HalnnRollsPCDTools:SuperiorSolutionsfor PrecisionMachining

Halnnisatrustednameinthecuttingtoolindustry,offeringspecialized RollsPCDtoolsdesignedtomeetthehigheststandardsofprecisionand efficiencyRollsPCDtools(PolycrystallineDiamond)areessentialfor machiningoperationsthatrequirelongtoollife,highcuttingspeed,and exceptionalsurfacefinish.Thisarticlefocusesonthekeyfeatures, benefits,andapplicationsofHalnnRollsPCDtools,providingvaluable insightsforprofessionalslookingforreliablesolutionsinrollsmachining.

Relatedpost:https://www.halnncbn.com/News/IndustryNews/628.html

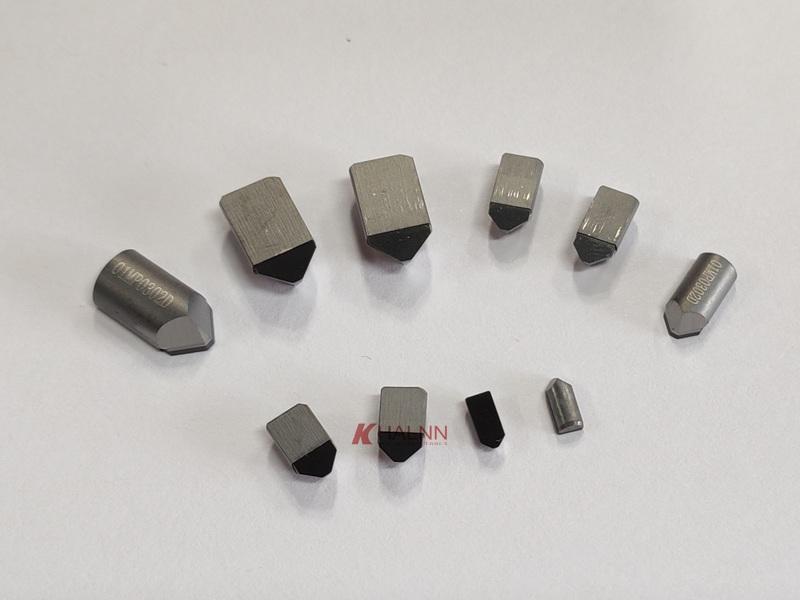

WhatAreRollsPCDTools?

RollsPCDtoolsarecuttingtoolsspecificallydesignedformachining rollsmadefromavarietyofmaterials,includingaluminum,steel,and othernon-ferrousmetals.PCD,orPolycrystallineDiamond,isahighly durablematerialformedbysinteringdiamondparticlesunderhigh pressureandtemperatureThisresultsinacuttingtoolwithsuperior hardnessandwearresistancecomparedtotraditionalcarbideorceramic tools.

Inrollsmachining,whereprecisionandsurfacequalityarecritical,Halnn RollsPCDtoolsstandoutfortheirabilitytohandlethetoughestmaterials whilemaintainingaccuracyoverextendedperiodsofuse.

KeyFeaturesofHalnnRollsPCDTools

1.ExceptionalHardnessandDurability

HalnnRollsPCDtoolsarerenownedfortheirexceptionalhardness, allowingthemtoperformefficientlyeveninthemostdemanding machiningoperations.Thishardnessensureslongtoollife,reducingthe frequencyoftoolchangesandincreasingoverallproductivity.

2.SuperiorWearResistance

ThankstotheuniquepropertiesofPCD,HalnnRollsPCDtoolsoffer outstandingwearresistance.Thisisparticularlyimportantwhen machininghardrollsormaterialsthatcauseexcessivetoolwear,suchas aluminumalloysorcastiron.Halnntoolsmaintainsharpcuttingedges overlongproductionruns,resultinginconsistentqualityandfewer interruptions.

3.High-SpeedCuttingCapabilities

HalnnRollsPCDtoolsareidealforhigh-speedmachiningoperations,as theycanwithstandtheincreasedtemperaturesandcuttingforcesthat comewithhighcuttingspeeds.Thismakesthemperfectforindustries wherefastproductioncyclesareessential,suchasautomotive,aerospace, andheavymanufacturing.

4.PrecisionandSurfaceQuality

Inrollsmachining,thesurfacefinishiscritical.HalnnRollsPCDtools ensureprecisionineverycut,providingsmooth,accurateresultswithout compromisingonsurfacequality.Thismakesthemidealforapplications thatdemandthehighestlevelsofprecision,suchasproducingrollsfor metalformingorfinishing BenefitsofUsingHalnnRollsPCDTools

1.ExtendedToolLife

Halnn’sRollsPCDtoolslastsignificantlylongerthantraditionalcarbide orceramictools,thankstotheirsuperiorhardnessandwearresistance.

Thisextendedtoollifetranslatestolowertoolingcostsandfewer interruptionsfortoolreplacement,increasingoverallproduction efficiency.

2.ImprovedProductivity

Bymaintainingsharpcuttingedgesoverlongperiods,HalnnRollsPCD toolsenablecontinuous,high-speedmachiningwithoutsacrificing precision.Thisleadstofasterproductiontimesandahigheroutputrate, makingthemanexcellentchoiceforindustriesfocusedonmass production.

3.CostEfficiency

AlthoughPCDtoolsmayhaveahigherinitialcostcomparedtoother cuttingtools,theirlonglifespanandreducedneedforreplacementmake themmorecost-effectiveinthelongrun.HalnnRollsPCDtools minimizedowntimeandmaintenancecosts,offeringsuperiorvaluefor money.

4.EnhancedMachiningQuality

TheprecisionanddurabilityofHalnnRollsPCDtoolsensure high-qualitymachiningresultswithminimalsurfacedefects.Thisis especiallyimportantinindustriesthatrequirerollswithexactingsurface finishes,whereevenminorimperfectionscanimpactthefinalproduct

ApplicationsofHalnnRollsPCDTools

1.AutomotiveIndustry

Intheautomotiveindustry,RollsPCDtoolsarewidelyusedfor machiningcomponentssuchasengineblocks,brakediscs,and transmissionparts.Thehigh-speedcuttingcapabilitiesofHalnnRolls PCDtoolsmakethemidealformachiningaluminumandother lightweightmaterialsusedinmodernvehicles.

2.AerospaceIndustry

TheaerospaceindustryreliesonRollsPCDtoolsformachining high-strength,lightweightmaterialsliketitaniumandaluminumalloys.

Halnn’sPCDtoolsprovidetheprecisionanddurabilityneededtoproduce componentswithtighttolerancesandhighsurfacequality.

3.HeavyManufacturing

Forlarge-scalemanufacturingoperations,HalnnRollsPCDtoolsoffer unparalleledperformanceinmachiningrollsusedinsteelmills,metal forming,andotherheavy-dutyapplications.Theirabilitytohandle extremecuttingforcesandtemperaturesmakesthemindispensablefor producinglarge,heavyrollswithconsistentaccuracy.

4.MetalProcessing

Inmetalprocessingindustries,suchasthoseinvolvingnon-ferrousmetals likealuminumorcopper,HalnnRollsPCDtoolsexcelatproviding superiorcuttingperformanceandsurfacefinish.Theirwearresistance ensurestheycanhandleabrasivematerialswhilemaintainingcutting precision.

WhyChooseHalnnRollsPCDTools?

Halnn’sexpertiseincuttingtooltechnologyensuresthatourRollsPCD toolsaredesignedtomeetthemostdemandingrequirementsofmodern machining.BychoosingHalnn,manufacturersbenefitfrom:

CustomizedToolingSolutions:HalnnprovidestailoredRollsPCD toolsthatmatchspecificapplicationneeds,ensuringoptimal performanceandefficiency

ProvenReliability:Ourtoolsarerigorouslytestedtoguarantee consistentresultsacrossarangeofmachiningconditions,making thematrustedchoiceforhigh-precisionapplications.

ComprehensiveSupport:Halnnoffersfullsupportthroughoutthe

toolselectionandimplementationprocess,helpingcustomersachieve thebestpossibleresultsfromourRollsPCDtools.

Conclusion

HalnnRollsPCDtoolsaretheperfectsolutionforindustriesrequiring precision,durability,andhigh-speedperformanceinrollsmachining Whetheryou’reinautomotive,aerospace,heavymanufacturing,ormetal processing,Halnn’sPCDtoolsprovidethereliabilityandefficiency neededtoenhanceproductionqualityandreducecosts.

FormoreinformationonhowHalnnRollsPCDtoolscanimproveyour machiningoperations,ortodiscusscustomizedsolutionsforyourspecific needs,contactHalnntoday.

Ourwebsite:https://wwwhalnncbncom/

Email:halnntools@halnn-groupcom

Whatsapp/Wechat:+8613271562251