A Practical Mechanic’s Guide to TKM Karting

5.6.2 Replacing the cylinder Head

It is important to re-tighten the four 13mm brass nuts in a diagonal order as shown in figure 5.6.1-1. If you do not you may warp the head. Set the torque wrench to about 6lbs/ft first and then 10 lbs./ft and then 13lbs/ft to finish.

The two cap head screws should be replaced last.

Check the Squish Band Clearance [5.7.6], as it may decrease when the head is re-tightened.

5.6.3 Cleaning the cylinder head.

A discoloration of the head due to a small amount of carbon deposit is OK and makes very little difference to performance. If it starts to get thick it could in theory cause an engine to fail scrutineering due to the reduced capacity of the cylinder.

Chip off the carbon lumps using a shaped piece of hard plastic.

You may finish off removing the carbon with fine wetted emery paper, but if you do then use it with great care and - DO NOT REMOVE ANY METAL!

Do not use any form of oven cleaner. Most contain caustic soda (Sodium Hydroxide) or similar substances that will erode aluminium. The author never uses chemical cleaners, but if you must use a chemical cleaner then test it first. Drill a hole in a spare piece of aluminium and take the curly swarf that comes off the drill bit and put half of it into the chemical cleaner. Leave it for a few hours and then compare it with the untreated swarf. - You may be surprised at the degree of erosion.

5.6.4 Checking the cylinder head.

After cleaning the head use a magnifying glass and a good light to examine the head for cracks, pitting and any other sign of damage.

5.7 Cylinder Barrel

You may be required to remove the barrel for scrutineering.

The barrel will be free to be lifted from the crankcase when the head is removed.

ChrisCompton(compark)2001 Page 1

A Practical Mechanic’s Guide to TKM Karting

5.7.1

Removing the barrel

Take care with the base gaskets. They can be reused if undamaged.

When removing the barrel, support the piston so it doesn't fall on to the crankcase.

In order to ensure that no dirt or loose components fall into the crankcase place a clean cloth over the exposed hole.

5.7.2

Replacing the barrel

This requires practice. Like many things when you have done it a few times it becomes easy, but the first time you try it may seem to be almost impossible.

• Place the engine on its side on a clean surface. If you leave it upright you will find it difficult to support the head, compress the rings and push the piston into place without running out of hands!

• Ensure all internal parts are spotless and lightly oiled with 2-Stroke oil.

• Ensure that it's the right way round. The exhaust port faces the rear!

• Align the ends of the piston rings with the pins in the slot [5.9.4].

• Using finger and thumb to compress first, the top ring and then the lower ring, gently insert the piston into the cylinder. Never force it. The piston and rings must be oiled. The rings must be aligned with the pins in the piston. The piston will slide easily into the barrel when everything is correct.

• Turn the engine over by hand to check free movement and, using a thumb on the top of the piston, 'wobble' the piston about to ensure that the rings are not stuck.

• Always check the Squish Band Clearance after replacing the barrel [5.7.6].

5.7.3

Cleaning the barrel

Remove any carbon from the ports using a plastic scraper. Never use chemical cleaners or oven cleaner. Removing the black anodising from around the ports may make the engine illegal. You can use

ChrisCompton(compark)2001 Page 2

A Practical Mechanic’s Guide to TKM Karting

white spirit and then WD40 on the outside of the engine but the cylinder must be lightly oiled with Two-Stroke engine oil.

5.7.4

Checking the barrel

The cross-hatching caused by honing the bore should still be clearly visible. The surface should not show vertical wear lines (Scoring).

Check for scoring - especially below the ports.

It is beyond the scope of this manual to completely check the bore. If you have any doubts you should send the engine away to be fully checked by Tal-Ko or a reputable engine re-builder.

5.7.5 The Squish Band Clearance

The Squish Band clearance is the gap between the top of the piston and the cylinder head. It is critical to good combustion within the cylinder. The book “Two-Stroke Performance Tuning” provides an excellent explanation [14.8].

This clearance is normally adjusted by the total thickness of the base gaskets (between the barrel and the crankcase). These gaskets come in various sizes and it is permitted to use up to three to achieve the correct Squish Band Clearance. These gaskets can be reused, but they must be replaced if they become brittle or damaged in any way.

Figure 5.7.4-1 Scoring below a port

ChrisCompton(compark)2001 Page 3

A Practical Mechanic’s Guide to TKM Karting

The Squish Band Clearance should be less than 0.914mm (0.036") and greater than 0.762mm (0.030"). As a general rule the best performance will be achieved by setting the minimum clearance. It should be checked often as the gaskets can become compressed so reducing the clearance.

Reducing the Squish Band Clearance further than these limits may cause the engine to fail scrutineering by causing a reduction in the head volume below the legal minimum. It may also place excessive stress on the piston assembly and may even cause the engine to overheat.

Machining of the head or barrel will result in a reduced Squish Band Clearance.

5.7.6 Measuring the Squish Band Clearance

To measure the Squish Band Clearance tighten the head down to its correct torque [5.6.2]. Insert a length of soft solder wire towards the sprocket side of the engine. It should be inserted far enough through the Spark Plug hole that a good length will be crushed against the cylinder head when the piston rises. (The type of solder with a flux core is ideal. The solder wire used by the author has an original diameter of 1.27mm). Turn the engine over by hand until top-dead-centre is passed and the solder is crushed.

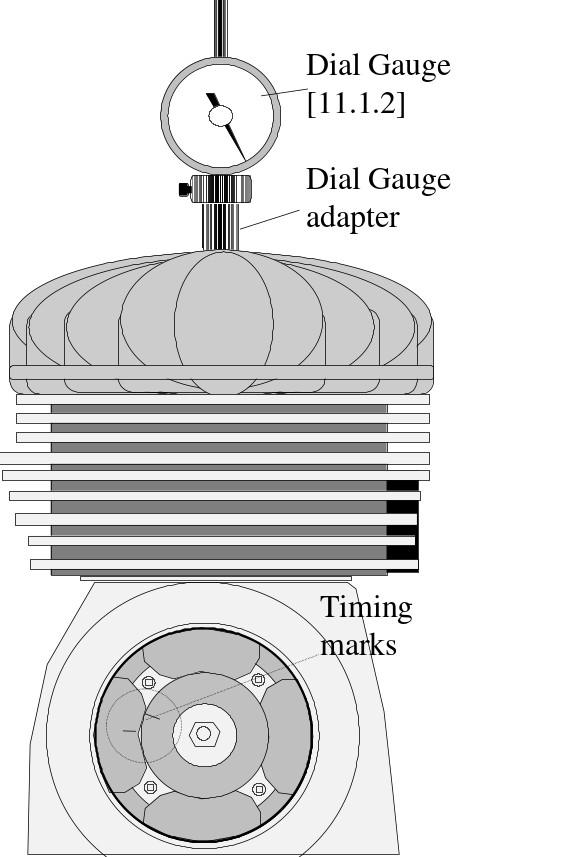

Figure 5.7.6-1 Squish Band Clearance

Remove the solder wire and carefully measure the width of the crushed end. Repeat this, using fresh solder inserted towards the ignition side of the engine.

ChrisCompton(compark)2001 Page 4

A Practical Mechanic’s Guide to TKM Karting

If the measurements are not the same then replace the base gaskets and try again. If it is still uneven then something is seriously wrong and the problem should be referred to an expert.

If the measurements are both the same, but not correct then change the gaskets to achieve the correct clearance.

5.8 Piston Assembly

You will need to remove the piston assembly in order to clean and check it. The author always replaces the circlips. Replace the small end bearing rollers if they show any sign of damage.

5.8.1

If you do not own a proprietary tool then removing and replacing the ear-less circlips used to keep the gudgeon pin in place requires practice.

• Place the engine on its side so that bits do not fall into the crankcase.

• Grease the dummy gudgeon pin [11.1.3].

• Push the gudgeon pin down away from the circlip so that a small gap is evident between the circlip and the gudgeon pin.

Removing the Piston assembly

Figure 5.8.1-1 Removing the Circlips-1

ChrisCompton(compark)2001 Page 5

A Practical Mechanic’s Guide to TKM Karting

• Using a small Instrument screwdriver with a blade width of about 1.5mm carefully move the circlip around the groove until the gap in the circlip is aligned with the edge of the slot in the piston.

• Insert the screwdriver under the end of the circlip.

Figure 5.8.1-2 Removing the Circlips-2

• Using the inside edge of the gudgeon pin as a fulcrum, raise the screwdriver handle lifting the free end of the circlip up so that it is just out of the groove.

• Grip the freed end of the circlip with snip-nose pliers (The points need to be small enough to fit into the groove) and rotate and pull it clear so that the gripped end turns in pulling the remainder of the circlip out of the groove.

• Remove the other circlip and discard them both.

Insert the Dummy Gudgeon Pin into the piston (rotate it to stop it sticking) until it starts to displace the Gudgeon Pin. Insert the threaded bar from the Gudgeon Pin Extractor [11.2.6] through the Gudgeon and Dummy Gudgeon pin and fix it in place with the two nuts with the domes facing inwards.

ChrisCompton(compark)2001 Page 6

A Practical Mechanic’s Guide to TKM Karting

Push the assembly through until the dummy gudgeon pin supports the needle Rollers and Thrust Washers in place. Take care not to place any load on the crank. If the gudgeon pin is tight then assemble the remainder of the Gudgeon Pin Extractor [11.2.6] and use it to jack the gudgeon pin out. Very little force will be required unless something is wrong so do not use a hammer or drift.

Remove the Gudgeon pin removal tool. The Piston and the con-rod can now be separated without the Needle Rollers flying in all directions.

Figure 5.8.1-3 Removing the Gudgeon Pin

Figure 5.8.1-4 Gudgeon Pin Extractor

ChrisCompton(compark)2001 Page 7

A Practical Mechanic’s Guide to TKM Karting

Figure 5.8.1-5 Removing the Con-Rod Assembly

Use a cable tie to secure the dummy gudgeon pin, 25 rollers, 2 aluminium and 2 steel thrust washers in place.

5.8.2 Replacing the Piston Assembly

Take your time and ensure that everything is very clean. Have your tools and new parts ready to hand.

• Assemble the rings on to the piston [5.9.4].

• Lay the engine down (inlet port facing down) so that any dropped component does not fall into the crankcase. It is also easier to work on in this position.

ChrisCompton(compark)2001 Page 8

A Practical Mechanic’s Guide to TKM Karting

• Assemble the 25 bearing rollers and dummy gudgeon pin into the crank shaft small end. Use 2-Stroke oil to hold them in place. Ensure that there are 25 pins.

• Oil the four thrust washers and place them on to the dummy gudgeon pin. (Note that the steel Washers may have a pressing flash around the edge. If so ensure that it does not interfere with the aluminium washer or the con rod.)

• Push the Gudgeon pin part-way into the piston.

• Oil the surfaces on the inside of the piston against which the Trust Washers bear.

• Carefully place the assembled small end bearing into the piston. Ensure that the gap in the top piston ring faces towards the front of the engine and the gap in the bottom ring faces the rear (exhaust port).

[5.9.4]. Note that older pistons may have the gaps in both rings facing the rear of the engine.

Figure 5.8.2-1 Small End Bearing.

ChrisCompton(compark)2001 Page 9

A Practical Mechanic’s Guide to TKM Karting

5.8.2-2

Figure 5.8.2-3 Old Piston Ring Alignment

• Ease the Alignment Spring [11.2.7] though the gudgeon pin and into the dummy gudgeon pin to bring both into alignment. Take care not to allow the spring to push the dummy gudgeon pin out of position.

Figure 5.8.2-1 Aligning the Dummy Gudgeon Pin

• When the spring is in place use finger pressure to push the gudgeon pin home and the Dummy Gudgeon pin out. If finger pressure is not

Figure

New Piston Ring Alignment

ChrisCompton(compark)2001 Page 10

A Practical Mechanic’s Guide to TKM Karting

enough then first ensure that a thrust washer has not slipped down between the dummy and real gudgeon pins and that nothing else is wrong before using the Gudgeon pin extraction tool to press it in [5.8.14]. Do not use a hammer!

Check that about 0.25mm (0.098”) of clearance exists between the thrust washers and the conrod.

That’s the easy bit done! If you found it difficult to get the ear-less circlips out then replacing them needs to be practised using an old piston before you try it on the new one, or see the note about eared circlips below.

• Adjust the position of the gudgeon pin so that a small amount of clearance is available below the groove into which the circlip sits.

• Place one end of the circlip into the groove so that the end of the circlip is aligned with the centre of the slot. Ensure that it is in the groove and not below it.

• The protruding half of the circlip can now be pushed down into the groove with your thumb. If it is too tight then use an aluminium drift to push it home.

• Have a few spare circlips ready! Do not crush the circlip or scratch the piston.

• When both circlips are in place, use a good light and a magnifying glass to re-check that both circlips are fully home.

Figure 5.8.2-2 Fixing the Circlip in Place

ChrisCompton(compark)2001 Page 11

A Practical Mechanic’s Guide to TKM Karting

Eared Circlips

Eared circlips are easy to insert and remove, but care must be taken to ensure that they do not wear due to the end of the gudgeon pin rubbing against them! Check them frequently.

When inserting eared circlips ensure that they are not crushed. Only compress them as much as is essential in order to insert them.

Use a magnifiing glass to ensure thet they are well seated. A reduced gap between the ears indicates a poorly seated circlip.

Do not re-use circlips.

5.8.3

Small-End Bearing Surface

The con rod should easily last between rebuilds, but check the small-end bearing surface (inside the hole) for any damage. A worn or damaged roller can damage the bearing surface.

5.9

Piston

The piston is a critical component and must be treated with respect. It is made from aluminium which can be easily damaged. It can tell a story about mixture and engine temperature.

If the piston is replaced then the piston rings must be replaced. New piston rings require a small amount of 'Running In' [5.4.1].

Figure 5.8.2-3 Fixing the Eared Circlip in Place

ChrisCompton(compark)2001 Page 12

A Practical Mechanic’s Guide to TKM Karting

5.9.1

Cleaning the Piston

Remove the piston rings [5.9.3]. Using a shaped plastic scraper remove any carbon that has built up on the top of the piston or in the piston ring grooves. It is possible to clean the top of the piston with fine wet emery, but this practice has no great merit.

5.9.2 Checking the Piston

The piston will not normally require replacing more often than every 9 hours, but if the piston is damaged in any way, or you suspect that it may be damage then replace it. The author has had an engine destroyed by a piston breaking at over 15000 rpm. The piston would have cost £50 to replace, the engine cost over £800! The author now checks pistons very carefully and replaces them when any damage or wear is evident. No degree of damage is acceptable!

If you use higher than normal rpm then the piston will be absorbing excessive amounts of stress. This will result in premature failure so replace it more frequently.

• Use a magnifying glass under a good light to check for hairline cracks, scuffing (around the skirt) and scratches (from tools and cleaning). A scratch will act as a focal point for stress and may cause premature failure.

• Check the piston ring location pegs with care. They are prone to damage.

• Check the Aluminium Thrust Washers and the mating surfaces on the inside of the piston for wear. The aluminium surfaces can become worn which will increase the end-float of the piston on the con-rod/gudgeon pin. This can be heard at tick-over as a 'clicking' sound.

ChrisCompton(compark)2001 Page 13

A Practical Mechanic’s Guide to TKM Karting

5.9.3 Removing the Piston Rings

Figure 5.9.3-1 Removing Piston Rings

Ease the rings open with your thumb nails until the ring can be lifted clear without scratching the piston.

5.9.4 Replacing the Piston Rings

Piston rings can be changed more frequently if you suspect leakage due to wear. The most likely cause of 'blow by' (shown by blackening down the side of the piston) is carbon in the slots causing the rings to stick.

Using nothing but your fingers and thumb nails, gently ease the rings open until they can be placed onto the Piston. [5.9.3-1] Take great care to avoid scratching the piston with the sharp ends of the rings.

Figure 5.9.4-1 New Piston Ring Alignment

ChrisCompton(compark)2001 Page 14

A Practical Mechanic’s Guide to TKM Karting

Note that the ring alignment may be different in older pistons. [5.8.2-3] The ‘gaps’ in the piston rings must be aligned to the pegs. Use a magnifying glass to check that the pegs are OK (they are very small).

The piston rings must be free to move freely within the slot cut into the piston.

5.9.5 Cleaning the Piston Rings

Piston rings are made from high quality steel and are resistant to most chemical cleaners. The author however still prefers to use a plastic scraper to remove carbon. It is essential to ensure that the ring is free to move within the slot cut into the piston.

5.9.6 Checking the Piston Rings

The pistons and rings need to be cleaned and inspected frequently. If scoring is evident then replace the rings. No damage of any kind is acceptable on the piston rings.

5.9.7 Measuring the piston ring gap

Piston rings come in various sizes as defined by the bore size into which they will correctly fit.

5.9.7-1 Piston Ring Size

The way to check the size of a piston ring is to place it into the cylinder, taking care to align it with the top surface of the cylinder and then measure the gap with a feeler gauge. If a ring of carbon exists around the top of the cylinder then ensure that the ring is below it.

Figure

ChrisCompton(compark)2001 Page 15

A Practical Mechanic’s Guide to TKM Karting

Note that the gap measured on a new Tal-Ko supplied engine was 0.011" (0.23mm) and on a (so called) tuned engine was 0.015" (0.38mm).

Do not crush an oversized ring to achieve a smaller gap, as this may cause the ring to 'lock' when the engine gets hot resulting in the engine seizing.

It may also allow leakage around the ring because if the ring is deformed it will not form a good seal against the cylinder wall.

5.10 The Bottom End

There are a few checks that can be made without expert knowledge or special tools. If any problems are found then refer it to an expert.

5.10.1 Crank Alignment

Never hold the ignition side nut in order to remove the starter nut. If you do you will cause a misalignment of the crank by rotating one ‘half crank’

Figure 5.9.7-2 Measuring the Piston Ring Gap

Figure 5.9.7-3 Crushed Piston Ring

ChrisCompton(compark)2001 Page 16

A Practical Mechanic’s Guide to TKM Karting

against the other around the crank pin. This problem may also occur with normal running and therefore the crank alignment needs to be checked frequently.

Figure 5.10.1-1 Crank Misalignment-1

When the crank is correctly aligned the axis of the two Half Cranks are coincident.

Figure 5.10.1-2 Crank Misalignment-2

If one side of the crank is held whilst torque is applied to the other this will result in one half crank rotating about the crank pin with respect to the other.

ChrisCompton(compark)2001 Page 17

A Practical Mechanic’s Guide to TKM Karting

Figure 5.10.1-3 Crank Misalignment-3

The axis of the sprocket side half crank is no longer coincident with the axis of the ignition side half crank, but the crankshaft bearing centres remained fixed by the crankcase.

Figure 5.10.1-4 Crank Misalignment-4

This results in each end of the crank shaft prescribing a circle as shown in exaggerated form [5.10.1-4]. This can cause vibration leading to engine failure.

The best way to identify a misaligned crankshaft is to carefully observe the gap between the ignition rotor and the stator whilst turning the engine over. With a good light and a magnifying glass you will see very small changes. Alternatively take four measurements, using a feeler gauge, at the same point on the stator whilst turning the rotor 90 degrees between each measurement. If any misalignment is detected send the engine back to a

ChrisCompton(compark)2001 Page 18

A Practical Mechanic’s Guide to TKM Karting

specialist (Tal-Ko) to be re-aligned. It should not be an expensive job, but it will lead to an expensive failure if it is not fixed.

5.10.2

Big End Bearings

If any vertical movement (a soft click) can be felt in the Big End Bearing when the crankshaft is gently pushed and pulled vertically then it is time to get it checked.

5.10.3 Oil Seals

Check the condition of the oil seals frequently. Their major function is to provide an 'air' seal so that a vacuum can be held in the crankcase. Should a seal leak air then this could result in poor running. This will be particularly evident at tick-over.

5.11 Ignition

Modern ignition systems, both PVL and Motoplat, are very robust and reliable. Other than cleaning and adjusting the timing there is not a lot to be done with them. Ensure that the HT lead is always earthed when turning the engine over or you may cause a spark to damage the internal electronics. This is best done by reconnecting the spark plug and laying it on top of the engine.

5.11.1 How the Ignition works

The author lost track of how ignition systems worked when magnetos went out of fashion, but luckily this doesn't matter. It is a sealed unit and no repairs can be made to it.

5.11.2 Looking After the Ignition

Keep the magnetic rotor clean and oil free. It attracts small bits of steel, which then get caught between the rotor and stator causing scratches or worse damage.

Check that connectors are clean and make a good connection. If the connectors get worn or broken then renew them using the correct parts and a crimping tool. Do not solder the connectors on as this will lead to early failure.

ChrisCompton(compark)2001 Page 19

A Practical Mechanic’s Guide to TKM Karting

Fix all cables in place with cable ties. Ensure that no load is on the HT cable at the coil end. Do not allow cables to flap!

The coil's rubber mount is essential and must not be damaged or perished.

It is possible to replace the Plug cap and HT lead on new PVL ignition systems, but if you do, ensure that you use the correct Tal-Ko part.

5.11.3 Setting the Ignition Timing

The value quoted for ignition timing is the 'lead' before Top-Dead-Centre (TDC). This equates to the vertical distance travelled by the piston between when the ignition fires and the highest point reached by the piston.

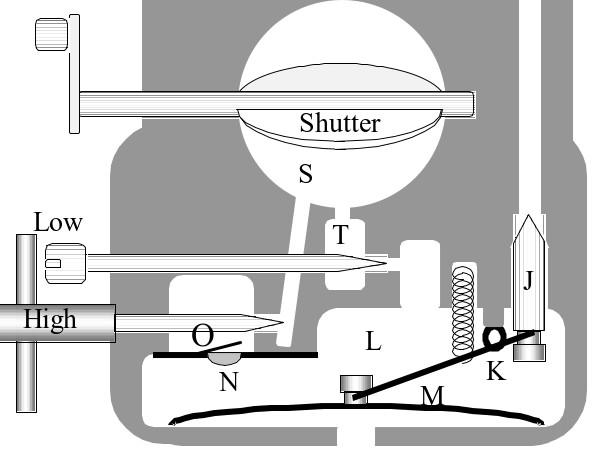

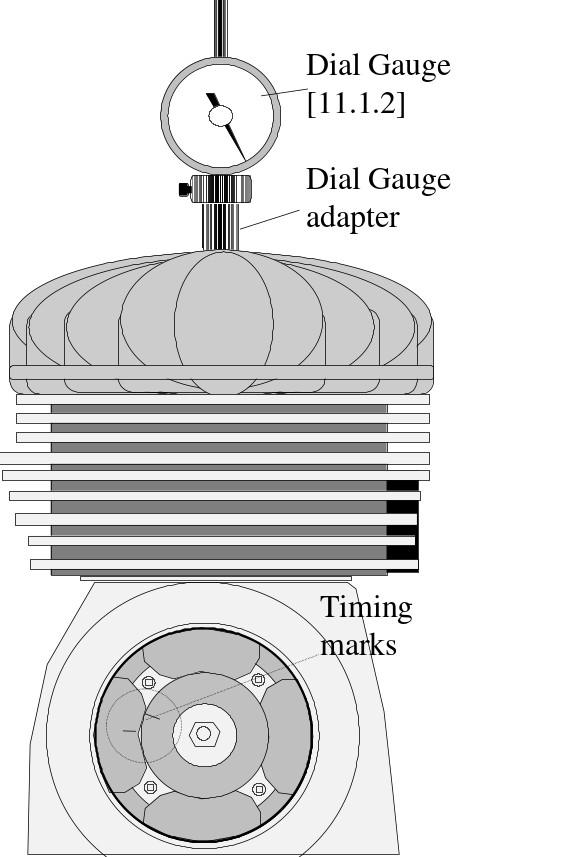

Turn the crankshaft until TDC is achieved. Rotate the dial on the dial guage to read zero at TDC. Turn the crankshaft back and forth a few times in order to check that the dial is zeroed at TDC. Rotate the crank until the timing marks are aligned. The dial gauge will now show the ignition timing setting (lead).

ChrisCompton(compark)2001 Page 20

A Practical Mechanic’s Guide to TKM Karting

5.11.3-1

Setting the Timing

Best performance will be achieved by setting the lead to a maximum value (most advanced) that will guarantee that it will be between the limits if tested during scrutineering. A typical setting for the Motoplat ignition is 2.9 mm. The limits for both types of ignition (Motoplat & PVL) are specified in the TKM regulations (15.3).

5.11.4 Checking that the Ignition works

Generally if there is a spark across the plug gap then the ignition works. If the sunlight is too bright to see the spark then use a rev counter: If it gives a reading then the ignition works.

Figure

ChrisCompton(compark)2001 Page 21

A Practical Mechanic’s Guide to TKM Karting

5.11.5

Wiring the Ignition Switch

It is a requirement of the regulations that all clutch karts have an ignition switch. The switch must be of a suitable type (Get it from Tal-Ko) and it must be correctly connected as described in the TKM Regulations [14.3].

Connect the earth side of the switch to the ignition earth on the engine. Connect the switch wiring to the ignition wire and earth using good quality snap connectors so that it can be disconnected when the engine is removed.

5.12 Spark Plugs

This is another subject that causes amateur engineers to go into spasms of in-depth opinion. The author uses the spark plugs recommended in the TKM Regulations [14.3]. Using an inappropriate plug or plug lead can cause overheating and engine seizure.

5.12.1

Checking and Cleaning Spark Plugs

When the plug is cool, clean any carbon deposit from it. Spray Brake cleaner and a toothbrush will do the job. Check the gap. It should normally be 0.64mm or 0.025 inches. If it has worn so that the gap has increased or it shows any sign of damage then dump it.

Since fitting a new plug, which turned out to be duff, the author never uses a new plug for a race. Keep a tested, but almost new plug for important races.

As a rule of thumb the author discards plugs after about two hours of running time, but this has no scientific basis.

5.13 Engine Sprocket

All of the power generated by the engine passes through the 9, 10 or 11 teeth of the Engine Sprocket. Change it if it shows signs of excessive wear. If you can see any distortion of the sprocket teeth then you should consider that to be excessive. It should never get so bad that cracks are evident. An old worn sprocket is less efficient than a new one and will absorb more energy.

ChrisCompton(compark)2001 Page 22

A Practical Mechanic’s Guide to TKM Karting

The rear sprocket is covered in paragraph 8.3.4.

5.14 Exhaust

The exhaust must be standard and marked TKM on the Chrome end. The only permitted modification is adjustment to the length of the flexible pipe and the fitting of noise reducing devices specified by local clubs.

5.14.1

How the Exhaust works

The exhaust is a normal 2-Stroke exhaust. The expansion chamber is encased in a parallel cylinder. The shape and size of the expansion chamber is critical to the function of the exhaust. It produces positive and negative pressure waves which move up and down the exhaust at the speed of sound resulting in the exhaust gases being evacuated from the cylinder

Figure 5.13-1 Worn Teeth

ChrisCompton(compark)2001 Page 23

A Practical Mechanic’s Guide to TKM Karting

and forcing the escaped mixture back into the cylinder. The book “TwoStroke Performance Tuning” [14.8] provides an excellent explanation of this .

Figure 5.14.1-1 the Exhaust

5.14.2 Cleaning the exhaust

The build up of carbon on the inside of the exhaust will reduce performance. Most of this carbon can be removed with a wire brush. Chemical cleaners can be used, but great care must be taken as they normally contain Sodium Hydroxide (Sometimes called caustic soda or caustic acid) which is dangerous. If any chemical cleaner is used then take care to follow the instruction provided with the product.

The chrome end cap is filled with fibreglass and must be remove before cleaning the exhaust.

Leave the exhaust lightly oiled, inside and out, to prevent rust.

ChrisCompton(compark)2001 Page 24

A Practical Mechanic’s Guide to TKM Karting

5.14.3 Assembling the exhaust

Take care when replacing the three self-taping screws as these will strip if over tightened. Be prepared to replace lost screws if they do come out. Alternatively place a jubilee clip around them to hold them in place. This is especially true if an End Can is fitted.

5.14.4 Fitting the exhaust correctly

The exhaust and the flexible pipe need to be a good fit in order to reduce noise levels. When cutting flexible pipe ensure that the end is square and makes a good seal. You may also need to bind the joint with heatproof webbing held in place with wire to achieve required noise levels. Use good springs of the correct size and type. If you can pull the joints apart by hand, they are not tight enough. Cross pairs of springs over if required.

Due to noise limit regulations it is essential that you carefully check the exhaust system;

• Ensure that there are no cracks and that there is no slack in the spiral joints in the flexible pipe.

• Renew the flexible pipe frequently.

• Rotate the exhaust so that the holes in End Can face down and back.

5.14.5 Setting the Exhaust Length

The Tuned Length (L) of an exhaust affects the peak power output of the engine. The longer the exhaust the lower the revs will be at which peak power output occurs.

Figure 5.14.3-1 Assembling the Exhaust

ChrisCompton(compark)2001 Page 25

A Practical Mechanic’s Guide to TKM Karting

Figure 5.14.5-1

Measuring the Tuned Length

Keep a selection of flexible pipe lengths in the range 60 to 100 mm. An ideal set would include the following lengths; 60, 65, 70, 75, 80,90 & 100 mm. The author has no set rule for selecting the correct exhaust length for any track/engine combination; 80 mm is a good starting point. Be prepared to change lengths and record changes in performance in order to develop your own table of lengths to suit each circuit/ engine/ conditions combination. For example; with an 80mm flex fitted, peak power may occur at 12500 rpm and with a 60mm flex fitted peak power may occur at 13500.

Discard any flexible pipe that has started to leak due to cracking. The engine vibration will ensure that any flexible pipe has a limited life. When removing or inserting flexible pipe always rotate it in the direction which closes the loops or it will break.

6. Clutch

The TKM clutch is a centrifugal clutch, which engages at about 6000 rpm.

Many karters are unfamiliar with clutches and many drivers believe that they will reduce performance. The author has found that since fitting a clutch the practice lap times have not changed, but positions have improved. The driver explains this as being due to having increased courage going into contended corners.

Read the following pages in the ‘TKM Regulations' [14.3]:

• ‘Clutch Fitting & Service’,

• The Clutch fiche.

ChrisCompton(compark)2001 Page 26

A Practical Mechanic’s Guide to TKM Karting

6.1 How the Clutch Works

When the engine is at rest, springs pull the Pressure plate back towards the Drive Hub and away from the Friction disc.

Figure 6.1-1 Free running Clutch

Figure 6.1-1 Free running Clutch

ChrisCompton(compark)2001 Page 27

A Practical Mechanic’s Guide to TKM Karting

Figure 6.1-1

Driving Clutch

When the engine runs it rotates the Drive Hub, Fixed Plate and Pressure plate Assembly. The Levers are weighted and have a cam shaped face, which rests against the Pressure Plate. As the engine accelerates above 6000 rpm, the levers rotate outwards under centrifugal force so that the cams force the Pressure Plate against the Friction Disc (clamping the friction disc between the Pressure Plate and the Fixed Plate). The Friction Disc drives the Sprocket Drum via the tabs on the circumference of the Friction Disc, which fit, into the slots in the back of the Sprocket Drum.

6.2 After each Event

The clutch should be cleaned, checked and the sprocket drum roller bearing re-greased after each event. This can be done with the engine still mounted in the kart.

• Remove the clutch/coil safety cover and coil assembly.

• Clean all round the engine crankcase and any other dirty bits.

• Prevent the Crankshaft from rotating with the Clutch Holding Tool [11.1.4] and remove the Starter Nut.

• The Sprocket Drum, roller bearing and two Thrust Washers can now be removed.

• Clean the clutch Friction Disc and other components of the Drive Hub assembly remaining on the Crankshaft, with brake cleaning spray [13.15]. Take care to avoid getting cleaner near the Crankshaft Oil Seal.

• Inspect the Sprocket Drum teeth [5.13]. Check the machined hole that forms the bearing outer in the Sprocket Drum for damage and lightly grease it with lithium grease. If the Sprocket is damaged then replace the Sprocket Drum and the bearing.

• Check the roller bearing and if any doubt replace it.

• Re-assemble the Sprocket Drum and other component [6.7].

• Re-assemble the clutch cover and coil.

ChrisCompton(compark)2001 Page 28

A Practical Mechanic’s Guide to TKM Karting

6.3 Removing the Clutch

Removing the clutch from the engine is a simple procedure, which does not require any special skills. It does however require the following special tools;

• Clutch Holding spanner, [11.1.4]

• Clutch Puller, [11.1.5]

• 24mm Ring Spanner.

The clutch can be removed whilst the engine is mounted in the kart, but it is easier to work with the engine on a bench.

• Remove the Sprocket Drum, Thrust Washers and Bearing. [6.2].

• Prevent the Crankshaft from rotating by holding the clutch with the special Clutch Holding spanner [11.1.4] and remove the large securing nut using a 24mm ring spanner. Remove the coned safety washer.

• Using the special Clutch Puller [11.1.5], remove the Drive Hub Assembly. It should come of the tapered shaft with a crack! If it does not come free try tapping (very carefully!) the head of the jacking bolt with a steel hammer.

• Lift out the Woodruff key from the crankshaft. Push one end in and the other will rise out.

• Clean and check the crank shaft for damage. Lightly grease the shaft to protect it from rust.

• Whilst the Clutch is removed it is a good opportunity to check that the Crankshaft oil seal looks OK.

ChrisCompton(compark)2001 Page 29

A Practical Mechanic’s Guide to TKM Karting

6.4 Dismantling the Drive Hub Assembly

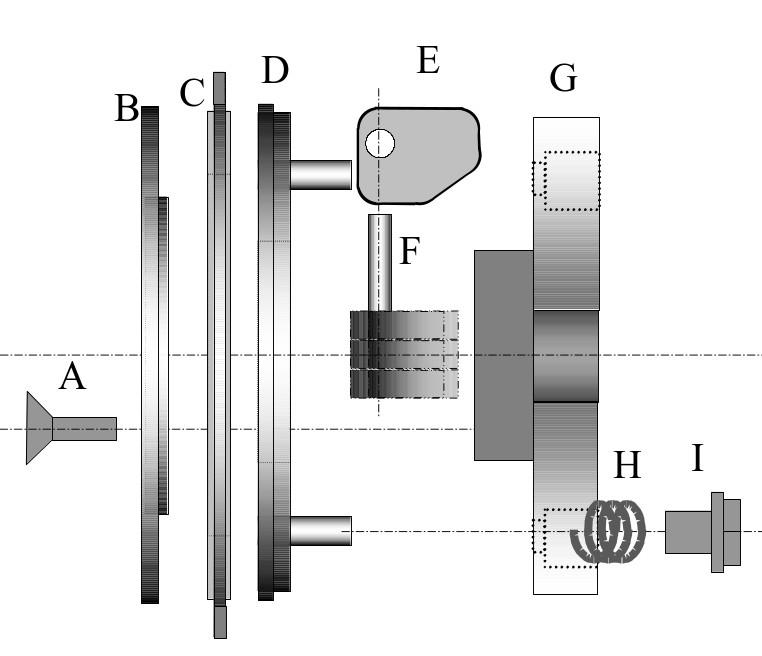

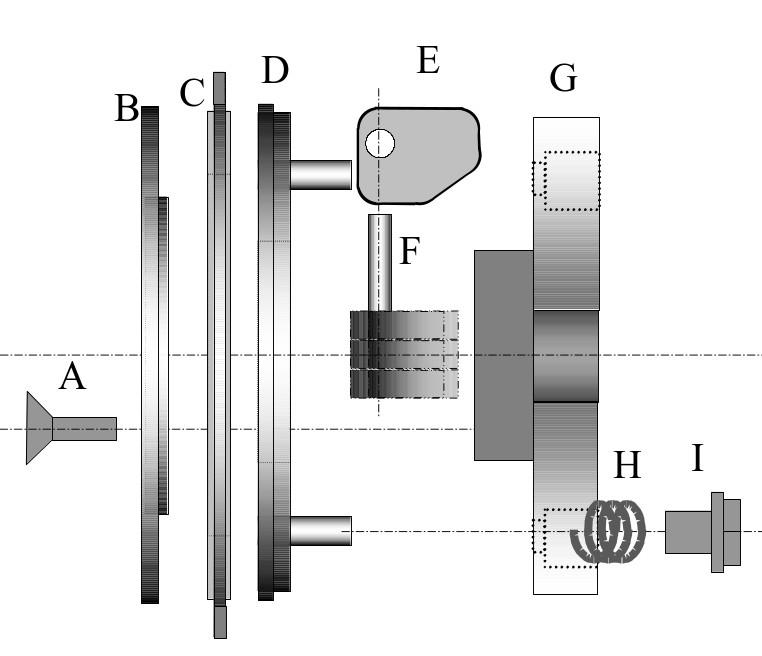

Figure 6.4-1 the Drive Hub Assembly

A – Three counter sink hex’ socket screws which secure the Fixed Plate (B) to the Drive Hub (G).

B - Fixed Plate.

C - Friction Disc.

D - Pressure Plate.

E - 3 x sets of three Levers.

F - 3 x Dowel Pins.

G - Drive Hub.

H - 3 x Pressure Plate Springs.

I - 3 x Spring Retainer Nuts.

• Remove the three socket head, counter-sunk screws (A) which secure the Fixed Plate to the drive hub. They should not be tight.

• Hold the Drive Hub Assembly with the Clutch Holding Tool [11.1.4] and loosen the three green Spring Retaining Nuts. – Remove the nuts (I) together, one turn at a time.

• The components of the Drive Hub assembly can now be separated.

ChrisCompton(compark)2001 Page 30

6.5

A Practical Mechanic’s Guide to TKM Karting

Servicing the Clutch

Clean all of the clutch components using spray Brake Cleaner [13.15]. (This will remove all grease from the roller bearing!)

• Inspect the Sprocket Drum and Bearing [6.2].

• Measure and record the thickness of the Friction Disc. This will give a means of predicting when the Friction Disc will need replacing. The minimum thickness is specified in the TKM Regulations [14.3] as 2.90mm.

• Remove and inspect the three Dowel Pins. If any wear, scoring or damage is visible then replace all three pins. Because the Dowel Pins are highly stressed they should be replaced whenever the Friction Disc requires replacement.

• Separate the 9 Levers and check them for damage. Moisture often gets trapped between them causing rust. Check the pivot holes for wear and elongation due to stress. If you have any doubts then replace them.

• Check the Friction Disc tabs for cracking.

• Check that the free length of the Pressure Plate Springs exceeds 12mm. If not replace them.

• Check and clean all other components.

6.5.1 Checking the Friction Plate

Remove the friction plate [6.4] and inspect it for impact damage and cracking.

ChrisCompton(compark)2001 Page 31

Figure 6.5-1 Impact Damage

A Practical Mechanic’s Guide to TKM Karting

6.6 Reassembling the Drive Hub

Ensure that all parts of the clutch are clean and that minimum amounts of grease are used. Under no account allow grease, oil, WD40 or any similar contaminant onto the Friction Disc or the ground surfaces of the Pressure Plate and Fixed Plate.

• Place the Drive Hub down with the Dowel slots facing up. Lightly grease the Dowel Pins and the Dowel Pin slots with anti-seize copperslip [13.15]. Assemble the Pins and Levers into the Drive Hub. They will just drop into place.

Figure 6.6-1 Pins and Levers in place

• Apply a small amount of copper slip [13.15] to the triangular corners to ensure that the Pressure Plate will move freely on the Drive Hub. Place the Pressure Plate over the Drive Hub and Lever assemblies. Ensure that the studs are correctly engaged and wipe off any excess grease.

• Holding the Drive Hub, lift the assembly, ensuring that the Pressure Plate falls fully into place, turn the assembly over and place it down onto the Friction Disc and Fixed Plate, so that the Pressure Plate studs are held up proud of the Drive Hub.

ChrisCompton(compark)2001 Page 32

Figure 6.6-2 Springs and Retaining Nuts

A Practical Mechanic’s Guide to TKM Karting

• Apply Blue Loctite to the Pressure Plate Studs. Place the three springs over the studs and screw on each of the spring retaining nuts, by just a turn (They will be tightened later).

• Turn the assembly over and apply a small amount of copper-slip [13.15] to the three countersink screws. Screw in the three countersink Fixed Plate securing screws. These should not be tightened, just lightly touched home. They will not come out because the Large Coned Safety Washer will hold them in place.

• Turn the assemble over and hold the Drive Hub with the Clutch Holding Tool [11.1.4]. Tighten the Spring Retaining Nuts down to about 2-½ lbs./ft

• If you have changed any components then check the height of the Spring Retaining Nut as required by the fiche. (Item 4 in the clutch fiche. [14.3]).

6.7 Refiting the Clutch

• Ensure that the Crankshaft is clean and very lightly greased. Replace the Woodruff Key into the Crankshaft and install the Drive Hub assembly. Ensure that it is well seated on to the tapered part of the Crankshaft. (Note that the Woodruff key is not the same as for the nonclutch Crankshaft. The clutch keyway is 3mm wide and the non-clutch keyway is 2.5mm wide.)

• Install the Coned Safety Washer with the dome facing outwards. Install the large clutch retention nut.

Figure 6.6-3 Checking the Clutch Nut Height

ChrisCompton(compark)2001 Page 33

A Practical Mechanic’s Guide to TKM Karting

• The nut needs to be tightened to 45 lbs./ft. Use the Clutch Holding Tool [11.1.4].

• Lightly grease the Internal Thrust Washer and place it onto the crankshaft with the inner radiused edge facing inward [6.8].

• Apply a small amount of lithium grease to the part of the Crankshaft that forms the bearing inner and slightly more grease to the bearing itself before installing it.

• Install the Sprocket Drum. Ensure that the tabs on the Friction Disc are correctly inserted into the slots on the peripheral of the Sprocket Drum.

• Lightly grease the small Thrust Washer and place it onto the crankshaft with the inner radiused edge facing inward [6.8].

Figure 6.7-1 Coned Safety Washer

Figure 6.7-1 Coned Safety Washer

ChrisCompton(compark)2001 Page 34

Figure 6.7-2 Sprocket Drum & Bearing

A Practical Mechanic’s Guide to TKM Karting

• As the Starter Nut is tightened to 15lbs/ft keep checking the Sprocket Drum free play. If it becomes clamped then stop and locate the problem.

If you tighten the starter nut with the Sprocket Drum slots not engaged with the Friction Disc tabs so that the Sprocket Drum is pressing on the Friction Disc tabs then you might crack the Friction Disc.

• The Sprocket Drum should move freely in and out along the crankshaft with about 0.3 mm of free-play [6.7-2]. If it does not, then check the orientation and size of the thrust washers [6.8].

6.8 Thrust Washers

The two thrust washers are not just ordinary washers; they are very accurately ground and must never be replaced with anything but the correct Tal-Ko part. The Internal Thrust Washer is supplied in three thicknesses to allow for adjustment of the Sprocket Drum clearance.

Both Thrust Washers have a chamfered inner edge.

The crankshaft manufacturing process leaves radiuses in the seat of the shoulders.

Figure 6.8-1 Thrust Washer Chamfer

Figure 6.8-1 Thrust Washer Chamfer

ChrisCompton(compark)2001 Page 35

Figure 6.8-2 Shoulder radiuses

A Practical Mechanic’s Guide to TKM Karting

The thrust washers MUST be installed onto the crankshaft so that they are seated against the shoulder and not installed back-to-front so that they are resting on the chamfer.

Figure 6.8-3 Thrust Washer - Correct

The internal radiused edges on the washers are very small and you may need a magnifying glass to see them.

This is true for both the internal (big) and the external (small) thrust washers.

6.9 Sprocket Drum Clearance

If you have not changed the Sprocket Drum or the Thrust Washers then the Sprocket Drum clearance should be OK. If the end float is much less than expected then you have assembled it incorrectly! To measure the Sprocket Drum clearance, use a feeler gauge. Check the free play and adjust it by changing the thickness of the Internal Thrust Washer.

6.10 Clutch: Major Overhaul

The term 'Major Overhaul' simply means replace the parts that need to be replaced.

The clutch needs to be overhauled when the thickness of the Friction Disc wears to less than 2.9mm or in any event after about 20 hours of running.

You will always need to replace:

• Roller Bearing

• Friction Disc

ChrisCompton(compark)2001 Page 36

A Practical Mechanic’s Guide to TKM Karting

• Three Dowel Pins.

The Sprocket Drum should be replaced if the sprocket is worn [5.13].

Replace any damaged, worn or suspect component.

7. The Carburettor

This section covers all of the engineering details that you will require in order to service a carburettor.

The only carburettor permitted is the Walbro WB19 marked with the TKM logo. It is robust and adequate. If the fuel is kept clean the carburettor should not require frequent maintenance.

No Choke is provided on the WB19 for TKM.

ChrisCompton(compark)2001 Page 37

A Practical Mechanic’s Guide to TKM Karting

7.1 How the Fuel Pump Works

Figure 7.1-1 How the Carburettor works

The Walbro carburettor has an integral fuel pump which works well as long as the Pulse pipe (short pipe running from a connector on the top of the carburettor to the crank case) is the correct part (fuel pipe is too soft), is in good condition and makes a good air seal at each end.

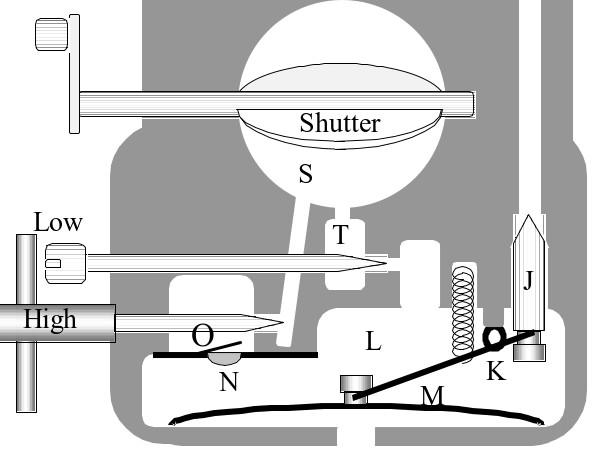

The fuel pump occupies the top of the carburettor. The fuel comes in at ‘A’ to fill the fuel input chamber ‘C’.

The Fuel Pump Diaphragm separates the pumping chamber 'E' from the Pulse chamber 'F'. The vacuum/pressure pulse from the crankcase comes in at ‘B’ and causes the Fuel Pump Diaphragm to expand and contract into the pumping chamber ‘E’.

This pulls fuel from the input chamber ‘C’ through the one way valve ‘C/D’ and pushes it out through the one way valve ‘G/H’. This pressurised fuel supply is then forced down through the filter ‘I’ to the metering valve ‘J’.

ChrisCompton(compark)2001 Page 38

A Practical Mechanic’s Guide to TKM Karting

7.1.1 Physical Layout of the Fuel Pump

It is not immediately obvious how the fuel pump works from the physical layout of the chambers. This diagram shows the view down on to the Fuel pump gasket and diaphragm after the top of the carburettor has been removed.

• C Fuel input chamber

• C/D

One way valve from C below to D above

• E&F Pumping Chamber E below diaphragm & Pulse chamber F above.

• G/H

One way valve from G below to H above

• I Filter chamber below diaphragm

7.2 Carburation

The carburettor functions are located at the bottom of the carburettor.

Figure 7.1.1-1 Fuel Pump Layout

ChrisCompton(compark)2001 Page 39

A Practical Mechanic’s Guide to TKM Karting

7.2.1

Metering the fuel

Figure 7.2.1-1 Fuel Pump Layout

The pumping action increases the fuel pressure enough to cause the inlet valve needle ‘J’ to be pushed off its seat. Fuel then passes into the metering chamber ‘L’. As the pressure in the metering chamber builds up the metering diaphragm ‘M’ starts to move down. Note that the lower side of the diaphragm is open to atmosphere. As the diaphragm moves down it causes the paddle lever ‘K’ to push the inlet valve needle back up thus reducing the fuel flow and maintaining a fuel supply, at a steady pressure, to the jets.

7.2.2 The Jets

The jets are like taps; as they are screwed out, the hole through which the fuel passes, gets bigger.

High Jet: - Fuel passes through the filter and one way valve ‘N/O’ to the High jet screw. The High jet screw controls the flow to outlet ‘S’.

Low Jets: - Fuel passes directly from the metering chamber ‘L’ to the Low jet screw. The Low screw controls the flow to the Low jet feed chamber ‘T’.

ChrisCompton(compark)2001 Page 40

Figure 6.1-1 Free running Clutch

Figure 6.1-1 Free running Clutch

Figure 6.7-1 Coned Safety Washer

Figure 6.7-1 Coned Safety Washer

Figure 6.8-1 Thrust Washer Chamfer

Figure 6.8-1 Thrust Washer Chamfer