WhatisCBNToolHardness?

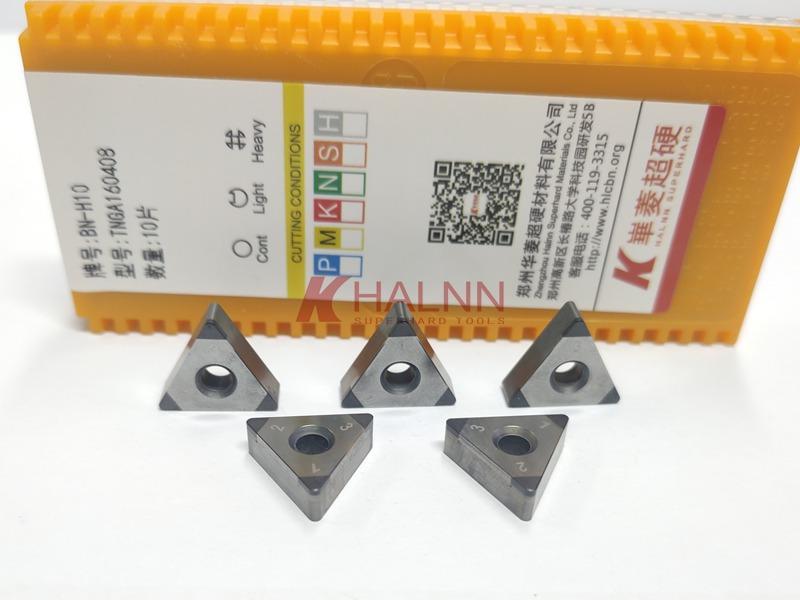

CBNtoolhardnessreferstotheresistanceofcubicboronnitride materialstodeformationandwearduringmachiningprocesses.This propertyiscrucial,asitdirectlyaffectsthetool'scuttingperformance, durability,andoverallefficiencyCBNtoolspossesshardnesslevelsthat rivaldiamond,makingthemsuitableforhigh-performanceapplications

ImportanceofHardnessinCBNTools

1.WearResistance:TheinherenthardnessofCBNtoolsallowsthem towithstandsignificantwearandtear,ensuringthatthecuttingedges remainsharpoverextendedperiods.Thisreducestoolreplacement frequencyandassociatedcosts.

2.CuttingEfficiency:Hardertoolscanoperateathighercuttingspeeds withoutcompromisingperformance,resultinginincreased productivityandmoreefficientmanufacturingprocesses.

3.PrecisionandSurfaceFinish:OptimalhardnessenablesCBNtools tomaintainsuperiorsurfacefinishesandprecisedimensions,essential forhigh-qualitymachiningapplications.

MeasuringCBNToolHardness

CBNhardnessismeasuredusingseveralstandardizedmethods:

VickersHardnessTest:Thistestusesadiamondindentertocreate anindentationunderaspecificload,withthesizeoftheindentation indicatinghardness.

RockwellHardnessTest:Thismethodmeasuresthedepthof penetrationofanindenterunderadefinedload,providingquickand directhardnessreadings.

MohsScale:Althoughlesscommoninindustrialsettings,thisscale ranksmaterialsbasedontheirscratchresistance,offeringageneral understandingofhardness.

FactorsAffectingCBNToolHardness

SeveralelementscaninfluencethehardnessofCBNtools:

MaterialComposition:Themixofrawmaterialsandadditivesused inproductionsignificantlyimpactshardnesslevels.

ManufacturingTechniques:Advancedtechniques,suchas high-pressuresintering,optimizethestructuralintegrityofCBNtools,

enhancingtheirhardness.

TemperatureandOperatingConditions:Theconditionsduringuse, includingcuttingspeedandcoolingmethods,canaffecttheeffective hardnessofthetools.

Whencomparedtoothercuttingtoolmaterialslikecarbideand high-speedsteel(HSS),CBNstandsoutduetoitssuperiorhardnessThis characteristicmakesCBNtoolsparticularlyeffectiveformachining hardenedsteelsandotherchallengingmaterials.Whilecarbidetoolsare versatile,theymaynotmatchthewearresistanceandlongevityoffered byCBNtoolsindemandingapplications.

CBNToolHardnessvs.OtherMaterials

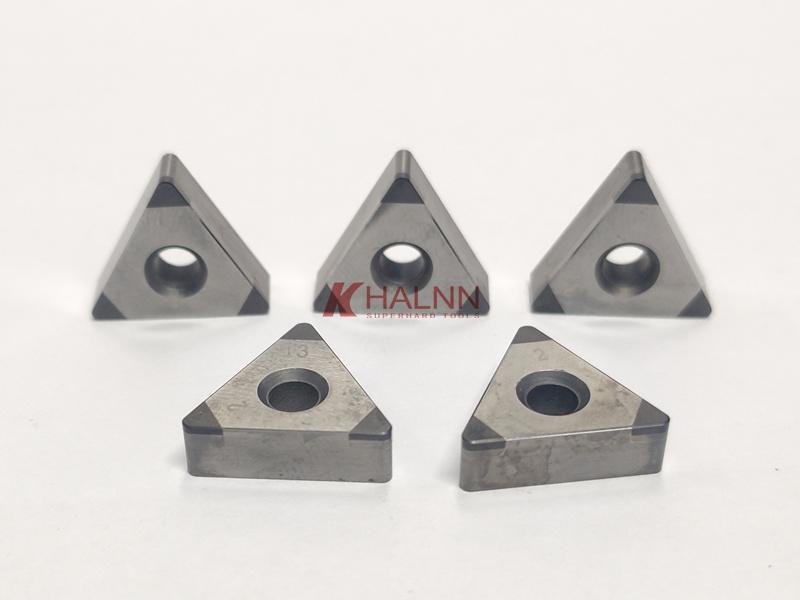

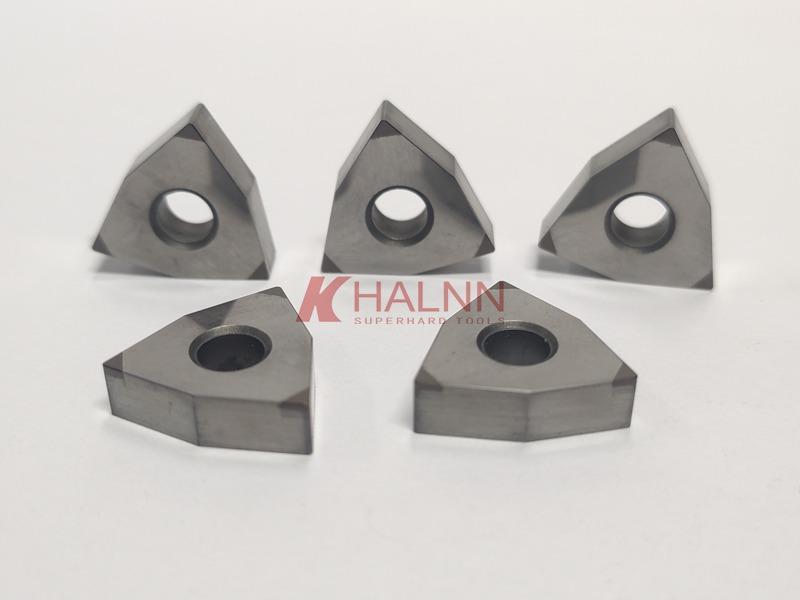

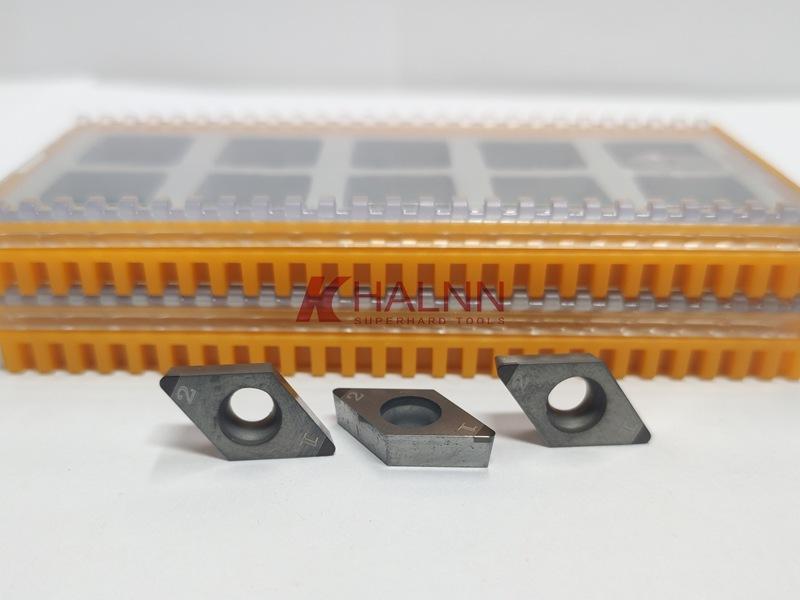

ApplicationsofCBNToolsBasedonHardness

CBNtoolsareparticularlybeneficialinhardturningandprecision machiningsectors,suchasaerospace,automotive,andtool manufacturing.Theabilitytoefficientlyhandlehardmaterialsallowsfor improvedtoollifeandoperationalefficiency,makingCBNtoolsa preferredchoiceinvariousindustries

Conclusion

CBNtoolhardnessisacriticalfactorinfluencingtheperformanceand longevityofcuttingtoolsinmachiningapplications.Byunderstanding theimportanceofhardnessandhowitcanbemeasuredandinfluenced, userscanmakeinformeddecisionsabouttoolselectionCBNtoolsoffer exceptionaladvantagesintermsofwearresistance,cuttingefficiency,and precision,makingthemaninvaluableassetinhigh-demandmachining environments.

Ourwebsite:https://www.halnn-group.com/

Email:halnntools@halnn-group.com

Whatsapp/Wechat:+8613271562251