MaximizingMachiningEfficiencywithPSC

EndMillHolders:AHalnnInnovation

Intherealmofprecisionmachining,theselectionoftoolholdersisacriticalfactor thatcansignificantlyimpactthequality,efficiency,andreliabilityofthemachining process.Amongthevarioustypesoftoolholdersavailable,thePSC(PolygonShank Coupling)EndMillHolderstandsoutasasuperiorchoiceformanymachining applications.Halnn,aleaderincuttingtooltechnology,offersanadvancedrangeof PSCEndMillHoldersdesignedtomeetthedemandingneedsofmodern manufacturing.

Relatedpost:https://wwwhalnnpcdcom/industrynews/893html

UnderstandingthePSCEndMillHold

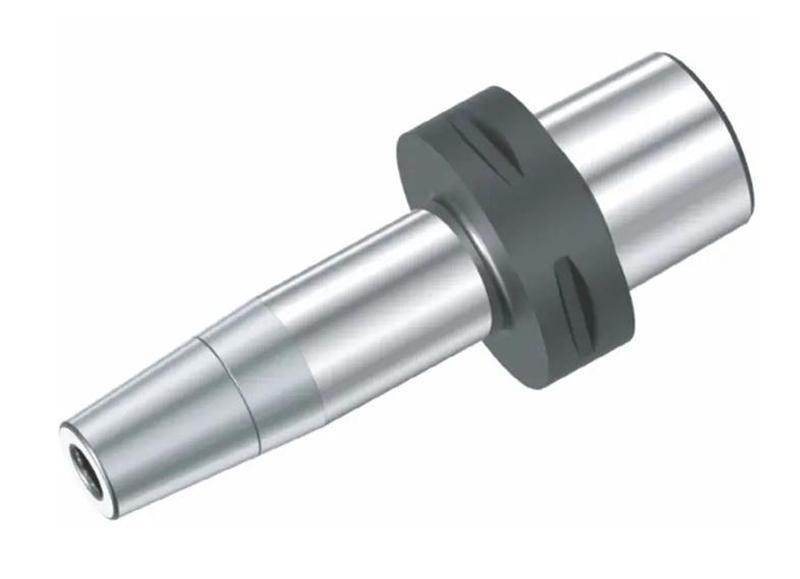

ThePSCEndMillHolder,knownforitsuniquepolygonalshankdesign,offers exceptionalstabilityandprecision.Thisinnovativedesignensuresasecureandrigid connectionbetweenthetoolholderandthemachinespindle,minimizingrunoutand vibrationduringmachining.Theresultisasignificantimprovementinthequalityof themachinedpartsandtheoverallefficiencyoftheprocess