REVISED 11/1/2024

5.3

REVISED 11/1/2024

5.3

Southeast Building SupplyInterests believesthatneitheroperationnorprofittakespreferenceoverthehealthandsafety of our employees and the protection of the environment. Southeast Building Supply Interests management considers no phaseofoperationoradministrationasbeingofgreaterimportancethanthehealthandsafetyofits employees andprotectionoftheenvironment.

Sincere efforts have been made to incorporate Environmental Health & Safety features into all operations. The most importantaspectsofanyjobare:

1. The protection of our employees’ health,

2. Our employees safety and the safety of those in their surrounding area, and

3. Preservation of the environment.

The following concepts are the fundamentals of Southeast Building Supply Interests Environmental Health & Safety policy and as such, will continue to be a part of the Environmental Health & Safety. All Southeast Building Supply Interests Environmental Health & Safety Programs are reviewed and updated every two years or as need to ensure thehealthandsafetyofSoutheastBuildingSupplyInterestsemployeesandtoremainincompliancewithall regulatory agencies.

1. Southeast Building Supply Interests shall consider it a part of managerial responsibilities to make timely corrective action where any conduct or condition may serve to jeopardize the safety, health or the environment.

2. Itshallbetheresponsibilityofeverymanagerandsupervisortocarryonoperationsundertheirjurisdiction insuchamannerastoaffordadequateprotectionforallemployees.

3. Itshallbeconsideredafunctionofallmanagersand supervisorstoseethatanemployeereceives allnecessary instruction and training as may be required to perform the job safely. In addition, managers and supervisors will be responsible for seeing that job instruction and safe work practices on the job are fullycompliedwithbyallemployees.

4. Each employee will be expected to adhere to the Environmental Health & Safety Programs, so that operations may be carried on in such a manner as to assure the safety and the health of our employees as well as the protection oftheenvironment.

5. Employees shall be expected to observe safe work practice rules, as well as instructions relating to the efficientperformanceofwork,andtomakesuggestionsforcorrections.

Southeast Building Supply Interests asks for your full cooperation and support in effectuating our company’s EnvironmentalHealth&SafetyPrograms.

Responsibility and commitment to employee health and safety begins at the top. It is the intent of Southeast Building Supply Interests to provide a safe and healthful work environment for all employees and to work in a manner that ensures the safety, health and environment of the general public and our customers. Everyreasonable effort shall be made to promote an incident-free environment through planning, hazard prevention and control, training, use of proper procedures, equipment and compliance with all applicable regulations and appropriateindustryguidelines.

WerecognizethattheeffectivenessoftheSoutheast Building Supply InterestsEnvironmentalHealth& Safety Program rests on the shoulders of each and every individual within our organization. Our commitment to a safe and healthful work environment is one of great importance. In turn, we ask that every employee adopt a strong commitment through their active involvement in our program for their own safety and health, that of their co-workers and for the benefit of the company as a whole. Employees are expected to use the Environmental Health & Safety equipment provided. Rules of conduct and rules of safety shall be observed. Safety equipment must not be destroyed or abused. It is imperative that all management personnel recognize and accept their responsibilities for maximum safety efforts. Their safety performance will be measured alongwiththeiroverallperformance.Webelieveasaresultofouryearsofexperience,thataneffectiveprogram is an integral part of good employee relations and ranks in importance with production, operating costs, product quality and customer satisfaction.

Southeast Building Supply Interests will provide leadership and guidance in ourEnvironmental Health & Safety Program. We are committed to the program’s effectiveness and continual improvement, as well as to providingtherequiredpolicies,tools,andsafeguardstoensureasafeworkenvironment.SeniorManagement accepts the responsibility to provide leadership, and to hold managers, supervisors and employees accountable for their performance.

Customers/Owners and Management must be informed of any hazards presented by work being performed or potential hazards discovered on any jobsite. Employees are responsible for reporting thesehazardstotheir immediatesupervisororCustomer/Owner.

Employee on-the-job safety is the primary responsibility of every manager and supervisor. They must acknowledge that Environmental Health & Safety protection are an integral part of their responsibilities. They shall ensure that Environmental Health & Safety issues are considered when planning work and those adequate resources are available to address safety concerns. Supervisors must ensure that work is executed in accordance with proper procedures and in compliance with best practices and legal requirements. Employee safety cannot succeed without the sincere ongoing effort of every manager and supervisor. Therefore, it is the responsibilityofeachtodothefollowing:

1. Set a good example by observing all safety and fire protection rules.

2. Accept responsibility for the effectiveness of the Environmental Health & Safety Program and for keepingit current.Makesafetyapriority.

3. Develop a positive attitude toward Environmental Health & Safety, and foster this attitude. Be enthusiasticaboutsafetyandfireprotection.

4. Ensurethatalloperationsareperformed withtheutmostregard forthesafetyandhealthofall personnel involved.Requireandusepersonalprotectiveequipment(PPE)whererequired.

5. Ensure that all new and existing employees within their scope of responsibility receive all required trainingas outlinedthroughoutthisprogram.Taketimetodiscuss safety daily.

6. Use frequentinspectionstoensurethatthework environment issafeandthatemployeesare working in asafemanner.Inspectoftenandintelligently.

7. Supervisors must report any hazards or potential hazards immediately to management and/or customer/owners.

8. Ensurethatallpersonnelattendscheduledsafetymeetingswith emphasisonnoteddeficiencies andcorrective actionstaken.Knowyouremployees.

9. Ensure that all documented Environmental Health & Safety deficiencies are reported through proper reporting channels, corrected immediately, and preventative measures are taken. Investigate thoroughly.

10. Ensure that all incidents are promptly reported using the tools provided in Chapter 3 of this Manual containsthevariousformsandprocedures.

Employeesareresponsibleforadoptingapositiveattitudetowardssafetyandhealththroughactivecooperation withtheirmanagerand/orsupervisor.

Additionally,compliancewithallaspectsofSoutheast Building Supply InterestsEnvironmentalHealth& Safety management programs and procedures is a requirement of employment. To this end, every employee is responsible for:

1. Practicing safe work behaviors in every job task. No employee shall be required to perform unsafe acts or workaroundunsafeconditions.

2. Promotingsafetyandhealthfortheirownoverallwell-beingandthatoftheirco-workers.Employees are encouraged to identify and express safety and health concerns to supervisors and managers,andshallnot besubjecttoreprisal.

3. Practicing good housekeeping and accepting responsibility for your own safe behavior.

4. Employees are responsible for following environmental, health and safety procedures, rules and regulations, aswellasstateandfederallymandatedsafetystandards.

5. Actively participating in all required training.

6. Utilizing all safety-related tools, health and environmental and materials provided.

7. Reporting to their immediate supervisor any and all environmental, health and safety deficiencies observed.

8. Implementing corrective and preventative actions as instructed.

9. Immediately reporting all work-related incidents, injuries, illnesses, and near misses to their immediate supervisor. Documentation is critical.

Safety management programs are to reduce work-related incidents (thereby injuries and illnesses), and to promote safety and health in every task undertaken by employees on behalf of the company. To this end, this Safety,Health&EnvironmentalManagementProgramwillincludethefollowing:

1. Aprogramforconductingroutineenvironmental,healthandsafetyinspectionstoidentifyand eliminateunsafeworkingconditionsorpractices andcontrolhealthhazards.

2. A comprehensive environmental, health and safety training program for all new and existing personnel.

3. Provisionsfortheuseofpersonalprotectiveequipmentbyallemployeesasdictatedbytheir respectivejobdescriptionsandworkareasofassignment.

4. Provisions for mechanical and physical safeguards to the maximum extent possible.

5. Compliance with company environmental, health and safety policies and procedures as a condition of employment.

6. Provisions for a thorough and prompt investigation of every incident to determine its cause, correctiveandpreventiveactiontakentoreducethelikelihoodofithappeningagain.

1. Report any type of incident involving a near-miss, property damage, physical impairment and/or personal injury/illness to your supervisor immediately.

2. Nevermoveaninjuredpersonunlessabsolutelynecessary.Furtherinjurymayresultifmovedimproperly. Make the injured worker comfortable until trained personnel arrive.

3. Keep all equipment in safe working condition and in its proper place. Inspect all equipment prior to use. Never use defective equipment. Never remove guards or work around machines if guards aremissing.Report any problemstoyoursupervisorimmediately.

4. Do not operate machinery, forklifts or attempt to lockout equipment if you have not been trainedtodoso. You must receive specific written and oral training as well as hands-on training for forklifts and lockout.

5. Noridingispermittedonforkliftsandotherequipmentasspecified.

6. Walk donotrun.

7. The use of or being under the influence of alcohol or drugs is prohibited during work hours. Medicationsthatslowreactionordisturbyoursenseofbalancearenotcompatiblewithworkingonorusing machinery.Ifindoubt,checkwithyourdoctor.

8. Never work aloft if you are subject to dizzy spells, fainting, apt to be nervous or sick.

9. Never handle cleaning compounds and hazardous materials without proper training and authorization and proper protective equipment.

10. Prior to using any chemical, review the Safety Data Sheets (SDS).

11. Practice good housekeeping at all times. Keep your work and break areas clean.

12. Use proper lifting techniques at all times. Do not use short cuts. Get assistance whenever the size orshape oftheloadwarrantsit.Neverjudgetheweightoftheloadbyattemptingtoliftit.

13. Do not block exit doors, fire extinguishers, electrical cords, and aisles.

14. Horseplay causes incidents and is subject to disciplinary action, up to and including discharge.

15. Fighting on the job is cause for disciplinary action, including discharge.

16. If there is something about your work that you do not understand, ask your supervisor. Always ask questions, never assume. Make sure that you understand your job responsibilities completely.

17. Working safely is a condition of employment. Anyone failing to obey safety instructions, rules or regulations or failing to do anything reasonably necessary to protect the life, health, safety and welfareof him/herselfandothersonthejobwillbesubjecttodisciplinaryactionordischarge.

18. Do not remove, displace, damage or destroy a safety device furnished for use on the equipment.

Askilledworkerisasafeworker–animportantmemberofanycompanyororganization.Allotheraspectsof a company, including its profitability, are directly affected by the safety performance of all the workers. Thus, the true capacity to produce efficiently and to get the job done correctly rests with the safe worker.

Most tragic mishaps are caused by the unsafe acts of the injured worker or their co-workers. A single mistake couldcostyoudearly.Strictattentiontoyourtaskcanavoidthis.

Southeast Building Supply Interests employees have the primary responsibility for their safety. An employee, whoisknowledgeableincorrectworkmethods,guidedbyaproperattitude,andworkingwithinthelimits of his/hercapabilities, isthemostlikelytypeofworkerto completethedaysafelyandsignificantly contribute to the organization.

As previously stated in this manual, it is the policy of Southeast Building Supply Interests to conduct all operationssafely,withtheprimarygoalofavoidinginjuriesanddamagetoproperty.However,safetypolicies and programs are not enough alone. That is where the organization known as OSHA and comes in. The first questionthatusuallycomestomindis“WhoorwhatisOSHA”?OSHAistheacronymfortheOccupational Safety and Health Administration. The focus and mission of OSHA was laid out long ago, in the OSH Act (Occupational Safety and Health Act) that created it. In 1970, the U.S. Department of Labor passed the Occupational Safety and Health Act to “assure so far as possible every working man and woman in the nation safe and healthful working conditions.” Section 5(a)(1) of that act, a section also known as the General Duty Clause, specifically states: “Each employer shall furnish to each of his employees employment and a place of employment which is free from recognized hazards that arecausing,orlikelytocause,deathorseriousphysicalharmtohisemployees.”

The following information is intended to provide our employees with their rights and responsibilities as identified in OSHA Fact Sheet.

OSHA: Employee Workplace Rights and Responsibilities

Record Type: Fact Sheets

Subject:OSHA:Employee WorkplaceRightsandResponsibilities

Information Date: 01/01/1995

Fact Sheet: 95-35

Fact Sheet No. OSHA 95-35

The Occupational Safety and Health Act of 1970 (hereafter called the Act) created the OccupationalSafety and Health Administration (OSHA) within the Department of Labor and encouraged employers and employees to reduceworkplacehazardsandtoimplementsafetyandhealthprograms.

An employee is anyone who works for an employer whose business affects commerce. Thus, OSHA covers virtuallyallprivatesectorworkersexcepttheself-employed.

The OSH Act gives employees many rights and responsibilities. They have the right to:

1. Reviewcopiesofappropriatestandards,rules,regulations,andrequirementsthattheemployershouldhave availableattheworkplace.

2. Request information from the employer on safety and health hazards in the workplace, precautions that may be taken, and procedures to be followed if an employee is involved in an incidentorisexposed totoxicsubstances.

3. Have access to relevant employee exposure and medical records.

4. Request the OSHA area director to conduct an inspection if they believe hazardous conditions or violations of standards exist in the workplace.

5. Have an authorized employee representative accompany the OSHA compliance officer during the inspection tour.

6. Transportation Assistance Act (STAA); or file a complaint within 90 days under Section 211 of the Asbestos Hazard Emergency Response Act, which protects employees of primary and secondary schools who complain of exposure to asbestos in their work area; or file a complaint within 60 days under Section 7 of the International Safe Container Act, which protects employees who reportsafetyhazardsassociated withcargocontainerstransportedonseeandlandcarriers.

7. Before OSHA issues, amends or deletes regulations, the agency publishes them in the FederalRegister so thatinterested personsorgroupsmay comment.

8. TheemployerhasalegalobligationtoinformemployeesofOSHAsafetyandhealthstandardswhichmay applytotheworkplace.Uponrequest,theemployermustmakeavailablecopiesofthose standards and the OSHA law itself. If more information is needed about workplace hazards than the employer can supply, it canbeobtainedfromthenearestOSHAareaoffice.

9. UndertheAct,employershaveageneral duty toprovidework andaworkplacefreefromrecognized hazards.OSHAmayissuecitationswhenviolationsofstandardsarefound,andforviolationsofthegeneral dutyclause,evenifnoOSHAstandardappliestotheparticularhazard.

10. The employer also must display in a prominent place the official OSHA poster that describes rights and responsibilitiesunderOSHAlaw.

Although OSHA does not cite employees for violations of their responsibilities, employees "shall comply with all occupational safety and health standards and all rules, regulations, and orders issued under the Act" that applytothem.Employeeresponsibilitiesandrightsinstateswiththeirown occupationalsafetyandhealth programsaregenerallythesameasforworkersinFederalOSHA states:

An employee should:

1. ReadtheOSHAposter atthejobsite.

2. Comply with all applicable OSHA standards.

3. Follow all employer safety and health regulations, and wear or use prescribed protective equipment while working.

4. Report hazardous conditions to the supervisor.

5. Report any job-related injury or illness to the employer, and seek treatment promptly.

6. Cooperate with the OSHA compliance officer conducting an inspection if he or EHS inquiries about safety andhealthconditionsintheworkplace.

7. Exercise rights under the Act in a responsible manner.

Each office in Southeast Building Supply Interests must have a written, comprehensive hazard communication program that addresses OSHA’s Hazard Communication Standard (29 CFR 1910.1200) also known as the “Right to Know Law”. The Standard is designed for your protection and states that you have a right toknowwhatchemicalsyouareworkingwithoraround.Itsintentionistomaketheworkplacesafer.Theprogram includes provisions, among other things for labels and labeling, safety data sheets, and an employee training program. The program also includes a list of the hazardous chemicals used and capturedintheSafetyDataSheets (SDS).Theintentoftheprogramistoprotectyou,theemployeewhendealingwithhazardouschemicalsorwith the potential for exposure to chemical emergenciesin the workplace.

The existence, location, and availability of medical records and records of employees' exposure to toxic substances and harmful physical agents must be provided by the employer to affected employees upon theirfirstenteringintoemploymentandatleastannuallythereafter.Wheneveranemployerplanstostopdoing business and there is no successor employer to receive and maintain these records, the employer must notify employees of their right of access to records at least three months before the employer ceases to do business. When OSHA standards require the employer to measure exposure to harmful substances, the employee (or representative)hastherighttoobservethetestingandtoexaminetherecordsoftheresults.Iftheexposurelevels are above the limit set by the standard, the employer must tell employees what will be done to bring the exposuredown.

OSHAencouragesemployersandemployeestoworktogethertoremovehazards.Employeesshould discusssafety andhealthproblemswiththeemployer,otherworkers,andunionrepresentatives(asapplicable). As a last resort, if a hazard cannot be corrected, an employee should contact the nearest OSHA area office. If necessary, the OSHA area director can order an inspection if the employee is willing to submit a formal complaint. See policy 4.1 “OSHA Inspection Protocol” found in this procedure.

Althoughthereisnothing intheOSHAlawthatgivesanemployeetherightto refusetoperforman unsafeor unhealthful job assignment, OSHA's regulations, which have been upheld by the U.S. Supreme Court, providethatanemployeemayrefusetoworkwhenfacedwithanimminentdangerof death or serious injury.

The conditions necessary tojustify a work refusal arevery stringent,however, and awork refusal shouldbe anactiontakenonlyasalastresort.Iftimepermits,theunhealthfulorunsafecondition shouldbereportedto OSHAorother appropriate regulatory agency.

Thus, employees have a right to seek safety on the job without fear of punishment. That right is spelled out in Section11(c)oftheAct.

The law says the employer cannot punish or discriminate against employees for exercising such rights as complaining to the employer, union, OSHA, or any other government agency about job safety and health hazards; or for participating in OSHA inspections, conferences, hearings, or other OSHA-related activities.

Workers believing they have been punished for exercising safety and health rights must contact the nearest OSHA office within 30 days of the time they learn of the alleged discrimination. A representativeofthe employee'schoosingcanfilethe11(c)complaintfortheworker.Followingacomplaint,OSHAwillcontact the complainant and conduct an in-depth interview to determine whetheraninvestigationisnecessary.

This is one of a series of fact sheets highlighting U.S. Department of Labor programs. It is intended as a general description only and does not carry the force of legal opinion. This information will be made availabletosensory impairedindividualsuponrequest.Voicephone:(202)219-8151.

The purpose of the policy is to establish an Environmental Health & Safety management system that will assist userstoquickly identify sectionswithin thehandbook. Additionally, establishexpectations for other locations improvement; identify training, inspections, documentation requirements and submission of data to Corporate. This documentation is essential to the livelihood of the Company and must be readily available to regulatoryagenciesandcustomers.

Establishing expectations and training are of the most important elements of any successful program. Expectation for other locations improvement must be established and communicated to all employees, if employees don’t know what is expected, how can we expect them to get there. Training is designed to ensure employees learn their jobs properly,reinforcepoliciesandprocedures.Trainingalsoprovides anopportunitytocommunicatesafetyprinciples and management commitment to a safe work place. Our primary goal is to eliminate and/or control both known and potential hazards, which our employeesfaceonthejob.Thismandatealsoappliestothesafetyof ourclientsand tothepeopleinthecommunitiesweserve.

Southeast Building Supply Interests, the Department of Labor (DOL) and Occupational Safety Health Administration(OSHA)andEnvironmentalProtectionAgency(EPA)requirethatweprovideemployeesasafe and healthy work environment, pre-work training in the recognition of hazards in the work place, continuous training in certain work environments and refresher training when an employee shows a lack of knowledgeintheperformanceofhis/herduties.

We believe that doing the right thing to protect employees from being injured and protect the environment can be accomplished through an aggressive training program. In addition, under the General Duty Clause, OSHA, the catch all-standard requires employers to provide a safe and healthy work environment for employees. Although our facilities may differ in training requirements, this policy will assist management with establishinganeffectivetrainingprogram.

Management must ensure active participation, personal ownership, region and other locations visibility thru employee interaction and rigorous management of the below listed items. We must first ask ourselves are weprojectingthepropersafetyattitude,awarenessandbehaviortoemployees.Settingapositiveexamplemay changebehavior,attitudesandhabits.

1. Coordinate, review and approve other locations Management incident investigation and analysis. This analysisincludesapreventiondiagnosisresultingcorrectiveactionrecommendation.

2. Review and revise, Environmental Health & Safety policies and procedures annually.

3. Implement a Behavior Based Safety Process.

4. Manage and maintain other locations reporting requirements.

1. Conduct Monthly Safety meetings

2. Conduct a Safety Audit of each locations on a quarterly bases and forward audit results to the EHS Teamto trackcorrectiveactionitems.

3. Monitor all incident investigation process and propose preventative/corrective action recommendationtoEHSTeam.

4. Manage locations action items for completion and timeliness.

5. Conduct Monthly Safety Inspection if required.

6. Manage and complete the incident investigation and reporting process.

7. Write,reviewandreviseJobSafetyAnalysis(JSA)toensureuptodateandforwardtotheEHSTeam for review.

Submission of Environmental Health & Safety goals from locations performance evaluation designed to identify strengths and weakness. Strength may be to keep your incidents at 0; weakness may be having incidents. Remember there are different types of incidents, injury, vehicle and equipment etc. Developmentplan may beto ensure training is completed, reduce spills. Set goals that will ensure employee safety, protect the environment and reduce liabilities. You should submit at least five goals anddevelopaplantoachievethosegoals.

Trainers shall be qualified to instruct employees about the subject matter that is being presented in training. Such trainers shall have satisfactorily completed a training program for teaching the subject they are expected to teach, or they shall have the academic credentials and instructional experience necessaryforteachingthesubjects. Instructors shall demonstrate competent instructional skills and knowledge of the applicable subject matter being taught.

Employeeswhosuccessfullycompletetraininginthesubjectbeingtaughtwillreceiveawrittencertificate. Anypersonwhohasnotsuccessfully completedrequiredtrainingwouldbere-trained.

Designated employees may be qualified or certified by their instructor to teach specific training courses afterhavingsuccessfullycompletedthenecessarytraining.

AnnualTrainingCalendarsaredesignedtoidentifycompany,customerandregulatorycompliance training. It is a tool used to establish training requirements that will allow managers time to schedule training without interferingwithpeakoperations.

Employees will receive personnel, job related, professional growth, development and regulatory compliancetraining.Regulatorycompliancetrainingisprovidedtoemployeeswhoareexposedto safetyand healthhazardsand/orhazardoussubstancesapplicabletojobrelatedfunctionand refreshertrainingwhen requiredthereafter.

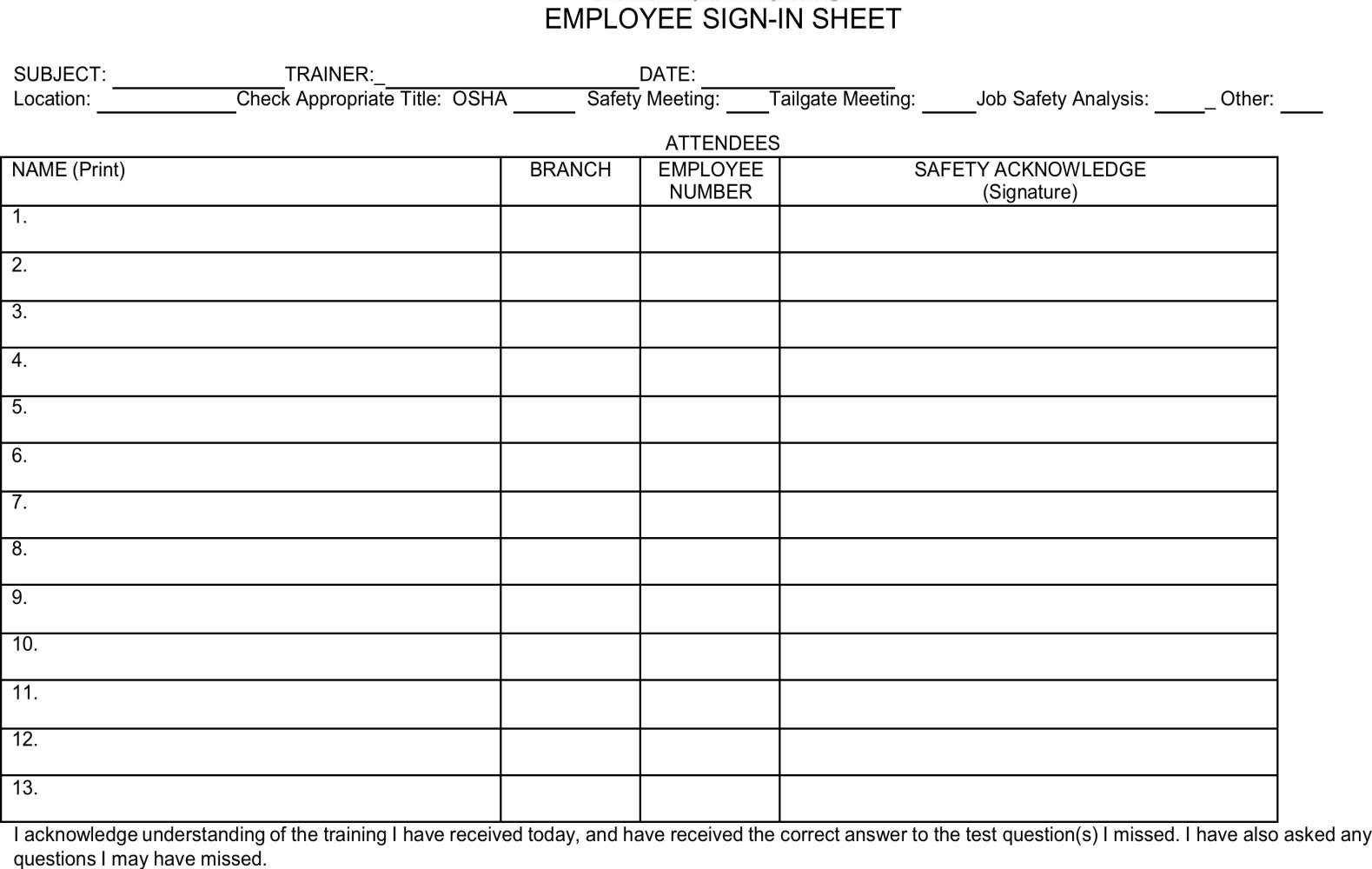

Training will be documented on “Training Sign-In sheet(s)” to verify subject being taught, individual’s name, employee number and signature acknowledging that he/she understood the training presented.Acopyof allsign-insheetswillbeforwardtotheTrainingDepartmenttobeenteredintothe individual training record.

Request for professional health and safety training courses shall be requested and approved by locations Manager or designated person. Prior approval must be granted before any employee can attend any course. This request must be submitted with all financial and research materials. The request form may help responsibleindividualsduringsubmissionofannualbudget.

Safetymeetingareheldtodiscusshazardsintheworkplaceandwaystocontrolthesehazards.Aminimumof 5 questionswill be asked and answered by students to ensure they understood the subject matter covered. These questions may be verbal or written test, if verbal, document the questionsaskedandattachtosignin-sheet.

Inspectionsshallbeconductedasrequired.Inspectionswillbedocumentedandprovidedduringauditsand/or when requested by the Environmental Health & Safety Department. Inspection checklist shall be tailored to fit individualoperations.

OSHA RECORDABLE VS. FIRST AID

In the event of an incident (Attachment 1) “Recordable, Medical Treatment vs First Aid” provide guidelines in determining employee status.

INJURY AND ILLNESS REPORTING/OSHA 300 LOG

Injury and Illness cases will be reported immediately to the Environmental Health & Safety Department, Chapter3“IncidentReportingPolicy”.Theseentrieswillbemadeonthe300Logwithin sevendaysoftheevent.

Applicantsshallundergoaphysicalwithsatisfactoryresultsbeforehire.Afteranincidentinvolving timeaway fromwork,employeesmustundergoamedicalexaminationandbeapprovedfordutybyaMedicalPhysician.

OSHA has establishedtraining andrecord keeping requirements.

Regulatory compliance is not the only reason to keep training records. Training documentation may be needed as part of an internal management or quality system. Training records are also useful when evaluating the effectivenessoftrainingprograms.

Training records are evidence that certain employees attended certain classes. Other forms of documentation can be useful to safety trainers. Training program contents can be used to document how the employees were trained. Quizzes can be used to help gauge training effectiveness. All thisdocumentationcan beapartofacompletetrainingrecordkeepingprogram.

Death

Loss of consciousness

Days away from work

Restricted work activity or job transfer X

Medical treatment beyond first aid:

1. Stitches 2. Broken bone

3. Prescription drugs 4. Return for treatment beyond first aid

Visit to a doctor or health care professional solely for observation

Diagnostic procedures including administering prescription medications that are used solely for diagnostic purpose

Any procedure that can be labeled first aid

Using non-prescription medications at non-prescription strength

Administrating tetanus immunizations

Cleaning, flushing, or soaking wounds on skin surface

Using wound covering, such as bandages, Band-Aid, gauze, pads, etc, or using Steri-Strips or butterfly bandages

Using hot or cold therapy X

Using any totally non-rigid means of support such as elastic bandages, wraps, non-rigid back belts, etc.

Using temporary immobilization devices while transporting an accident victim (splints, slings, neck collar, or back boards

Drilling a fingernail or to relieve pressure or draining fluids from blisters

Using eye patches

Using simple irrigation or a cotton swab to remove foreign bodies not embedded in or adhered to the eye

Using irrigation, tweezers, cotton swab or other simple means to remove splinters or foreign materials from areas other than the eye

Using finger guards

Using massages & Drinking fluids to relieve heat stress

Southeast Building Supply Interests Open Door Policy provides employees with a way of voicing concerns about business practices directly to senior managers – easily, effectively, confidentially and without fear of recrimination. This initiative, which encourages open and honest communication, is part of Southeast Building Supply Interests commitment to our operating principles and our vision of remaining successful, socially responsible and proactive towards safety.

Southeast Building Supply Interests wants to ensure all our employees continue to work in an enjoyable, relaxed and safe environment. The Open Door initiative is designed to encourage you to report any instances ofunsafe or unhealthy working practices, dishonesty or malpractice – in complete confidence and without any fear ofcomeback.

WHAT

Southeast Building Supply Interests encourages employees to report any working practices that are incompatible with thissowe canprotectyourworking environment.Thesecouldinclude:

• Dangers to health and safety

• Environmental damage

• Criminal activity

• Failure to comply with a legal obligation

• Financial malpractice or fraud

• Improper conduct or unethical behavior

• Attempts to conceal any of these practices

• Equipment damage

WHAT

Ifyouidentifyasituationintheworkplacewhichyoufeelisunsafe,unhealthyordishonestyoumay be happy to talk to your line manager about it in the first instance. Open Door offers you an alternative route, one you can optfor if youwould prefertoreport the matter in confidence directly to ourseniormanagers.

Whichever you choose, the information will remain completely confidential. Open Door supports you inraising important issues, ensuring your concerns will be acknowledged by management who will consider thepoints youhaveraisedandtakeanynecessaryaction.

RESPONSIBLE PERSON

ThepersonwithauthorityandresponsibilityforimplementingtheprogramisJimStockman,Presidentof Southeast Building SupplyInterests ThewrittenpreventionprogramandtheSafetyManualareprovidedin hardcopyatthetimeofinitialemploymentaswellaselectroniccopyforyourreviewthroughthefollowing:

PURPOSE

To establish a system for ensuring that employees comply with safe and healthy work practices.

RESPONSE

1) Employeeswhofollowsafeandhealthfulworkpracticeswillberecognizedthroughvarious methods. These methods include, but are not limited to, personal incentives, electronic media, bulletinboard postings, lettersofrecognition,andverbalrecognition.

2) Beforehisorherfirstjobassignment,everynewemployeewillreceiveathoroughsafety orientation. TheywillbegivenacopyoftheCompany’s“EmployeeHandbook”beforetheirfirstworkassignment andinstructedinjobspecificsafeworkpractices.

3) Employees who violate this program, safety rules, regulations, procedures or policies will be disciplined.

4) Disciplinary actionmay rangefromimmediateverbalreprimanduptoandincludingimmediate discharge, depending upon the seriousness and frequency of the offense. Prior disciplinary actions andworkrecordof theemployeewillalsobeconsidered.

PURPOSE

Toestablishasystemtocommunicatewithemployeesinaformreadily understandablebyallaffectedemployees onmattersrelatingtooccupationalsafetyandhealth.

RESPONSE

Employees are encouraged to report any and all unsafe conditions or hazards at the work site. Form SS-1 isprovided forthispurpose.Itisourpolicythatemployeesshouldnothaveconcernsorreasonforfearof reprisal from anyone in communicating their interests.

Additionalmeansforcommunicatingwithemployeeswillbethroughelectronicmedia,meetings,safetymeetings, postings,memorandums,trainingprograms,andsafetyteams.

PURPOSE

To establish a procedure for identifying and evaluating work place hazards.

RESPONSE

Scheduled periodic inspections will be conducted to identify unsafe conditions and work practices when:

• New substances, processes, procedures, or equipment are introduced to the work place that representa newoccupationalsafety andhealthhazard;and

• Whenever we are made aware of new or previously unrecognized hazards.

This form is for use by employees who wish to provide a safety suggestion or to report an unsafe work place conditionorpractice.

Description of unsafe condition or practice:

Cause or other contributing factor:

Employee’s suggestion for improving safety:

Has this matter been reported to the project manager/crew leader? Yes □ No □

Employee Name (optional):

Department:

Employeesareadvisedthatuseofthisformorotherreportsofunsafeconditionsorpracticesareprotectedbylaw. ItwouldbeillegalforourCompanytotakeanyactionagainstanemployeeinreprisalforexercisingrightsto participateincommunicationsinvolvingsafety.

PURPOSE

To provide a systematic approach to occupational injury and illness investigation and ensure corrective actions(s) are taken to prevent similar injuries and illnesses from taking place in the future.

RESPONSE

All occupational injuries, illness, near misses, or incidents with property or equipment damage, will be investigated. The investigation will be documented on the appropriate form and turned into the Safety Department.

PURPOSE

Toprovidemethodsand/orproceduresforcorrectingunsafeorunhealthyconditions,workpracticesandwork proceduresinatimely mannerbasedontheseverity ofthehazard.

RESPONSE

1. Allunsafeorunhealthyconditions,workpracticesandworkprocedureswillbecorrectedwhenobserved ordiscovered;and,

2. Whenanimminenthazardexistswhichcannotbeimmediatelyabatedwithoutendangering employees and/orproperty,allexposedpersonnelwillberemovedfromtheareaexceptthosenecessarytocorrectthe existing condition. The employeesretained toabatethehazard willbe provided the necessary safeguards andtrainingpriortoentering.

PURPOSE

To provide adequate training and instruction to our employees.

RESPONSE

1. All new employees, or current employees given new job assignments, will be trained and instructed torecognizethehazardsofthejob.

2. Additionaltrainingwillbegivenwhensubstances,processes,proceduresorequipmentare introduced to the workplace that may present a new hazard, or when we are made aware of a new or previously unrecognizedhazard.

3. Supervisorswillbetrainedtofamiliarizethemselveswiththesafetyandhealthhazardstowhichemployees undertheirimmediatedirectionandcontrolmaybeexposed.

4. Records of scheduled or periodic inspections required to identify unsafe conditions and work practices, including person(s) conducting the inspection, unsafe condition and work practices that havebeen identified and actions taken to correct the unsafe conditions and work practices, will be maintained for at least one yearasrequired.

5. Documentation of safety and health training for each employee, including employees name or other identifier, trainingdates,type(s)oftraining,andtrainingprovider,willbemaintainedforatleastoneyear as required.

The purpose of this policy is to increase the level of employee awareness associated with talking on cell phones while driving.

There has been much press about hazards of driving while using cell phones and some states have enacted laws prohibiting cell phone use while driving. Published studies show that cell phone use is equivalent to drivingunderthe influence, even with a “nohands”device.

Giventhatmanyemployeeshavecellphonesandusethemwhile“ontheclock”,oftenwhiledriving companyowned, leased, rental or privately-owned vehicles on company business, the risk of accident, and of potential liabilityforthecompanyisapparent.

Employeesarenottomakeorreceivebusiness callsortextmessagesonacellphoneofanykind(including hands free) while operating a vehicle. This includes both company-owned and privately-owned cell phones, as well as hands-free units. In addition, employees are not to make or receive any calls or text messages on a cell phone, be they business or personal in nature, if driving a company-owned or leased vehicle. All vehicles must be pulled off the road and parked prior to making or accepting a call on your cell phone.Useofacompany-ownedcellphonewhile driving or use of a cell phone while operating a company-owned or leased vehicle is only permitted in emergency situations, namely to report an accident,tocallforassistanceintheeventofcartrouble,oryouor anotherpersonareinimminent danger. Unlesstheaboveconditionsare met, CellPhonesshouldbeused onlyduring personal breaks

The purpose of this orientation is to provide an overview to new hires to raise his/her awareness level ofhazardsin ourworkplace.

The Department of Labor (DOL), Under the General Duty Clause, Occupational Safety and Health Administration(OSHA)requireseachcompanytoprovideasafeandhealthyworkenvironmentforallemployees, contractors,subcontractorsandvisitors.

ToaccommodateDOLandOSHA,allperson(s)enteringany SoutheastBuildingSupplyInterestsworkplacewillattend a safety orientation in the recognition of hazards in the workplace, and receive Personal Protective Equipment(PPE)ifrequired.

ItwillbetheresponsibilityofManagerstoensurethatnewemployeesreceiveasafetyandcommercialdriverfleet safety orientationbeforeenteringany SoutheastBuildingSupplyInterests workareas.

It will be the responsibility of EHS Department to conduct the new hire orientation.

Safety requirements for new hires will be discussed during this orientation. A safety orientation is an informal training period that identifies safety policies, procedures and hazards in the workplace selection, use of personal protectiveequipment.

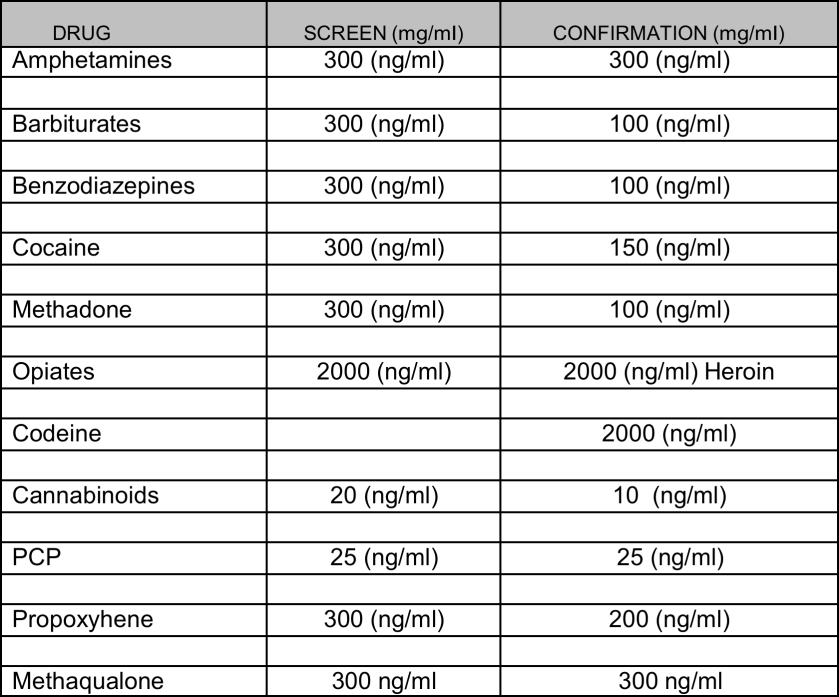

Allnewhiresarerequiredtotakeacontrolledsubstanceand/oralcoholtest;withanegativeverificationresultbefore the safety orientation begins. Verification for controlled substance and alcohol results may be obtained by calling theEHSDepartment.

Employees who are rehired after three months will attend the Employee Safety Orientation before starting work.

This orientation will be presented on a power-point presentation or orally. New employee orientation will cover 6 safety related topics. The employee must show satisfactory knowledge of the concepts before completing the trainingandallowedtoperformtheirjobduties.Thesetopicsinclude:

1. Injury & Illness Prevention Program

2. Hazard Communication Standards

3. Fall Protection/ Ladder Safety

4. Heat Illness Prevention

5. Fire Protection/ Emergency Action Plan

6. Electrical Safety

Southeast Building Supply Interestsbelievesthatintheeventofanincidentitisimperativethatwedetermine fairly whether or not it was preventable. Regardless of whether it is personal injury, vehicle, spill/theft, property damageanincidentreviewmustbecompleted.

The purpose of the Incident Review is to not put blame on the individuals involved, but to find out the facts, complete a root cause analysis, and determine what lead up to the event to prevent future occurrences.

1. All incidents shall be reviewed by Management and the EHS Department. All employees involved in the incidentmustbepresentaswell,includingleadsupervisors,mentorsandallwitnesses.

a. Executive management, department heads, or other applicable parties may be involved if circumstanceswarrant. The Head of Finance will be CC: on all incident review notifications having the option to attend or not.

2. TheManagerorresponsibleappointeewillscheduleandcompletethereviewwithinfive(5) working days of the incident. The Safety Department Head may be conducting the review to ensure consistency.

a. Completed incident reports, all pictures and any other supporting documents must be sent to EHSandreviewparticipantspriortothereviewbeingscheduled.

b. Review participants should have the information no less than twenty four (24) hours prior to attending the review.

3. “Standard Incident Review Questions” (attachment A) should be used as a guide, but additional questions may be necessary to gather all applicable information or details to ensure consistency.

4. Once interviews are completed, the responsible employee and non-essential parties will be excused fromthereviewandcorrectiveactionswillbediscussed.

a. Corrective actions must be fair, practical and proportional to the severity of the incident and its root cause.

b. Training assigned should benefit the individual:

i. The review must be communicated to all employees to aid as a notice or prevention and act as deterrent for possible future incidents.

ii. Incidents must be classified as preventable or nonpreventable and the root cause must be determined.

iii. Corrective action must have target or completion dates.

5. ReviewattachmentB,StandardCorrectiveActionFormanddistributetoallpartiesafterthe review is completed.

6. Statusofcorrectiveactionsornoticeofcompletionoftheassignedcorrectiveactionsmustbe forwarded to the EHS Department as well as the appropriate individuals by designated personnel within 48 hours after the target date.

7. The results of all reviews shall be logged in the “Incident review” spreadsheet and corrective action trackeduntilclosure.

Employee Name:

Date of Review:

Job Title:

Date of Hire: Date of Incident:

Type of incident: Injury Vehicle: Spill: Theft: Other: Review Attendees: Did management accompany you to clinic?

Did you have a post-accident Drug Screen? Have you had prior incidents? If yes, List:

Injury

1. Whattimedidthisincidenthappen?

2. Wheredid this incidenthappen?

3. Howdid thisincidenthappen?

4. Werethereotherinjuries?

5. Were there any witness?

6. Whathappened?

Spill How much?

Did it spill into a stream or lake? Was spill cleaned up? Theft

1. Where was the equipment parked?

2. Was there adequate lighting?

3. Do you have barbed wire?

4. Was the alarm on and working?

5. What is your key protocol?

6. Describe the surrounding area:

7. Were your vehicles locked?

8. Was the equipment visible? Vehicle

1. Were you wearing your seatbelt?

2. Wereyoutalkingonthecellortwo-way?

3. When was the vehicle last inspected?

4. Did you have your mirrors adjusted correctly? Management Systems

1. Was a JSA used? 2. Did you use a spotter?

2. If an SSE has a mentor been assigned? Date assigned: / /

3. Was the employee wearing appropriate PPE?

4. When was the last safety meeting and what subject covered?

Ask questions during the review to evaluate the culture in supporting Company Policies and Procedure.

Comments:

Location: Date of Review:

Employee Interviewing: Incident: Attendances:

Complete date

The purpose of this policy is to reduce the safety risk involved in performing various tasks in which the wearing of jewelry or loose clothing might create a personal safety hazard. This policy applies to all Southeast Building Supply Interests employees, temporary workers as well as contractor employees working within any Southeast Building Supply Interests facility or jobsite. Customer site safety requirements – facilities, project(s) or job locations may requireadditionalguidelinesthatwemustadheretowhileontheirpremises/property.

The use and/or wearing of certain items and/or types of jewelry are restricted within all Southeast Building Supply Interests facilities or jobsites. Employees are expected to follow safe procedures and take an active part in the work of protecting themselves, their fellow employees. Southeast Building Supply Interests ensures every precaution willbetakentoprovideasafeworkplace.

Supervisors shall implement, raise awareness and facilitate enforcement of this policy with all employees, temporary workersandvisitorsatallfacilitiesandjobsites.Supervisorsareresponsiblefor:

• Working with Environmental Health & Safety Department to initiate any necessary administrative action requiredtoenforcesafeworkpractices.

• Anticipatingallworkhazards.

• Inspecting areas to ensure that this policy is being adhered to; and

• Providing safety awareness training, as needed.

• Taking the appropriate corrective action for employees not complying with the policy.

Employees,otherthanthoseworkinginanofficeenvironmentshallnotwearloosefittingclothingor dangling jewelry (necklaces, watches, rings, bracelets, scarves, body piercings, facial jewelry) that’s exposed or hangs loosely away from the body can become entangled in or stuck against objects, catch on equipment, tools, or cause electricalshock.Removealljewelry andstoreitordonotbringittowork.

Machinery, moving equipment, tools having rotating or reciprocating parts can pull parts of the body into the machine. Once entangled, the caught up end can pull you into the equipment causing very serious injuries. Consequences ofwearingjewelry atworkcouldresultin:

• torn earlobes

• injured fingers, hands, wrists, neck

• amputated fingers or limbs

• electric shock

• lost-timefromwork

• the need for medical care

• crushing

• lacerations

• amputation

• scalping

Also, most watches, rings other metallic objects are electrically conductive. If you were to come in contact with a live electrical component, the circuit could be completed through your ring. This has can cause very deep and serious electricalburns.Clothingshouldprotectyou,notendangeryou.

A tight fitting watch may be worn unless an individual is working on or near electrically energized equipment.

Iflong sleeveshirts are worn,the sleevesshouldkeptcuffsbuttonedsotheywill fitsnuglyaroundthe wrist. The frontofanyshirtmustbekeptbuttonedandthetailtuckedin.Donotforgetthattearsorloosethreadscangetcaught also.Wornclothingcanbejustasdangerousaslooseclothing.

Short hairstyles are preferred for individuals working around machines. Beards and moustaches shouldalso be kept trimmed. Unless required to wear a respirator (Refer to policy 6.13). Unconstrained long hair that is over shoulder length mustbeeither:

• Tied up or neatly secured in back

• Covered

• Wornunderthehardhat

Additionally, security badges should only be worn around machinery or moving equipment if connected to a breakawaylanyard.

Southeast Building Supply Interests is committed to maintaining a workplace in which safety is a part of everything wedoandisasimportantasanythingwedo.OneexpressionofourcommitmenttosafetyisthisIncidentReporting and Investigation Policy. And to ensure proper treatment, investigation and classification of occupational injuries/illnessthatoccurhavebeencompleted.

As a general rule, investigations should be conducted for:

• All injuries (even the very minor ones)

• Allaccidentswithpotentialforinjury

• Property and/or product damage situations

• All “Near Misses” where there was potential for serious injury

Near miss, incident reporting and investigation allow you to identify and control hazards before they cause a more serious incident. The purpose of an incident investigation is to determine the work element and root causes of incident,andtoassistin providingthecompany withasolutiontopreventrecurrence.

Allincidentsnomatterhowminorwillbereportedimmediatelytoyoursupervisor.Allwrittenreportsforincidents including personal injury, general liability, property/ equipment damage, motor vehicle damage, spills, fires or explosionsmustbefilledoutcompletelyandgiventoyoursupervisorbytheendofyour scheduledworkdayon thedateofitsoccurrence.

The Incident Report Form is available and may be sent electronically, e-mail, regular mail (including in- house), hand-delivered, or faxed. In addition, the Manager, or designee will be verbally informed of the incident immediately or soon as practicable.

All incident reports must be submitted to EHS Department within 24 hours of the incident. If full details of the incident,injury,investigationandcorrectiveactionsarenotavailablewithinthistimeframe,the essentialdetails of the incident or injury as they are known should be submitted initially. Additional information, including detailsofsupervisorinvestigationandcorrectiveactions,shouldbesubmittedviaemailtoEHSDepartmentandthe ClaimsAdministrator.

First aid requirements are established in Chapter 3.2, First Aid, EHS handbook.

Controlled substance and alcohol testing shall be conducted immediately or within 24 hours of incident.

ACCIDENT:Theworkaccidentisabroadtermcoveringawidevarietyofeventsincluding,butnotlimited to,personal injuriesandoccupationalillness(i.e.,chemicalexposures,cumulativetrauma,etc.).

CONTRIBUTING FACTORS: Circumstances that led to an incident that, if removed, would have prevented or lessenedtheconsequences:suchas,systemfailures,training,communication,etc.

CORRECTIVE ACTIONS: Steps to be taken to prevent the recurrence of the circumstances that resulted in the incident.CorrectiveActionsareassignedacompletiondateandaresponsibleperson.

IMMEDIATELY: Means as soon as practically possible but no longer than 8-hours after the death or serious injury or illness has occurred. Serious injury or illness includes inpatient hospitalization for more than 24- hours for other than medicalobservation, theloss ofany bodypart,orany seriousdegreeofpermanentdisfigurement.

INCIDENT: The work “incident” is a broad term covering a wide variety of events including but not limited to, fires, chemical spills and releases, unusual odors, personal injury, near miss, plant or property damage, fire and/or explosion.

INCIDENTREPORTPROCEDURE:Asystemthatisdesignedtocollectincident/injuryinformationandassign corrective actions generated from an incident. This procedure will be used to ensure completion of corrective action items by tracking the date of completion; the individual assigned the corrective action, and issuinge-mailtothose whohavegonebeyondtheassignmentcompletiondate.

NEAR- MISS INCIDENT: An event (i.e. slip, trip, weight shifting) enhanced by a hazard which could have resulted in a personal injury, plant or property damage, or a fire or explosion. Near miss incidents should also be reported and investigated. These incidents often serve as warnings that more serious consequencescouldhaveresulted. Preventingrecurrenceisthereforestillimportant.

OSHA: Occupational Safety and Health Administration.

ROOT CAUSE: The most basic cause(s) that can reasonably be identified and that management have control to fix.

SERIOUSINJURY:AnoccupationalinjuryorillnessresultinginLostWork,RecordableMedicalAid,two(2)ormore employees from a single incident, or an injury or illness as deemed serious by the EHST Director.

INCIDENT REVIEW FACILITATOR: The facilitator will be someone who has been formally trained in incident investigation.

EMPLOYEE: Any employee involved in a work-related accident has the following responsibilities:

a. Seek medical attention, as soon as practical.

b. Not place themselves or others at risk of injury.

c. Report the incident immediately to hisor hersupervisor.

d. Complete the Incident Report Form.

e. Ensuring management and EHS Department is kept informed of current conditions.

f. Cooperate in any investigation that may follow the accident or incident.

g. Participateinthedevelopmentofappropriateriskcontrolmeasurestopreventrecurrenceof similar incidents.

h. Useriskcontrolmeasuresasrequiredandanyotheractiontaken,whichisdesignedtoprotecthealth and safety.

i. Temporary labor personnel will be directed to report all incidents to include near miss and injuries tohis/her Southeast Building Supply Interests supervisor immediately Additional information is contained in Chapter2.3EHSmanual.

j. Contracted employees will be directed to report all incidents to include near miss and injuries to his/her Southeast Building Supply Interests supervisor immediately Additional information is contained in Chapter2.3EHSmanual.

MANAGERS AND SUPERVISORS: The supervisor’s primary responsibilities when an incidents or accidentoccursareasfollows:

a. Implement this procedure in their area of responsibility and accountability.

b. After immediate rescue, actions to prevent further loss should occur. For example, maintenancepersonnel shouldbesummonedtoassessintegrityofbuildingsandequipment,engineeringpersonneltoevaluate theneedforbracing ofstructures,and special equipment/response requirementssuchassaferendering ofhazardousmaterialsorexplosivesemployed.

c. Investigating the cause of the incident or accident since he/she is most familiar with the hazards and precautionsofthetask,as wellasthetrainingandcapabilitiesoftheinjuredworker.

d. See that the employee receives prompt medical treatment and/or first aid as necessary.

e. Assist in the arrangement of transportation to a certified occupational health medical facility for the injured employee.

f. Escort the injured employee to the certified occupational health medical facility.

g. Have the employee drug and alcohol tested.

h. Immediately notify EHS Department and the Claims Administrator of the accident or incident.

i. Initiate an investigation to determine the cause(s) of the Incident.

j. Take pictures of the incident (if applicable).

k. Secure the site (if applicable).

l. Gather information.

m. Complete the “Incident Report Form” and provide a preliminary report on the facts of the incident andsend totheEHSDepartmentandClaimsAdministratorwithintwenty-four(8)hours.

n. Commence an internal investigation using the all related documentation as soon as practicable after the incident but within 8 hours involving: Manager, Supervisor, EHS, employee, any other relevant personnel.

o. Initiateimmediatecorrectiveactions.

p. Collect incident information and track to completion all corrective actions arising from an incident.

q. Implement identified risk control measures to prevent recurrence of incidents.

r. Verify that each has been investigated and that all corrective actions have been completed.

ENVIRONMENTAL HEALTH & SAFETY (EHS) DEPARTMENT: The EHS Department primary responsibilities when an incidents or accident occurs are as follows:

a. Review all incident investigation reports, maintain the documentation, and evidence for all incident investigations,anddistributeextractsofthatinformationtootherdepartmentsorfor incident prevention purposes. Evidence such as people, positions of equipment, parts, and papers must be preserved, secured, andcollectedthroughnotes,photographs,witnessstatements,flagging,andimpoundmentofdocuments andequipment.

b. Initial identification of evidence immediately following the incident might include a listing of people, equipment, and materials involved and a recording of environmental factors such as weather, illumination,temperature,noise,ventilation,etc.

c. Shall maintain an incident reporting system that is designed to collect incident information and track to completion allcorrectiveactionsarising fromanincident.

d. Maintain the Incident Reporting and Investigation Policy.

e. Provide administrative and technical support to the application of the incident investigation process asrequired.

f. Act as an advisory capacity to ensure compliance with corporate policy and legislated requirements.

g. Facilitate communication of critical or significant information as defined in the incident investigationprocess.

h. Monitor the incident management process to ensure the root causes are identified and adequate measuresare implementedtopreventrecurrence.

i. Assist in making appropriate recommendations to prevent a recurrence of the accident or incident.

j. Report serious accidents, when required to OSHA.

ADMINISTRATOR: When an occupational injury or illness is reported, the Claims Administrator will havethefollowingresponsibilities:

a. Files the necessary claims, reports, and work with the Human Resources Department as necessary.

b. Contact and work with insurance company’s claim adjusters or administrators.

c. Cooperates in investigating the cause of the incident or accident.

d. Followsthemedicalprogressoftheworkerwiththetreatingphysician,includingreturnto workdates, andlightdutyassignmentswhennecessary.

e. Tracks the injuries/illnesses causing lost or restricted work days.

f. Advises the supervisors of any physical limitations, modification, or restriction the employee may have upon return to work.

g. Provide the injured employee with the appropriate Workers’ Compensation forms as required by State RegulatoryCompensationLaws.

h. Maintains the required government postings and records (OSHA 300 Log) on reported injuries and illnesses.

i. Return,withinthedayofinjury/illness,ifpractical.Acopyofthecompletedmedicalreleaseto full duty form a certified occupational physician is required.

j. Ifinjury/illnessinvolves aday away fromwork, a completed medicalreleaseform a certified occupationalphysicianisrequiredpriortoreturningtowork.

k. If injury/illness involves restricted work days, follow all directions given from certified occupationalphysician.

Athoroughinvestigationwillrevealtherootcauseoftheincident.Theincidentinvestigationprocess entails:

a. Collection of facts.

b. Analysis of the facts to determine what happened:

• What was the immediate cause of the incident, accident or near miss?

• What other (contributing) causes may have played some part in setting up the accident?

• What employee actions or workplace conditions may have led to those causes?

• Were safe work procedures established, and were they adequate?

• Was adequate training provided on the procedures?

• Were the procedures regularly implemented and enforced?

c. Determine the contributing root cause.

d. Ask open ended questions.

e. Development of corrective actions.

f. Communication of lessons learned as appropriate.

The report should not unduly assess blame but rather spell out the specific corrective measures needed to prevent similaraccidentsfromhappening.Thesupervisor’sinputisparticularlyimportanttoidentify appropriateactions topreventasimilarinjury.

Forward copies of the investigation the Claims Administrator and EHS Department, so they can track and helpensure the implementation of corrective actions. Finally, management or other responsible party must ensure that the correctiveactionscalledforinthereportareimplementedinatimelyfashion.

The primary goal of an accident investigation is to prevent recurrence. Share the lessons learned from the accident investigationwithothersperformingsimilaroperationssotheymightimplementtheIdentified corrective actions.

Thoroughinvestigationofallaccidentsandnearmisseswillhelpyouidentifycausesandneeded corrections, and can helpyoudeterminewhy accidents occur, wherethey happen, and any accident trends.Suchinformation iscriticaltopreventingandcontrollinghazardsand potentialaccidents.

REPORTING FATALITIES AND MULTIPLE HOSPITALIZATION INCIDENTS - Within 8 hours of the death of any employee from a work-related incident or the in-patient hospitalization of 3 or more employees as aresult of a work-related incident, Rain for Rent must report the fatality/multiple hospitalization by telephone or in persontoOSHA.

WHERETOREPORT -GenerallysuchincidentstotheOSHAAreaOfficethatisnearesttotheincident.Iftheoffice is closed you must report the incident to OSHA’s toll-free central telephone number at 800-321- 6742.

CONTENTS - In such instances, Southeast Building Supply Interests should report the following information to OSHA:

• The name of the establishment

• The location of the incident

• Thetimeoftheincident

• The number of fatalities or hospitalized employees

• The names of any injured employees

• The name of the employer’s contact person and phone number

• Abriefdescriptionoftheincident.

FATALITY BY HEART ATTACK - Southeast Building Supply Interests must report fatalities that were caused by heart attack while at the work place.

FATALITY/HOSPITALIZATION THAT OCCURS AT A LATER DATE - If the fatality or multiple hospitalizations occurs within 30daysof a workplace incident, Southeast Building Supply Interestsmust report toOSHA under these provisions.Otherwisethereisnoobligationtoreport.

PROVIDING RECORDS TOOSHA - Upon request, Southeast Building Supply Interests must provide copies of the records maintained under section 1904 to OSHA and other appropriate government representatives within 4 business hours.

ANNUAL OSHA INJURY AND ILLNESS SURVEY - If Southeast Building Supply Interests receives OSHA’s annual surveyform, SoutheastBuilding Supply InterestsmustcompleteitandreturnittoOSHA.

INVESTIGATIVE REPORT – Complete this section of the form for all incidents, accidents or near miss. Then complete the appropriate following sections:

• EMPLOYEE INJURY - When you, as an employee of the company, incur any injury to yourself while working.Areportmustbemadeevenifthereisnoapparentinjury.

• INCIDENTS INVOLVING EQUIPMENT, PROPERTY DAMAGE, and SPILL, THEFT or VANDALISM –Damage, theft or vandalism of equipment or company property whether leased or owned. Any spill, whetheratoneofourfacilities,customers,orinroute.

• MOTORVEHICLE-Whenyouaretheoperatorofacompany-ownedvehicle,rentedvehicleoroperating yourownvehicleoncompanybusinessonpublicorprivateproperty,andyourvehiclemakes contact with another vehicle or property. A report must be made even if there is no apparentdamageorinjury.

• EMPLOYEE/WITNESS STATEMENT FOR INCIDENT OR INJURY - Employee or witness complete this section for all incidents.

All personnel who have the role and responsibility for incident reporting will be trained in the requirements of this program by completing the online Incident Investigation training. The training covers incident root cause, reporting,investigationandrecordingprocedures.

All employees are responsible for adhering to this policy. Failure to comply with these procedures may be groundsfor disciplinaryaction.

The following shall be maintained for five years at the Corporate Headquarters:

Contact the EHS Dept. immediately (615) 752-0700. Please complete within 24 hours of incident. Complete entire first section, then appropriate following section.

Date of incident/injury : Time of incident/injury :

Person reporting incident Injury ☐ Vehicle ☐ Property/Equipment Damage ☐ Theft/Vandalism ☐ Spill ☐

Where did the incident occur: Sun Solar Location ☐ Customer ☐ In Transit ☐ Other

Address where incident/injury occurred:

Describe the events that led up to the incident:

Full description of incident:

Cause of incident:

Corrective Action:

Witness name: Phone #

Witness description of incident:

Witness name: Phone #

Witness description of incident:

➔ A controlled substance and alcohol test will be given immediately after all incidents with property damage.

Date Drug & Alcohol test given:

Estimate of Damages $

Pictures Yes No

Managers signature Date

Injured Employee’s Full Name:

Employee Number:

Employee’s Address:

Date Hire: Date of Birth:

Phone Number:

# Of days per week:

Job Title:

Employment Status: Full Time Part Time Temporary Time Began Work: AM PM # Of hours worked per day:

Gender: Male Female

Employee’s Supervisor: Date Notified Supervisor:

Was employee injured on the job: Yes No

# Of Days Expected to be off work: Last Date Worked: 1St Day Missed:

Was Employee’s Pay Continued: Yes No Has Employee Returned to Work: Yes No

Was Safety Equipment Provided: Yes No N/A What Was Provided:

Was it in use at the time of the injury: Yes No

Did safety equipment preform as designed: Yes No

Was a machine part involved: Yes No Describe:

Were others involved in the accident/incident: Yes No

Names:

Type of Injury (cut, bruise, ect.):

Part of body (right hand, back, ect.):

Was 1st Aid Given on Site: Yes No If Yes, what treatment:

Did employee receive medical treatment: Yes No Where:

Clinic/ hospital address:

Was employee hospitalized: Yes No

Phone #:

Description of equipment involved: Equipment #: Nature of Incident:

Customer’s Name & Address:

Date of contact:

Party responsible for loss:

Theft: Equipment Failure: Damage to Equipment: Damage to others by equipment:

Amount:

Did equipment cause injury / damage to others: Yes No

Describe:

If Theft, list items / $ Value (use additional page if necessary):

EMPLOYEE / WITNESS STATEMENT FOR INCIDENT OR INJURY

Your name: Address:

Phone No.

Are you the injured person? or witness ? Your job title:

An incident investigation is not performed in order to place blame, but to discover all possible causes sothat recurrencemaybeprevented.

Describewhatyouweredoingbefore,during,andaftertheincidentoccurred,andwhatyousaworheard:

Date of report: Full Name (Print)

Signature:

The purpose of this policy is to present a summary of the basic elements for a first-aid program at the workplace. The first priority in the treatment of an injured employee is to obtain proper medical attention.In anextreme emergency,immediatefirst aid may benecessary.Those elements include:

• Identifyingandassessingtheworkplacerisksthathavepotentialtocauseworkerinjuryorillness.

• Designing and implementing a workplace first-aid program that:

• Aims to minimize the outcome of accidents or exposures

• Complies with OSHA requirements relating to first aid

• Includes sufficient quantities of appropriate and readily accessible first-aid supplies and first- aid equipment,suchasbandagesandicepacks.

Assigns and trains first-aid providers who:

• Receive first-aid training suitable to the specific workplace

• Receive periodic refresher courses on first-aid skills and knowledge.

In the event we are working in an area where a medical facility is not reasonably accessible to provide treatmenttotheinjured,apersonwithavalidcertificateinfirstaidtrainingwillbeavailableatthejobsite.First Aid Training should be American Red Cross or American Heart Association, ortheirequivalent.Employees areencouragedtobeCPRtrainedalso.

The first aid kits must be inspected by the location manager The supplies must be adequate, with necessary supplies that reflect the kinds of injuries that occur, and must be stored in each work area where they are readily available for emergency access. The contents of the first-aid kit shall be inspected monthly by the safety coordinator. Update inventory list to ensure that the expended items are promptly replaced. The contents of the first-aid kit shall be arranged to be quickly found and remain sanitary. First-aid dressings shall be sterile in individually sealed packages for each item. The minimum first-aid supplies will be determined by the risk associated with work activities. First aid kits should be visible or a sign should be displayed indicating its storage location. Drugs, antiseptics, eyeirrigationsolutions,inhalants,medicines,orproprietary preparations shallnotbeincludedin first-aidkits(29CFR1910.151(b).

Firstaid kitsshallconformtotherequirementsofANSI Standard Z308.1.and containatleast the following items or an approved equivalent. First aid kit contents may be substituted to meet unique job specific requirements whenapprovedby aqualifiedperson.(7-1-97)

First aid kits shall be regularly inspected to ensure completeness and to check the condition of the contents. (7-1-97)

Itemsotherthanfirstaidmaterialsshallnotbestoredinthefirstaidkit.(7-1-97)

Firstaidkitsshallbemaintainedattheten(10),sixteen(16),twenty-four(24),orthirtysix(36)unitlevel. (71-97)

Ten (10) package kit: one (1) package adhesive bandages, one inch (1") (sixteen (16) per package); one (1) package bandage compress, four (4) inch (one (1) per package); one (1) package scissors and tweezers (one (1) each per package); one (1) package triangular bandage, forty (40) inches (one (1) per package); one (1) package antiseptic soap or pads (three (3) per package); one (1) micro shield, one (1) pair latex gloves; four (4) packages of choice when approved by a qualified person. (7-1-97)

Sixteen (16) package kit: one (1) package absorbent gauze, twenty-four (24) inches x seventy-two (72) inches (one (1) per package); one (1) package adhesive bandages, one (1) inch (sixteen (16) per package); two (2) packages bandage compresses, four (4) inches (one (1) per package); one (1) package eye dressing (one (1) per package); one (1) package scissors and tweezers (one (1) each per package); two (2) packages triangular bandages, forty (40) inches (one (1) per package); one (1) packageantiseptic soap orpads (three (3) per package); one (1) micro shield, one (1) pair latex gloves; six (6) packages of choice when approved byaqualifiedperson.(7-1-97)

Twenty-four (24) package kit: two (2) packages absorbent gauze, twenty-four (24) inches x seventy- two (72) inches (one (1) per package); two (2) packages adhesive bandages, one (1) inch (sixteen (16) per package); two (2) packages bandage compresses, four (4) inches (one (1) per package); one (1)packageeyedressing(one(1)perpackage);one(1)packagescissorsandtweezers(one(1)each perpackage); six (6) packages triangular bandages (one (1) per package); one (1) package antiseptic soap or pads (three (3) perpackage);one(1)microshield,two(2)pairlatexgloves;eight(8) packagesofchoicewhenapproved byaqualifiedperson.(7-1-97)

Thirty- six (36) package kit: four (4) packages absorbent gauze, twenty-four (24) inch x seventy-two inch(one (1) per package); two (2) packages adhesive bandages, one (1) inch (sixteen (16) per package); five (5) packagesbandagecompresses,four(4)inch(one(1)perpackage);two(2) packageseyedressing(one(1) perpackage);eight(8)packagestriangularbandages,forty(40)inches (one (1) per package); one (1) package antiseptic soap or pads (three (3) per package); two (2)microshields,three(3)pairlatexgloves;one(1)packagescissorsandtweezers;eleven(11)packagesof choicewhenapprovedbyaqualifiedperson.(7-1-97)

Always call 911 to obtain qualified medical assistance for persons who require emergency medical treatment. In areas where 911 is not available, the numbers of physicians, hospitals or ambulances shall be conspicuously posted by the safety coordinator. If you are trained and provide first aid, direct or transport the injured person to a medical facility for further evaluation. First aid is emergency care provided for injury or suddenillnessbeforeemergencymedicaltreatmentis available. The first-aid provider in the workplace is someone who is trained in the delivery of initialmedical emergency procedures, using a limited amount of equipment to perform a primary assessment andinterventionwhile awaiting arrival of emergencymedical service (EMS) personnel.

Suddeninjuriesorillnesses,someofwhichmaybelife-threatening,occuratwork.TheOSHAFirst Aidstandard (29CFR1910.151)requirestrainedfirst-aid

providers at all workplaces of any size if there is no “infirmary, clinic, or hospital in near proximity to the workplace which is used for the treatment of all injured employees.” In addition to first-aid requirements of (29 CFR 1910.151), OSHA standards also require training in cardiopulmonary resuscitation (CPR) because sudden cardiac arrest from asphyxiation, electrocution, or exertion may occur.

If an employee is expected to render first aid as part of his or her job duties, the employee is covered by the requirements of the Occupational Exposure to Blood borne Pathogens standard (29 CFR 1910.1030). This standardincludesspecifictrainingrequirements.

• Do not dispense or administer any medications, including common pain relievers.

•Do not put any ointments or creams on wounds or burns; use ice, cold pack or cold water.

• Wear examination gloves and eye protection when rendering assistance for any situation involvingcontactwithbloodorotherbodily fluids.

Thefirstpriorityinthetreatmentofaninjuredemployeeistoobtainpropermedicalattention.Inanextreme emergency immediate first aid may be necessary. The following are common first aid treatments for the various ailments listed.

Symptoms: Nausea,dizziness,unconscious,lipsorearlobesarebluebreathinghasstopped,bizarrebehavior.

Treatment: Remove to fresh air, give rescue breathing.

BLEEDING

Symptoms: Brightredbloodspurtingfromwound.

Treatment: Directpressureoverwoundtocontrolbleeding.

Symptoms: Darkredbloodflowingsteadily.

Treatment: Applysterilebandagefirmlyoverwound.Donotbreakbloodclot.

BLEEDING

Symptoms: Faintness,paleface,thirst,sighing,aweakrapidpulse. Treatment: Lay thevictimdown,keepwarmandquiet.Callanambulance.

Symptoms: Caused by exposure to heat, or dry caustic chemicals, or acids, or alkalis.

Treatment: Cold applications for minor burns. For liquid chemical burns, wash affected area with large amounts of water, usually for 15 minutes. For dry chemicals, carefully brush or blow away chemicals, then washareawithlargeamountsofwater.

Symptoms: Compareinjuredtouninjuredlimb,longerorshorter?Lookfordeformityatthejoint.

Treatment: Supportalonglinesofdeformity.Donotattempttoreposition.

Symptoms: Unconscious, breathing stopped. Burn at the point of contact.

Treatment: Shutoffelectricityorinsulateyourselffromanelectricalsource,thenrescuethevictim.Giverescue breathingand/orCPRasnecessary.

Symptoms: Face pale. Eyelidsdroop. Cold sweat. Aweak, rapid pulse.

Treatment: Laythevictimdown,loosenclothing.Keepwarmandquiet.Checkforotherinjuriesifpersonfalls.

Symptoms: Pain, swelling, tenderness, bruising.

Treatment: Support the limb above and below fracture. Apply well-padded splints if injured must be moved.

Symptoms: Open wound, bleeding, bone protruding.

Treatment: Bandagewound.Applysplintsinlineofdeformityifinjuredmustbemoved.Donotstraighten fracture.

Symptoms: Bleedingmaybenoticedfromeyes,nose,ormouth.Bloodorserumfromears.Swellingofhead wound.

Treatment: Elevatehead.Laybandageoninjury,avoidingpressureonthewound.Nevergiveastimulant. Check the victim periodically for a state of consciousness.

Symptoms: Coldwetskin,dizziness, headaches,nausea,weakness.

Treatment: Lay the victim down, loosen clothing. Keep cool. Carefully give fluids.

Symptoms: Sharp stinging pain. Faint feeling. Sick to stomach. Lump in groin.

Treatment: Place injured on his back, elevate knees. Apply cold pack to lump.

Symptoms: Facepale,eyelidsdroopy,skincoldandclammy.Unconscious.Treatment: Lay thevictimdown,elevatefeet.Loosenclothing.Keepwarmandquiet.

Symptoms: Pain, swelling, a pinpoint wound.

Treatment: Apply restricting band 3 inches above wound and not too tight. If alone, walk slowly for help. Be calm. Don't squeeze or cut the wound.

1. If you are sick and have symptoms of a Communicable Disease (cough, sneezing, sore throat or fever),we askthatyoustayhomeuntilyouarebetter.

2. All employees who have symptoms of acute respiratory illness are recommended to stay home andnot cometoworkuntiltheyarefreeoffever,signsofafever,andanyothersymptomsforatleast24hours, withouttheuseoffever-reducingorothersymptom-alteringmedicines(e.g.coughsuppressants). Employeesshouldnotifytheirsupervisorandstayhomeiftheyaresick.

3. Vehicles will be routinely disinfected with supplied disinfectant to wipe down

4. Personal Protective equipment should not be shared between employees, if you need additional PPEcontact yoursupervisor.

5. All employees are asked to use extreme care and appropriate personal hygiene

◦ Cover mouth with arm or tissue when coughing or sneezing

◦ Wash hands with Soap and water for at least 20 seconds. Use alcohol-based hand sanitizer whenavailable.

◦ Wipe down personal items on a regular basis

◦ Refrain from touching face

◦ Keep Social Distancing from each other