Halnn:AdvancedWindTurbineBlade MachiningTools

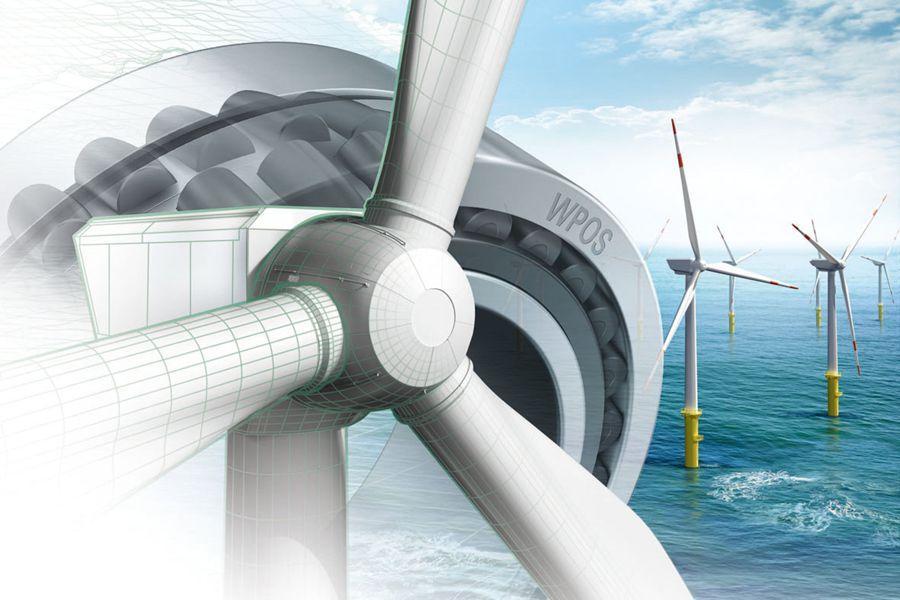

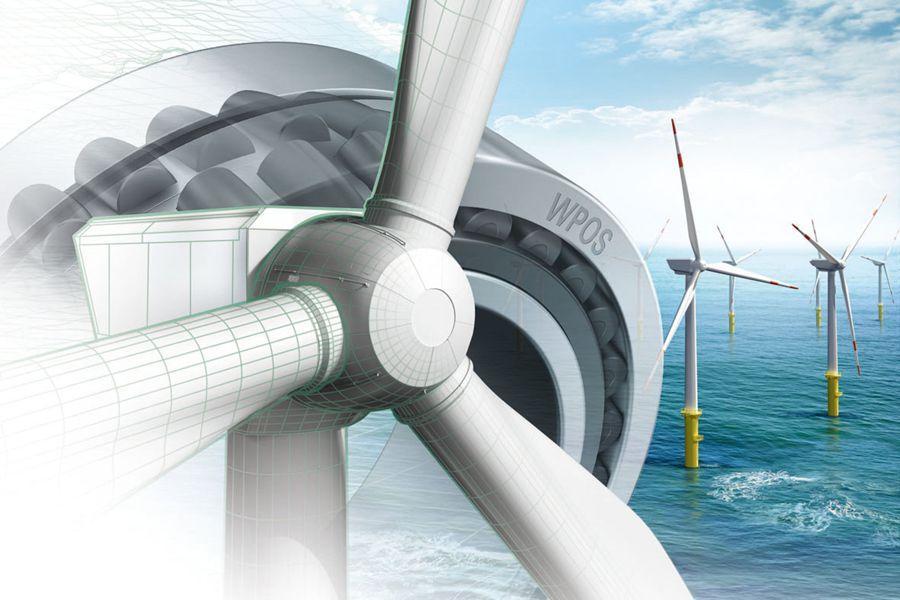

Thedemandforrenewableenergyhasledtotherapidexpansionofwindenergyprojects worldwideAcriticalcomponentinthisindustryisthewindturbineblade,whichrequiresprecise andefficientmachiningtoensureoptimalperformanceandlongevity.Halnnisattheforefrontof providingadvancedwindturbineblademachiningtools,designedtomeetthestringent requirementsofthissector.ThisarticleexploresthevarioustoolsofferedbyHalnn,their applications,andthebenefitstheybringtowindturbineblademanufacturing Relatedpost:https://www.halnncbn.com/News/IndustryNews/593.html

TheImportanceofPrecisioninWindTurbineBlade Machining

Windturbinebladesarelarge,complexstructuresthatmustwithstandextremeenvironmental conditionsPrecisionintheirmachiningisessentialtoachieveaerodynamicefficiency,structural integrity,andlong-termdurabilityThemachiningprocessinvolvesvarioussteps,including cutting,shaping,andfinishing,eachrequiringspecializedtoolstomaintainthehigheststandards ofaccuracyandquality.

Halnn'sWindTurbineBladeMachiningTools

Halnnoffersacomprehensiverangeofmachiningtoolsspecificallydesignedfortheunique challengesofwindturbineblademanufacturing.Ourtoolsareengineeredtodeliversuperior performance,reducemachiningtime,andextendtoollife,ensuringcost-effectiveandefficient productionprocesses.

1.CarbideCuttingTools

Halnn'scarbidecuttingtoolsareidealfortheroughandfinishmachiningofwindturbineblades Thesetoolsaremadefromhigh-qualitycarbidematerialsthatofferexcellentwearresistanceand cuttingperformanceTheyaresuitableformachiningcompositematerialsandmetalscommonly usedinturbineblades,suchasfiberglass,carbonfiber,andaluminumalloys

2.Diamond-CoatedTools

Forapplicationsrequiringexceptionalprecisionandsurfacefinish,Halnn'sdiamond-coatedtools aretheperfectsolutionThesetoolsfeatureadiamondcoatingthatprovidesunmatchedhardness andwearresistance,makingthemidealforcuttingandshapingthecompositematerialsusedin windturbinebladesThediamondcoatingensuresasmoothfinish,reducingtheneedfor additionalfinishingprocesses.

3.PCD(PolycrystallineDiamond)Tools

Halnn'sPCDtoolsaredesignedforhigh-speedmachiningofwindturbinebladesPCDisan

extremelyhardmaterialthatoffersexcellentthermalstabilityandabrasionresistanceOurPCD toolsareperfectforhigh-precisionmachiningoperations,ensuringminimaltoolwearand extendedtoollife,eveninthemostdemandingapplications

4.CBN(CubicBoronNitride)Tools

CBNtoolsfromHalnnarespecificallydesignedformachininghigh-hardnessmaterialsusedin windturbineblades.CBNissecondonlytodiamondinhardness,makingitidealforcutting throughtoughmaterialswhilemaintainingsharpnessandprecisionThesetoolsareparticularly effectiveinmachininghardenedsteelsandotherdifficult-to-machinematerials

BenefitsofHalnn'sWindTurbineBladeMachining Tools

ChoosingHalnn'smachiningtoolsforwindturbineblademanufacturingoffersseveralsignificant benefits:

SuperiorPrecisionandAccuracy

Halnn'stoolsareengineeredtoprovidethehighestlevelsofprecisionandaccuracy,ensuringthat eachblademeetstheexactspecificationsrequiredforoptimalperformance

EnhancedToolLife

Ourtoolsaremadefrompremiummaterialsandfeatureadvancedcoatings,resultinginextended toollifeandreducedneedforfrequentreplacementsThisleadstoloweroperationalcostsand

ImprovedSurfaceFinish

Halnn'sdiamond-coatedandPCDtoolsdeliverexceptionalsurfacefinishes,reducingtheneedfor additionalfinishingprocessesandensuringthatbladesareaerodynamicallyefficient.

CostEfficiency

Withlongertoollifeandenhancedmachiningperformance,Halnn'stoolscontributetosignificant costsavingsinthemanufacturingprocess.Ourtoolshelpreducemachiningtimeandminimize waste,leadingtomoreefficientproductioncycles

Versatility

Halnn'srangeoftoolsisversatileandcapableofhandlingavarietyofmaterialsusedinwind turbinebladesWhethermachiningcomposites,metals,orhigh-hardnessmaterials,ourtools deliverconsistentperformanceandreliability

WhyChooseHalnn?

Halnniscommittedtoprovidinginnovativemachiningsolutionsthatmeettheevolvingneedsof thewindenergysectorHere’swhyHalnnstandsoutasatrustedpartnerinwindturbineblade manufacturing:

increasedproductivity

ExpertiseandExperience

Withyearsofexperienceintheindustry,Halnnhasdevelopedadeepunderstandingofthe challengesfacedinwindturbineblademachining.Ourexpertiseallowsustooffersolutionsthat aretailoredtomeetthespecificneedsofourcustomers

CustomSolutions

AtHalnn,werecognizethateverymanufacturingprocessisuniqueWeworkcloselywithour customerstodevelopcustommachiningsolutionsthataddresstheirspecificrequirementsand challenges

QualityAssurance

QualityisatthecoreofeverythingwedoatHalnnOurrigorousqualitycontrolprocessesensure thateverytoolweproducemeetsthehigheststandardsofperformanceandreliability.

TechnicalSupport

Halnnprovidescomprehensivetechnicalsupporttohelpourcustomersgetthemostoutofour toolsFrominitialsetuptoongoingmaintenance,ourteamisavailabletoassistateverystage

Conclusion

Intherapidlygrowingwindenergysector,precisionandefficiencyinwindturbineblade manufacturingareparamountHalnn’sadvancedwindturbineblademachiningtoolsaredesigned

tomeetthesedemands,offeringsuperiorperformance,extendedtoollife,andcostefficiencyBy choosingHalnn,youarepartneringwithacompanydedicatedtoinnovation,quality,andcustomer satisfactionContactHalnntodaytolearnmoreaboutourmachiningsolutionsandhowwecan supportyourwindturbineblademanufacturingneeds

Ourwebsite:https://www.halnncbn.com/ Mailaddress:halnntools@halnn-groupcom WhatsApp:+8615515925975