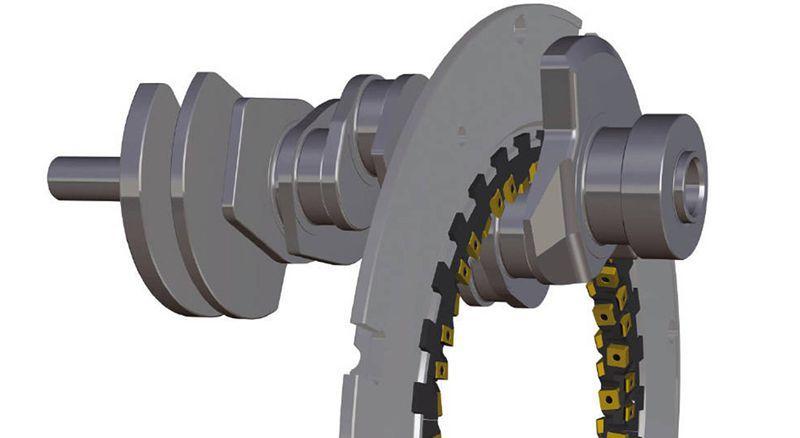

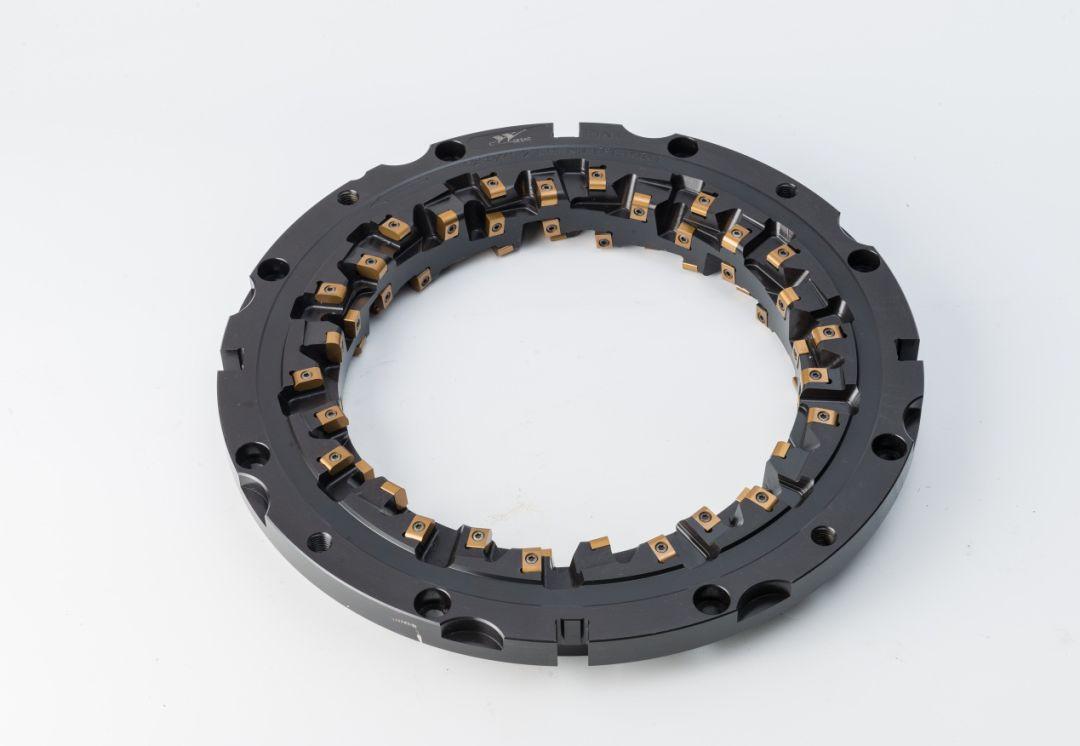

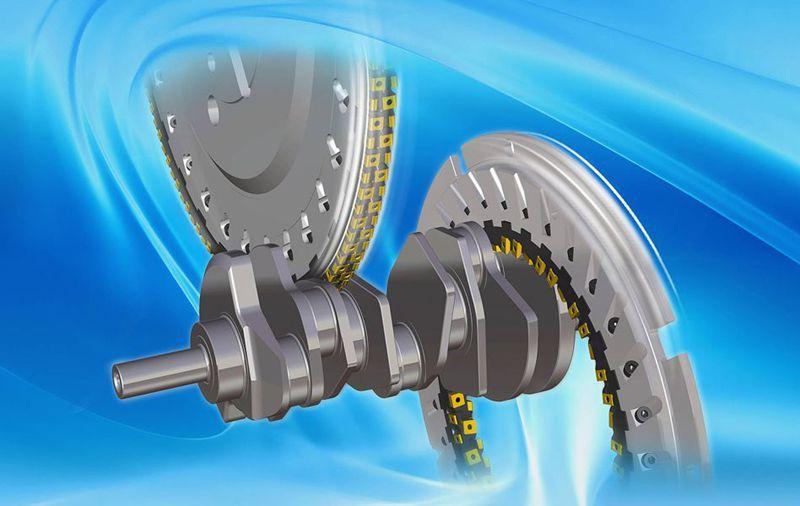

InternalCrankshaftMillingCutter:

PrecisionandPerformancewithHalnn

Introduction

Intheworldofenginemanufacturing,precisionisparamountOneofthemostcritical componentsofanengineisthecrankshaft,andmachiningitaccuratelyisessentialforoptimal performanceInternalcrankshaftmillingcuttersplayavitalroleinthisprocessInthisarticle,we willexplorethefeatures,benefits,andapplicationsofinternalcrankshaftmillingcutters,witha specialfocusonHalnn'sindustry-leadingsolutions

Relatedpost:https://www.halnncbn.com/News/IndustryNews/595.html