physician and senior biotech executive, I am committed to relentlessly contributing to the future of medicine by enabling our global partners to develop and manufacture life-saving therapies.”

Speaking about the current market environment, he admits that the biotech market, particularly in Europe, remains slow post-pandemic. “Many small and midsized companies face risk aversion when investing in early-stage projects. While the US market has shown signs of recovery, Europe’s rebound is expected to follow.”

“Still, although the market environment represents a challenge, this is not insurmountable. HALIX is building a compelling narrative to attract customers in an increasingly competitive landscape,” he reflects, saying

that opportunities for growth are manifold. “One clear opportunity is in expanding viral vector manufacturing. With the rapid rise of gene therapies and viral vector-based vaccines, HALIX is well-positioned to establish itself as a leader in this burgeoning sector.”

Geographic market expansion is also on the agenda. “By targeting new markets, in North America and Asia, HALIX can forge partnerships both with biotech start-ups and with established pharmaceutical companies. Establishing a physical presence or strategic alliances in these regions will diversify our client base and accelerate growth.”

He further affirms that strengthening strategic partnerships will be key, saying that collaborating with early-stage biotech companies, academic institutions, and research organizations will enable HALIX to secure long-term relationships and play a vital role in the early development phases of groundbreaking therapies.

“Naturally, HALIX also reflects the latest trends and is set to invest in advanced technologies. Embracing automation, digital manufacturing, and datadriven process optimization will enhance our scalability and efficiency. Hand in hand with this goes the diversification of our services. We plan to expand our offerings to include comprehensive end-to-end solutions to further solidify our position as a trusted healthcare CDMO partner.”

“Ultimately, the greatest opportunity lies in maintaining a patient-first approach by ensuring

the highest quality standards and focusing on therapies that address unmet medical needs.”

HALIX has become a valued partner for leading pharmaceutical companies over the years and has entered into a number of contracts for the production of oncolytic immunotherapies and vaccines. For example, the company played a pivotal role in the global response to the Covid-19 pandemic through its partnership with AstraZeneca for the production of its Covid-19 vaccine. This partnership has demonstrated HALIX’s ability to operate with urgency, quality, and scale, establishing the company as a reliable biopharmaceutical manufacturing partner.

Similarly, the collaboration with RocketVax, a Swiss biotech company based in Basel, exemplifies HALIX’s commitment

to supporting innovative vaccine development. “By contributing to the development of a novel nasal Covid-19 vaccine, HALIX continues to showcase its expertise in advancing cuttingedge science with the potential to address future pandemics. These partnerships reflect our dedication to delivering life-changing therapies and vaccines to patients worldwide.”

As a patient-centric healthcare CDMO, HALIX is driven by the belief that healthcare is a human right, and the company works tirelessly with its customers to ensure medicines are accessible to those who need them most.

Equally important is HALIX’s commitment to sustainability.

“We are actively working to reduce plastic waste and have designed a fully electric facility, eliminating the use of gas for heating. Our innovative ‘cold WFI’ system leverages membrane technology, reducing energy consumption compared to traditional systems,” says Dr Hilbrich.

“We are also making significant investments in automation, digitalization, and artificial intelligence in order to enhance operational efficiencies. These advancements will enable us to optimize processes, streamline production, and deliver improved services tailored to the evolving needs of our partners and customers.”

Since joining HALIX four months ago, Dr Hilbrich has led the development of the XPEDITE strategy framework, a pathway to further enhancing the company’s position as a trusted and sought-after partner.

“Over the next 18 months, executing this framework will be crucial in positioning HALIX as a competitive player in the biotech CDMO market,” he affirms, in concluding.