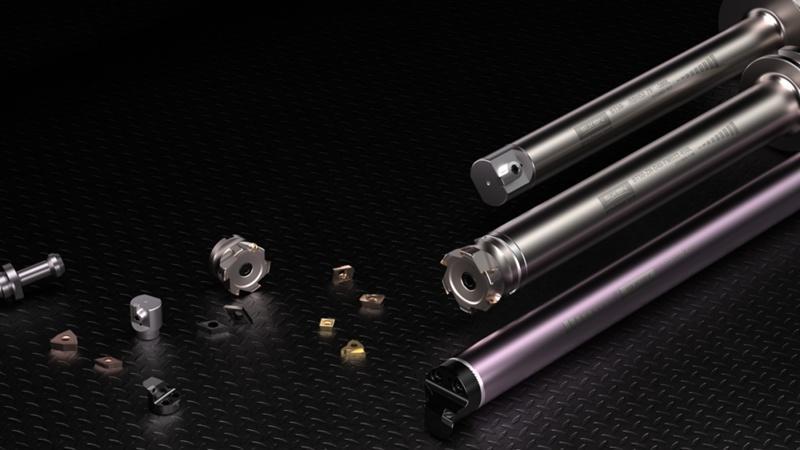

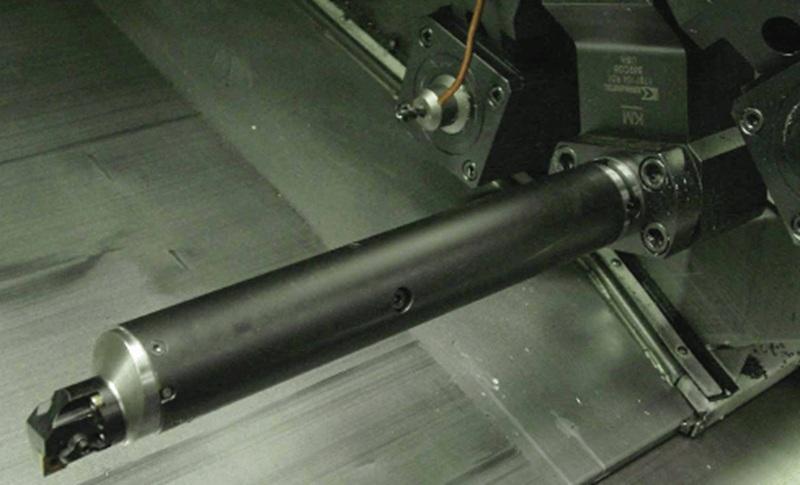

VibrationDampedMachiningTools: EnhancingPrecisionandEfficiency

Intheprecisionmachiningindustry,controllingvibrationiscriticaltoensuring high-qualitysurfacefinishes,maintainingdimensionalaccuracy,andextendingtool lifeVibrationdampedmachiningtoolsaredesignedtoaddressthesechallenges, makingthemessentialforanymachiningoperationaimingforsuperiorresults.Inthis article,wewillexploretheimportanceofvibrationdampedmachiningtools,their benefits,andhowHalnn,aleadingnameintheindustry,offersinnovativesolutionsto meettheseneeds

Relatedpost:https://www.halnnpcd.com/industrynews/895.html

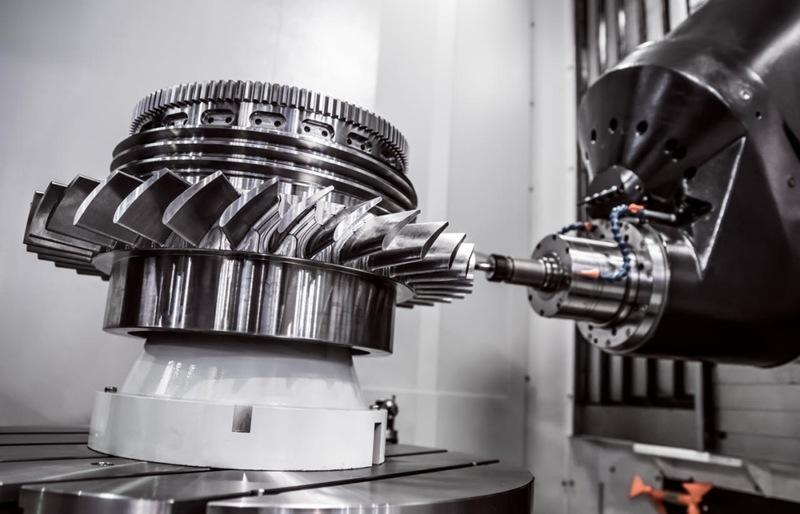

TheImportanceofVibrationDampinginMachining

Vibrationduringmachiningoperationscanleadtoseveralissues,including:

PoorSurfaceFinish:Uncontrolledvibrationsresultinroughsurfaces,which mayrequireadditionalfinishingoperations,increasingproductiontimeandcosts

DimensionalInaccuracy:Vibrationscancausedeviationsfromspecified dimensions,leadingtopartsthatdonotmeetqualitystandards.

ToolWear:Increasedvibrationsacceleratetoolwear,reducingthelifespanof cuttingtoolsandincreasingreplacementcosts.

ReducedEfficiency:Vibrationscanlimitcuttingspeedsandfeeds,reducing overallmachiningefficiencyandproductivity.