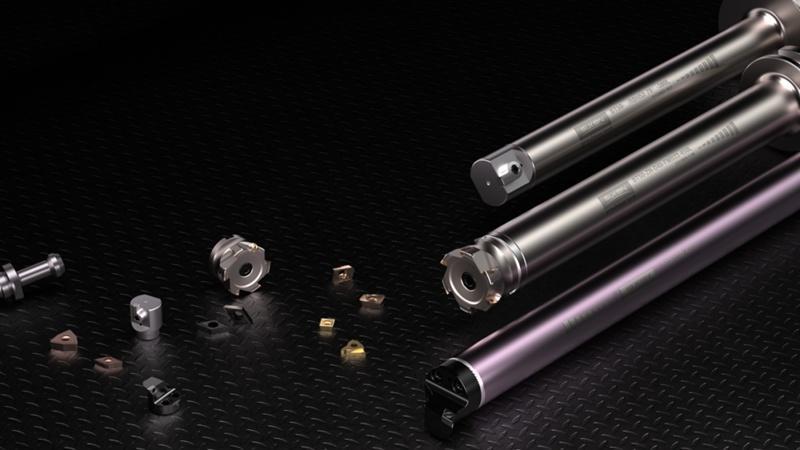

DampenedToolsforLongOverhang

Machining:EnhancingPrecisionwithHalnn

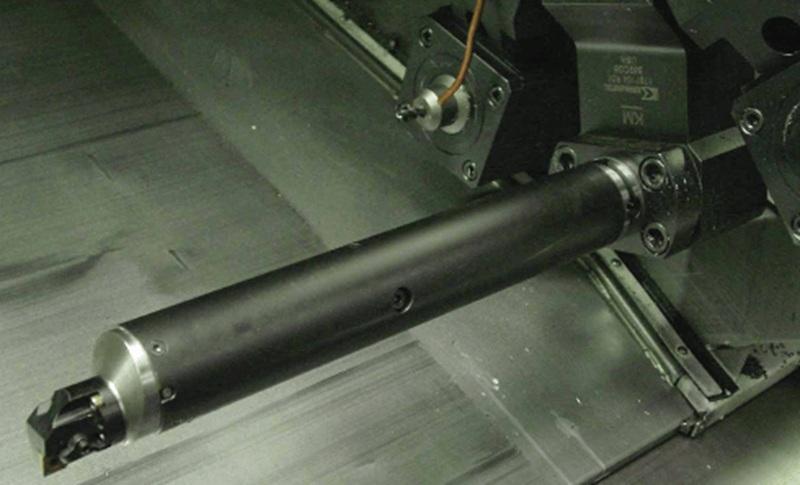

Machiningoperationsoftenencounterchallenges,particularlywhenworkingwith longoverhangs.Vibration-inducedissuescanleadtopoorsurfacefinishes,reduced accuracy,andshortenedtoollifeHalnn,aleaderinadvancedmachiningsolutions, offersarangeofdampenedtoolsspecificallydesignedtoaddressthesechallenges. Thisarticledelvesintotheimportanceofdampenedtoolsforlongoverhang machiningandhighlightshowHalnn'sinnovativesolutionscanenhanceyour machiningprocesses

Relatedpost:https://www.halnn-group.com/news/1830.html

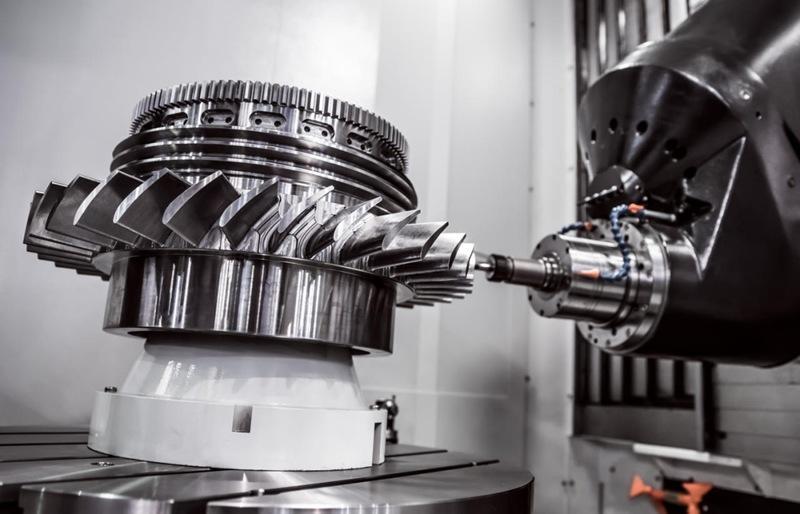

UnderstandingLongOverhangMachining

Longoverhangmachiningreferstooperationswherethetoolextendssignificantly fromitssupportorholder.Thisextendedreachisessentialforaccessingdeepor hard-to-reachareas,butitcomeswithitsownsetofchallengesTheprimaryissueis theincreasedsusceptibilitytovibrations,whichcanleadto:

Chatter:Unstablecuttingactionthatproducesapoorsurfacefinish

ToolDeflection:Deviationofthetoolfromitsintendedpath,resultingin dimensionalinaccuracies.

ReducedToolLife:Acceleratedwearandtearduetoconstantvibrations.