CastIronMillingInserts:EnhancingYour MachiningEfficiencywithHalnn

Introduction

Intheworldofmachining,castironstandsoutasamaterialthatrequiresspecialized toolstohandleitsuniquepropertiesCastironmillinginsertsarecrucialforachieving precision,efficiency,andcost-effectivenessinmachiningprocesses.Halnn,aleaderin cuttingtooltechnology,providestop-qualitycastironmillinginsertsdesignedtomeet thedemandingrequirementsofthismaterial.Thisarticledelvesintothefeatures, benefits,andapplicationsofHalnn’scastironmillinginserts,offeringvaluable informationtohelpyouoptimizeyourmachiningoperations. Relatedpost:https://wwwhalnncbncom/News/IndustryNews/613html

WhatAreCastIronMillingInserts?

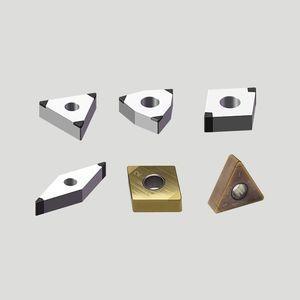

Castironmillinginsertsarespecializedcuttingtoolsusedinmillingmachinesto removematerialfromcastironworkpiecesTheseinsertsaretypicallymadefrom advancedmaterialssuchascarbide,ceramic,orcoatedmetals,designedtowithstand thehardnessandabrasivenessofcastironHalnn’scastironmillinginsertsare engineeredtodeliversuperiorperformance,ensuringdurabilityandefficiencyinyour machiningtasks

KeyFeaturesofHalnn’sCastIronMillingInserts

1AdvancedMaterialComposition:Halnn’sinsertsaremadefromhigh-quality materialslikecarbideandceramic,ensuringhighwearresistanceanddurability.

2SpecializedCoatings:TheinsertsfeaturecoatingssuchasTiN(TitaniumNitride) andTiAlN(TitaniumAluminumNitride)thatenhanceperformancebyreducing frictionandincreasingtoollife

3.OptimizedGeometry:Halnndesignsitsinsertswithgeometriestailoredforcast ironmachining,improvingcuttingefficiencyandsurfacefinish.

4HighThermalStability:Theinsertsmaintaintheirhardnessandperformance evenathightemperatures,makingthemidealforthedemandingconditionsof castironmachining

BenefitsofUsingHalnn’sCastIronMillingInserts

1.EnhancedDurability:Thehigh-qualitymaterialsandcoatingsusedinHalnn’s insertsensuretheylastlonger,reducingtheneedforfrequentreplacements.

2SuperiorCuttingPerformance:Optimizedgeometriesandadvancedcoatings resultinefficientmaterialremovalandexcellentsurfacefinishes.

3Cost-Effectiveness:Longertoollifeandimprovedmachiningefficiencytranslate toloweroverallproductioncosts.

4Versatility:Halnn’sinsertsaresuitableforvariouscastirontypes,providing flexibilityinyourmachiningoperations.

ApplicationsofCastIronMillingInserts

CastironmillinginsertsfromHalnnareusedacrossvariousindustrieswherecastiron componentsareprevalentKeyapplicationsinclude:

1.AutomotiveIndustry:Machiningengineblocks,brakecomponents,andother castironautomotiveparts

2.AerospaceIndustry:Millingcastironcomponentsusedinaircraftstructuresand engines

3.IndustrialMachinery:Manufacturingheavy-dutymachineryparts,including gears,housings,andframes

4.ConstructionEquipment:Producingcastironpartsforconstructionandmining equipment

WhyChooseHalnnforCastIronMillingInserts?

Halnnstandsoutinthemarketforitscommitmenttoquality,innovation,and customersatisfactionHere’swhyyoushouldchooseHalnn’scastironmillinginserts:

1.ExpertiseandExperience:Withyearsofexperienceinthecuttingtoolindustry, Halnnhasdevelopedadeepunderstandingofmachiningchallengesand solutions.

2InnovativeSolutions:Halnncontinuouslyinvestsinresearchanddevelopment tobringcutting-edgetechnologiesandproductstoitscustomers.

3CustomerSupport:Halnnoffersexcellentcustomersupport,ensuringyouget therighttoolsandguidanceforyourspecificneeds.

Conclusion

Halnn’scastironmillinginsertsaredesignedtomeettherigorousdemandsofcast ironmachining,providingenhanceddurability,superiorperformance,and cost-effectivenessBychoosingHalnn,youareinvestingintoolsthatwillimprove yourmachiningefficiencyandproductquality.FormoreinformationaboutHalnn’s castironmillinginsertsandothercuttingtoolsolutions,visitourwebsiteorcontactus directly.

ContactInformation:

Website:https://wwwhalnncbncom/

Email:halnntools@halnn-group.com

WhatsApp:+8615515925975

ExploreHalnn’srangeofhigh-performancecastironmillinginsertsandelevateyour machiningoperationstonewheights