Halnn:MasteringPrecisionwith VibrationDampingTurningBars

Intheworldofprecisionmachining,eventhesmallestvibrationscanleadtoimperfectionson workpieces,reducedtoollife,andcompromisedaccuracyEffectivevibrationcontrolis essentialformaintainingmachiningquality,enhancingproductionefficiency,andextending machinelifeThisarticleexploresthesignificanceofvibrationdampingturningbars,their functionality,benefits,andapplications,whilehighlightingHalnn'sinnovationsandexpertise inthisfield

Relatedpost:https://www.halnncbn.com/News/IndustryNews/607.html

UnderstandingVibrationDampingTurningBars

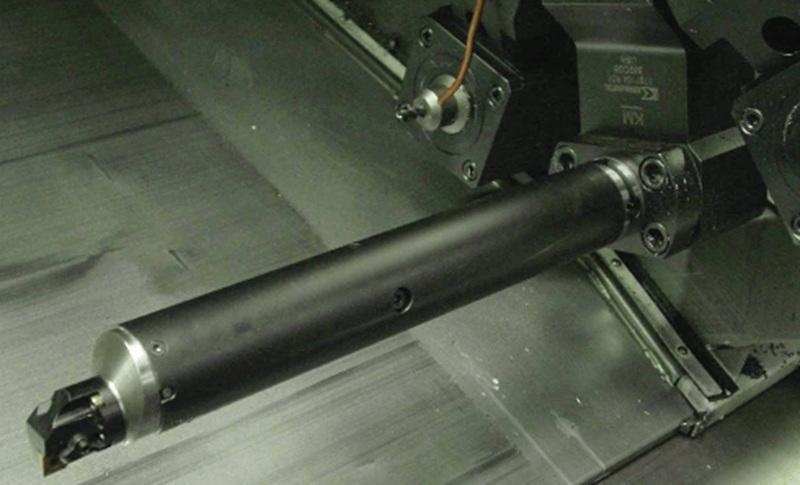

Vibrationdampingturningbarsarespecializedtoolsdesignedtominimizevibrationsduring themachiningprocess.Byincorporatingadvancedmaterialsandengineeringtechniques, thesebarsabsorbanddissipatevibrationalenergy,enhancingmachiningstabilityand precision

KeyFeaturesandMaterials

Vibrationdampingturningbarstypicallyconsistofarobustouterbodyandaninternal dampingmechanismThismechanismoftenincludestunedmassdampers,viscoelastic materials,orotherinnovativetechnologiestocounteractvibrationalforceseffectively

DifferencefromStandardTurningBars

Standardturningbarsmaysufficeforbasictasks,butvibrationdampingturningbarsare engineeredtoaddressvibrationsspecifically.Thismakesthemindispensablefor high-precisionandheavy-dutyapplicationswhereperformanceandreliabilityareparamount

TheImportanceofVibrationControlinMachining

Vibrationcontroliscriticalinmachiningforseveralreasons:

SurfaceFinish:Vibrationscausechattermarksandirregularitiesontheworkpiece surface,degradingfinishquality.

ToolLife:Excessivevibrationsacceleratetoolwear,reducingthelifespanofcutting tools.

Accuracy:Vibrationscanleadtodeviationsfromintendeddimensionsandtolerances, compromisingpartaccuracy.

Real-WorldChallenges

Intheautomotiveandaerospaceindustries,evenminorvibrationscanresultinsignificant performanceissues,makingprecisevibrationcontrolessential

HowVibrationDampingTurningBarsWork

Thesebarsusevariousdampingtechniquestomitigatevibrations,categorizedintopassive andactivedamping

PassiveDamping

Passivedampinginvolvesmaterialsandstructuresthatinherentlyabsorbvibrations Viscoelasticmaterials,forexample,convertvibrationalenergyintoheat,reducingvibration amplitude.

Halnn'sTechnologicalAdvantage

Halnn’svibrationdampingturningbarsintegratecutting-edgepassivedampingtechniques withsuperiormaterials,ensuringexceptionalperformanceDesignedforrobustnessand reliability,ourbarsdeliverconsistentresultsindemandingmachiningenvironments

BenefitsofUsingVibrationDampingTurningBars

ImprovedSurfaceFinishandDimensionalAccuracy

Minimizingvibrationshelpsachievesmoothersurfacefinishesandmaintaintight dimensionaltolerances,essentialforhigh-qualitymachining

IncreasedToolLife

Reducedvibrationsmeanlessstressoncuttingtools,significantlyextendingtheirusablelife andloweringoveralltoolingcosts

EnhancedMachiningStabilityandProductivity

Withbettercontrolovervibrations,machiningoperationsbecomemorestable,enabling highercuttingspeedsandfeeds,thusboostingproductivity

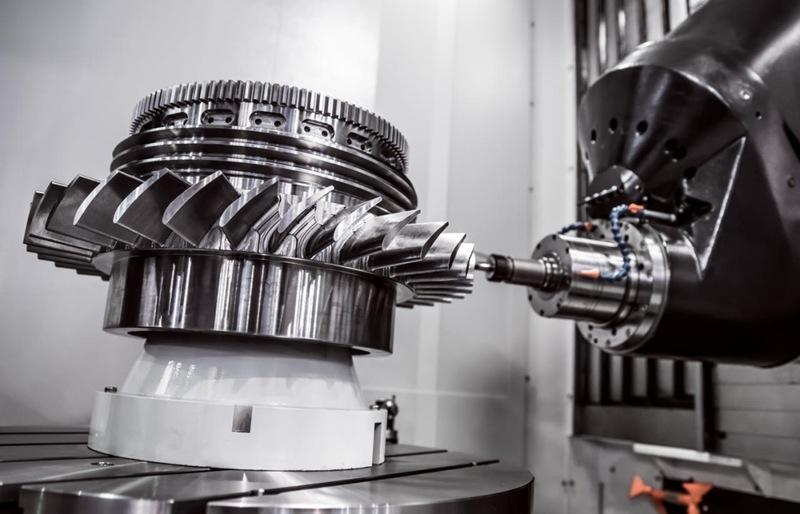

ApplicationsAcrossIndustries

Automotive:Engineblocks,cylinderheads,transmissioncomponents.

Aerospace:Structuralcomponents,engineparts

GeneralManufacturing:Precisionmolds,dies,andfixtures.

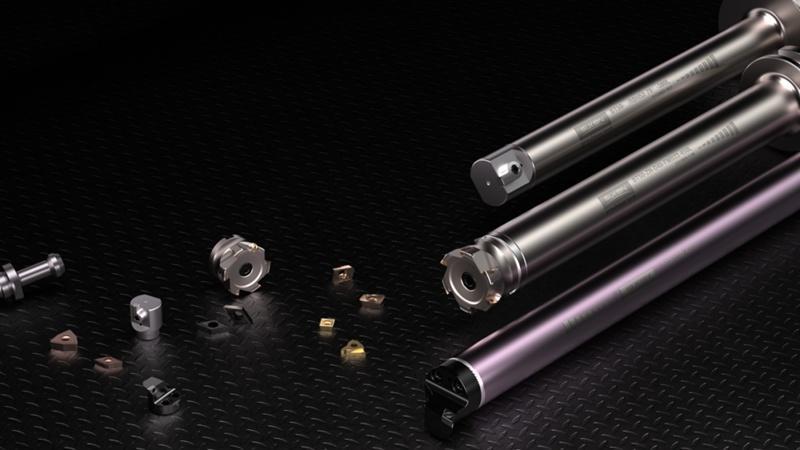

Halnn'sRangeofVibrationDampingTurningBars

Halnnoffersavarietyofvibrationdampingturningbarstailoredtovariousapplications, ensuringoptimalperformanceandefficiency.

ModelsandSpecifications

StandardDampingBars:Idealforgeneral-purposemachining

Heavy-DutyDampingBars:Designedforhigh-stressapplications

CustomDampingBars:Tailoredsolutionsforuniquemachiningchallenges

FeaturesandBenefits

HighRigidity:Ensuresminimaldeflectionandoptimalperformance

AdvancedDampingMechanisms:Superiorvibrationabsorptionforenhancedstability.

Versatility:Suitableforawiderangeofmaterialsandmachiningoperations

HowtoChoosetheRightVibrationDampingTurning

Bar

FactorstoConsider

Material:Ensurecompatibilitywiththeworkpiecematerial

Application:Matchthebartothespecificmachiningoperation.

MachineCompatibility:Verifythatthebarfitsthemachinetool'sspecifications

TipsforSelection

ConsultHalnn'stechnicalsupportteamforpersonalizedrecommendations.

Considerthecomplexityandprecisionrequirementsofthemachiningtask

Evaluatethecost-benefitratiointermsoftoollifeandproductivitygains.

MaintenanceandBestPractices

ProperUsageandMaintenance

Followthemanufacturer'sguidelinesforinstallationandusage.

Regularlyinspectthebarsforsignsofwearanddamage

Cleanandstorethebarsproperlytopreventcorrosionanddegradation.

MaximizingToolLifeandPerformance

Useappropriatecuttingparameterstominimizestressonthetools

Implementregularmaintenanceschedulestokeepthebarsinoptimalcondition.

TroubleshootingCommonIssues

VibrationIssues:Checkforproperinstallationandcompatibility

WearandTear:Replaceworn-outbarstomaintainmachiningquality.

Conclusion

Vibrationdampingturningbarsareessentialforachievinghigh-qualitymachiningresults Theyenhancesurfacefinish,dimensionalaccuracy,andtoollife,makingthemindispensable inprecisionmachiningHalnn,withitsexpertiseandinnovativesolutions,offersarangeof vibrationdampingturningbarstailoredtomeetdiversemachiningneeds.BychoosingHalnn, youinvestinsuperiorperformance,reliability,andproductivity

FormoreinformationortoexploreHalnn'sproductofferings,visitourwebsiteorcontactour technicalsupportteamtoday.

Ourwebsite:https://wwwhalnncbncom/ Email:halnntools@halnn-group.com WhatsApp:+8615515925975