CamshaftMillingTools:EnhancingPrecisionand EfficiencywithHalnn

Intheworldofinternalcombustionengines,thecamshaftplaysacrucialrolein controllingvalvetimingandsynchronization.Thecamshaft,withitspreciselyshaped lobes,ensurestheengine'ssmoothoperationbymanagingtheopeningandclosingof valvesToachievetherequiredprecisionandperformanceincamshaftmanufacturing, specializedcamshaftmillingtoolsareessential.Thisarticlefocusesontheimportance ofcamshaftmillingtools,thesolutionsprovidedbyHalnn,andhowthesetools enhancemachiningefficiencyandprecision.

Relatedpost:https://wwwhalnn-groupcom/news/1834html

UnderstandingCamshaftMillingTools

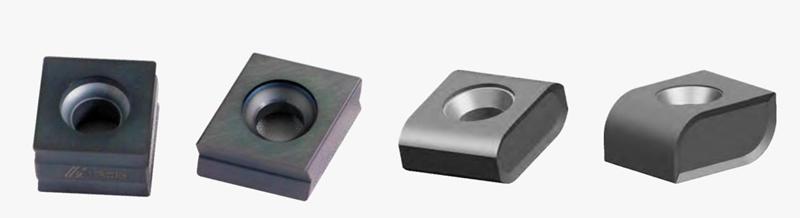

Camshaftmillingtoolsaredesignedtomachinethelobesandjournalsofcamshafts withhighprecisionThesetoolsincludeavarietyofinserts,cutters,andtailor-made solutionstomeetthespecificneedsofcamshaftproduction.Theprimarygoalof camshaftmillingistoachieveaccurateshapesandfinishesthatensureoptimalengine performance.