The roots of the company date back to the early 1960s when Tinti Srl was founded in Castelfranco Emilia, specializing in the production of components for the agricultural sector. Over the years, the company grew and became a partner to major companies operating in the region. In 1973, the Borsari family took over the management of the company, bringing an entrepreneurial mindset that modernized and reorganized the business, equipping it with a structured and professional operational capacity.

The subsequent years tell the story of a dynamic company, capable of producing efficiency and continuous growth. Its relentless pursuit of quality and attention to service enabled the company to weather some of the darkest periods for the Italian industry, positioning itself as one of the few companies capable of growing alongside its clients and becoming a reliable partner. The company’s production began to cover all the main sectors of precision components, from hydraulics, automotive, earthmoving, agriculture, to food production. During these years, the company obtained the main industry certifications, demonstrating the highest levels of

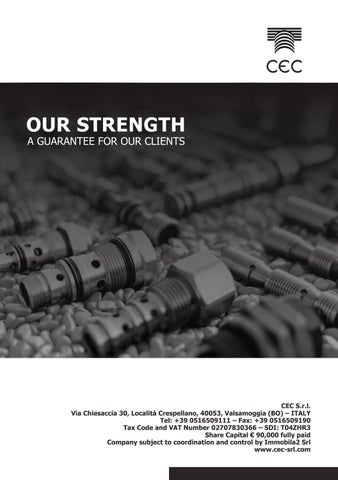

quality and professionalism achieved. In 2001, the company changed its corporate name to CEC Srl. In 2007, it moved from its historic location in Castelfranco Emilia to a new 10,000 m² production site in Crespellano (Bologna), where, in addition to precision machining, preassemblies, complete assemblies, accessory processes, and specific parts are carried out. In 2019, the company reached 100 employees, with increasingly ambitious goals propelling it toward the future. By 2022, the company employed 130 people and reached a turnover of €40,000,000.

These are the foundations upon which all of our company’s production activity is built.

Our services, machinery, production processes, and qualified personnel are all distinctive elements of a company in constant growth, with the main objective of achieving complete customer satisfaction while maintaining high standards of production quality. For this reason, CEC Srl is focused on the search for technologically advanced solutions to meet the specific requirements of all types of clients, in full compliance with the required quality standards.

Our machinery fleet consists of state-of-the-art equipment, with updates and adjustments to meet the evolving demands of mechanical processing forming the core of our company’s structure. Within our company, we have approximately 94 CNC (Computer Numerical Control) machines.

Ghiringhelli

SERIES M100

Brother

SERIES SPEEDO

Production is managed and monitored by over 105 specialized and highly qualified staff members, who perform checks during the programming phase and on the machines themselves. Production monitoring and management are ensured by a management software system, which allows us to provide the customer with real-time updates on the status of their order. CEC Srl produces high-precision turned parts (valves, sliders, rods, cartridges, cylinders, pinions, fittings, etc.) in various materials (9SMnPb28, 35SMnPb10, 42CrMo4, 16NiCr4Pb, ETG88/100, C45, ESP65, bronze, brass, aluminum) exclusively based on customer designs and specifications. Additionally, the company manufactures production batches ranging from 1,000 to 30,000 pieces, closely monitoring and using appropriate control and measurement instruments. Where required, the company also performs heat treatments (carburizing, carbonitriding, tempering, etc.), plating (zinc plating, chroming, nickel plating, anodizing, etc.), internal and external grinding with tolerances as tight as 2 microns, and component assembly.

It is also certified by ACGM with a rating of one star ++ on the legality rating. For about a year, it has been implementing an ‘assessment’ process for the integration of the Organization, Management, and Control Model (M.O.G.C.) pursuant to Legislative Decree No. 231/2001.