Halnn:TheUltimateGuidetoGLC®CBN GrindingWheel

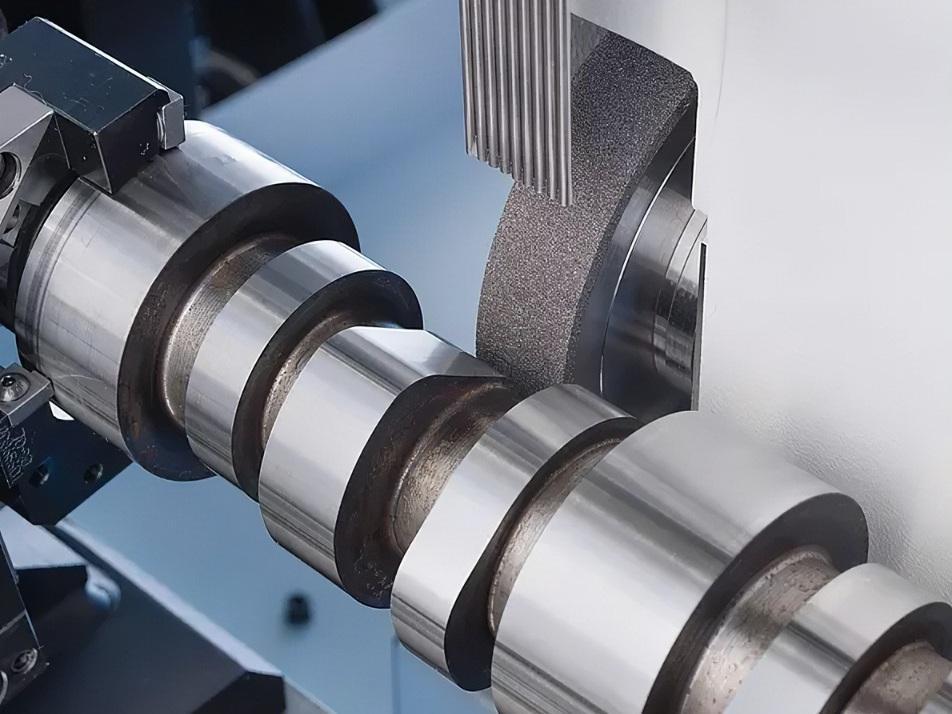

Grindingisacriticalprocessinmodernmanufacturing,especiallywhenit comestomachininghard-to-processmaterialsHalnn,aleaderin superhardcuttingtools,presentstheGLC®CBNGrindingWheela revolutionarysolutiondesignedtoenhancegrindingefficiencyand precision.Thisarticledivesdeepintothefeatures,applications,and benefitsoftheGLC®CBNGrindingWheel,showcasingwhyit’sthe ultimatechoiceforhigh-performancegrinding.

Related post: https://halnn-cuttingtools.com/?cbn-tools/cbn-grinding-wheel.html