Halnn:CuttingParametersofCBNTools

UnderstandingthecuttingparametersofCBN(CubicBoronNitride) toolsisessentialforachievingoptimalmachiningperformance.CBN toolsareknownfortheirexceptionalhardnessandthermalstability, makingthemidealformachininghardenedmaterials.Thisarticle exploresthecriticalcuttingparametersthatinfluencetheeffectivenessof CBNtools,providingvaluableinsightsforuserswhilepromotingHalnn's expertiseintheindustry.

Relatedpost:https://www.halnncbn.com/News/IndustryNews/634.html

KeyCuttingParameters

1.CuttingSpeed(Vc)

Cuttingspeed(Vc)isthespeedatwhichthecuttingedgeofthetool movesrelativetotheworkpiece.ForCBNtools,therecommended cuttingspeedgenerallyrangesfrom100to200m/min.Thechoiceof cuttingspeedcansignificantlyimpacttoollifeandsurfacefinish.Higher speedstendtoenhancematerialremovalratesbutmayalsoincreasetool wearifnotmanagedcorrectly.

2.FeedRate(f)

Thefeedrate(f)definesthedistancethetooladvancesduringone revolutionoftheworkpiece.ForCBNtools,atypicalfeedrateranges from0.1to0.3mm/rev.Properlysettingthefeedrateiscrucialfor achievingabalancebetweenproductivityandsurfacequality.An appropriatefeedratehelpstoensureeffectivechipremovalandprevents excessiveheatgeneration.

3.DepthofCut(ap)

Depthofcut(ap)referstothethicknessofthematerialremovedina singlepass.ForCBNtools,optimaldepthsettingsusuallyrangefrom0.5 to2mm.Thedepthofcutinfluencescuttingforcesandheatgeneration; therefore,it’svitaltochooseadepththatmaximizesefficiencywithout

FactorsInfluencingCuttingParameters

SeveralfactorscaninfluencetheselectionofcuttingparametersofCBN tools:

MaterialCharacteristics:Thehardnessandtoughnessofthe workpiecematerialarecriticalindeterminingsuitablecutting parameters.Hardermaterialsmaynecessitatelowercuttingspeedsor feedratestopreventprematuretoolwear.

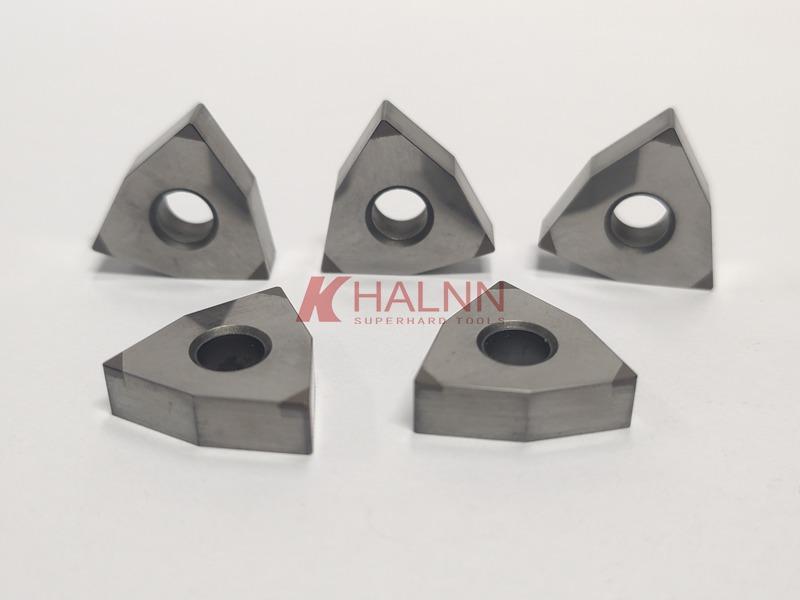

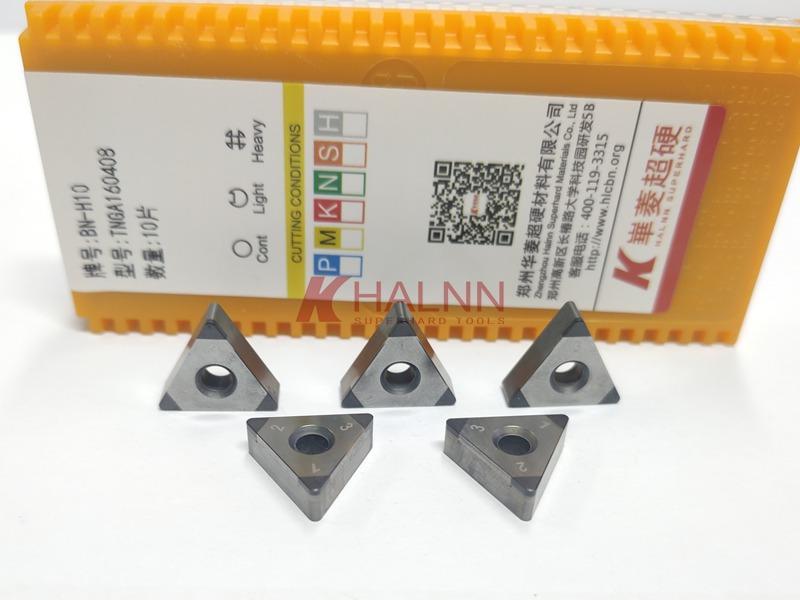

ToolGeometry:ThedesignandgeometryoftheCBNtool,including itscuttingedgeandcoating,canaffectitsperformance.Selectingthe righttooldesignisessentialforoptimizingmachiningprocesses.

MachineCapabilities:Thecapabilitiesofthemachiningequipment,

suchasmaximumspindlespeedandrigidity,willimpactthe achievablecuttingparameters.Ensuringthatthemachineis well-suitedtothechosenparametersiskeytosuccessfulmachining.

OptimizingCuttingParameters

Tooptimizecuttingparameterseffectively:

ConductTrialRuns:Initialtrialrunscanhelpidentifythebest parametersforspecificmaterialsandapplicationsDatacollected duringthesetrialscaninformnecessaryadjustments.

AnalyzePerformanceData:Regularlyreviewingdatarelatedtotool wear,surfacefinish,andmaterialremovalrateshelpsinfine-tuning parametersforimprovedperformance.

ConsiderMaterial-SpecificRecommendations:Tailoringcutting parametersbasedonthespecificmaterialbeingmachinedisessential. Differentmaterialsresponduniquelytocuttingspeeds,feedrates,and depthsofcut.

Conclusion

UnderstandingandeffectivelymanagingthecuttingparametersofCBN toolsarevitalforachievingsuperiormachiningresults.Byconsidering factorssuchascuttingspeed,feedrate,anddepthofcut,userscan enhancebothtoolperformanceandlongevity.Halnnisdedicatedto providingadvancedsolutionsandexpertiseinCBNtoolapplications,

ensuringthatourcustomerscanmeettheirmachiningobjectives efficiently.

Formoreinformationonoptimizingcuttingparametersortoexploreour rangeofCBNtools,pleasevisitHalnn’swebsiteorcontactourexperts forpersonalizedassistanceByfollowingtheguidelinesoutlinedinthis article,userscanmaximizetheirmachiningefficiencyandqualitywith Halnn’sinnovativeCBNsolutions.

Ourwebsite:https://www.halnncbn.com/

Email:halnntools@halnn-group.com

Whatsapp/Wechat:+8613271562251