EnhancingWindTurbineBladeProduction withHalnnPCDInserts

Introduction

Windenergyisacrucialcomponentoftheglobalrenewableenergylandscape,andtheefficiency ofwindturbineslargelydependsonthequalityoftheirblades.Precisionanddurabilityarekeyin themanufacturingofwindturbineblades,andPolycrystallineDiamond(PCD)insertshave becomeanessentialtoolinachievingthesegoals.Halnn,aleaderinthetoolingindustry,provides high-qualityPCDinsertsspecificallydesignedforwindturbinebladeproductionThisarticlewill explorethebenefitsandapplicationsofHalnn'sPCDinserts,providingvaluableinformationfor manufacturerslookingtoenhancetheirproductionprocesses

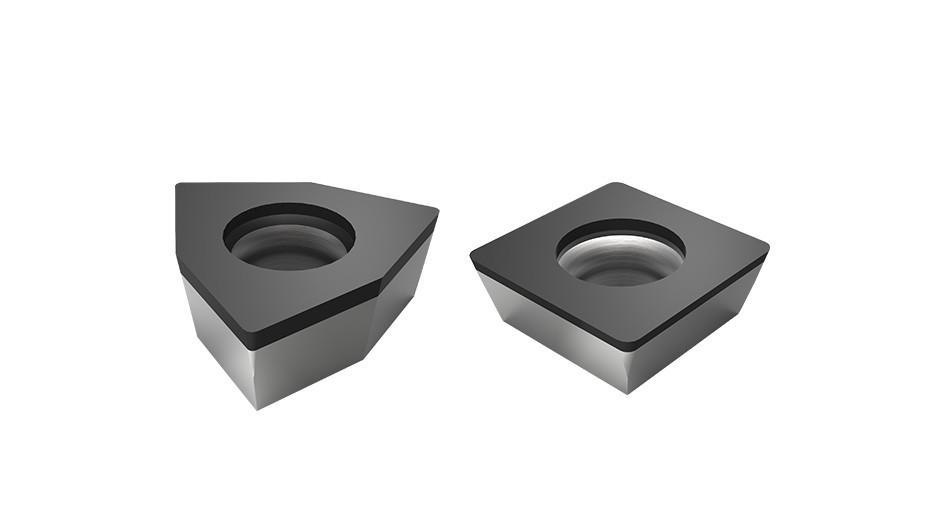

WhatarePCDInserts?

PCDinsertsarecuttingtoolsmadefrompolycrystallinediamond,amaterialknownforits exceptionalhardnessandwearresistanceTheseinsertsareusedinvariousmachiningprocessesto achievehighprecisionandefficiency.

WhyChoosePCDInsertsforWindTurbineBlades?

SuperiorHardnessandWearResistance

PCDinsertsofferunmatchedhardnessandwearresistance,makingthemidealformachiningthe compositematerialsusedinwindturbineblades

HighPrecisionandSurfaceFinish

HalnnPCDinsertsprovideexcellentprecisionandsurfacefinish,crucialfortheaerodynamic efficiencyanddurabilityofwindturbineblades

EnhancedProductivity

UsingPCDinsertsreducestoolchangefrequencyandincreasescuttingspeeds,leadingtohigher productivityandcostsavings

LongToolLife

PCDinsertshaveasignificantlylongertoollifecomparedtotraditionalcarbidetools,reducing downtimeandmaintenancecosts

HalnnPCDInserts:FeaturesandBenefits

CustomizedSolutions

HalnnofferscustomizedPCDinsertstailoredtothespecificneedsofwindturbineblade manufacturers,ensuringoptimalperformanceandefficiency

AdvancedManufacturingTechniques

HalnnusesadvancedmanufacturingtechniquestoproducePCDinsertswithsuperiorqualityand consistency,ensuringreliableperformanceindemandingapplications

ComprehensiveSupport

Halnnprovidescomprehensivesupport,includingtechnicalassistanceandtraining,tohelp customersoptimizetheirmachiningprocessesandachievethebestresults

MachiningCompositeMaterials

PCDinsertsareidealformachiningthecompositematerialsusedinwindturbineblades, providingcleancutsandreducingtheriskofdelamination.

FinishingOperations

HalnnPCDinsertsareperfectforfinishingoperations,ensuringasmoothsurfacefinishthat enhancestheaerodynamicpropertiesofwindturbineblades.

DrillingandMilling

PCDinsertscanbeusedindrillingandmillingoperationstoachievepreciseholesandcomplex shapes,essentialfortheassemblyandperformanceofwindturbineblades.

CaseStudies

ImprovedEfficiencyinBladeManufacturing

Aleadingwindturbinemanufacturerreporteda30%increaseinproductionefficiencyanda20% reductionintoolcostsafterswitchingtoHalnnPCDinserts

EnhancedBladePerformance

Anothermanufacturerachievedasignificantimprovementinbladeperformanceandlongevity, thankstothesuperiorsurfacefinishandprecisionprovidedbyHalnnPCDinserts

TipsforSelectingtheRightPCDInserts

MaterialCompatibility

EnsurethePCDinsertsarecompatiblewiththespecificcompositematerialsusedinyourwind turbineblades

ApplicationRequirements

Considerthespecificmachiningoperations,suchascutting,drilling,ormilling,andchoosePCD insertsdesignedforthosetasks.

ManufacturerSupport

ChooseareputablemanufacturerlikeHalnn,whichofferscomprehensivesupportandcustomized solutionstomeetyouruniqueneeds

MaintenanceandCareforPCDInserts

RegularInspection

RegularlyinspectPCDinsertsforwearanddamagetomaintainoptimalperformanceandextend toollife.

ProperHandling

HandlePCDinsertswithcaretoavoidchippingordamage,ensuringtheyremaininexcellent conditionforuse

CorrectUsage

Followmanufacturerrecommendationsforcuttingspeeds,feeds,andotherparameterstoachieve thebestresultswithyourPCDinserts.

Conclusion

PCDinsertsareavitaltoolintheproductionofhigh-qualitywindturbineblades,offeringsuperior hardness,wearresistance,andprecision.HalnnPCDinsertsprovidecustomizedsolutions, advancedmanufacturingtechniques,andcomprehensivesupport,makingthemtheidealchoice formanufacturerslookingtoenhancetheirproductionprocesses.BychoosingHalnnPCDinserts, youcanachievehigherproductivity,betterbladeperformance,andsignificantcostsavings

FrequentlyAskedQuestions(FAQs)

WhatarePCDinserts,andwhyaretheyusedinwindturbine bladeproduction?

PCDinsertsarecuttingtoolsmadefrompolycrystallinediamond,knownfortheirexceptional hardnessandwearresistanceTheyareusedinwindturbinebladeproductiontoachievehigh precisionandefficiencyinmachiningcompositematerials

HowdoHalnnPCDinsertsenhanceproductivity?

HalnnPCDinsertsreducetoolchangefrequency,increasecuttingspeeds,andprovidelongertool life,leadingtohigherproductivityandcostsavings

CanHalnnprovidecustomizedPCDinsertsforspecific applications?

Yes,HalnnofferscustomizedPCDinsertstailoredtothespecificneedsofwindturbineblade manufacturers,ensuringoptimalperformanceandefficiency

WhatmaintenancepracticesshouldbefollowedforPCD inserts?

Regularinspection,properhandling,andfollowingmanufacturerrecommendationsforcutting speedsandfeedsareessentialformaintainingPCDinserts

WhatsupportdoesHalnnofferforitsPCDinserts?

Halnnprovidescomprehensivesupport,includingtechnicalassistanceandtraining,tohelp customersoptimizetheirmachiningprocessesandachievethebestresults

ByleveragingthebenefitsofHalnnPCDinserts,windturbineblademanufacturerscanachieve superiorquality,enhancedproductivity,andsignificantcostsavings.Formoreinformationorto purchaseHalnnPCDinserts,contactustoday

Ourwebsite:https://www.halnncbn.com/

Mailaddress:halnntools@halnn-groupcom

WhatsApp:+8615515925975