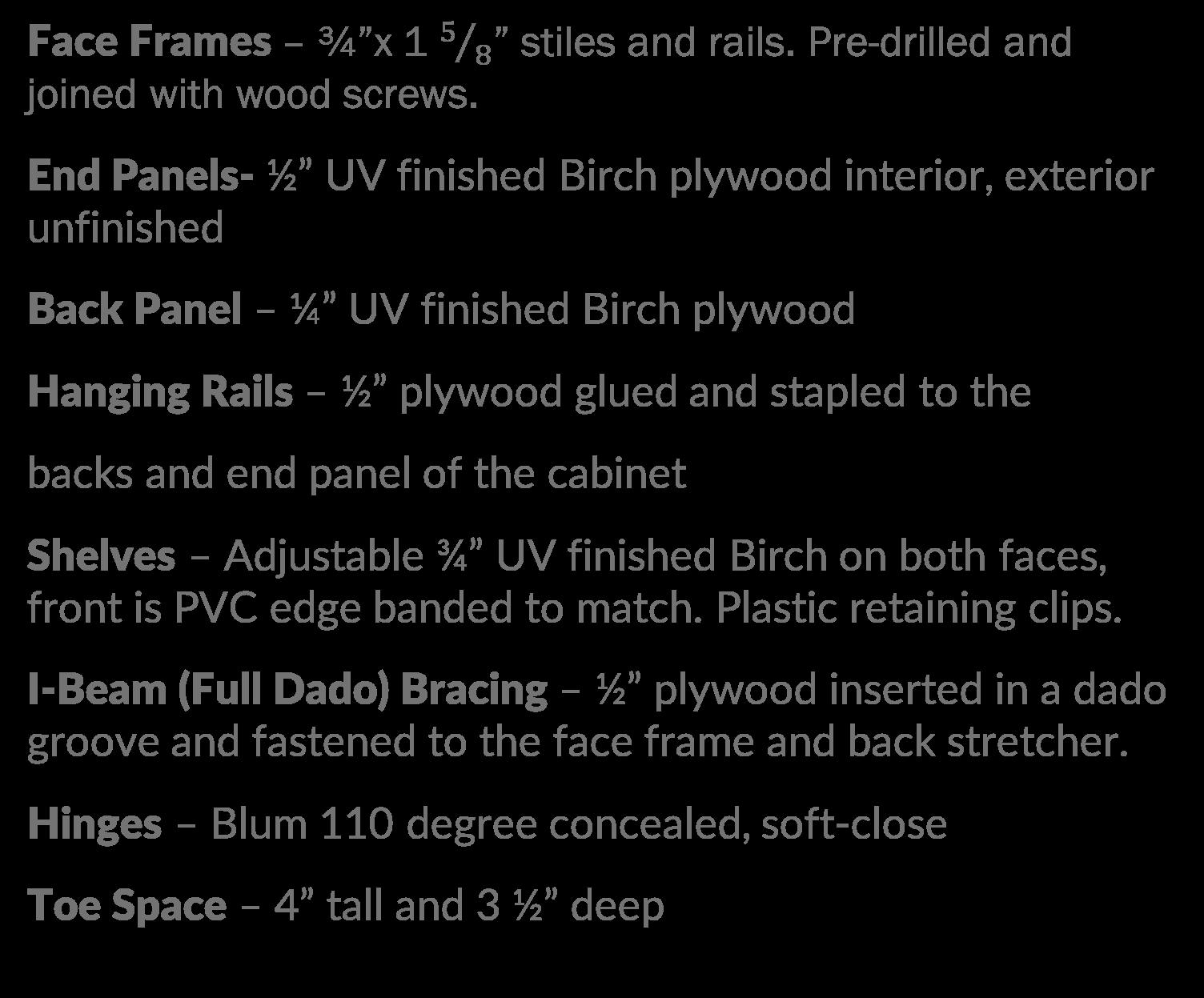

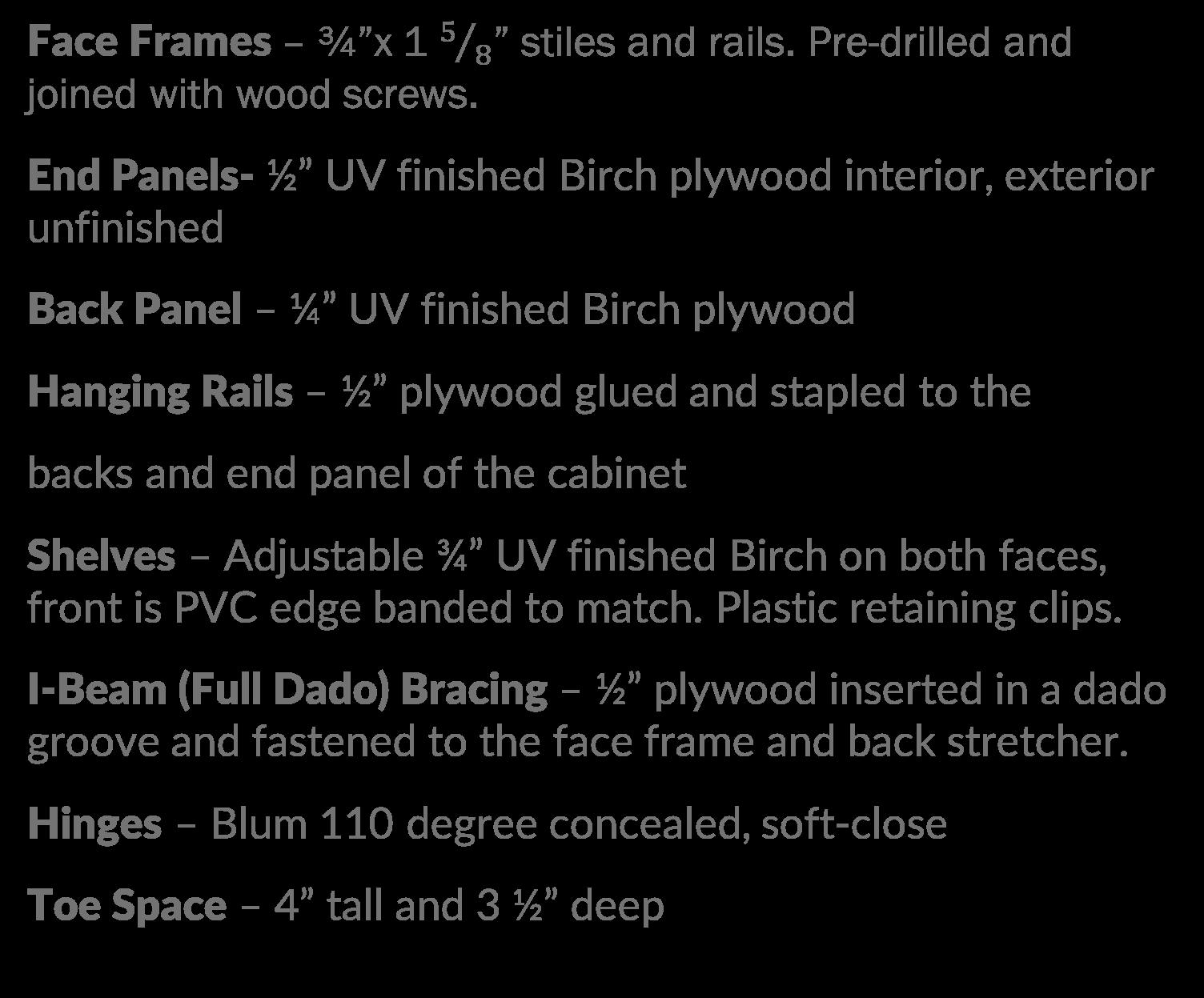

FRAMED CONSTRUCTION

End Panels- 16 mm UV finished Birch plywood interior, exterior unfinished

Back Panel – ¼” UV finished Birch plywood

Hanging Rails – 16 mm plywood doweled and glued.

Shelves – Adjustable 18 mm UV finished Birch on both faces, front is PVC edge banded to match. Plastic retaining clips.

Bottoms/Tops – Wall: 18 mm plywood

Bases, Vanity, Talls: 16 mm plywood

Hinges – Blum 107 degree concealed, soft-close

Toe Space – 4 ½ ” tall and 3 ½” deep

CARB stands for California Air Resources Board, also known as Air Resources Board (ARB). It is a department of the California Environmental Protection Agency. It was established in 1967 with the purpose of maintaining and improving air quality and researching causes and solutions of air pollution. CARB’s mandates, such as CARB 2 compliant MDF, are strictly and usually are considered the standard across the United States.

CARB Phase 1 and Phase 2 are part of California’s Composite Wood Products Regulation (CWP Regulation), which took effect in 2009 with Phase 1. The regulation has to do with reducing formaldehyde emissions from composite wood products, hardwood plywood, particleboard and medium density fiberboard (MDF). In the 2009 rollout of the CARB’s Airborne Toxic Control Measure (ATCM), formaldehyde emissions were capped at .08 parts per million (ppm). CARB Phase 2 went into effect in 2010 and has much lower formaldehyde emissions than the previous phase; set at .05 ppm. A main reason why the CARB ATCM is the strictest air quality measure is because it CAPS emissions levels. Other air quality standards are averages.

Kith, Eudora, and KithONE use Post catalyzed Conversion Varnish clear coats by Sherwin Williams

• Pigmented catalyzed Varnish for the Paints

• Solvent-based Stains.

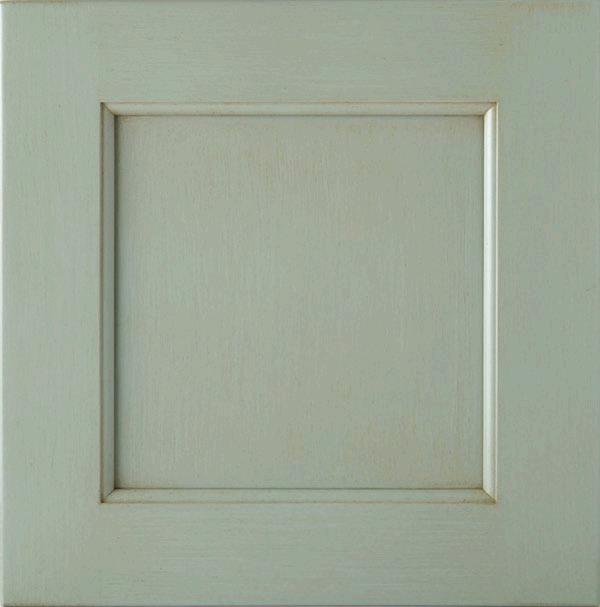

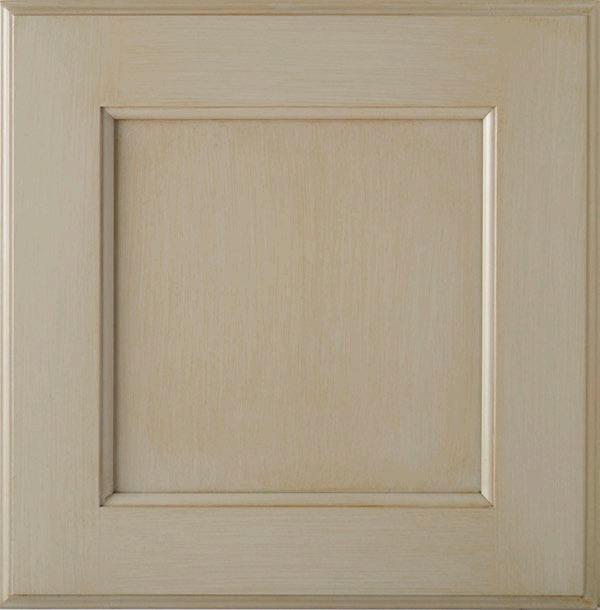

Enhanced Finishes: Vintage, Brushed Brown and Gray, Heirloom

Brown, and Gray, Traditional Glaze (Coffee, Chocolate, and Pewter) and Rub-Through will receive a top-coat after the enhancement is applied.

Machine & Hand Sanding

Primer Coat then Forced Cured

Hand Sand

Pigmented Topcoat #1

Force Cured

Hand Sand

Pigmented Topcoat #2

Force Cured

Machine & Hand Sanding

NGR Spray Stain

Hand-Wiped Stain

Sealer Coat #1

Force Cured

Hand Sand

Toner Sealer

Top Coat Force Cured

Machine and Hand Sanding – i.e. White Wood Sanding – The process where the parts are prepped for the finish room.

Forced Cure – Sometimes called “Baked on Finish”. The coatings are forced to cure faster by heating the parts in an oven.

• The color is achieved by applying 2 coats of a dye-based spray stain

• NGR Stains have a more consistent color tone over the piece finished. NGR stands for Non-Grain Raising. Color is more consistent, but you sacrifice depth of color.

Hand-wiping a complementing heavily pigmented stain to the base color of a wood component to accent the detail and wood grain.

• Glazes (additional charge)

See spec book for details

• Pewter

• Chocolate

• Coffee

• Available on both Stains and Paints

• Available on all door styles (except Metro) and all wood species

• Glazing is applied to all finished areas except the backs of doors and drawer fronts

The component is given a worn look by sanding the base color to the wood.

• Rub-Through (additional charge)

See spec book for details

Rub-Through is available on all door styles and wood species (except Metro)

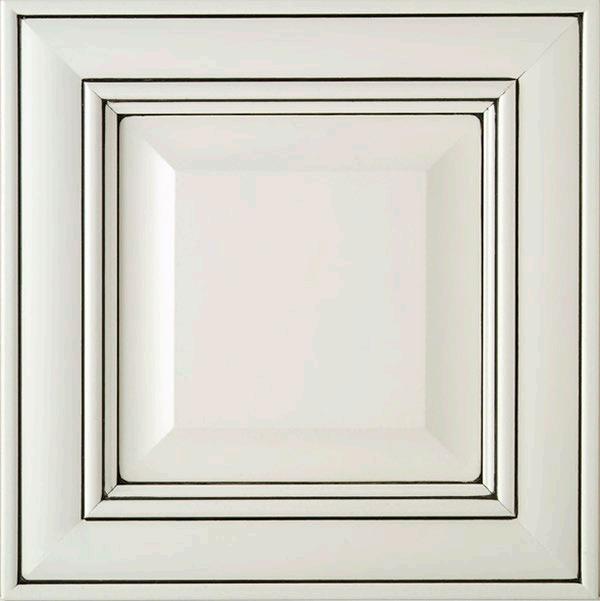

Applying a light brown glaze over the base color of a wood component with a paintbrush which gives the part a soft contrasting brush stroke look.

• Brushed Brown Glaze (additional charge)

See spec book for details

• Brushed Brown Glazing is applied to Painted Maple doors only.

Rub-Through

• Brushed Brown is applied to all finished areas except the backs of doors and drawer fronts

• Not Available on Ebony

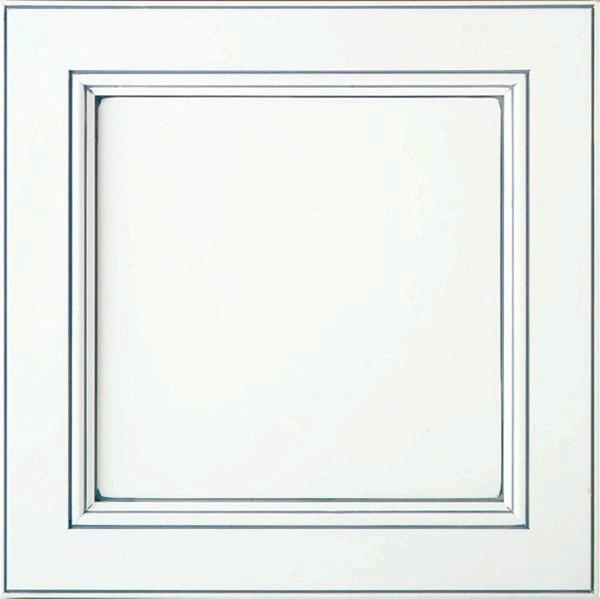

Applying a gray glaze over the base color of a wood component with a paintbrush which gives the part a soft contrasting brush stroke look.

• Brushed Gray Glaze (additional charge)

See spec book for details

• Brushed Gray Glaze is applied to painted maple doors only

• Brushed Gray is applied to all finished areas except the backs of doors and drawer fronts

• Not available on Ebony