TheImportanceofVibrationDampingTools

inModernMachining:AFocusonHalnn

Intheworldofprecisionmachining,thesignificanceofmaintainingstabilityand accuracycannotbeoverstatedVibrationdampingtoolshaveemergedasacrucial innovation,addressingoneofthemostpervasivechallengesinmachiningvibration. Thisarticledelvesintotheroleofvibrationdampingtools,withaspecialfocusonthe cutting-edgesolutionsofferedbyHalnn,aleadingnameintheindustry. Relatedpost:https://wwwhalnncbncom/News/IndustryNews/610html

WhatAreVibrationDampingTools?

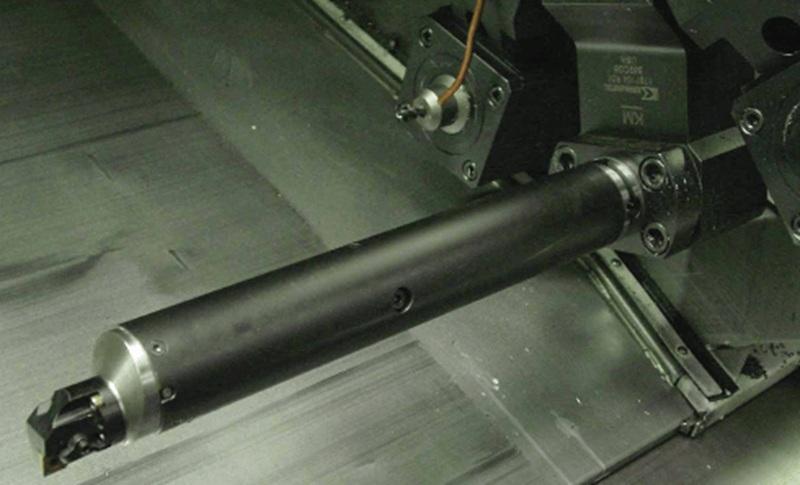

Vibrationdampingtoolsarespecializedmachiningtoolsdesignedtomitigatethe effectsofvibrationsduringcutting,milling,drilling,andothermachiningprocesses. Thesetoolsareengineeredtoabsorbanddissipatevibrationalenergy,whichis essentialformaintainingtheprecisionandqualityofmachiningoperations.

HowDoTheyWork?

Theworkingprincipleofvibrationdampingtoolsinvolvestheuseofadvanced

materialsanddesigntechniquesthatenhancethetool'sabilitytodampenvibrations Thesematerialsoftenincludecompositesandalloysknownfortheirhighdamping properties.Thedesignmayfeatureinternaldampingmechanismsthateffectively reducetheamplitudeofvibrations,ensuringsmootherandmorestablemachining.