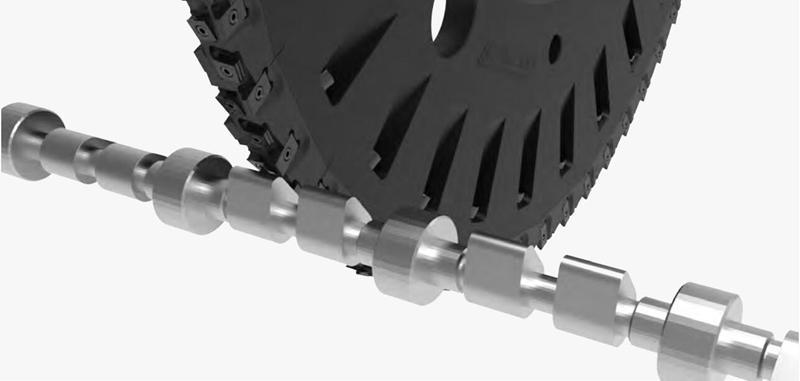

CamshaftMillingCutters:Precision ToolsforEnginePerformanceby Halnn

Intheworldofautomotiveandmechanicalengineering,thecamshaftisavital componentthatcontrolsthetimingofenginevalvesTheprecisionwithwhicha camshaftismanufactureddirectlyaffectstheefficiency,performance,anddurability ofanengineToachievethehighlevelofaccuracyrequiredincamshaftproduction, specializedtoolsareessential.Thisarticlefocusesoncamshaftmillingcutters, highlightingtheirimportanceinthemachiningprocessandtheadvancedsolutions offeredbyHalnn,aleadingmanufacturerofcamshaftmillingtools. Relatedpost:https://wwwhalnncbncom/News/IndustryNews/619html