EnhancingMachiningPrecisionwith Anti-VibrationDampingToolBars:AHalnn

Innovation

Inthedemandingworldofprecisionmachining,eventheslightestvibrationscan compromisethequalityofthefinalproduct.Suchvibrationscanleadtopoorsurface finishes,reduceddimensionalaccuracy,anddecreasedtoollifeAddressingthese challenges,Halnnproudlyintroducesitsstate-of-the-artanti-vibrationdampingtool bars,designedtoelevatemachiningperformanceandreliability Relatedpost:https://www.halnn-group.com/news/1828.html

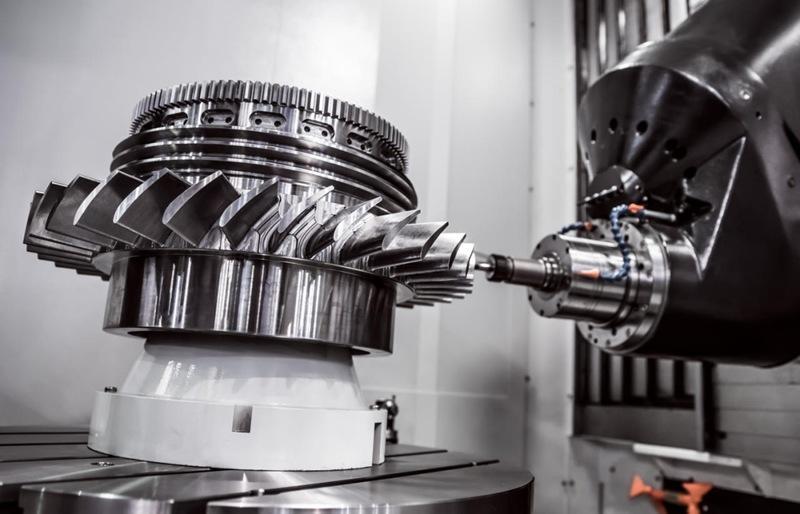

UnderstandingAnti-VibrationDampingToolBars

Anti-vibrationdampingtoolbarsarespecializedtoolsengineeredtomitigate vibrationsduringmachiningprocesses.Theyincorporateadvancedmaterialsand sophisticateddesignsthatabsorbanddissipatevibrationalenergy,ensuringsmoother operationsandhigherprecision.

HowDoTheyWork?

ThecorefunctionalityofthesetoolbarsliesintheirconstructionTheyutilize viscoelasticmaterialsandcompositestructuresthatcounteracttheforcesgenerating

vibrationsByabsorbinganddissipatingvibrationalenergy,thesetoolbarsstabilize themachiningprocess,leadingtoimprovedsurfacefinishesandaccuracy.

BenefitsofUsingHalnn'sAnti-VibrationDampingTool Bars

Halnn’santi-vibrationdampingtoolbarsofferamultitudeofadvantages,making themanessentialcomponentinhigh-precisionmachiningenvironments:

ImprovedSurfaceFinish

Bysignificantlyreducingvibrations,thesetoolbarshelpachievesuperiorsurface finishes.Thisiscrucialinindustrieswheresurfacequalityisparamount,suchas aerospaceandautomotivemanufacturing

EnhancedDimensionalAccuracy

StablemachiningconditionsfacilitatedbyHalnn'stoolbarsensurethatdimensional tolerancesaremaintained,resultinginhigherqualitycomponents