CamshaftMilling:AdvancedTechniquesand SolutionsbyHalnn

Inaninternalcombustionengine,thecamshaftplaysacrucialroleinoperatingvalve movementandsynchronization.Itconsistsofashaftwithseverallobes,each dedicatedtoavalveThecamlobespressonthevalves(oranintermediate mechanism)toopenthemastheyrotate,ensuringprecisetimingandoptimalengine performanceHalnnoffersacompetitiverangeofstandard,TailorMade,and Engineeredsolutionsforcamshaftmachining,designedtomeetthehighdemandsof modernengines

Relatedpost:https://www.halnncbn.com/News/IndustryNews/618.html

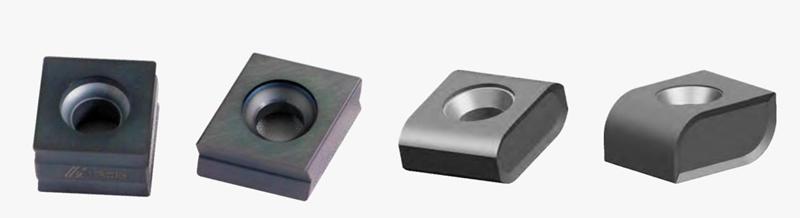

Therequirementsforcamshaftsareevolvingalongsidecrankshafts,focusingon enhancedperformance,reducedfuelconsumption,andloweremissions.Toachieve thebestresults,Halnnprovidescamshaftmillingsolutionsthatenablethe simultaneousmachiningofseveralcams.Ourcuttersareavailableinsolidversionsor assegmentsolutions,featuringinsertswithwell-tunedgrades,optimizedgeometries, anduptoeightcuttingedgesforsafeproductionandreducedcosts.

Halnn'sCamshaftMillingTools

TheCamshaftMillingProcess

MachiningStages:

1.Roughing:

Machiningeachsupportjournal,timinggearjournal,andthreadedjournalouter circle

Carvingthecamandeccentricwheel.

2.Semi-Finishing:

Roughgrindingthecamandeccentricwheel

3.Finishing:

Finegrindingthetimingpinjournal,thrustsurface,andbearingjournalouter circle.

Polishingsupportjournals,cams,andeccentrics

DetailedCamshaftMachiningSteps

1.CamSurfaceRoughing:

Positioning:Utilizingthebearingjournalendfaceforaxialpositioning,the timinggear,andsupportshaftoutercircleasreferencesAroller-typeauxiliary supportisemployedduringmachining.

2.CamSurfaceFinishing:

DoubleCamGrindingMachine:Thismachinehastwosetsofmastersthatare automaticallyreplaced,improvingcamprofileaccuracybycontrollingthe grindingwheeldiameter.

DoubleCycleCamGrinder:Capableofcontinuouslygrindingtheentire camshaft.Itfirstcoarselygrindsallcamsatahighfeedrateandthenfinely grindsthem,followedbycorrection

AnalysisofCamshaftMachiningProcess

1.CubicBoronNitrideGrindingWheel:

Improveswheellife,reduceswear,andenhancesprecision.

2.CNCCamGrinder:

Utilizescomputerprogrammingtoeliminatetheimpactofcamaccuracyon overallprecision.

3.Electric-HydraulicControl:

Employsapulsemotorforwheelframesynchronization

4.High-SpeedGrinding:

Utilizesmultiplehigh-strengthgrindingwheels.

5.GrindingWheelShaftSwingingDevice:

Reducescamsurfaceroughness

6.Pre-SelectionDevices:

Includespre-selectedcoarseandfinegrindingallowances.

7.ActiveMeasuringDevice:

Ensurescontinuousmeasurementduringthegrindingprocess

8.AutomaticCompensationandTrimmingDevices:

Maintainsconsistentprecisionandquality.

1.GrindingWheelNotRound:

Problems:Single-boardmachineprocessing,chaoticprogram,unstablesize,and poorbeating.

Solution:Replacethebearingjournalturningdeviceandinspectthecontrol systemregularly.

2.CamLiftTolerance:

Problems:Machinetoolwear,reduceddieaccuracy.

Solution:Regularinspection,trimming,andtimelymasterreplacement. Changingtheworkpiecerotationdirectionduringcamsurfacegrindingcan improvecamcurveaccuracy.

3.CamBaseBounceOutofTolerance:

Problems:Machinetoolwear,reduceddieaccuracy.

Solution:Regularinspection,trimming,andreplacementofthemasterand couplingguideshaft

WhyChooseHalnnforCamshaftMillingSolutions

Halnnunderstandsthecriticalimportanceofprecisionandqualityincamshaftmilling. Ourrangeofcamshaftmillingtools,includingcamshaftmillinginsertsandcutters,is designedtodeliverexceptionalperformance.BychoosingHalnn,yougainaccessto cutting-edgemillingsolutionsbackedbyextensiveindustryexpertiseanda commitmenttocustomersatisfaction.

ContactHalnn

Formoreinformationaboutourcamshaftmillingtoolsandsolutions,visitourwebsite athttps://wwwhalnncbncom/Youcanalsoreachusviaemailat halnntools@halnn-group.comorWhatsAppat+8615515925975.

Halnnisdedicatedtoprovidingvaluableinformationandtop-qualityproductstomeet theneedsofourclientsTrustHalnnforallyourcamshaftmillingrequirementsand

experiencethedifferencethatprecisionandqualitymake