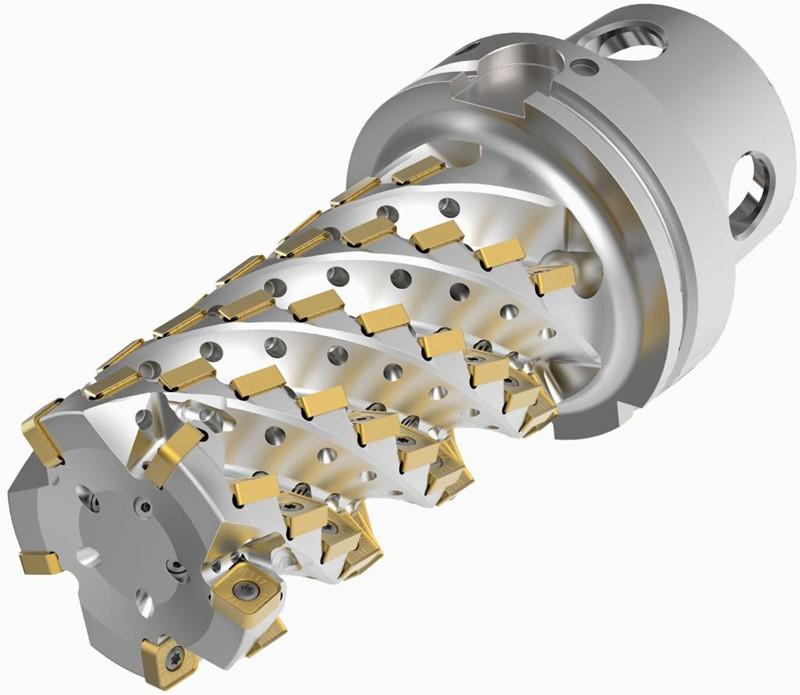

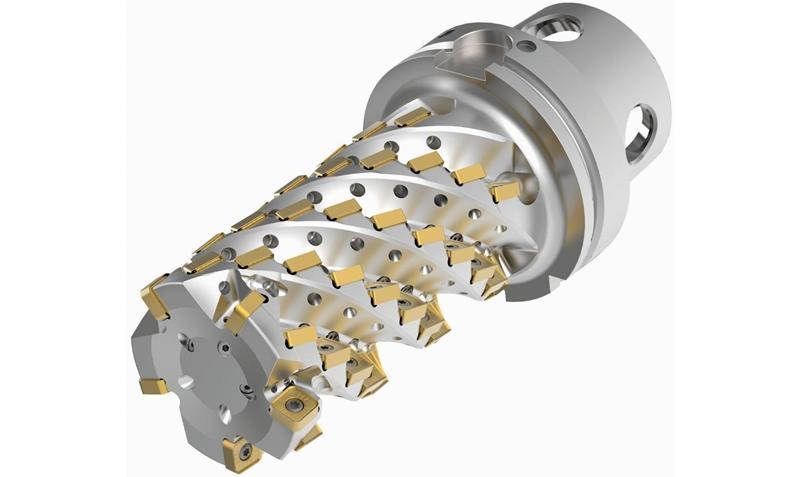

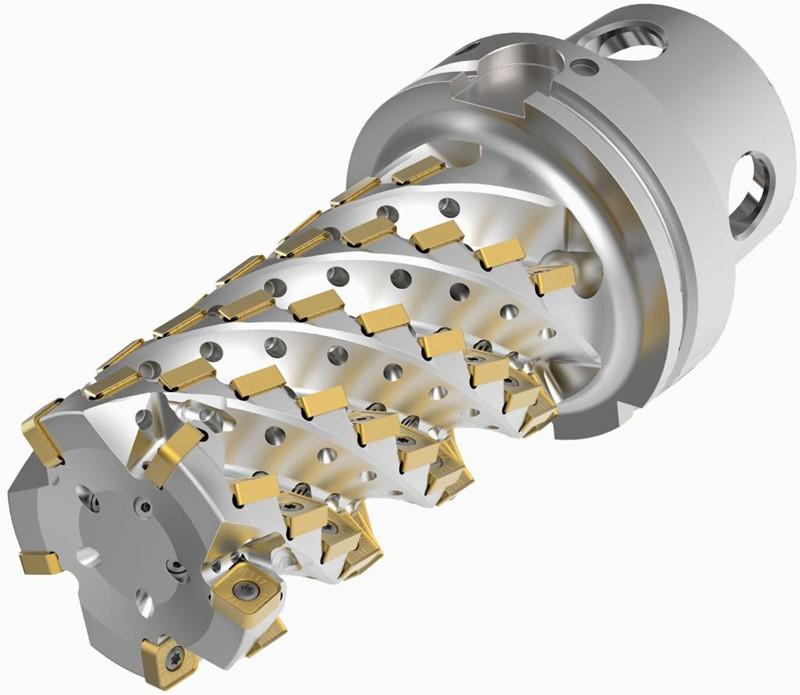

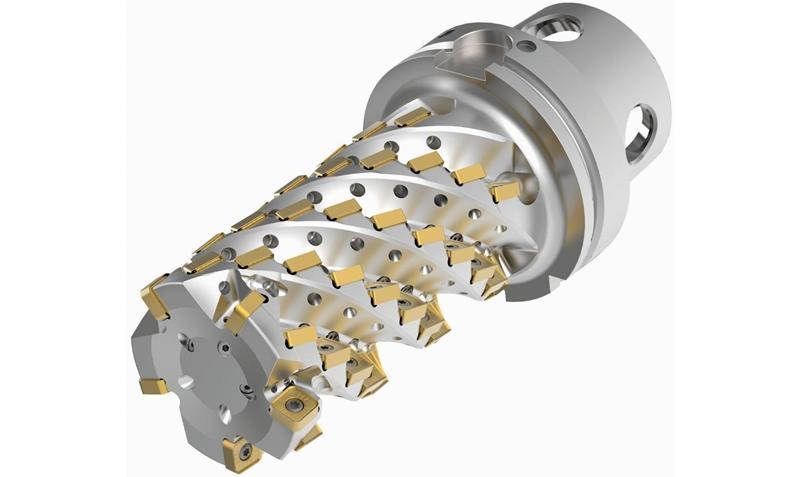

HalnnIndexableGearHobbingCutter:

RevolutionizingGearManufacturing

Intherealmofgearmanufacturing,precisionandefficiencyareparamount.Theindexablegear hobbingcutterisavitaltoolthataddressestheseneedseffectivelyThisarticlefocusesonthe specificsofindexablegearhobbingcutters,theiradvantages,applications,andhowHalnnis leadingthewayinthistechnologicaladvancement

WhatisanIndexableGearHobbingCutter?

Anindexablegearhobbingcutterisacuttingtooldesignedfortheprecisemachiningofgears. Unliketraditionalhobbingcuttersthatrequireresharpening,indexablegearhobbingcuttersuse replaceablecarbideinserts.Theseinsertscanbeeasilyreplacedonceworn,maintainingthe cutter'sperformancewithouttheneedforresharpening

Relatedpost:https://www.halnncbn.com/News/IndustryNews/599.html

KeyComponentsofanIndexableGearHobbingCutter

ToolBody:Themainstructurethatholdsthereplaceableinserts

IndexableInserts:High-performancecuttingedgesthatcanbereplacedwhenwornout.

ClampingMechanism:Ensuresthesecurepositioningoftheinsertsduringoperation

AdvantagesofIndexableGearHobbingCutters

IncreasedEfficiency

Indexablegearhobbingcuttersaredesignedtooperateathighercuttingspeeds,significantly reducingcycletimes.Thisleadstoincreasedproductivity,especiallyinhigh-volumeproduction environments

Cost-Effectiveness

Thereplaceablenatureoftheinsertsmeansthatonlythewornpartsneedtobereplaced,rather thantheentiretoolThisreducestheoveralltoolingcosts,makingtheprocessmoreeconomical

ConsistentPrecision

Thedesignofindexableinsertsensuresconsistentcuttingperformance,resultinginhigh-quality gearswithminimalvariationThisconsistencyiscriticalforapplicationsrequiringhighprecision

ReducedDowntime

Thequickreplacementofinsertsminimizesdowntime,whichiscrucialincontinuousproduction environments.Thisensuresthatmanufacturingprocessesremainefficientandproductive.

ApplicationsofIndexableGearHobbingCutters

AutomotiveIndustry

Theautomotivesectorreliesheavilyonprecisiongearsfortransmissionsandothercomponents. Indexablegearhobbingcuttersareidealforproducingthesehigh-qualitygearsefficiently

AerospaceIndustry

Inaerospace,gearsmustmeetstringentprecisionandreliabilitystandards.Indexablegearhobbing cuttershelpachievethesestandards,ensuringtheproductionoftop-qualitygears

HeavyMachineryManufacturing

Forheavymachinery,robustandreliablegearsareessential.Indexablegearhobbingcutters providethedurabilityandprecisionrequiredformanufacturingthesecomponents

OtherIndustrialApplications

Beyondautomotiveandaerospace,indexablegearhobbingcuttersareusedinvariousindustries wherehigh-qualitygearproductionisnecessary

HalnnInnovationsinIndexableGearHobbingCutters

Halnniscommittedtoadvancingthetechnologyofindexablegearhobbingcutters.Ourtools undergorigoroustestingandqualitycontroltoensuretheydeliversuperiorperformanceand longevity.

UniqueFeaturesofHalnnGearHobbingCutters

AdvancedCoatings:Ourcuttersfeatureadvancedcoatingsthatenhancewearresistanceand cuttingperformance.

OptimizedGeometry:Thegeometryofourcuttersisdesignedtoreducecuttingforcesand improveefficiency

High-QualityMaterials:Weusetop-gradematerialstoensurethedurabilityand effectivenessofourhobbingcutters

CaseStudiesandSuccessStories

Halnngearhobbingcuttershavebeensuccessfullyimplementedinvariousindustries,leadingto significantimprovementsinproductionefficiencyandcostsavings.Forinstance,amajor automotivemanufacturerreporteda30%increaseinproductivityafterswitchingtoHalnn indexablegearhobbingcutters.

CustomerTestimonials

"OurswitchtoHalnnindexablegearhobbingcuttershastransformedourmanufacturingprocess Thetoollifeandprecisionareexceptional,andwe'veseenconsiderablecostsavings."–John Smith,ManufacturingDirectoratAutoTechIndustries

ChoosingtheRightIndexableGearHobbingCutter

Selectingtheappropriateindexablegearhobbingcutterinvolvesconsideringseveralfactors:

MaterialCompatibility:Ensurethecutterissuitableforthematerialbeingmachined

CutterSizeandGeometry:Choosebasedonthegearsizeandrequiredtolerances

SpecificApplicationNeeds:Considerthespecificrequirementsofyourapplication,suchas cuttingspeedandsurfacefinish

MaintenanceandCareforIndexableGearHobbing Cutters

BestPractices

Regularmaintenanceandinspectionofthetoolandinsertsarecrucialtooptimizeperformance

Replaceinsertsbeforetheywearexcessivelytomaintaincuttingefficiency

TipsforExtendingToolLife

Useappropriatecuttingparameters

Avoidexcessivecuttingspeedsandfeedrates

Ensurepropercoolingandlubricationduringthecuttingprocess

CommonIssuesandTroubleshooting

InsertWear:Regularlyreplaceinsertsandusetheappropriategradeforthematerial

ToolVibration:Checktheclampingmechanismandmachinestability.

SurfaceFinishIssues:Adjustcuttingparametersandinspectinsertsforwearordamage

FutureTrendsinGearHobbingTechnology

AdvancesinMaterialsandCoatings

Newmaterialsandcoatingswillcontinuetoenhancetheperformanceandlongevityofgear hobbingcutters

InnovationsinCutterDesign

Ongoingresearchanddevelopmentwillleadtofurtherimprovementsincutterdesign,increasing efficiencyandprecision.

ImpactofIndustry4.0andAutomation

Theintegrationofsmarttechnologiesandautomationwillmakegearhobbingprocessesmore efficientandadaptive,reducinghumaninterventionandincreasingaccuracy

Conclusion

Indexablegearhobbingcuttersarerevolutionizinggearmanufacturingwiththeirefficiency, precision,andcost-effectiveness.Halnnisattheforefrontofthisinnovation,providingadvanced toolsthatmeetthedemandsofmodernmanufacturingBychoosingHalnnindexablegearhobbing cutters,youareinvestingintoolsthatofferexceptionalperformanceandlongevity.

FormoreinformationonHalnnindexablegearhobbingcuttersandtodiscussyourspecificneeds, pleasevisitourwebsiteorcontactoursalesteamLetHalnnhelpyouachieveunparalleled precisionandefficiencyinyourgearmanufacturingprocess

Ourwebsite:https://wwwhalnncbncom/ Mailaddress:halnntools@halnn-groupcom