HalnnRollsCBNTools:High-Performance SolutionsforRollsMachining

Inthedemandingworldofrollsmachining,wherehighhardness, precision,andwearresistancearecritical,choosingtherightcuttingtools canmakeallthedifferenceHalnn,aleadingcompanyincuttingtool technology,offersarangeofspecializedRollsCBNtoolsthatdeliver exceptionalperformanceformachininghardenedrollsusedinindustries suchassteelmills,automotive,aerospace,andheavymachinery.This articlefocusesonRollsCBNtools,providingvaluableinsightsintotheir benefits,applications,andhowtheyenhancemachiningprocesses, helpingmanufacturersachieveoptimalresults.

Relatedpost:https://www.halnnpcd.com/industrynews/910.html

WhatAreRollsCBNTools?

RollsCBNtoolsarecuttingtoolsmadefromCubicBoronNitride(CBN), asuper-hardmaterialsecondonlytodiamond.CBNtoolsaredesignedto machinehardmaterials,suchashardenedsteel,castiron,andhigh-alloy rolls,whicharecommonlyusedinheavyindustriesTheunique propertiesofHalnnRollsCBNtoolsmakethemidealforhandling high-heatandhigh-wearenvironments,deliveringsuperiorperformance inbothcontinuousandinterruptedcuttingprocesses.

WhyRollsRequireSpecializedCBNTools

Rollsaretypicallymanufacturedfrommaterialswithhighhardnessand wearresistance,makingthemchallengingtomachineusingtraditional cuttingtoolslikecarbideorceramic.Rollsmachiningdemandsprecision anddurability,asimpropertoolingcanleadtopoorsurfacefinishes, reducedtoollife,andfrequenttoolchanges.HalnnRollsCBNtoolsare specificallyengineeredtoaddressthesechallenges,offering:

Highheatresistance:CBNmaintainscuttingperformanceathigh temperatures,ensuringconsistentmachiningwithouttooldegradation.

Exceptionalwearresistance:Thisextendstoollife,reducing downtimecausedbytoolchangesandminimizingproductioncosts.

Superiorhardness:CBNissignificantlyharderthanothermaterials, makingitidealformachininghardenedrollswithprecision

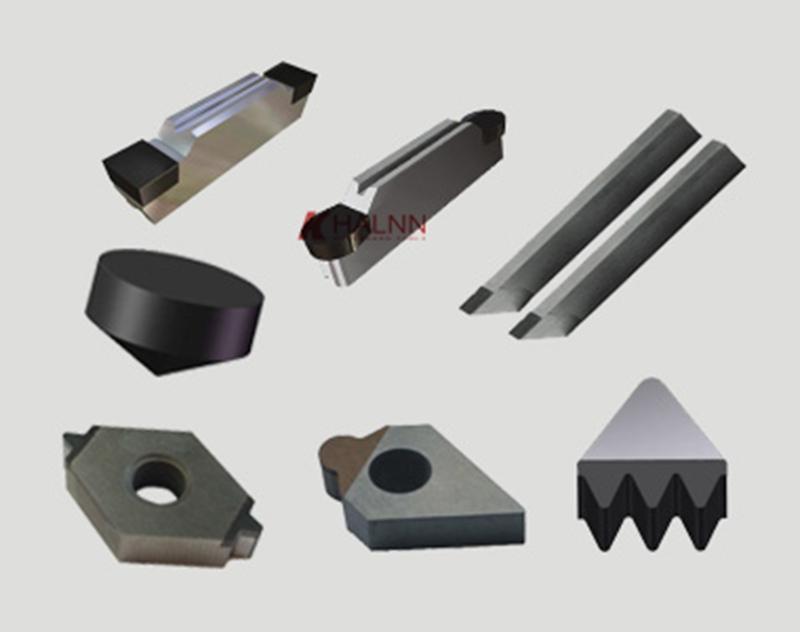

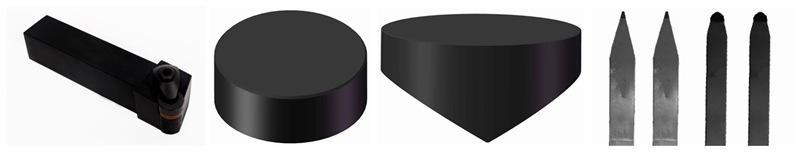

TypesofHalnnRollsCBNTools

HalnnprovidesawiderangeofRollsCBNtools,eachdesignedtomeet specificmachiningneeds:

1.RollsCBNInserts

RollsCBNinsertsaredesignedforturning,grooving,andmilling operationsonhardenedrolls.Theseinsertsareknownfortheirdurability, heatresistance,andabilitytodeliverprecisecuts,evenathighcutting speedsHalnnRollsCBNinsertsareidealforhigh-volumeproduction environmentswheretoollifeandconsistencyareparamount

2.RollsPCBNInserts

RollsPCBN(PolycrystallineCubicBoronNitride)insertsarespecifically engineeredformachiningextremelyhardmaterialslikechilledcastiron andhigh-alloysteel.HalnnRollsPCBNinsertsoffersuperiorwear resistanceandtoughness,makingthemsuitableforbothroughingand finishingoperationsonrollsthatdemandhigh-performancetooling.

3.RollsPCBNTools

HalnnRollsPCBNtoolsarespecializedcuttingtoolsdesignedforthe uniquechallengesofrollsmachining.Thesetoolsareengineeredto withstandthehighmechanicalandthermalstressestypicalinrolls

production,providingconsistentperformanceandextendedtoollife.

KeyFeaturesofHalnnRollsCBNTools

1.UnmatchedWearResistance

ThewearresistanceofHalnnRollsCBNtoolsisoneoftheirdefining features,allowingthemtooutlasttraditionalcuttingtoolsbyasignificant margin.Thismeansfewertoolchanges,lessdowntime,andmore efficientproductionprocesses.

2.HighHeatResistance

CBNtoolsaredesignedtoperforminhigh-temperatureenvironments, suchasthoseencounteredduringhigh-speedmachiningofhardenedrolls.

HalnnRollsCBNtoolsmaintaintheircuttingedgesevenatelevated temperatures,ensuringasmoothandconsistentmachiningprocess.

3.PrecisionandSurfaceFinish

HalnnRollsCBNtoolsoffersuperiorcuttingprecision,resultingin high-qualitysurfacefinishesonrolls.Thisisparticularlyimportantfor industrieswheretheaccuracyofrollsdirectlyimpactsthequalityofthe finalproduct.

4.DurabilityinInterruptedCutting

Inrollsmachining,interruptedcuttingiscommonduetothepresenceof groovesorsurfacepatterns.HalnnRollsCBNtoolsaredesignedto handlethesetoughconditionswithoutchippingorlosingperformance, ensuringreliableoperationandlongertoollife.

BenefitsofUsingHalnnRollsCBNTools

1.ExtendedToolLife

ThedurabilityofHalnnRollsCBNtoolsallowsforsignificantlylonger toollifecomparedtocarbideorceramictools.Thisreducestheneedfor frequenttoolchangesandminimizesproductioninterruptions,ultimately leadingtolowertoolingcosts.

2.EnhancedProductivity

Withlonger-lastingtoolsandreduceddowntime,manufacturerscan maintainhigh-speedmachiningwithoutcompromisingquality.Halnn RollsCBNtoolsenablefasterproductioncycles,improvingoverall

3.CostSavings

AlthoughCBNtoolshaveahigherupfrontcostthantraditionalcutting tools,theirextendedtoollifeandimprovedmachiningperformanceresult inlong-termcostsavings.HalnnRollsCBNtoolsofferexcellentvalueby reducingtoolchangefrequency,minimizingdowntime,anddelivering high-qualityresults.

4.ImprovedMachiningAccuracy

HalnnRollsCBNtoolsareknownfortheirabilitytodeliverprecisecuts, eveninthemostchallengingmachiningenvironments.Thisensures accuraterolldimensionsandsuperiorsurfacequality,reducingtheneed foradditionalfinishingprocessesandenhancingoverallproductquality.

ApplicationsofHalnnRollsCBNTools

HalnnRollsCBNtoolsarewidelyusedinindustrieswhererollsplaya criticalroleinproduction,including:

1.SteelMills

Rollsusedinsteelproductionaretypicallymadefromhardenedmaterials likehigh-speedsteelandchilledcastironHalnnRollsCBNtoolsare idealformachiningthesematerials,offeringhigh-speedperformanceand extendedtoollife

2.AutomotiveIndustry

Theautomotiveindustryreliesonrollstoproducehigh-strength

componentssuchasenginepartsandbrakediscs.HalnnRollsCBN insertsdelivertheprecisionanddurabilityneededtomachinethese componentswithaccuracyandefficiency.

3.AerospaceIndustry

Inaerospacemanufacturing,rollsareusedtoproducehigh-strengthalloys suchastitaniumandaluminum.HalnnRollsPCBNtoolsareperfectfor machiningthesematerials,offeringthenecessaryheatresistanceand cuttingprecision.

4.MetalworkingandHeavyManufacturing

Forindustriesthatinvolvelarge-scalemetalworkingandtheproduction ofheavymachinery,HalnnRollsCBNtoolsprovideunmatched performanceandreliability,ensuringsmoothandefficientmachining processes.

SelectingtheRightRollsCBNTool

WhenselectingtherightRollsCBNtoolforyouroperation,it’simportant toconsiderfactorssuchas:

Materialhardness:ChoosetheappropriateCBNgradebasedonthe materialoftheroll.

Cuttingspeed:Higherspeedsmayrequiretoolswithgreaterheat resistance

Machiningconditions:Forinterruptedcutting,ensurethetoolhas thenecessarytoughnesstowithstandmechanicalshocks.

Toolgeometry:Propertoolgeometryensuresoptimalcutting performanceandsurfacequality.

ExpertConsultation

Halnnoffersexpertconsultationtohelpyouchoosethemostsuitable RollsCBNtoolforyourspecificmachiningneeds.Ourexperiencedteam canprovidecustomizedsolutionstailoredtoyourproduction requirements,ensuringoptimalperformanceandcost-efficiency.

Conclusion

HalnnRollsCBNtoolsareengineeredtomeettheuniquechallengesof rollsmachining,offeringunparalleledhardness,wearresistance,and precision.Whetheryou'reworkingwithhardenedsteel,high-alloy materials,orchilledcastiron,Halnnprovidescuttingtoolsthatdeliver superiorperformance,extendedtoollife,andimprovedproductivity.By choosingHalnnRollsCBNtools,manufacturerscanachieve higher-qualityresults,reduceproductioncosts,andensureefficient machiningprocesses

FormoreinformationonhowHalnnRollsCBNtoolscanenhanceyour productionprocesses,contactustodaytolearnaboutourcomprehensive rangeofcuttingsolutions.

Ourwebsite:https://wwwhalnn-groupcom/ Email:halnntools@halnn-groupcom Whatsapp/Wechat:+8613271562251