CeramicInsertCuttingSpeed:UnlockingPeak PerformanceinMachiningOperations

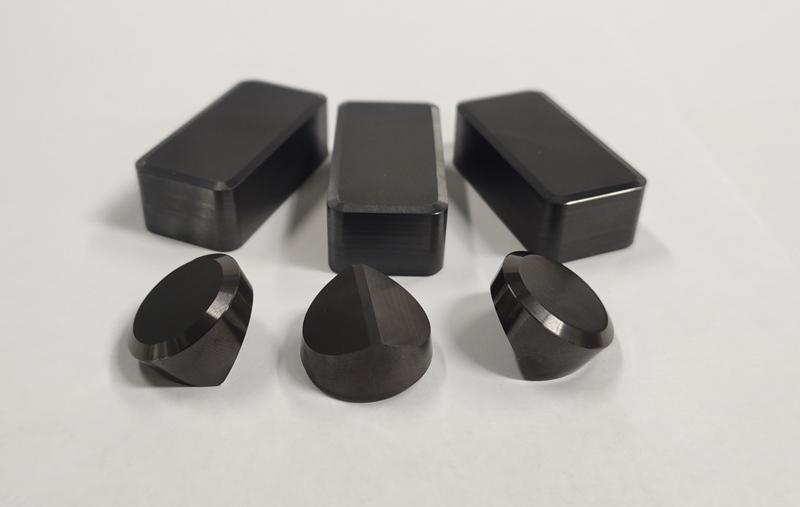

Halnn'sCeramicInsertsforOptimalCuttingEfficiency

Inmodernmachining,ceramicinsertshavebecomeindispensable,especiallywhen workingwithhardmaterialslikecastironandhardenedsteelOneofthemost significantfactorsinoptimizingtheperformanceofceramicinsertsiscuttingspeed. Understandingandproperlyadjustingthecuttingspeedcansignificantlyaffect productivity,toollife,andsurfacefinish.Thisarticledelvesintotheimportanceof cuttingspeedwhenusingceramicinsertsandhowHalnn,aleaderincuttingtool technology,offerssolutionsforpeakperformance.

Relatedpost:https://wwwhalnn-groupcom/news/1840html

WhyCuttingSpeedisCrucialforCeramicInserts

Cuttingspeedreferstothespeedatwhichthecuttingtoolengageswiththeworkpiece, typicallymeasuredinmetersperminute(m/min)Forceramicinserts,cuttingspeedis

criticalbecausethesetoolsaredesignedtooperateefficientlyathightemperatures, makingthemparticularlyeffectiveforhigh-speedmachining.

Unlikecarbideinserts,whichrelyonmoderatecuttingspeedsandoftenrequire coolant,ceramicinsertscanoperateatsignificantlyhigherspeeds,oftenwithoutthe needforcoolant.Thisallowsmanufacturerstoincreaseproductivitywhile maintainingexcellentsurfacefinishesandreducingtoolwear

RecommendedCuttingSpeedsforCeramicInserts

Toachievethebestresultswithceramicinserts,itisessentialtousetheappropriate cuttingspeedsforthematerialbeingmachinedTypically,ceramicinsertsareusedat cuttingspeedsof:

CastIron:800to1,200m/min

HardenedSteel(HRC45-65):150to300m/min

Theoptimalceramicinsertcuttingspeeddependsonseveralfactors,suchasthe hardnessofthematerial,thetypeofceramicinsert,thegeometryofthetool,andthe specificmachiningoperation(roughingvsfinishing)

Halnnrecommendscarefullyadjustingthecuttingspeedaccordingtothetypeof workpiecematerialandthedesiredoutcomeForexample,hardermaterialslike hardenedsteelrequirelowercuttingspeedstoensurethattheinsertdoesn’tweartoo quickly,whilecastironcantypicallybemachinedatmuchhigherspeeds

AdvantagesofHighCuttingSpeedswithCeramic Inserts

Runningceramicinsertsathighcuttingspeedsprovidesseveralkeyadvantages:

1.IncreasedProductivity

Highercuttingspeedsmeanfastermachiningtimes,whichleadstoincreased productivityandshortercycletimes.

2.ExtendedToolLife

Ceramicinsertsaremoreresistanttowear,evenathightemperatures.Whenused correctlyathigherspeeds,theyoftenoutlastcarbideinserts,reducingtheneedfor frequenttoolchanges.

3.SuperiorSurfaceFinish

High-speedmachiningwithceramicinsertsdeliversasmoothersurfacefinish, especiallyinfinishingoperations.Thesharpnessandthermalstabilityofceramic insertsenableprecisecutswithminimaldefects.

4.CostEfficiency

Althoughceramicinsertsmayhaveahigherupfrontcostcomparedtocarbideinserts, theirdurabilityandabilitytooperateathigherspeedswithoutcoolantcanleadto significantcostsavingsovertime

Halnn’sCeramicInserts:DesignedforOptimalCutting Speeds

AtHalnn,wearededicatedtoprovidingcutting-edgesolutionsforhigh-performance machining.Ourceramicinsertsareengineeredfordurability,efficiency,andprecision, eveninthemostchallengingapplications

KeyfeaturesofHalnn’sceramicinsertsinclude:

HighWearResistance:Halnn’sceramicinsertsmaintaintheircuttingedgelonger, evenincontinuoushigh-speedoperations,leadingtoreduceddowntimeand lowercosts.

ExcellentThermalStability:Designedtowithstandtheheatgeneratedby high-speedmachining,Halnn’sceramicinsertsdonotrequirecoolant,reducing thecomplexityofyouroperations

Versatility:Halnnoffersawiderangeofceramicinserttypesandgeometries, allowingyoutochoosetheperfecttoolforyourspecificapplication,whether you'remachiningcastiron,hardenedsteel,orotherhardmaterials. MaximizingPerformance:BestPracticesforCeramic

InsertCuttingSpeed

Achievingoptimalperformancewithceramicinsertsrequirescarefulconsiderationof cuttingspeedandadherencetobestpractices:

1.AdjustSpeedforMaterialType

DifferentmaterialsrequiredifferentcuttingspeedsForsoftermaterialslikecastiron, usehigherspeedstomaximizeproductivity.Forhardermaterials,reducethespeedto preventprematurewearontheinsert

2.ChoosetheRightInsertGeometry

Theshapeandgeometryoftheinsertplayasignificantroleindeterminingthebest cuttingspeedInsertsdesignedforroughingoperationstypicallyhandlelowerspeeds andhighermaterialremovalrates,whilethosedesignedforfinishingcanoperateat higherspeedswithlessmaterialremoval

3.DryMachining

Halnn’sceramicinsertsaredesignedfordrymachining.Operatingwithoutcoolant preventsthermalshockandprolongstoollife,especiallyathighspeeds.

4.MonitorToolWear

Regularinspectionoftoolweariscrucialtoensuringthatthecuttingspeedis appropriateIfexcessivewearorchippingisobserved,reducingthecuttingspeedor alteringfeedratesmayhelpextendtoollife.

Conclusion:ThePowerofCuttingSpeedwithHalnn CeramicInserts

Therightcuttingspeedcanunlockthefullpotentialofceramicinserts,driving improvedproductivity,bettersurfacefinishes,andlongertoollifeAtHalnn,weare proudtoofferadvancedceramicinsertsolutionsthatallowmanufacturerstooptimize cuttingspeedsformaximumefficiencyandperformance

Byselectingtheappropriatecuttingspeedforyourapplicationandmaterial,youcan elevateyourmachiningprocessestonewlevelsofprecisionandefficiencyHalnnis heretosupportyouwithpremium-qualityceramicinsertsthatperformreliablyeven inthemostdemandingenvironments

FormoreinformationonhowHalnn’sceramicinsertscanenhanceyourmachining operations,contactourtechnicalteamtoday.Wearecommittedtohelpingyou achieveyourmanufacturinggoalswiththehighestlevelofexpertiseandinnovation Ourwebsite:https://www.halnncbn.com/ Email:halnntools@halnn-groupcom WhatsApp:+8613271562251