DampingAnti-SeismicToolBar:Enhancing MachiningPrecisionandStabilitywithHalnn

Inmodernmachining,precisionandstabilityareparamountTheabilitytoproduce partswithexactspecificationsandhigh-qualitysurfacefinishescansignificantly impacttheefficiencyandprofitabilityofmanufacturingprocessesOnecritical advancementinachievingthesegoalsistheuseofdampinganti-seismictoolbars. Halnn,aleaderinthemachiningtoolindustry,offerscutting-edgesolutionsthatset thestandardforvibrationcontrolandmachiningexcellence.

Relatedpost:https://wwwhalnncbncom/News/IndustryNews/608html

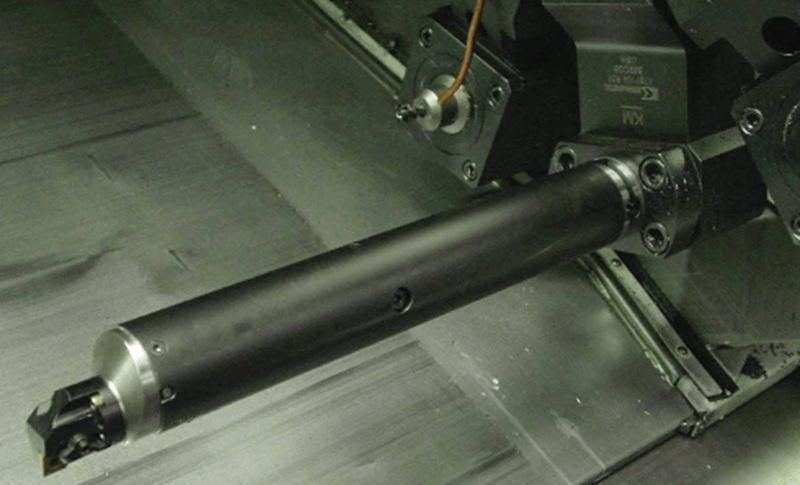

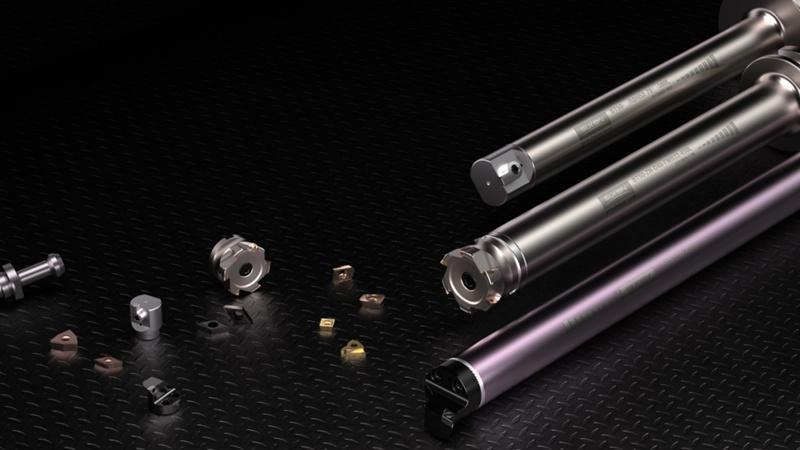

UnderstandingDampingAnti-SeismicToolBars

Dampinganti-seismictoolbarsarespecializedtoolsdesignedtoreduceandcontrol vibrationsduringthemachiningprocess.Thesetoolsincorporateadvancedmaterials andengineeringdesignstoabsorbanddissipatevibrationalenergy,ensuringamore stableandprecisecuttingoperation.Thisresultsinimprovedsurfacefinish, dimensionalaccuracy,andoverallmachiningefficiency.