Halnn:TheUltimateSolutionforMachining

SuperalloyswithCeramicInserts

Superalloys,knownfortheirexceptionalstrength,hightemperatureresistance,and corrosionresistance,arewidelyusedinaerospace,energy,andautomotiveindustries

However,theiruniquepropertiesalsomakethemextremelychallengingtomachine usingconventionalcuttingtoolsToaddressthesechallenges,Halnnoffers highperformanceceramicinsertsspecificallydesignedformachiningsuperalloys, providingsuperiorwearresistance,extendedtoollife,andincreasedproductivity

Relatedpost:https://halnn-cuttingtools.com/?ceramic-tools/superalloy.html

WhyChooseCeramicInsertsforSuperalloy Machining?

Superalloys,suchasInconel,Hastelloy,andWaspaloy,aredifficulttocutduetotheir highhardness,workhardeningtendency,andpoorthermalconductivity.Traditional carbidetoolsstrugglewithrapidwearandhighcuttingforces,leadingtoincreased machiningcostsandfrequenttoolchanges.

Halnn’sceramicinsertsovercomethesechallengeswiththefollowingadvantages: SuperiorHeatResistance:Capableofwithstandingextremetemperatures,reducing theneedforcoolantandpreventingthermaldegradation.

ExtendedToolLife:Highhardnessandoxidationresistanceensurelongerinsert durabilitycomparedtocarbidetools.

HigherCuttingSpeeds:Allowsforsignificantlyhigherspeeds,improvingmachining efficiencyandreducingproductiontime.

ReducedCuttingForces:Minimizestooldeflectionandensuresprecisionin finishingoperations

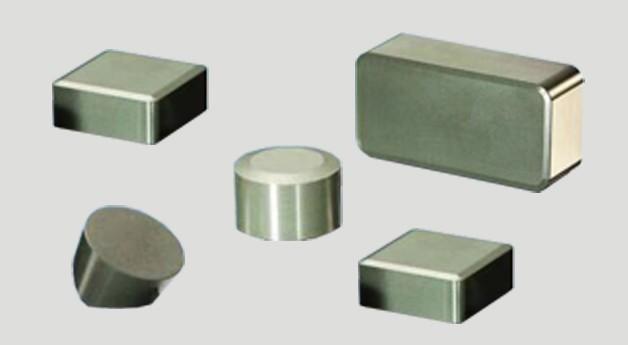

Halnn’sAdvancedCeramicInsertSolutions

1.Whisker·ReinforcedCeramicInserts

Theseinsertsincorporatewhiskerreinforcementtechnology,enhancingfracture toughnessandallowingforaggressivecuttingconditions.Idealforheavyroughing andinterruptedcutsinsuperalloymachining

2.SiliconNitrideCeramicInserts

Engineeredforexceptionalthermalstabilityandhigh·speedmachining,theseinserts arebestsuitedforcontinuouscuttingofsuperalloys,deliveringanexcellentbalance betweenwearresistanceandtoughness

3.CoatedCeramicInserts

Withaspecializedcoating,theseinsertsprovideenhancedresistancetobuilt·upedge formationandoxidation,ensuringconsistentperformanceinprolongedmachining operations

ApplicationsofHalnnCeramicInsertsin

SuperalloyMachining

·AerospaceIndustry:High·precisionmachiningofturbineblades,enginecomponents, andstructuralparts

·EnergySector:Processingofheat·resistantalloysusedinpowergenerationandgas turbines.

·AutomotiveIndustry:Manufacturingofhigh·performanceenginepartsand turbochargercomponents.

MaximizingPerformancewithHalnn’sCeramic

Inserts

ToachievethebestresultswhenmachiningsuperalloyswithHalnnceramicinserts, considerthefollowingmachiningparameters:

·Usehighcuttingspeedstotakeadvantageofceramic’sthermalresistance

Employstablemachinesetupstominimizevibrationsandensureconsistent performance

Optimizefeedratesanddepthofcuttomaximizeproductivitywithout compromisingtoollife

·Implementdrymachiningorminimallubricationtoenhanceinsertperformanceand reducecontaminationrisks

Conclusion

Whenitcomestomachiningsuperalloys,Halnn’sceramicinsertsprovidetheultimate solution,deliveringunmatchedefficiency,durability,andprecision.Withadvanced materialtechnologyandtailoreddesigns,Halnnensuressuperiorperformancein demandingapplications.

DiscoverhowHalnnceramicinsertscanrevolutionizeyourmachining operationscontactustodaytolearnmoreaboutourcutting·edgesolutions!