EnhancingCamshaftProductionEfficiency withHalnn'sAdvancedCamshaftMilling Inserts

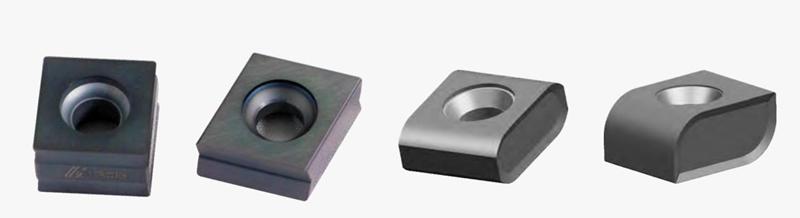

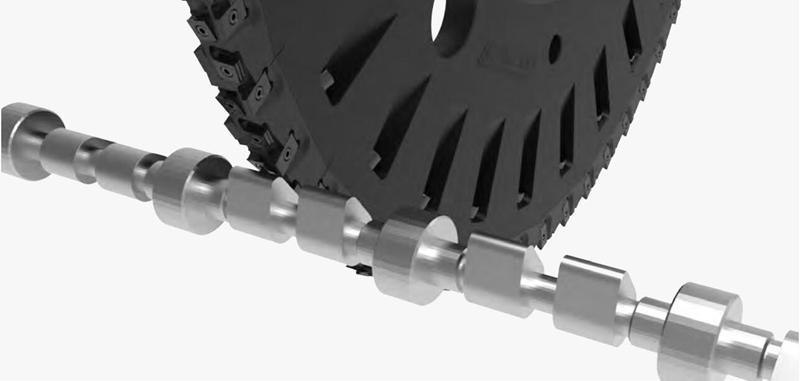

Inthemanufacturingofinternalcombustionengines,thecamshaftisacrucialcomponent responsibleforcontrollingvalvetimingandensuringoptimalengineperformance.Precisionin camshaftmanufacturingisnon-negotiable,aseventheslightestdeviationcanleadtosignificant engineinefficiencies.Thisiswherecamshaftmillinginsertscomeintoplay.Halnn,aleaderin cuttingtooltechnology,providesadvancedcamshaftmillinginsertsdesignedtoenhance productionefficiencywhilemaintainingthehigheststandardsofprecisionandquality.

Relatedpost:https://wwwhalnnpcdcom/industrynews/903html