UnderstandingCBNToolCooling

CBNtoolcoolingreferstothemethodsemployedtomanageheat generatedduringthecuttingprocess.Propercoolingisvitalfor preventingthermalshock,extendingtoollife,andmaintainingconsistent machiningqualityAsCBNtoolsoperateathighspeedsandendure intensepressure,therightcoolingstrategycansignificantlyimpact overallperformance

TheImportanceofCBNToolCooling

1HeatManagement:Duringmachining,frictiongeneratesheatthat canleadtotoolwearandthermaldamage.Effectivecooling dissipatesthisheat,ensuringtoolsoperatewithinoptimaltemperature

ranges.

2.ToolLongevity:Propercoolingtechniquescanextendthelifeof CBNtoolsbyreducingwearratesandpreventingoverheating, allowingforincreasedproductionefficiencyandreduceddowntime.

3.WorkpieceQuality:Excessiveheatcannegativelyaffectthe workpiece,leadingtothermaldistortionandcompromisedsurface finishes.Effectivecoolinghelpsmaintaintheintegrityofboththetool andtheworkpiece.

1.FloodCooling

Floodcoolinginvolvestheapplicationofacontinuousstreamofcoolant

directlytothecuttingarea.Thismethodeffectivelyremovesheatand lubricatesthecuttinginterface,significantlyenhancingtoolperformance. Whilefloodcoolingishighlyeffective,itmayincreasecoolant consumptionandrequiremoreextensivecleanup.

2.MistCooling

Mistcoolingutilizesafinemistofcoolant,providingefficientcooling withreducedcoolantconsumption.Thistechniqueminimizeswastewhile maintainingvisibilityduringmachiningoperations.Mistcoolingis particularlybeneficialforCBNtools,asitofferssufficientlubrication whileloweringtemperatures.

3.CryogenicCooling

Cryogeniccoolingemploysliquidnitrogentodramaticallylowerthe temperatureofboththetoolandworkpiece.Thismethodisespecially effectiveinhigh-speedmachiningenvironments,asitnotonlyreduces thermalbuildupbutalsoenhancestoollife.Cryogeniccoolinghasbeen showntosignificantlyimprovetheperformanceofCBNtoolsunder challengingconditions

4.MinimumQuantityLubrication(MQL)

MQLinvolvesdeliveringsmallamountsoflubricantdirectlytothe cuttingarea,reducingfrictionandwearThismethodisparticularly

suitableforCBNtools,asitminimizescoolantusagewhilemaintaining cuttingefficiency.MQLisaneco-friendlyalternativethatoffers significantbenefitsintermsofcostandcleanup.

BestPracticesforCBNToolCooling

TomaximizetheeffectivenessofCBNtoolcooling,considerthe followingbestpractices:

ChoosetheRightCoolingMethod:Assessyourspecificmachining requirementsandselectacoolingtechniquethatalignswithyour operationalgoals.

UseQualityCoolants:Optforhigh-qualitycoolantsdesignedfor CBNtools,ensuringtheymeetthenecessaryviscosityand

performancestandards.

RegularMaintenance:Implementaroutinemaintenanceschedule foryourcoolingsystemstoensureoptimalperformanceandprevent issuesrelatedtocoolantdegradationorsystemfailure.

Conclusion

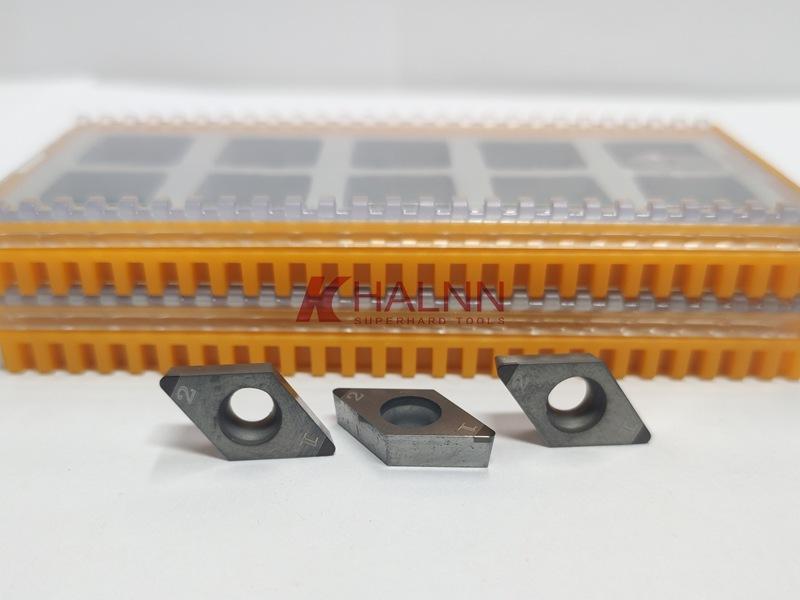

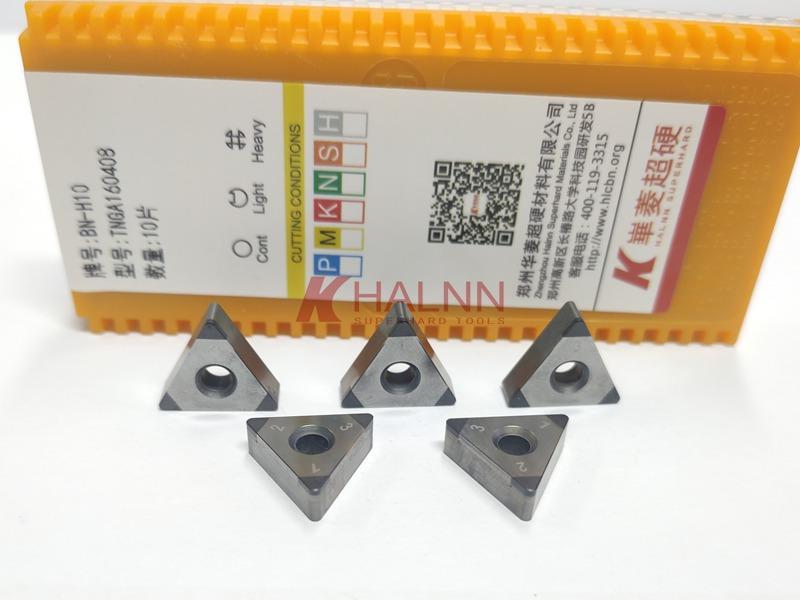

EffectivecoolingisparamountforthesuccessfuloperationofCBNtools Byunderstandingandimplementingtheappropriatecoolingtechniques, userscansignificantlyenhancetheperformanceandlongevityofHalnn CBNtools.Investinginpropercoolingstrategiesnotonlyimprovestool lifebutalsoensureshigh-qualitymachiningresults.

AtHalnn,wearecommittedtoprovidingthehighestqualityCBNtools andcoolingsolutionstailoredtomeetyourspecificneeds.Exploreour rangeofproductsanddiscoverhoweffectiveCBNtoolcoolingcan elevateyourmachiningprocesses

Ourwebsite:https://wwwhalnncbncom/

Email:halnntools@halnn-groupcom

Whatsapp/Wechat:+8613271562251