BTADeepHoleDrills:PrecisionEngineering byHalnn

Introduction

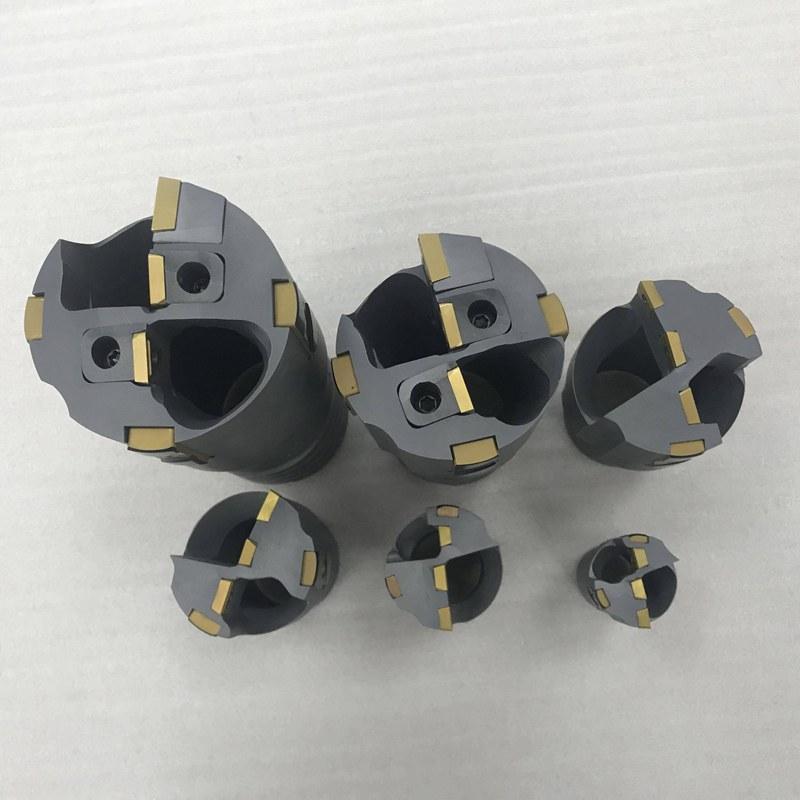

Inindustrieswhereprecisionanddeptharecritical,BTAdeepholedrillsplayan indispensableroleWhetherinaerospace,oilandgas,orheavymachinery manufacturing,thesedrillsareessentialforcreatingdeep,straightholeswith exceptionalaccuracyHalnn,aleaderinadvanceddrillingsolutions,offersarangeof high-qualityBTAdeepholedrillsdesignedtomeetthemostdemandingindustrial needsThisarticledelvesintothespecificsofBTAdeepholedrills,theirapplications, benefits,andhowHalnn’sexpertiseensuressuperiorperformanceandreliability.

Relatedpost:https://wwwhalnn-groupcom/news/1836html

WhatareBTADeepHoleDrills?

BTA(BoringandTrepanningAssociation)deepholedrillsarespecializedtools engineeredtodrilldeep,preciseholesinavarietyofmaterials.Thesedrillsare characterizedbytheiruniqueinternalcoolantsystem,whichefficientlyremoveschips fromtheholewhilecoolingthecuttingedge.Thissystemallowsfordeeperdrilling withminimaldeviationandhigh-qualitysurfacefinishes,makingBTAdrillsa preferredchoiceforapplicationsrequiringprecision.

KeyFeaturesofBTADeepHoleDrills

1.HighPrecision

BTAdeepholedrillsaredesignedtomaintainaccuracyoverlongdrillingdistances. Theinternalcoolantflowhelpsstabilizethedrillingprocess,reducingtheriskof

deflectionandensuringtheholeremainsstraightandtrue

2.EfficientChipEvacuation

ThecoolantsysteminBTAdrillsplaysadualrole:itcoolsthecuttingedgeand evacuateschipsefficientlyThispreventsclogging,reducesheatbuildup,and maintainsasmoothdrillingprocess,eveninchallengingmaterials.

3.DurabilityandLongevity

Halnn’sBTAdeepholedrillsarecraftedfromhigh-qualitymaterials,ensuringthey withstandthestressesofdeepdrillingoperationsThecombinationofrobust constructionandefficientcoolingcontributestotheirextendedlifespan.

4.Versatility

BTAdeepholedrillsareversatiletoolsthatcanbeusedonawiderangeofmaterials, includinghardmetals,alloys,andcompositematerials.Thisversatilitymakesthem suitableforvariousindustries,fromaerospacetoautomotiveandbeyond.

ApplicationsofBTADeepHoleDrills

AerospaceIndustry

Intheaerospacesector,precisionisparamountBTAdeepholedrillsareusedto createcriticalcomponents,suchaslandinggear,engineparts,andstructuralelements, wheredeep,accurateholesarenecessary.Halnn’sBTAdrillsensurethatthese componentsmeetthestringentstandardsrequiredinaerospacemanufacturing

OilandGasExploration

Theoilandgasindustrydemandstoolsthatcanwithstandharshenvironmentsand drillthroughtoughmaterialsHalnn’sBTAdeepholedrillsareidealfordrillingin suchconditions,providingthereliabilityandprecisionneededfordeepdrillingin rock,steel,andotherchallengingsubstrates

AutomotiveIndustry

Intheautomotivesector,BTAdeepholedrillsareusedformachiningengineblocks, transmissioncomponents,andotherpartsthatrequiredeep,preciseholesHalnn’s drillsenablemanufacturerstoachievethetighttolerancesandsmoothfinishes necessaryforhigh-performancevehicles

HeavyMachinery

Forheavymachinerymanufacturers,deepholedrillingisoftenrequiredforhydraulic cylinders,shafts,andothercomponentsHalnn’sBTAdeepholedrillsprovidethe durabilityandprecisionneededtoproducethesecriticalpartsefficientlyand accurately

BenefitsofUsingHalnn’sBTADeepHoleDrills

SuperiorPrecision

Halnn’sBTAdeepholedrillsareengineeredtodeliverunmatchedprecision,ensuring thateventhemostchallengingdrillingtasksarecompletedwithaccuracy.This precisionreducestheneedforsecondaryfinishingoperations,savingtimeandcost.

IncreasedProductivity

Withefficientchipevacuationandhigh-speeddrillingcapabilities,Halnn’sBTAdeep holedrillsenhanceproductivity.Operatorscanachievefasterdrillingrateswithout compromisingonquality,leadingtomoreefficientproductionprocesses

Cost-Effectiveness

AlthoughBTAdeepholedrillsrepresentasignificantinvestment,theirdurability, precision,andefficiencyresultinlong-termcostsavingsReducedtoolwear,fewer replacements,andlowermaintenancecostscontributetoamorecost-effectivedrilling solution

CustomizationOptions

Halnnofferscustomizationoptionstomeetthespecificneedsofdifferentindustries andapplications.Whetherit’saparticulardrillsize,length,orcoating,Halnn’s expertsworkcloselywithclientstodevelopsolutionstailoredtotheirexact requirements.

MaintenanceandCareforBTADeepHoleDrills

TomaximizethelifespanandperformanceofBTAdeepholedrills,regular maintenanceisessential.Thisincludes:

RoutineInspections:Regularlycheckingthedrillforsignsofwearordamagecan preventmoresignificantissuesdowntheline.

ProperCleaning:Keepingthedrillclean,especiallythecoolantchannels,ensures efficientchipevacuationandcoolingduringoperation.

Re-sharpeningServices:Halnnoffersre-sharpeningandrefurbishingservicesto restorethecuttingedgeofthedrill,extendingitsservicelifeandmaintainingits performance.

WhyChooseHalnnforBTADeepHoleDrills?

Halnnisatrustednameintheindustry,knownforitscommitmenttoquality, innovation,andcustomersatisfaction.OurBTAdeepholedrillsaredesignedwiththe latesttechnologyandmaterialstomeettherigorousdemandsofmodern manufacturingBychoosingHalnn,youbenefitfrom:

ExpertiseandExperience:Withyearsofexperienceinthefield,Halnn’steam ofexpertsunderstandstheuniquechallengesofdeepholedrillingandoffers solutionsthatdeliverresults.

High-QualityProducts:OurBTAdeepholedrillsaremanufacturedtothe higheststandards,ensuringreliabilityandprecisionineverydrill.

CustomerSupport:Halnnisdedicatedtoprovidingexceptionalcustomer service,frominitialconsultationtoongoingsupportandmaintenance.

Conclusion

BTAdeepholedrillsarevitaltoolsforindustriesthatrequireprecision,durability,and efficiencyindeepdrillingoperationsHalnn’sBTAdeepholedrillsstandoutfortheir superiorengineering,versatility,andlong-termvalue.Whetheryou’reinaerospace, oilandgas,automotive,orheavymachinerymanufacturing,Halnnprovidesthe solutionsyouneedtoachieveexcellenceindeepholedrilling.

CalltoAction

FormoreinformationaboutHalnn’sBTAdeepholedrillsortodiscussyourspecific requirements,contactourteamtoday.VisitourwebsiteorcallustolearnhowHalnn canhelpyouachievesuperiorresultsinyourdrillingoperations

Ourwebsite:https://wwwhalnncbncom/ Email:halnntools@halnn-group.com