A Practical Mechanic’s Guide to TKM Karting

2.1

2.1

5.7.1

5.7.2

5.7.3

5.7.4

5.7.5

5.7.6

5.8 Piston Assembly....................................................................................46

5.8.1 Removing the Piston

5.8.2

5.8.3

5.9 Piston

5.9.1 Cleaning the Piston..........................................................................54

5.9.2 Checking the Piston

5.9.3 Removing the Piston Rings

5.9.4 Replacing the Piston Rings.............................................................55

5.9.5

5.9.6

5.9.7

5.10

6.1

5.12.1

6.9

5.14.4

5.14.5

6.10 Clutch: Major Overhaul.......................................................................78

7. The Carburettor..................................................................78

7.1 How the Fuel Pump Works...................................................................79

7.1.1 Physical Layout of the Fuel Pump...................................................80

7.2 Carburation.............................................................................................80

7.2.1 Metering the fuel 81

7.2.2 The Jets 81

7.2.3 Positions of the Jets........................................................................82

7.2.4 The Shutter 83

7.3 Tools........................................................................................................84

7.3.1 Work area;.......................................................................................84

7.4 Removing & Servicing the Carburettor...............................................84

7.4.1 Frequency of Servicing 84

7.4.2 Removing the Carburettor 85

7.4.3 Sequence.........................................................................................85

7.5 Servicing the Pump................................................................................86

7.5.1 Dismantling the Fuel Pump 86

7.5.2 Cleaning the Fuel Pump..................................................................86

7.5.3 Checking the Fuel Pump 87

7.5.4 Assembling the Fuel Pump 87

7.6 Servicing the Metering Mechanism 87

7.6.1 Dismantling the Metering Mechanism.............................................87

7.6.2 Cleaning the Metering Mechanism 90

7.6.3 Checking the Metering Mechanism 90

7.6.4 Reassembling the Metering Mechanism.........................................90

7.7 Checking the Pop-Off............................................................................91

7.7.1 Checking for Leaks 91

7.7.2 Measuring the Pop-Off 91

7.7.3 Adjusting the Paddle Lever Arm......................................................92

7.7.4 Adjusting the Pop-Off 93

7.8 Re-fitting the Carburettor......................................................................94

7.9 Carburettor Return Springs..................................................................95

7.10 Fuel line and petrol tank.....................................................................95

7.11 Preventing water from entering the carburettor..............................96

7.12 Carburettor service kits 96

7.12.1 D10-WB 618..................................................................................96

7.12.2 K10-WB 618 96

8. Kart Maintenance...............................................................97

8.1 Special Tools Required.........................................................................97 8.2 Basics......................................................................................................97

8.2.1 After a wet race; 98

8.3 Sprocket Alignment & Wear.................................................................98

8.3.1 Engine Sprocket Alignment 98

8.3.2 Rear Sprocket Alignment 99

8.3.3 Effects of Sprocket Misalignment..................................................100

8.3.4 Sprocket Damage & Wear.............................................................100

8.4 Chain......................................................................................................100

8.4.1 Selecting Chain Length..................................................................100 8.4.2 Chain Tension

8.4.3 Adjusting Chain Tension

8.4.4 Cleaning Chains............................................................................102

8.4.5 Checking Chains for Wear

8.4.6 Checking Chains for Damage

8.5 Back Axle Assembly............................................................................104

8.5.1 Removing the axle assembly........................................................104

8.5.2 Positioning the Axle in the Bearings

8.5.3 Bent Axle

8.5.4 Checking for a bent axle;...............................................................107

8.5.5 Replacing an Axle

8.5.6 Checking Sprocket & Brake disc alignment 108

8.6 Chassis..................................................................................................109

8.6.1 Back end parallel to front...............................................................110

8.6.2 Rear axle Bearing Supports

8.6.3 Chassis Twisted?

8.6.4 Front Stub axle lugs.......................................................................111

8.7 Body-work.............................................................................................111

8.7.1 Removing the Side-Pods

8.8 Brakes....................................................................................................112

8.8.1 How the Brake System Works......................................................112

8.8.2 Removing the Complete Brake System 113

8.8.3 Cleaning the Brake System 113

8.8.4 Checking the Brake System..........................................................114

8.8.5 Replacing the Brake Pads 114

8.8.6 Draining Old Brake Fluid 115

8.8.7 Refilling & Bleeding the Brake System..........................................115

8.8.8 Adjusting the Brake System..........................................................116

8.8.9 New Brake System? 117

8.9 Wheels 117

8.9.1 Checking Wheels...........................................................................117

8.9.2 Wheel Sizes 117

8.9.3 Front Wheel Spacers 118

8.9.4 Checking and changing front wheel bearings...............................119

8.9.5 Rear Hub Carriers..........................................................................119

8.9.6 Rear Wheel Hubs 119

8.10 Tyres 120

8.10.1 Looking after Tyres......................................................................120

8.10.2 Tyre wear 120

8.10.3 Removing tyres 121

8.10.4 Replacing Valves.........................................................................122

8.10.5 Replacing Tyres 122

8.11 Seat height adjustment......................................................................124

9. Steering.............................................................................125

9.1 How the Steering Mechanism Works.................................................125

9.1.1 What is Castor angle?

9.1.2 What is Camber angle?.................................................................127

9.1.3 How the Stub Axle and Lug geometry work..................................127

9.2 Tools required......................................................................................129

9.3 Centring the steering with the front wheels parallel 129

9.3.1 To Set the Steering Straight and Central......................................130

9.3.2 Centring Bar

9.4 Checking the King Pin Bolts & Bearings..........................................131

9.5 Checking the Stub Axle.......................................................................131

9.5.1 Stub Axle Bent Vertically...............................................................131

9.5.2 Stub Axle Bent Horizontally

9.6 Checking the Stub-Axle Lugs 134

9.6.1 Checking the camber angle of the lugs.........................................134

9.6.2 Checking the castor angle 135

9.7 Checking the Track rods.....................................................................135

9.7.1 Track rod ends...............................................................................135

9.7.2 Checking that track rods are straight............................................136

9.8 Checking the Steering column...........................................................137 10. Buying a

This guide is designed to provide a novice karter with the engineering information required to prepare a Formula TKM kart for racing.

If you are new to karting, you need to contact one of the Karting schools offering introductory karting courses. Karting schools often advertise in 'KARTING' magazine. You will not be permitted to race until you have completed an appropriate course.

If you are intending to buy a formula TKM kart, wait until you have completed the introductory course.

If you have no one to give you advice then ask other club members. It is my experience that you will always get help, but keep an open mind about any advice that is offered.

Start racing as soon as possible because that's what it's all about.

1.1 Essential reading

• 'How to Start Kart Racing' & ' Kart Racing Regulations’ from the Association of British Kart Clubs (ABkC).

• ‘Formula TKM Regulations & Technical Guide’.

• Any local rules or restrictions specified by your club.

The Official TKM Video and 'The Complete Guide to Formula TKM Karting' are both well worth the cost. These are all listed in section 14 of this guide.

1.2 References

Where a reference is made to another paragraph within this guide it is shown in square brackets, thus: [3.4.5]. This indicates that associated information, or a more detailed description is available in paragraph 3.4.5.

1.3 What’s in this guide?

This ‘Practical Mechanics Guide to TKM Karting’ is a combination of the author’s personal aide-mémoire and a set of detailed engineering notes. It is not authoritative and doesn’t claim to be 100% accurate. It does however

contain many good ideas and is intended to form the basis of the readers own engineering notes. The content was assembled over a two-year period during which the author worked as an amateur mechanic on Gillard-204/TKM karts, but most of the information is relevant to all TKM karts.

It contains a great deal of detail that many karters will not require, but no apology is offered for including it. The author would have been very grateful for such detailed information when he was first confronted with a kart.

This is, in part, a step-by-step guide and is best read whilst working on the kart.

This guide does not cover complete engine rebuilds, racing techniques or strategy.

I have a varied background in many aspects of mechanical engineering, but I’m currently working as a Computer Systems Engineering Consultant, which has nothing whatsoever to do with Karting. I gained a lot of experience rebuilding two and four stroke motor bikes starting with small BSAs in the mid 60s graduating up to 250cc Hondas in the 70s.

I am relatively new to karting, but I regarded that as an advantage when I was writing this guide. I am still able to clearly understand the problems encountered by new karters.

I will attempt to answer any questions and would greatly appreciate any additions or corrections to this guide via my e-mail address: ‘chris@compark.co.uk'.

This section contains a few notes on preparing your kart for practice and racing.

Before your first race ensure that your engine is correctly run-in [5.4] and that your kart is safe. It is essential to get advice and help from the dealer who sold you the kart. Don’t expect to get on the track for the first time without help from someone with experience.

The following adjustments are needed in order to make your kart suit you.

2.2.1

Try the seat that is fitted to the kart, it should hold you firmly. If the seat doesn’t fit then buy one that does. Adjust the seat height so that it is clear of the ground. Seat height can affect handling [8.11].

2.2.2

The total weight of the kart & driver must exceed the minimum weight requirement at the end of the race. Weigh both kart and driver in full race kit with the tank at least half filled. If you don’t have access to full size scales then find some flat ground, and weigh one wheel at a time with bathroom scales. Ensure that the steering is fixed in one position and that the other three wheels are lifted to exactly level the kart. Add the four readings together with the weight of the driver in racing gear, to give the overall weight.

The best place to fix weights is low down on the side of the seat. You must use two bolts and it is best to use large washers and nylock nuts.

If you can’t comfortably reach the pedals then go back to the dealer who sold you the kart or the kart’s manufacturer to get professional help.

2.2.3

Your club will normally allocate a racing number to you. Most clubs will allow you to choose your own racing number if you wish. If you join more than one club ensure that you find a racing number that both clubs will accept because it’s a lot of bother to keep changing numbers.

If the backing squares keep falling off, because they will not stick to the side pods then;

• Clean the surface with brake cleaner,

• Roughen with fine emery,

• Use double-sided carpet tape to fix them in place.

Keep a detailed record of environmental data, kart settings and performance. It will prove to be an improving and valuable resource. In order to improve it is essential to constantly review your record. Listed below are examples of what your record should include.

Environmental data;

• Weather,

• Temperature,

• Track state.

Settings;

• Tyre type, Tyre Pressures, Tyre temperature & State at the end of the race,

• Track width & Toe out/in,

• Exhaust flexible pipe length,

• Gearing,

• Carburettor settings & Fuel consumed,

• All set-up changes.

Performance;

• Grid positions,

• Lap times,

• Events during the race, i.e. spins, contact etc.,

• Finish positions.

Example record sheets are included at the end of this guide [15].

This assumes that the kart has been fully checked and prepared prior to race day.

• Check the fuel level - bear in mind the overall weight of the kart at the end of the race.

• Bleed out all air from the fuel line by blocking the air intake and turning the engine over [4.6.1].

• Remove, clean and check the spark plug. Use a brake cleaner spray to remove any oil [5.12].

• Check and record tyre pressures [4.9].

• Check wheel retention nuts are tight. Do not over-tighten the front wheel retention nuts [8.9.3].

• Check the chain tension [8.4].

• If the engine has not been run for a week or more then there is a danger that the carburettor’s needle valve may be stuck down. Check that the needle valve is free, by gently pushing up on the diaphragm with a pencil through the small hole in the bottom of the carburettor (Take care!).

• Check that the brake works OK. You should be able to lock the wheels when the kart is pulled along the ground by the brake pedal. NEVER allow WD40 near the brake pads or disc.

2.5

Ensure that you are on the dummy grid and ready to race with time to spare. It can be very upsetting to lose a position at the front of the grid because you discover a soft tyre when you take the kart off the stand or you have forgotten to bleed the fuel pipe.

Always have a plug spanner and a spare plug ready in case the kart fails to start.

Move your trolley off the dummy grid and into the Trolley Park as soon as possible.

It is not unusual to see a dramatic change in the track state whilst waiting on the dummy grid, so be prepared to change the tyre pressures or the tyre

type while on the grid. Practice fast wheel changes with the kart on the ground.

2.6 Starting the Kart

This is always a traumatic event, even when you have done it a hundred times before.

2.6.1 Starting clutch karts

The driver must be seated in the kart. The engineer should say “Ignition ON, Brake ON” to the driver before starting the engine. Ensure that the starter socket is fully engaged on the starter nut.

The driver may need to place a hand over the air intake in order to choke the engine. The engine should start immediately.

Don’t rev the engine! It may overheat the clutch or worse. If you need to ‘rev’ the engine to keep it ticking over then the carburettor is not correctly adjusted [4.2.5].

2.6.2 Starting non-clutch karts

The faster you go before dropping the back wheels the more likely it is to start. It will not start if you are pushing too slowly no matter how far you push it. The driver should use a small amount of throttle and may need to place a hand over the air intake in order to choke the engine.

When push starting don’t get hit by the following karts. When the kart engine has started you must keep running at the same speed after the kart. DO NOT STOP! Look round both sides before running off the dummy grid. Push starting on the grid is dangerous - please take care.

2.6.3 If your Kart won’t start

If your kart does not start within the length of the dummy grid, something is wrong so don’t keep pushing it.

Assuming that you have followed the instructions in the previous paragraphs [2.6.1 & 2.6.2] then:

• For Clutch Karts, check that the ignition switch is ON.

• Ensure that there is no air in the fuel line [4.6.1].

• Set the jets to the initial settings [4.2].

• Check that the tick-over is correctly set [4.2.5].

• Clean the spark plug and check for a spark [4.5]. This may not be possible in bright sunlight.

THE SPARK PLUG MUST BE CONNECTED AND EARTHED WHEN THE ENGINE IS ROTATED [5.11].

If you have a rev counter then check for HT (High Tension) to the spark plug by spinning the engine. If the counter counts then the HT is probably OK.

Try to start it again. Ensure that you are pushing very fast before dropping the back wheels. If it still won’t start:

• Remove the Air Intake Box, place the palm of your hand over the air intake and turn the engine over. If there is a normal amount of suction then the piston & rings are OK. If when you remove your hand, fuel dribbles out of the air intake then the fuel pump is OK.

• Change the spark plug. It may work OK when out of the engine, but be failing under pressure.

• Change the carburettor.

Try to start it again. If it still won’t start then seek an expert’s advice.

What you do after each race is as important to winning as what you do before it.

2.7.1 In the track run-off area

Take a note of the temperature and state of the tyres [4.9] and the maximum rev’s recorded (if you have a rev counter). Listen and take a note of any other drivers’ comments about track conditions etc.

Weigh the kart after the practice session on the official scales. There is often a small variation between scales used at various tracks.

You should establish a procedure that ensures that nothing gets missed between sessions. The following bullet points show the authors procedure. The items are ordered so that the essential ‘between races’ checks are made first. If you have reason to suppose that your kart may be damaged or potentially unsafe in any way then that should be your first priority, but otherwise;

• Check the tyre temperature, state and pressures [4.9],

• Check the fuel levels - remember overall weight [4.6],

• Check the spark plug condition when it has cooled [4.5],

• Make and record any required set-up changes,

• Check that nothing is loose - check all nuts and bolts, including the little grub screws in the back axle bearings [8.5.2], are tight!

• Visually check for any damage to the steering mechanism - check that the track rods are straight.

• Check the sprocket alignment [8.3] and chain tension [8.4],

• Check for any damage to the axle assembly by rotating it [8.5],

• Visually check for any damage to the chassis & body work,

• Check & clean the air filter. If it’s raining then it will need drying with paper towels. A spare air filter is useful. Check that the two long screws that hold the carburettor to the engine are tight.

Don’t forget to complete your record sheets!

If the kart has collided with the scenery or another kart then perform the checks described in sections 8 & 9. Do not be tempted to race an unsafe kart, you could end up fined or injured and you will certainly be unpopular!

This section is an overview of kart and engine maintenance. You will find that for each hour of racing you will need to spend several more looking after

your kart. You should spend time with your kart and get to know its every detail.

3.1 Cleaning

Always strip and clean your kart after each event [8.2]. You will find loose nuts, bent bits and other problems that would otherwise have gone unnoticed. If you do not have the time to completely strip the kart then at least clean and check it. Don't forget to wash the air filter in warm soapy water. Note that it is illegal and dangerous to use petrol for cleaning in the pits. The author never uses petrol for cleaning because of the risk of fire and explosion.

3.1.1

Special care must be taken to avoid rust. After a wet race both the engine [5.2.2] and the kart [8.2.1] must completely dried.

3.2 Chassis check

Make a careful visual check of all chassis joints for cracks. A quick check of chassis alignment can be made by finding a bit of flat ground and with the driver seated set both front wheels strait and check that the weight on each front wheel is the same. Now turn the steering full right and then full left and check that the sides go up and down evenly [8.6 & 9.].

3.3. Petrol/Oil mix

Keep your fuel clean and don’t forget to put 2-Stroke oil in it [4.6]!

3.3.1 Petrol

You must use unleaded petrol. ‘Super Unleaded’ is preferred. Note that if you change petrol brand or rating then you may need to change carburettor settings [4.2].

3.3.2 '2-Stroke' Oil

Only use High Performance 2-Stroke engine oil. Castor based 2-Stroke engine oil is best for lubrication but, synthetic oil does not cause as much carbon build up.

The author has no knowledge about the merits of various brands and types of engine oil, but there is plenty of advice and in-depth opinion about! The common advice is to use the highest quality castor/synthetic mixed oil. If you are in any doubt then get the advice of Tal-Ko.

Don't change from the 1/16 ratio advised unless you are sure about what you are doing! If you forget to put oil in the petrol (you won't be the first) then you will be taking your engine home in a bucket.

The author stores fuel for up to five weeks without problems. Ensure that when it is stored in the kart tank that the breather is sealed, that there is no fuel in the fuel line and that the carburettor is connected or that the end of the fuel supply line is sealed

Try not to run the engine above 15500 revs and get it checked/re-built every 9 hours. Yes - it will run for longer, but its performance may start to decline and the risk of catastrophic failure will increase. If you consistently run above 15500 revs then get you engine re-built more often (every 2 or 3 events if you max-out on revs).

If you need to run on a tight budget then keep your revs below 15000, your mixture slightly rich (high & low jets) and your engine can be made to run safely for much more than 9 hours without greatly reducing its power.

This guide assumes that best performance is the objective and sticks to 9 hours between rebuilds.

This section covers the engineering procedures that you will require at the track-side and in the pits, in order to get the best performance from your engine and kart.

Formula TKM - BT82 engines are intended to be raced in standard unmodified form but there are a few bits that can be legally ‘set-up’ to achieve maximum performance.

Several books and a truckload of folklore and advice is available covering the subject of kart set-up.

The manufacturer designed and tested the chassis to give optimum performance with settings in a mid position. So if you are in any doubt, adjust the settings to a mid position and you will not be far out. Take care with second-hand karts, as parts may not be as the designer intended. e.g. The back axle may have been changed for a length which is different to the design length.

You can only improve if you measure the validity of set-up changes against actual track times and finishing positions. Record and analyse settings and results in order to identify the best settings.

Keep a detailed record of set-up changes. The sort of things that should be recorded are;

• Reasons for making the change and its effect

• Times/positions achieved with various set-ups

• Engine/carburettor combinations used

• Initial carburettor settings & changes to carburettor settings.

• Exhaust length used & changes to exhaust length.

When you start racing you will not be able to detect the difference that small set-up changes make, so be bold and experiment with large changes. This will enable you to understand the difference that particular changes can make. Ensure that you keep a detailed record of the changes and their effect. Spend time now and again reviewing your records.

Long small diameter screwdriver for adjusting the low jet.

Long nose pliers for removing and replacing various springs.

Plug spanner

13mm extended socket and wrench

Torque wrench

Toe-out alignment tool [11.2.4] & Tape measure

A set of good quality ‘T’-bar Allen keys.

4.2 Carburettor set-up

The carburettor must be clean and the Pop-Off must be correctly set [7.7]. The air filter should be clean and dry.

The author does not fully understand the science of carburettor adjustment. He has read all available publications and has listened to much advice, most of it contradictory. Set out here is a method that has evolved by trial and error.

4.2.1 Setting the Jets

Figure 4.2.1-1 Carburettor Jets

The low jet is a plain screw head and the high jet is a ‘T’ bar [7.2.2].

4.2.2 Initial settings

Turn both jets in until lightly seated. Turn the High jet out to 1/3 turn on cold days, 1/2 turn on hot days.

Turn the Low jet out 11/4 turns on cool days and 11/2 turns on hot days.

4.2.3

The engine should run OK with these initial settings, but will require tuning to achieve best performance.

Note that if the mixture is too weak it can result in damage to the engine.

• If the engine smokes and four-strokes at corners then the mixture is too rich. Weaken the mixture by closing the low and high jets together in increments of 1/16 of a turn.

• If it is slower than others along the straight because it won’t rev high enough (i.e. It flattens out at below 15000 and sounds ‘fluffy’) then it is too rich at the high end. Weaken the mixture by closing the high jet in increments of 1/16 of a turn. If the track temperature is high then turn the low jet out by equal amounts.

• If the top end fades or pops and spits then the mixture is too weak. Open the high jet in increments of 1/8 of a turn.

• If it has poor pulling at low revs coming out of corners, but no engine smoke is visible. The mixture is too weak at the low end. Open the low jet in increments of 1/8 of a turn.

4.2.4

After the engine has run then remove the cylinder head [5.6] and check the top of the piston.

• Wet & oily indicates that the mixture is too rich (smokes a lot out of corners?),

• Dry & black indicates that the mixture is perfect,

• Dark Grey indicates that the mixture is a bit too lean,

• Light Grey indicates that the mixture is so weak that it may result in engine damage.

Always remove and replace the head with great care [5.6]

4.2.5 Setting Tick-over on Clutch Karts

Ensure that the carburettor is clean and serviceable, that the Pop-Off is correctly set [7.7] and the jet screws are set to the initial settings [4.2.2].

You may find it easier to remove the Air Intake Box assembly complete with the Back-plate in order to gain access to the idle adjust screw. If you do, you will need to put spacers in place off the back-plate (8mm Nylock nuts are ideal) in order to prevent the carburettor securing screws from ‘bottoming’.

The chain and the back wheels need to be in place and free to rotate.

SAFETY - Ensure that the kart stand is steady and secure, that the wheels are clear to rotate, that there is nothing close to snag and that you keep well clear.

With the engine running adjust the idle adjust screw until the rev counter shows between 4500 and 5000 rpm. If you do not have a rev counter then

• Pull the brake on lightly,

• Screw in the idle adjust screw in until the clutch just starts to bite,

• Back off a touch.

To test the setting: With the engine running depress the accelerator just enough to spin the back wheels. Release the accelerator and as soon as the revs have stabilised but with the wheels still spinning pull the brake hard on. The engine revs should not drop as the back wheels lock.

Ensure that the throttle cable is adjusted so that the throttle is fully open when the accelerator is down. Also ensure that when the accelerator is fully depressed the pedal stop screw prevents the cable and throttle shaft arm from being stressed.

The timing should be set to a level close to maximum, but safe for scrutineering [5.11]. It should require no further adjustment.

4.4

Increasing the length of the exhaust's flexible pipe will improve power at low revs and decreasing it will improve power at high revs [5.14.5].

After each heat/race, when the spark plug is cool remove it and check its condition [5.12]. Clean it - Spray brake cleaner works well. Check it carefully for damage and wear. Check and adjust the gap (0.025” or 0.64mm). The spark plug is such a critical component that the author will always discard it for a new plug if in any doubt.

It is not permitted to use petrol for cleaning in the pits. It’s dangerous to use petrol for cleaning at any time and the author strongly advises against its use.

The fuel supply must be kept clean! If it is not, the carburettor will fail. Ensure that all containers and funnels are clean. Store them in a plastic bag and don’t let them touch the ground. Petrol/oil mix is a magnet to grit and grit kills carburettors..

Use the advised fuel oil mixtures [3.3] specified in TKM Regulations [14.3].

The engine will not run well or may not run at all if there is air in the fuel line. Check the tops of loops in the fuel line for air bubbles. To remove air from the fuel line:

• Remove the spark plug from the engine, reconnect it to the HT lead and lay it on top of the engine. This ensures that the HT is earthed. If the spark is not earthed it may damage the ignition.

• Turn the engine over with the air intake blocked. This can be done by placing the palm of your hand over the trumpet, but is best done with the Air Intake Box removed by placing your hand directly over the carburettor intake. This also allows you to check that fuel is pumping into the carburettor OK. You should see fuel run out of the low jet bypass outlet [7.2.2] after a couple of rotations.

Karts fitted with a clutch:

• Block the air intake

• Turn the engine over using the electric starter until the air bubbles are gone.

Karts not fitted with a clutch:

• As before, but turn the back wheels by hand.

If this does not work because too much air prevents the pump from priming then;

• Remove the fuel pipe from the top of the carburettor and pinch the fuel pipe shut.

• Place the end of the pipe into a spare fuel container and release the pinch.

• Lower the container until the fuel runs through the pipe into the container.

• If it does not run out because there is not enough fuel in the line to start the siphon then (DO NOT SUCK IT THROUGH) blow down the breather pipe.

• When the fuels runs out fit it back onto carburettor.

• Start the bleeding process again [4.6.1].

The engine is made to very close tolerances and carbon deposits within the engine can make a significant difference to performance. Ensure that the inside of the engine is kept free of carbon [5].

The following items are worthy of attention:

• Ensure that the aluminium trumpet is flush to the inside of the Air Intake Box.

• Use some additional method of fixing the trumpet and grommet to the air-box. Tank tape is ideal. You will not be allowed to continue racing if it gets knocked off.

• Ensure that the H.T. lead is tied down so that it can not be accidentally snagged and pulled off!

4.9 Tyres

See also 8.10.

This is another area where a lot of contradictory opinion is available and here is some more!

4.9.1

Slicks need to heat up to work. Cold slicks don't work! The higher the pressure the quicker they heat up and, to some extent, the hotter they will become. Slicks should be inflated to the lowest pressure that allows them to heat up to a good working temperature within 1 or 2 laps. The normal pressure range for slicks is 14 < 36 psi. On an average dry day, on an average racetrack, 22-psi front and 24 psi rear is a good starting point. If they overheat (over 65°C) they will 'go-off' (melt) and bits of rubber will fly off them!

For short races or timed laps then the pressure should be higher, to warm the tyres quicker. On long races the pressures should be reduced so that the tyres do not overheat.

Older slicks need more heat to work. They develop a ‘hard’ surface and become a lot less grippy than new slicks.

Check slicks immediately on leaving the racetrack. They should be hot to the touch (but not uncomfortably so), slightly sticky and slightly grained. If they did not heat up enough they will be cool and have a smooth, glazed surface. If they overheated they will be hot and heavily grained with sticky bits of rubber coming off the edges.

4.9.2

The author has never been completely happy with his understanding of the pressures needed for wet tyres. There is a lot of folk law around and in any wet race the tyre pressure variation between karts is sometimes extreme. It is always a balance between getting the maximum grip and being sure that the tyres will survive.

Wets need to warm up to work well, but when its very wet you may not achieve the level of grip needed to warm the tyres. Generally;

• 28 < 35 psi when it is very wet, but consider that if the tyres are never going to get warm then you may get more grip with softer tyres. Also consider that if the racetrack starts to dry then the tyres may be ruined and the cost of replacement may be a factor.

20 < 28 psi in the wet.

12 < 20 psi for a drying racetrack. They should not overheat at these lower pressures.

Keep a spare set of old wets for times when the racetrack is drying and you don’t want to sacrifice a good set of wets. They can be run at high pressure to provide good grip on a drying racetrack.

4.10 Track width

The track width can be adjusted in order to change the amount of grip available and to ‘balance’ the kart.

4.10.1 Over-steer, Under-steer and Balance.

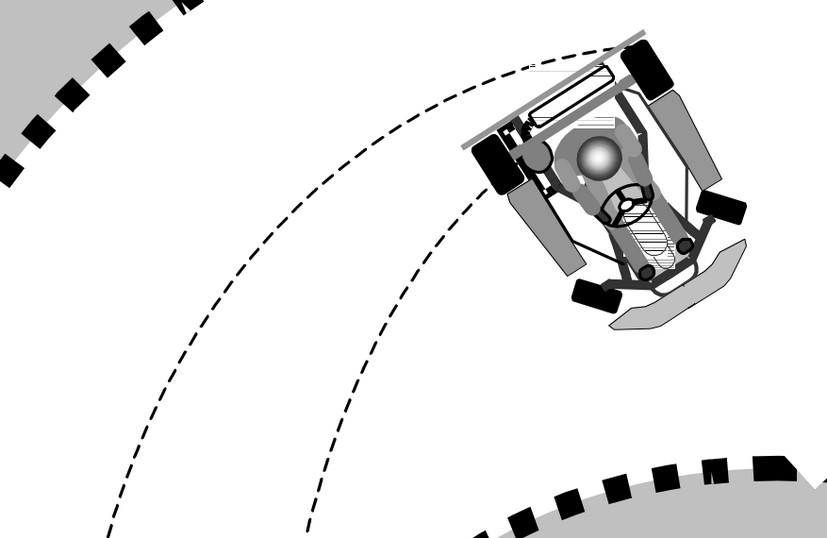

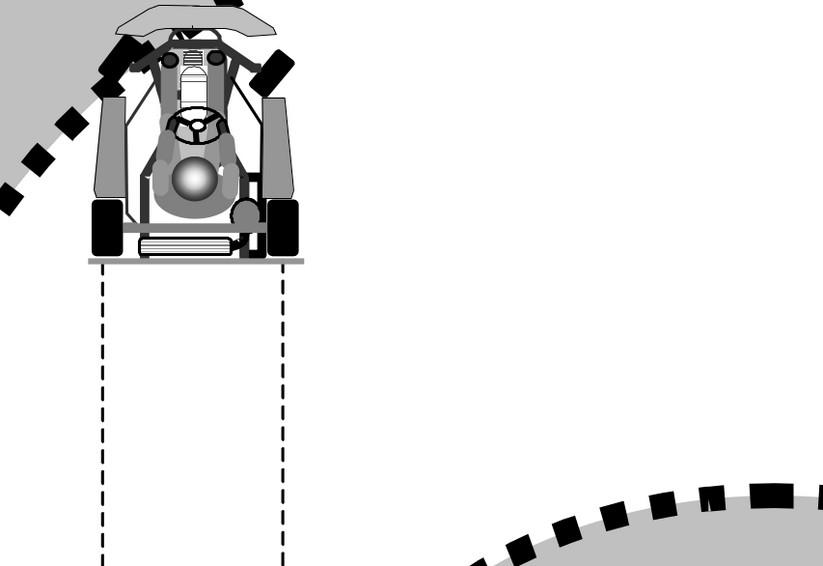

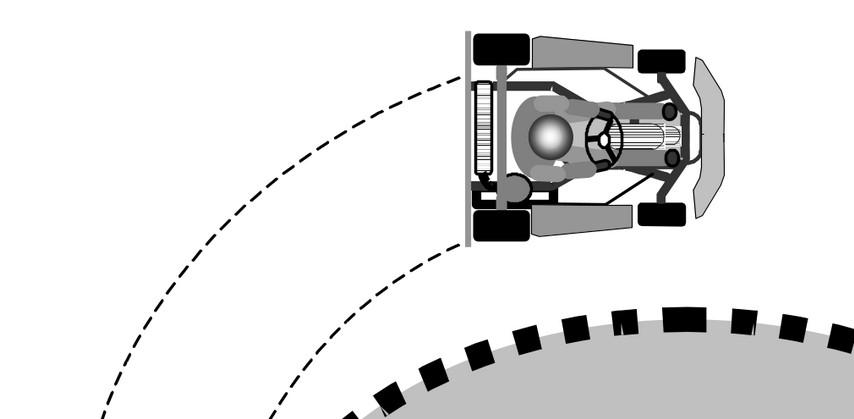

Over-steer:

When a kart has too much grip at the front or too little at the back it oversteers. The back wheels slide away putting the kart into a spin.

Figure 4.10-1 Track

Under-steer:

When a kart has too much grip at the back or too little at the front it understeers. The front wheels slide straight on and do not move the front of the kart round.

In balance:

Figure 4.10.1-1 Over-Steer Figure 4.10.1-2 Under-SteerWhen the kart is correctly balanced it will slide neatly sideways as it goes round the corner. This ideal is not possible for all corners, but a good compromise can be achieved.

Figure 4.10.1-3 Balanced

4.10.2 Effects of Track Adjustment

Increasing track width by moving the wheels out, reduces the downward force on the outside wheels thus giving less grip on corners. The result of this is to reduce the amount of lateral force that the grip can support but providing more predictability in the way in which the kart slides.

Figure 4.10.2-1 Track Adjustment

Decreasing track width by moving the wheels in, increases the downwards force on the outside wheels so increasing the grip, but it also increases the rolling moment (causing the inside wheels to rise) and increasing the possibility that the kart will lose grip suddenly. This is called ‘skipping’. This will result in the kart sliding more violently and with less predictability.

For novice racers the author suggests that the kart is set up for minimum slide, but no skip so that when it does slide it can be controlled.

4.10.3 A (Crude) Method of Setting the Track Width.

Adjust the track to mid position for both front and back wheels. Making small adjustments move all four wheels in until the back of the kart just starts to skip on the tightest corners and then back out a touch. Move the front wheels in or out to balance kart.

4.10.4 Asymmetric Track Settings.

The author has never been tempted to try different track settings on each side. It may be possible to gain a small advantage on some tracks. More experienced racers may do it. If you give it a try please let the author know what was achieved.

4.10.5 Back Axle

There is nothing sophisticated about the back axle! The lack of a differential gear means that the inside wheel will always drag and not contribute towards grip on a corner. A Kart will corner faster and carry more speed out of a corner if the set-up allows the inside rear wheel to lift.

4.11 Front wheel Toe-in/Toe-Out.

Toe-out means that both front wheels point slightly outwards when the kart is going straight. Toe-in means that they point inwards.

When the track is dry they should normally be set parallel so that there is no Toe-in or Toe-out.

Setting slight Toe-in (about 1-3mm) will cause the front tyres to ‘scrub’ and warm up quickly, possibly providing more grip at the front and giving better stability especially on bumpy tracks. The drag produced may reduce the top speed of the kart slightly.

In the wet setting Toe-out greatly improves the handling [4.14.2].

4.12 Engine to Axle Gearing

The objective is to set up the gearing to provide the best performance.

More teeth on the back sprocket lowers the gearing allowing the engine to reach higher revs. This gives better acceleration, but possibly a lower top speed on long straights.

In time trials a slightly higher gear may provide the best times, but in racing a slightly lower gear may provide the best finishing position.

Use results and lap times to arrive at the best gearing, but remember to keep your revs below 15500rpm.

If you are racing at an unfamiliar track then find out what gearing the winning drivers use. Sneak up behind them when they are not looking and peek, or just ask!

The author has found that new karters may gain more success with 1 or 2 teeth less on the back sprocket than more experienced drivers use.

Consider that a new karter may not be able to compete on the corners due to inexperience and therefore may benefit more from a slightly higher gear, which gives more speed on long straights. Experiment to find your optimum ratio by changing the gear ratio up and down by 1 or 2 teeth.

Note that it is the gear ratio that matters. If the back sprocket is too large then reduce the engine sprocket by 1 tooth and the back sprocket by ratio. As a rule use the largest practical engine sprocket as this will result in less wear to the engine sprocket and chain, but bear in mind the risk of a large back sprocket hitting the ground.

4.12.1

Wets have a larger diameter than slicks and therefore the gearing needs to be changed in order to compensate for this. To give the same gearing the rear sprocket should be a couple of teeth bigger with wets.

You will need to experiment to get the best gear for each track/condition combination.

Check the chain tension after each race [8.4.2]. Use proprietary chain lubricant to re-grease it after each race.

There are no hard and fast rules for wet set-up. Most drivers have their own set-up ideas, but there are some general rules, which apply. The following settings are starting points from which you will need to experiment.

4.14.1 Chassis

A flexible kart gives better grip in the wet than a stiff kart. To make your kart chassis more flexible;

• Slacken the nerf bars (side pod brackets) front bolts,

• Slacken top additional seat stay bolts, or remove the stays completely.

• Slacken front and rear bumper bar bolts.

These bolts should be longer than normal to allow spare thread when slackened. The nuts must be nylock to prevent them from vibrating off.

The seat should also be moved up and forward by about an inch. This produces two effects;

• It raises the centre of gravity. This is needed to lift the rear wheel in the wet when less grip is available.

• It provides better grip at the front end. This can be achieved by drilling several sets of holes in the seat and by using additional spacers under it.

4.14.2 Wheels

Track:

In the wet the kart will have a much greater tendency to over-steer. The track settings should be altered to correct this. Make the rear track narrower so that each wheel is further in than for a dry setting by the following amounts.

Rear Track Settings:

• Very wet - 15<20 mm

• Wet - 10<15 mm

• Drying - 5<10 mm

(These settings are illustrative. The actual values that you use may differ greatly. You need to experiment to get the best settings.)

Set the front track to balance the kart. This will usually mean making the front track wider than for dry running.

Toe-Out:

Setting a small amount of Toe-out gives better grip in the wet. This is in part because it warms up the tyres quicker and in part because it changes the steering and front wheel geometry [9.1.3].

To measure the Toe-out the author uses the (rather naff looking, but works OK) special tool [11.2.4] to provide precise measuring points. Avoid lumps. bumps and other defects on the tyre as that will effect the measurement.

Measurements should be taken in line with the tyre surface. Toe-out is normally stated as the difference between A and B.

Toe-out settings:

• Very wet

• Wet

• Drying

10 mm

5 mm

2 mm

(These settings are illustrative. The actual values that you use may differ greatly. You need to experiment to get the best settings.)

A more accurate (and more expensive) alternative is to purchase a set of 'Tracking Discs'.

All tracks differ. The best set-up at one track will not be the best at another. Weather and temperature will also affect the tracks characteristics. Be prepared to alter kart set-up to suit the track, weather and temperature.

Don't forget to keep a careful and detailed record of set-up for each track.

Figure 4.14.2-1 Measuring Toe-OutThis section covers all of the engineering details that you will require in order to service your engine. It does not attempt to describe how to perform a complete rebuild of a BT82 Engine. For that you will require specialised knowledge and tools. It does however describe stripping, cleaning and rebuilding to a level that is required by, and should therefore be within the ability of, every karter. Scrutineers may require to inspect the head and ports of the engine and therefore you do need to be able to at least remove and refit the head and barrel. There are a few potential problems that are described below but as long as you take care when stripping and reassembling the engine, it is well within the ability of anyone with basic engineering skills.

Note: - ALWAYS tighten fastenings to the torque settings specified in the TMK regulations [14.3].

If any problems occur which are beyond your ability to resolve and in any case after about 9 hours of racing the engine should be sent back to Tal-Ko or to a reputable engine re-builder for checking and rebuilding.

If you are not sure of your skills or have never rebuilt a two-stroke engine before then use an engine that is about to be sent away for rebuilding to practice on.

A few specialist tools are required to strip and rebuild the engine as far as this guide goes.

5.1.1

A Torque Wrench which can be set in the range 4 < 50 lbs./ft. This may require a small and a medium size torque wrench.

5.1.2

The only special cases here are a long reach 13mm socket for the four Head retaining nuts and a short 13mm socket with the top edge ground away and a flexible drive for the Manifold Bend retaining nuts.

5.1.3 Special Tools

Dummy Gudgeon Pin [11.1.3].

Gudgeon Pin Extractor [11.2.6].

Clutch Holding Tool [11.1.4].

Clutch Puller [11.1.5].

Sprocket Extractor [11.1.6].

5.1.4 Measuring Tools

Feeler Gauge.

Steel Rule.

Small Micrometer.

Vernier Calliper.

5.2 Basics

When stripping the engine ensure that every nut, screw, bolt or component removed is carefully stored in an organised manner. The author has a selection of biscuit tins and plastic bowls for this purpose.

5.2.1 Basic Checks

The following list specifies the basic things that need to be done after a meeting.

• First slacken the spark plug and then remove the engine, complete with carburettor and Air Intake box, from the chassis [5.5.1].

• Clean the outside of the engine and carburettor using white spirit and a brush. Take care to avoid getting cleaning fluid into the crankshaft bearings or cylinder. Do not get WD40 or oil onto the spark plug or into the plug cap. The plug cap is held on by friction and if this friction is diminished by WD40 it may fall off during a race.

• The carburettor can be left on the engine if it is performing well and does not require servicing, otherwise it should be removed and stored it in a plastic bag [7.4].

• Remove, clean and check the spark plug [5.12].

• Clean and check the clutch and grease the sprocket bearing after each event [6.2].

• Make a visual check for any damage.

5.2.2 After a Wet Race

After a wet event it is important to strip and dry the inside of the engine. Water is sucked into the engine along with the fuel/air mixture. If the engine is left wet, the steel components will start to rust. This will reduce engine life and in severe cases, result in engine failure.

Remove the cylinder head and barrel and then warm the engine to dry it. This could be done with a hair dryer!

5.2.3 Engine Record

Keep a record of engine hours and of the condition of the engine [15.3]. This should include:

• State of the clutch, including the thickness of the Friction Disc.

• When carbon was removed from the inside of the engine and how bad the build-up was.

• Degree and nature of engine wear.

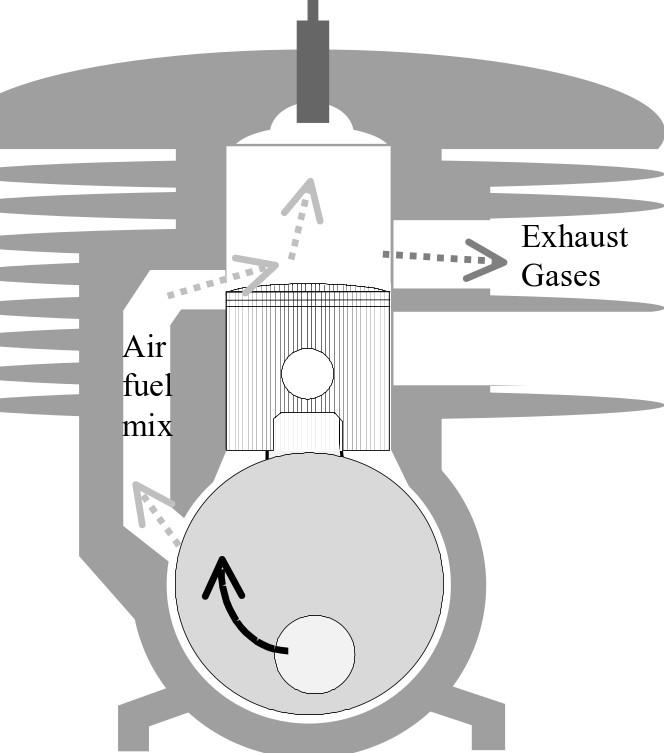

5.3 How the BT82 works

The BT82 Engine is a Piston Port Two Stroke engine. This means that the inlet and exhaust ports are blocked and opened by the position of the piston and not by any other valve mechanism.

As the piston moves up towards compression the Transfer & Exhaust ports are blocked allowing the air/fuel mixture in the cylinder to become compressed ready for ignition. The rising piston creates a part vacuum in the crankcase. Because the inlet port is opening, air/fuel mixture from the carburettor is drawn into the crankcase.

Figure 5.3-1 Engine

When the piston is at the top of its stroke and the mixture in the cylinder is compressed the ignition fires and drives the piston back down. As the piston moves down the exhaust port is opened allowing the pressurised exhaust gases to escape. As the piston moves further down the inlet port is closed and the air/fuel mixture already in the crankcase is compressed.

Figure 5.3-2 Engine - Compression

When the piston is fully down the transfer port is opened and the pressurised air/fuel mixture flows from the crankcase into the cylinder driving out the remaining exhaust gasses. Some of the air-fuel mixture is pushed out of the exhaust port into the exhaust expansion chamber. A pulse wave reflected from the exhaust will then force much of it back into the cylinder [5.14]. If you want to know more about this process then read the book “Two Stroke Performance Tuning” [14.8].

5.4 Running in

Read “Getting the best from your Engine” in the TKM Regulations [14.3] & the 'ENGINE' chapter in 'The Complete Guide to Formula TKM Karting' [14.6]. What you do for the first hour of an engine's life will greatly affect the remainder of its life. New or fully rebuilt engines must be run in for a full hour. Ensure that the carburettor is set slightly rich. The engine should smoke slightly. Build up the revs slowly over the hour. Check the mixture by removing and checking the cylinder head between sessions [4.2.4].

Check the head and manifold bend securing nuts are at the correct torque between each run.

5.4.1 Running a New Piston In

If just the piston and rings have been replaced [5.9] then you will need to run the engine in for a short time. Run at low revs (9000 < 10000) and with a slightly rich mixture for at least 5 minutes.

5.5 Removing and replacing the Engine

This is a very straightforward task, but if the engine is replaced incorrectly it can result in severe problems.

5.5.1 Removing the Engine

• Remove the Chain Guard and disconnect the fuel pipe taking care to ensure that it is sealed so that fuel does not escape and dirt does not get in (note that a 6mm screw fits well). Disconnect the accelerator cable from the carburettor. Remove the Rev-counter aerial from the HT lead. Disconnect the ignition switch connectors [5.11.5]

• Slacken the bolts that hold the engine mount clamps to the Chassis frame so that the engine is free to slide on the frame. Remove the four (or eight) bolts which hold the Axle Sprocket to its carrier and then remove the Axle Sprocket and chain.

• Remove the Exhaust retaining springs and remove the exhaust. Use a small wad of cloth to block the exhaust port ensuring that no dirt or loose threads get in to the engine.

• The engine can now be lifted clear of the chassis, but do not lift it by the Air Intake box.

5.5.2 Replacing the Engine

When lifting the engine it is very tempting to lift it by the Air Intake box and the Manifold Bend. This is fine, but take care that the Air Intake box does not come off leaving you with just the Air Intake box in your hand and a smashed engine on the floor.

To reinstall the engine, reverse the sequence for removing it [5.5.1] and then;

• Check sprocket alignment [8.3.1],

• Adjust the chain tension [8.4.3],

• Check the accelerator cable setting [7.8],

• Bleed the air out of the fuel pipe [4.6.1].

5.5.3 Engine Mounts

The engine mount allows the BT82 Engine to be fitted to the engine mounting tubes on the chassis frame. Chassis differ so that an engine mount must be matched to the chassis type. The engine mount should normally be removed before sending an engine away to be serviced or rebuilt.

5.5.4 Removing the Engine Mounts

Mark the mount to ensure that it goes back on the same way round.

Remove the four ‘cap head ‘ screws securing the engine mount to the bottom of the crankcase.

5.5.5 Checking the Engine Mounts

The two aluminium clamps are close to the ground and will often get worn and damaged. This should not be so severe that the heads of the clamping screws become damaged. Look for cracks in the grooves, which fit onto the tubing. No cracking is acceptable.

If either of the screw threads strip then replace the mount.

Replacement cap head screws MUST be the correct lengths. If too long then they may bottom and strip the threads. If too short they will not be strong enough.

Figure 5.5.4-1 Engine Mount Clamps5.5.6 Replacing the Engine Mounts

Ensure that the screws are tight and the mount goes back on the correct way round.

5.6 Cylinder Head

The aluminium cylinder head is a critical component and must be treated with respect. It is quite soft and will distort or crush if it is not treated with appropriate care.

5.6.1 Removing the cylinder Head

The Cylinder head must be cool before it is removed. It is important to remove the two cap head screws first and then the four 13mm brass nuts in a diagonal order as shown. This will prevent the risk of warping the head.

5.6.1-1 Cylinder Head Nuts

• Remove the Cap head screws first.

• Loosen the nuts slowly in a diagonal order. Loosen (1) first by a 1/4 turn and then (2) etc. returning to (1) after (4). Do not remove any one nut before the others are slackened.

• Collect the 4 nuts, 2 screws and 6 washers and store them safety.

• Note that the barrel will now be free to be lifted off the crankcase.

Figure