UnderstandingCrankshaftCuttingTools

DefinitionandPurpose

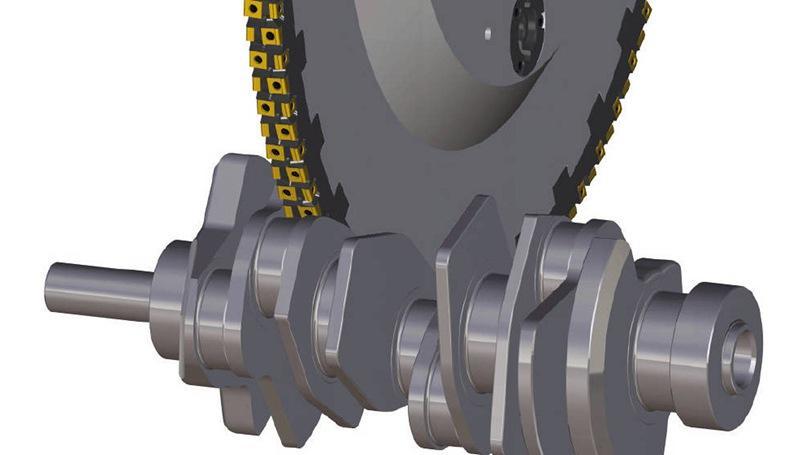

Crankshaftcuttingtoolsarespecializedinstrumentsusedtomachinecrankshafts,acrucial componentininternalcombustionengines.Thesetoolsaredesignedtocut,shape,andfinish crankshaftswithhighprecision,ensuringtheymeetexactspecifications

TypesofCrankshaftCuttingTools

·ExternalCrankshaftMillingCutters:Usedformachiningtheoutersurfacesofcrankshafts Theyareessentialforensuringthecrankshaft'sexternalfeaturesareaccuratelyshapedand finished.

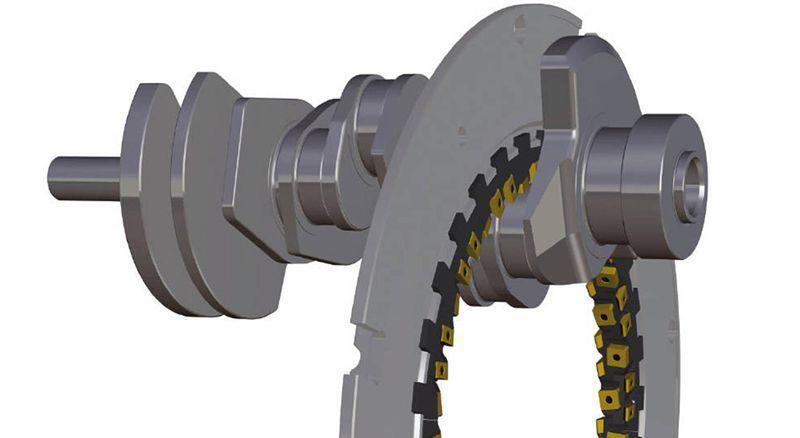

·InternalCrankshaftMillingCutters:Designedforinternalmachiningtasks,suchas cuttinginternalgroovesandslotswithinthecrankshaft.

ImportanceofCrankshaftCuttingToolsinEngine Manufacturing

RoleinEnginePerformance

Theperformanceandreliabilityofanengineheavilydependontheprecisionofitscrankshaft.

Crankshaftcuttingtoolsensurethateverycrankshaftmeetstherequiredstandards, contributingtotheengine'soverallefficiencyanddurability.

ChallengesinCrankshaftMachining

Machiningcrankshaftsiscomplexduetotheirintricateshapesandtheneedforhighprecision Theprocessrequirestoolsthatcanhandlethetoughmaterialsanddemandingconditions involvedincrankshaftmanufacturing

DetailedTypesofCrankshaftCuttingTools

ExternalCrankshaftMillingCutters

Externalcrankshaftmillingcuttersarecrucialforshapingandfinishingtheoutersurfacesof crankshafts.Thesecuttersmustberobustandprecisetohandletheexternalcontoursand ensureasmoothfinish

KeyFeaturesofHigh-QualityCrankshaftCutting Tools

MaterialComposition

High-qualitycrankshaftcuttingtoolsaretypicallymadefromdurablematerialssuchas carbideandhigh-speedsteel,whichofferexcellentwearresistanceandlongevity.

CoatingsandTreatments

CoatingslikeTitaniumNitride(TiN),TitaniumCarbo-Nitride(TiCN),andAluminum TitaniumNitride(AlTiN)enhancetheperformanceofcuttingtoolsbyreducingfrictionand increasinghardness

DesignandGeometry

Thedesignandgeometryofcrankshaftcuttingtoolsarecriticalforachievingoptimalcutting performanceAdvanceddesignsensureefficientmaterialremovalandprecisefinishing

AdvantagesofUsingHalnnCrankshaftCuttingTools

SuperiorQualityandPrecision

HalnncrankshaftcuttingtoolsarerenownedfortheirsuperiorqualityandprecisionOurtools areengineeredtodeliverexceptionalperformance,ensuringeverycutisaccurateand consistent

InnovativeTechnology

AtHalnn,weutilizecutting-edgetechnologyandinnovativeprocessestomanufactureour crankshaftcuttingtoolsThiscommitmenttoinnovationensuresourtoolsmeetthehighest industrystandards.

CustomerTestimonialsandCaseStudies

OurclientsconsistentlypraisethereliabilityandperformanceofHalnncrankshaftcutting tools.Casestudieshighlightsignificantimprovementsinproductionefficiencyandproduct

qualityafterimplementingourtools

HowtoChoosetheRightCrankshaftCuttingTools

FactorstoConsider

Whenselectingcrankshaftcuttingtools,considerthematerialofthecrankshaft,therequired surfacefinish,andtheproductionvolume.Thesefactorswillinfluencethetypeand specificationsofthetoolsneeded

CustomSolutions

Halnnofferscustomtoolsolutionstailoredtospecificapplications.Ourteamworksclosely withclientstodeveloptoolsthatmeettheiruniquerequirements,ensuringoptimal performanceandefficiency.

BestPracticesforUsingCrankshaftCuttingTools

ProperSetupandMaintenance

Propersetupandmaintenanceofcrankshaftcuttingtoolsarecrucialforachievingthebest resultsRegularmaintenanceandcorrectsetuphelpextendtoollifeandmaintaincutting performance.

FAQsofcrankshaftcuttingtools

Whatarecrankshaftmillingcutters?

Crankshaftmillingcuttersaretoolsspecificallydesignedformachiningthesurfacesof crankshafts,ensuringtheymeetprecisespecifications

Whatarethedifferencesbetweenexternaland internalcrankshaftmillingcutters?

Externalcrankshaftmillingcuttersmachinetheoutersurfaces,whileinternalcrankshaft millingcuttersareusedforinternalfeatureslikegroovesandslots

Whatarecrankshaftcuttingtools?

Crankshaftcuttingtoolsarespecializedtoolsdesignedformachiningcrankshafts,whichare criticalcomponentsininternalcombustionenginesThesetoolsareusedtoshape,cut,and finishcrankshaftstomeetprecisespecifications.

Whattypesofcrankshaftcuttingtoolsareavailable?

Thereareseveraltypesofcrankshaftcuttingtools,including: ExternalCrankshaftMillingCutters:Usedformachiningtheexternalsurfacesofthe crankshaft.

InternalCrankshaftMillingCutters:Designedforinternalmachiningtasks,suchascutting groovesandrecessesinsidethecrankshaft.

Whyisprecisionimportantincrankshaftcutting tools?

Precisioniscrucialincrankshaftcuttingbecausethecrankshaft'saccuracydirectlyaffects engineperformanceandreliabilityPrecisecuttingensuresthatthecrankshaftmeetsstringent dimensionalandtolerancerequirements.

Whatmaterialsarecrankshaftcuttingtoolsmade from?

CrankshaftcuttingtoolsaretypicallymadefromdurablematerialssuchascarbideThese materialsofferexcellentwearresistanceandlongtoollife,essentialforhandlingthetough materialsusedincrankshaftmanufacturing

Howdoexternalandinternalcrankshaftmilling cuttersdiffer?

Externalcrankshaftmillingcuttersareusedtomachinetheoutersurfacesofthecrankshaft, ensuringpropershapingandfinishingInternalcrankshaftmillingcutters,ontheotherhand, areusedtomachineinternalfeatureslikegroovesandrecesseswithinthecrankshaft.

Whatarethebenefitsofusinghigh-quality crankshaftcuttingtools?

High-qualitycrankshaftcuttingtoolsprovideseveralbenefits,including:

·Improvedprecisionandsurfacefinish

Increasedproductionefficiency

·Reducedtoolwearandlongertoollife

Consistentmachiningperformance

Howdoestooldesignaffectcrankshaftcutting performance?

Thedesignandgeometryofcrankshaftcuttingtoolsarecriticalforoptimalcutting performance.Advancedtooldesignsensureefficientmaterialremoval,reducedcuttingforces, andimprovedsurfacefinish

Whatarethebestpracticesformaintaining crankshaftcuttingtools?

Propermaintenanceiskeytomaximizingtheperformanceandlifespanofcrankshaftcutting toolsBestpracticesinclude:

·Regularinspectionforwearanddamage

Propercleaningandstorage

·Usingappropriatecuttingparameters

Ensuringcorrecttoolsetupandalignment

Cancrankshaftcuttingtoolsbecustomized?

Yes,manymanufacturers,includingHalnn,offercustomcrankshaftcuttingtoolstailoredto specificmachiningneedsCustomtoolsaredesignedtomeetuniquerequirements,ensuring optimalperformanceandefficiency.

Howdoesthechoiceofcuttingparametersimpact crankshaftmachining?

Cuttingparameterssuchascuttingspeed,feedrate,anddepthofcutsignificantlyimpactthe machiningprocess.Optimizingtheseparameterscanenhancecuttingefficiency,reducetool wear,andimprovetheoverallqualityofthecrankshaft

Whatadvancementshavebeenmadeincrankshaft cuttingtooltechnology?

Recentadvancementsincrankshaftcuttingtooltechnologyincludethedevelopmentofnew toolmaterials,advancedcoatings,andimprovedtoolgeometries.Theseinnovationsenhance toolperformance,durability,andmachiningaccuracy

WherecanIfindreliablecrankshaftcuttingtools?

Halnnisareputableproviderofhigh-qualitycrankshaftcuttingtools.Weofferawiderange oftoolsdesignedforvariouscrankshaftmachiningapplications,ensuringprecision,efficiency, andreliability

TechnicalSupportandServices

Halnnofferscomprehensivetechnicalsupportandservicestoassistclientswiththeir crankshaftcuttingtoolneedsOurexpertteamisavailabletoprovideguidanceandanswer anytechnicalquestions.

Conclusion

Crankshaftcuttingtoolsarevitalfortheprecisemachiningofcrankshafts,ensuringhigh performanceandreliabilityofengines.Halnn'ssuperiorqualityandinnovativetechnology makeustheleadingchoiceforcrankshaftcuttingtoolsBychoosingHalnn,youareinvesting intoolsthatdeliverexceptionalperformance,efficiency,andvalue.

Formoreinformationonourproductsandservices,visitHalnn'sofficialwebsiteorcontact ourcustomersupportteam.Exploreourrangeofcrankshaftcuttingtoolsanddiscoverhow wecanhelpyouenhanceyourmanufacturingprocesses

Email:halnntools@halnn-group.com

Whatsapp/Wechat:+8613271562251

Ourwebsite:https://www.halnntools.com/