CompositionofPCDstandardinserts

PCD(PolycrystallineDiamond)insertsareengineeredusingasophisticatedprocessthatinvolves synthesizingdiamondparticlesandbindingthemtogetherwithametalmatrixThecomposition typicallyconsistsof:

DiamondParticles:Theseareultra-finediamondcrystals,oftenintherangeofnanometersto micrometersinsize.Theseparticlesareselectedfortheirhighhardnessandwearresistance.

MetalMatrix:Thediamondparticlesarebondedtogetherwithinametalmatrix,usually cobalt-basedornickel-based.Thismatrixservestoholdthediamondparticlesinplaceand providestructuralintegritytotheinsert

Themanufacturingprocessinvolvessubjectingthediamondparticlesandmetalmatrixtohigh pressureandhightemperatureconditions,allowingthemtobondtogetherinasolidmass.The resultisadense,homogeneousmaterialwithdiamondparticlesuniformlydistributed throughouttheinsert

ApplicationsofPCDStandardInserts

SomecommonindustrieswherePCDinsertsareutilizedincludeaerospace,automotive,mold anddie,woodworking,andelectronicsmanufacturing.Theseinsertsarefavoredfortheirability todeliverhighprecision,excellentsurfacefinish,andextendedtoollife,makingthem indispensableinmodernmachiningoperations.

SpecificMachiningOperations:

PCDstandardinsertsexcelinawiderangeofmachiningoperations,including:

-Turning:PCDinsertsareusedforturningoperationstomachinecylindricalcomponentswith highprecisionandsurfacequalityTheycaneffectivelycutmaterialssuchasaluminum,copper, andnon-ferrousalloys

-Milling:Inmillingoperations,PCDinsertsareemployedtocreateintricateshapesandcontours onworkpiecesTheyarecapableofhigh-speedmillinganddeliversuperiorperformancein materialslikecarbonfiber-reinforcedplastics(CFRP)andfiberglass.

-Drilling:PCDinsertsareutilizedfordrillingoperationstocreatepreciseholesinvarious materials,includingcomposites,ceramics,andnon-ferrousmetals.Theyofferexcellenthole quality,dimensionalaccuracy,andresistancetotoolwear

-Reaming:PCDinsertsarealsousedforreamingoperationstoachievetighttolerancesand superiorsurfacefinishesinboresTheyaresuitableforreamingapplicationsinaluminum, titanium,andotherdifficult-to-machinematerials.

AdvantagesinDifferentMaterials:

PCDstandardinsertsofferseveraladvantageswhenmachiningdifferentmaterials:

-Non-ferrousMetals:PCDinsertsprovideexceptionalperformancewhenmachiningnon-ferrous metalssuchasaluminum,copper,andbrass.Theydeliverhighcuttingspeeds,excellentsurface finish,andprolongedtoollife,makingthemidealforaerospaceandautomotiveapplications

-Plastics:PCDinsertsarewell-suitedformachiningplasticsduetotheirlowfrictionandheat generationTheyproducecleancutswithminimalburrsandpreventmaterialmeltingor

deformation,ensuringhigh-qualityfinishedparts.

-AbrasiveComposites:PCDinsertsexcelinmachiningabrasivecompositematerialslikeCFRP, GFRP,andMMCs(MetalMatrixComposites).Theyoffersuperiorwearresistanceandedge retention,enablingefficientmachiningofthesechallengingmaterialswhilemaintaining dimensionalaccuracyandsurfaceintegrity.

Insummary,PCDstandardinsertsareversatiletoolsthatfindapplicationsacrossawiderangeof industriesandmaterialsTheirabilitytodeliverprecision,efficiency,andextendedtoollifemakes themindispensableformodernmachiningoperations.

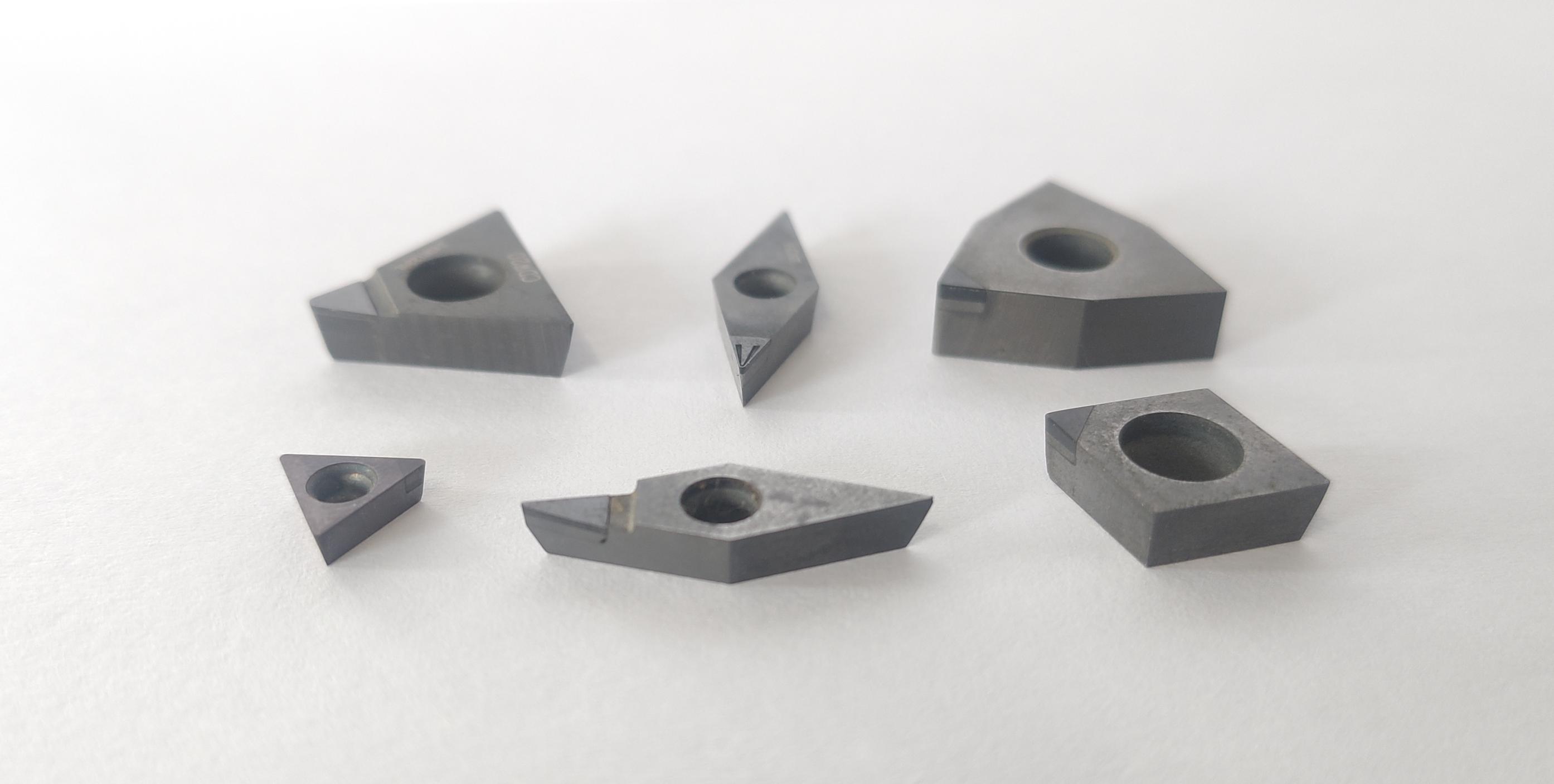

DesignandGeometryofPCDStandardInserts

StandardInsertShapesandSizes:

PCD(PolycrystallineDiamond)standardinsertsareavailableinavarietyofshapesandsizesto accommodatedifferentmachiningrequirementsSomecommoninsertshapesincludesquare, round,triangular,andrhombic,eachtailoredforspecificmachiningoperations.Additionally, insertscomeinvarioussizes,typicallyspecifiedbydimensionssuchaslength,width,and thicknessStandardsizesarewidelyavailableinthemarket,butcustomsizescanalsobe fabricatedtomeetspecificapplicationneeds

GeometryConsiderations:

ThegeometryofPCDstandardinsertsplaysacrucialroleintheirperformanceandeffectiveness duringmachining.Keygeometryconsiderationsinclude:

-RakeAngle:Therakeangledeterminesthedirectionofthecuttingforceandtheefficiencyof chipremoval.Positiverakeanglesaresuitableforsoftmaterials,whilenegativerakeanglesare preferredforhardermaterials

-ClearanceAngle:Theclearanceangleensuresthatthecuttingedgedoesnotrubagainstthe workpiece,minimizingfrictionandheatgenerationProperclearanceangleselectiondependson factorssuchasmaterialtype,cuttingspeed,anddepthofcut.

-CuttingEdgePreparation:ThecuttingedgeofPCDinsertscanbepreparedinvariouswaysto optimizecuttingperformance.Commonedgepreparationsincludehoning,chamfering,and radiuscutting,eachservingtoenhancecuttingefficiency,reducecuttingforces,andimprove surfacefinish.

CustomizationOptions:

PCDstandardinsertscanbecustomizedtomeetspecificmachiningrequirements,offering flexibilityandversatilityintooldesignCustomizationoptionsinclude:

-SpecialProfiles:Insertscanbetailoredtofeaturecomplexprofilesoruniquegeometriesto accommodatespecificpartfeaturesormachiningchallenges

-ChipbreakerDesigns:Chipbreakerscanbeintegratedintotheinsertgeometrytocontrolchip formationandimprovechipevacuationduringmachining,particularlyindifficult-to-machine materials.

-CoatingApplications:InadditiontoPCDcuttingedges,insertscanbecoatedwithvarious coatingstoenhancewearresistance,reducefriction,orimprovethermalstability,dependingon theapplication.

Bycarefullyconsideringinsertdesignandgeometry,manufacturerscanoptimizemachining performance,achievehigherproductivity,andextendtoollife,ultimatelyenhancingoverall machiningefficiencyandquality.

SelectionCriteriaforPCDStandardInserts

ChoosingtherightPCD(PolycrystallineDiamond)standardinsertsisessentialforachieving optimalmachiningperformanceandefficiencySeveralkeyfactorsshouldbeconsideredduring theselectionprocesstoensurecompatibilitywiththemachiningmaterial,conditions,andcost considerations

1MaterialCompatibility:

DifferentmachiningmaterialsrequirespecificPCDinsertgradesandcompositionstoachievethe desiredcuttingperformanceandtoollifeConsiderthefollowingmaterial-relatedfactors:

-Hardness:Selectinsertswiththeappropriatediamondparticlesizeanddistributiontomatch thehardnessoftheworkpiecematerial

-Abrasiveness:Chooseinsertswithhigherabrasionresistanceformachiningabrasivematerials likecompositesorceramics

-ChemicalStability:Ensurethattheinsertmaterialischemicallycompatiblewiththeworkpiece materialtopreventchemicalreactionsandtoolwear

2MachiningConditions:

Theoperatingconditionsofthemachiningprocesssignificantlyimpactinsertselection.Consider thefollowingmachiningparameters:

-CuttingSpeed:Selectinsertscapableofwithstandingtherequiredcuttingspeedswithout compromisingtoollifeorcuttingedgeintegrity

-FeedRate:Chooseinsertsthatcanhandlethedesiredfeedrateswhilemaintainingdimensional accuracyandsurfacefinish.

-DepthofCut:Determinethemaximumdepthofcutneededandselectinsertswithadequate strengthandstabilitytowithstandcuttingforces.

3.CostConsiderations:

WhilePCDinsertsmayhaveahigherinitialcostcomparedtoconventionaltooling,theyoffer significantlong-termbenefitsintermsoftoollifeandmachiningefficiency.Considerthe followingcost-relatedfactors:

-InitialInvestment:EvaluatetheupfrontcostofpurchasingPCDinsertsrelativetothemachining budgetandexpectedreturnoninvestment

-ToolLife:AssesstheexpectedtoollifeofPCDinsertsunderspecificmachiningconditionsand compareitwithalternativetoolingoptions

-MachiningEfficiency:Considertheoverallproductivitygainsandcostsavingsassociatedwith usingPCDinserts,includingreduceddowntime,higherthroughput,andimprovedpartquality

Bycarefullyevaluatingmaterialcompatibility,machiningconditions,andcostconsiderations, manufacturerscanselecttherightPCDstandardinsertstooptimizemachiningperformance, extendtoollife,andmaximizecost-efficiencyintheiroperations

MaintenanceandCareofPCDStandardInserts

PropermaintenanceandcareareessentialformaximizingthelifespanandperformanceofPCD (PolycrystallineDiamond)standardinsertsByfollowingrecommendedproceduresforcleaning, inspection,edgehoning,refurbishment,storage,andhandling,manufacturerscanensurethat theirPCDinsertsdeliverconsistentresultsandremaininoptimalconditionthroughouttheir usage.

1.CleaningandInspection:

Regularcleaningandinspectionhelpidentifyanysignsofwear,damage,orcontaminationon PCDinserts.Followthesesteps:

-Useasoftbrushorcompressedairtoremovechips,debris,andcoolantresiduesfromtheinsert surfaceandchipbreakerareas.

-Inspecttheinsertsundermagnificationforsignsofchipping,edgewear,orcoatingdamagePay attentiontocuttingedges,rakefaces,andflanksurfaces.

-Ifnecessary,useamildsolventorcleaningsolutiontoremovestubbornresidues,ensuringnot todamagetheinsertoritscoating.

2.EdgeHoningandRefurbishment:

ToextendtheusefullifeofwornPCDinserts,consideredgehoningorrefurbishmenttechniques:

-UtilizediamondhoningtoolsorabrasivewheelstosharpenorhonethecuttingedgesofPCD insertsThisprocesshelpsrestoreedgesharpnessandcuttingperformance

-Forinsertswithsignificantwearordamage,considerrefurbishmentservicesofferedby reputablesuppliers.Theseservicesmayincluderegrinding,re-coating,orre-tippingoftheinserts torestoretheiroriginalgeometryandfunctionality

3StorageandHandling:

Properstorageandhandlingarecrucialforpreventingdamage,contamination,ordegradationof PCDinserts:

-StorePCDinsertsinclean,dryenvironmentswithstabletemperatureandhumidityconditions topreventcorrosionoroxidation

-Useprotectivepackaging,suchasplasticcontainersorfoaminserts,toshieldinsertsfrom physicaldamageduringstorageandtransportation

-HandlePCDinsertswithcaretoavoiddropping,banging,orscratching,whichcancause micro-fracturesorsurfacedefectsthatcompromiseperformance

-Whenhandlinginserts,usecleanglovesorhandlingtoolstominimizecontactwithskinoils,dirt, orcontaminantsthatcandegradetheinsert'scuttingperformance

FrequentlyAskedQuestionsaboutPCDStandardInserts(FAQs)

Q1:WhatarePCDstandardinserts,andhowaretheydifferentfromothercuttingtools?

A1:PCD(PolycrystallineDiamond)standardinsertsarecuttingtoolsusedinmachining applicationstoachievehighprecisionandefficiency.Unlikeconventionalinserts,PCDinserts featurediamondparticlesbondedtogetherinamatrixmaterial,offeringsuperiorhardness,wear resistance,andthermalconductivity.

Q2:WhataretheadvantagesofusingPCDstandardinserts?

A2:PCDstandardinsertsofferseveraladvantages,including: -Exceptionalwearresistance,allowingforprolongedtoollifeandreduceddowntime -Highcuttingspeedsandfeedrates,leadingtoimprovedproductivity. -Enhancedsurfacefinishanddimensionalaccuracy,contributingtosuperiorpartquality -Compatibilitywithawiderangeofmaterials,includingnon-ferrousmetals,plastics,and composites

Q3:WhatindustriesandapplicationsaresuitableforPCDstandardinserts?

A3:PCDstandardinsertsfindapplicationsinvariousindustries,includingaerospace,automotive, woodworking,andelectronicsmanufacturingTheyareidealformachiningmaterialssuchas aluminum,copper,fiberglass,carbonfiber,andceramics.Commonapplicationsincludeturning, milling,drilling,andreamingoperations

Q4:HowdoIselecttherightPCDstandardinsertformymachiningapplication?

A4:WhenselectingPCDstandardinserts,considerfactorssuchas: -Materialbeingmachined

-Machiningoperation(turning,milling,drilling,etc)

-Cuttingconditions(speed,feedrate,depthofcut)

-Insertgeometryandedgepreparation

Q5:WhatistherecommendedmaintenanceroutineforPCDstandardinserts?

A5:RegularmaintenanceisessentialforprolongingthelifeofPCDstandardinserts.Itincludes cleaning,inspection,edgehoning,andproperstorageInspectinsertsforwear,damage,or contamination,andcleanthemregularlyusingmildsolventsorcleaningsolutions.Edgehoning canbeusedtorestoresharpness,andinsertsshouldbestoredinclean,dryenvironmentsto preventdamage.

Q6:CanPCDstandardinsertsbereconditionedorrefurbished?

A6:Yes,PCDstandardinsertscanberefurbishedthroughregrinding,re-coating,orre-tipping processesofferedbyspecializedsuppliers.Refurbishmentcanextendtheusefullifeofwornor damagedinserts,restoringtheircuttingperformanceandgeometry

Q7:WhatarethecostconsiderationsassociatedwithPCDstandardinserts?

A7:WhilePCDstandardinsertsmayhaveahigherupfrontcostcomparedtoconventionalinserts, theirsuperiorwearresistanceandlongertoollifeoftenresultinloweroverallmachiningcosts Considerthetotalcostofownership,includinginitialinvestment,toollife,machiningefficiency, andpartquality,whenevaluatingthecost-effectivenessofPCDinserts

TheseFAQsaimtoaddresscommonquestionsaboutPCDstandardinserts,providinguserswith valuableinsightsintotheirapplications,advantages,selectioncriteria,maintenance,andcost considerations