Parts Manual

972L Wheel Loader

RFB1-UP (Machine)

WYE1-UP (Engine)

NA71-UP (Transmission)

NA81-UP (Transmission)

FJ41-UP (Torque Converter)

HY81-UP (Torque Converter)

TXS1-UP (Torque Converter)

ZWJ1-UP (Torque Converter)

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS

COUPLER GP-QUICK 1962

EDGE GP-CUTTING 1970

EDGE GP-SEGMENT 1971

EDGE-END 1972

EDGE-SEGMENT.....................................................1973

FORK GP-PALLET..................................................

GUARD GP-BUCKET CORNER..........................

PLATE AS-WEAR...................................................

PLATE GP-WEAR

PLATE-WEAR

PROTECTOR

PROTECTOR GP-LINKAGE

TIP AS-ABRASION

TIP AS-GENERAL PURPOSE .............................1994

TIP AS-PENETRATION .........................................1995

TIP GP-ABRASION.................................................1996

TIP GP-EXTRA-DUTY 1998

1.

MACHINE IDENTIFICATION

GENERAL INFORMATION

Components such as engines, transmissions, axles, etc.

Cat machines are identified by Product Identification and work tools will continue to use an 8 character Serial Numbers (PIN). Some components included in a Number (S/N). machine may be identified by Serial Numbers (S/N).

Typical components that will be serialized include engines, transmissions, bulldozers, and rippers. The machine and engine are further identified by arrangement numbers and in some cases modification numbers. These numbers are shown on the product identification plate(s) and on the master plate in the operator's compartment.

Cat dealers need all of these numbers to determine accurate parts identification.

2.ORDERING PARTS

Effective First Quarter 2001 the Cat Product Identification Number (PIN) changed from 8 to 17 characters. In an effort to provide uniform equipment identification, Caterpillar and other construction Quality Cat replacement parts are available from Cat equipment manufacturers are moving to comply with the dealers throughout the world. Their parts inventories are latest version of the product identification numbering up to date and include all parts normally required to standard. Non-road machine PINs are defined by ISO protect your investment in Cat machines. Dealers may 10261. The new PIN format will apply to all Cat offer repair kits or remanufactured parts to allow machines and generator sets. The PIN plates and frame selection of the most effective repair alternative for a marking will display the 17 character PIN. The new particular situation. When ordering parts, your order format will look like the following: should specify the quantity, part number, part name, and the serial number/product identification number of the machine for which the parts are needed.

Where:

3.PARTSMANUALORGANIZATION

Product information in this manual is presented as "information elements" that represent all of the components for the specific model. Engine Arrangement and Seat Group are examples of information elements. The information elements are organized alphabetically by part name and secondarily by part number within each major section of the manual.

4. TABLEOF CONTENTS

1. Caterpillar's World Manufacturing Code (characters 1- A table of contents (TOC) is found at the beginning of the 3) manual. The TOC lists each section of the manual with a

2. Machine Descriptor (characters 4-8) complete list of all information elements organized as they appear in the manual. Page numbers are provided

3. Check Character (character 9) for quick reference to detailed parts identification illustrations and serviceable consist lists.

4. Machine Indicator Section (MIS) or Product Sequence Number (characters 10-17). These were previously

5.MAINTENANCEPARTSINDEX referred to as the Serial Number.

Machines and generator sets produced before First

The Maintenance Parts Index, located near the Quarter 2001 will maintain their 8 character PIN format. beginning of the manual, references most frequently used maintenance part numbers, providing description, quantity, usage and page number. This information is organized alphabetically by part description.

6. INDEX

GENERAL INFORMATION

12. ILLUSTRATION REFERENCE LETTERS

The index located near the front of the manual is an When necessary, illustrations contain reference letters alphabetical listing of all information elements included in (A, B, C etc.) that are intended to track lines and the manual. Page numbers are provided for quick harnesses from one point to another. They are also used reference to detailed parts identification illustrations and to show where to reconnect illustrations that have been serviceable consist lists. separated.

7. PARTNUMBERINDEX

13.ABBREVIATIONSANDSYMBOLS

A numerical index listing all part numbers and the O.D. – OutsideDiameter corresponding page number(s) appears at the back of I.D. – Inside Diameter the manual. A – Not Part Of This Group B – Use As Required

8. CAPTIONS C – ChangeFrom Previous Type D – Order By The Meter

Captions located at the beginning of each information E – Order ByTheCentimeter element identify the part number and part name along F – Not Shown with additional descriptive information. PIN and S/N G – Order By The Inch information found in each caption should be used to I – ReferToHydraulicInformationSystem select correct information for a specific machine. Field M – Metric Part replacement options, identification of optional R – RemfgPartMayBeAvailable attachment components, and where used ("part of") Y – Separate Illustration information is also provided. Z – Not Serviced Separately

The first line of a caption is shown in larger type font to

14. DESCRIPTION OF TYPE CHANGES indicate the beginning of an information element. Captions for additional pages that may be required to Type - A type is defined as any configuration change that illustrate an information element will be shown in requires an additional Information Element for an standard type font and will include the term (contd.). Arrangement, Group, or Assembly. If serial number breaks for types are not available, a type # ( Type 1, 9. NON-SERVICED PARTS

Type 2, etc.) will be displayed in the caption. These

In some instances it is necessary to display non-serviced "type" changes are identified with a "C" note (change

parts that are a link to a lower level serviceable consist from previous type) in the Parts List. Only the "types" that lists. These non-serviced part numbers are shown in apply to this Parts Manual will be included. Additional italic type indicating that they are not available. types may exist causing "C" notes to appear on an Information Element when no other types areshown.

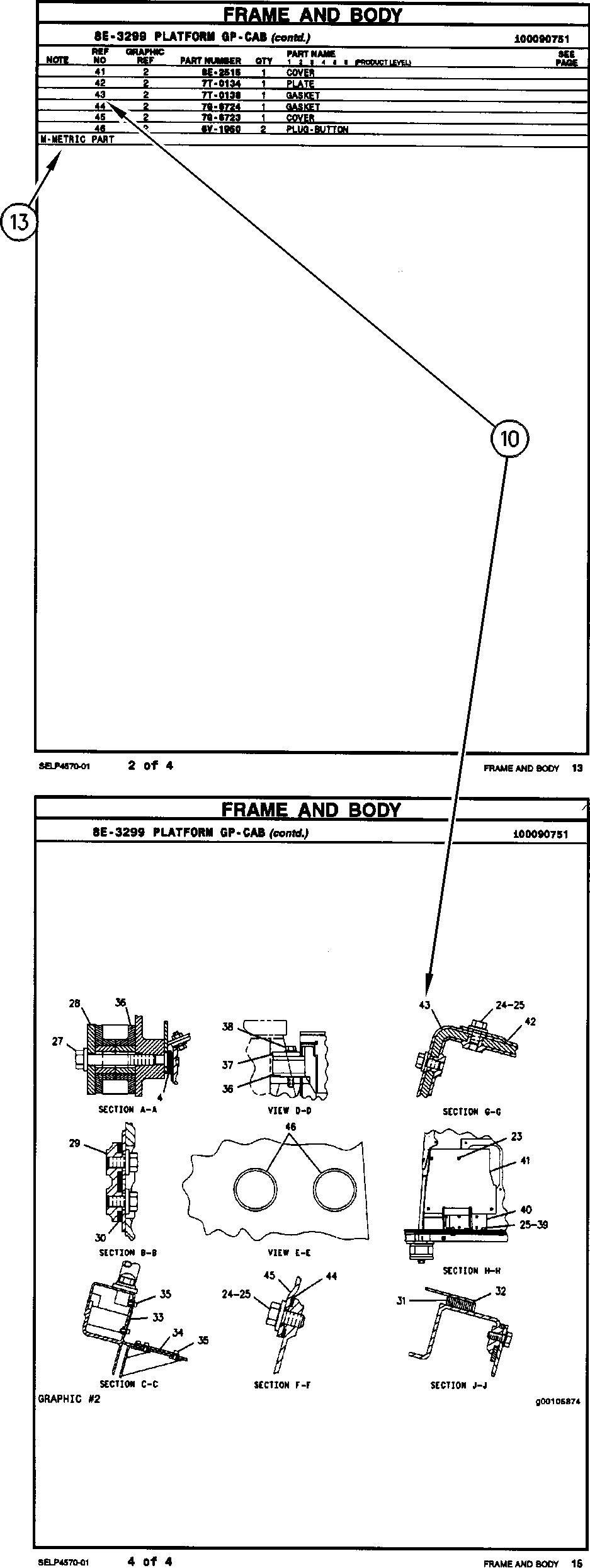

10. PARTS LIST REFERENCE NUMBERS

15.<END>

Numbers shown in the Ref No column correspond to This symbol indicates the end of an information element. numbers used in the associated graphic(s). An alphabetic suffix may be added to a reference number to

NOTE: identify lower level consist items. Numbers shown in the Graphic Ref column refer to the graphic number identifier Continuing improvement and advancement of product displayed in the lower left corner of each illustration. The design may cause changes to your machine which may Graphic Ref number may be used in combination with not be included in this publication. Whenever a question the item Ref No to determine the correct part number. arises regarding your Cat product or this publication, There may be intentional omission of a Ref No in a please consult your Cat dealer for the latest available consist list as information is updated to reflect the latest information. serviceable part numbers.

11. INDENTED PART NAMES

When a part name is indented in a parts list, it is part of (included in) the group or assembly under which it is indented.

REPAIR ALTERNATIVES

REMANUFACTURED COMPONENTS

As an optionwhen making repairs consider Cat Remanufactured Components. Components that areavailable through the Cat Remanufactured Program are identified three ways in the parts book:

• with the letter R in the note field of the parts list

• with an R* at the beginning of the first line of the caption

• with an *R at the end of the first line of the caption

TypicalcomponentsincludedintheRemanufacturing Programinclude:

ALTERNATORS

CONNECTING RODS

CRANKSHAFTS - UNDERSIZE

CRANKSHAFTS-UPGRADETONEW

CYLINDER HEADS

ELECTRONICCONTROL MODULES(ECM)

ELECTRONIC SENSORS

FUELINJECTORS

FUEL NOZZLES

FUEL PUMPS

GOVERNORS

OIL PUMPS

PISTONS

SHORTBLOCKS

STARTERS

TURBOCHARGERS - COMPLETE

TURBOCHARGER CARTRIDGES

WATER PUMPS

CatRemanufactured engines formany enginearrangements arealsoavailable.

SUPPLEMENTAL COOLANT ADDITIVES

CUSTOMER BENEFITS:

Protects againstcavitation, foam, erosion,corrosion,andscale buildup incoolingsystems.

• Providesmeasuredcoolant conditioner.

DESCRIPTION:

Additives depletefrom thecoolant with normal operation.For this reason, Supplemental Coolant Additives (SCA) must be added to all heavy duty coolants at regular intervals. In addition, when not using a fully formulated, pre-charged antifreeze, like Cat DEAC, an initial charge of SCA must be added to the cooling system. The amount of SCA added to the system is dependent on the capacity of the system.

The SCA for initial fill is provided as a liquid. SCA's for maintenance intervals are available in liquid form and as a spinon element. (No Spin-on available for 3600 Family of Engines)

NOTE:

The amount of SCA added at initial fill is not the same as the amount added at maintenance intervals.

Thecoolant additive elements can be usedwith any ethylene or propylene glycol type antifreeze which meets ASTM D4985 or ASTM D5345 Specifications.

NOTE:

For use with standard heavy duty coolant only, not for use with Extended Life Coolant.

PARTSNEEDED:

(6-8)

(8-10)

(1)

(1) 6V-3542 (1)

(10-13) 3P-2044 (1) 8T-1589 (1)

(1)

(1)

(1)

(1) 49-64 (13-17) 3P-2044 (2)

(1)

(1) 64-83 (17-22)

3P-2044 (2) 8T-1589 (1)

83-114 (22-30)

(1) 6V-3542 (1)

3P-2044 (3) 8T-1589 (1) 3P-2044 (1)

(1)

(1) 114-163 (30-43) 3P-2044 (5) 3P-2044 (1) 6V-3542 (1)

(2) 163-242 (43-64) 3P-2044 (8)

3P-2044 (2) 9N-3718 (2)

*Normal maintenanceperiod is 250 hrs. See your Operation and MaintenanceManual for complete coolant maintenance instructions.

( ) Indicates quantity required.

MANUAL RESET)

(TRANSMISSION ECM)

(MAIN)

AUTOMATIC RESET) (AUTOMATIC RESET)

MANUAL RESET)

(STARTER)

MAINTENANCE PARTS

SYSTEM

MAINTENANCE PARTS

MAINTENANCE PARTS

MAINTENANCE PARTS

ACCUMULATOR GP-BRAKE–CHARGED 1156 1157

ACCUMULATOR GP-BRAKE–UNCHARGED 1158

ACCUMULATOR GP-HYDRAULIC–CHARGED ................................................................1161 1218

ACCUMULATOR

ACCUMULATOR

ACCUMULATOR GP-RIDE CONTROL–CHARGED

ACCUMULATOR GP-RIDE CONTROL–UNCHARGED 1219

ACTUATOR GP-POWER 811 ACTUATOR GP-POWER (POWER TRAIN GUARD) 811 ADAPTER

AXLE

AXLE

AXLE

BLADE AS-WIPER (800-MM) (FRONT WINDOW)

CAB AR-ENCLOSED ROPS

CAB AR-ENCLOSED ROPS–STEEL MILL

GP (115-DEG, COLOR)

CAMSHAFT GP

CAP AS-FILLER (7/8-9-THD)

CAP AS-FILLER (LOCKABLE) (HYDRAULIC TANK)

CAP AS-FILLER (M18X2-THD)

CAP AS-FUEL (LOCKABLE, VENTED)

CAP AS-VENTED. 1877

CAP GP-AIR CLEANER

CAP GP-FUEL FILLER................................................

CAP GP-PROTECTION–CORROSION

CAP-FILLER (BRAKE, DIFFERENTIAL, XMSN OIL)

CAP-VENTED (VENTED).........................................

CARRIAGE GP-FORK...............................................

CARRIAGE GP-FORK–HOOK-ON

CARTRIDGE GP-TURBOCHARGER

CIRCUIT

WINDOW)

(ALTERNATE EXIT, REMOVE OMM)

(FLYING DEBRIS, READ

FILM-WARNING (ROPS, FOPS, READ OMM) 2007

FILM-WARNING (ROTATING FAN) 2018

FILM-WARNING (SEAT BELT, INTERNATIONAL)....................................................2021

FILM-WARNING (SEAT BELT) 2005

FILM-WARNING (UNIVERSAL, READ OMM). 2005

(ETHER START).

(LUBRICATION PUMP)

FILTER AS-AIR (STANDARD FILTRATION) (PRECLEANER) 1820

AS-ENGINE OIL...............................................84

AS-WATER SEP & FUEL (ULTRA HIGH EFFICIENCY)..............................................................

ELEMENT-AIR (HIGH DEBRIS) .................

ELEMENT-AIR (ULTRA HIGH EFFICIENCY)..............................................................

ELEMENT-BREATHER (HYDRAULIC TANK) 1440 FILTER ELEMENT-CAB AIR.....................................1722 1723 FILTER ELEMENT-CAB AIR (STANDARD FILTRATION)............................................................1722 1723 FILTER ELEMENT-FUEL 186

ELEMENT-OIL...............................................

GP-ENGINE OIL

GAUGE GP-SIGHT (OIL LEVEL) 644 647

GAUGE GP-SIGHT (OIL LEVEL) (POWER TRAIN OIL) 634 636 638 640 642

GAUGE-LIQUID LEVEL (SIGHT GLASS) (HYDRAULIC TANK OIL) 1438

GEAR GP-BEVEL & PINION.....................................670 672 674 676

GEAR GP-FRONT 49

GEAR GP-OUTPUT TRANSFER 678

GRILL GP-RADIATOR .................................................905 907

GUARD AR-HEAVY DUTY.........................................908 909

GUARD AR-LIGHT. 909

GUARD GP-AXLE 910

GUARD GP-BELT...........................................................50

GUARD GP-BOTTOM..................................................911 912

GUARD GP-BUCKET CORNER. 1980

GUARD GP-FAN 110

GUARD GP-FRONT 913

GUARD GP-HITCH & STEERING............................914

GUARD GP-LIFT CYLINDER.................................. 1249

GUARD GP-LIGHTING 915 916 917 918

GUARD GP-LINES. ......................................................919

GUARD GP-LOADER

LINES GP-TORQUE CONV COOLER 750 752 754

LINES GP-TURBOCHARGER OIL. 93

LINES GP-WATER–RADIATOR.................................130

LINK GP-STEERING FRAME LOCK......................1051

LINK GP-TILT 1634 1635 1637 1639

LINKAGE AR-BUCKET...............................................1639 1640

LITERATURE GP (STANDARD CAB) 5

LUBRICATION AR-AUTOMATIC 1052 1053 1054

LUBRICATION AR-AUTOMATIC–AUTOLUBE.......1052

LUBRICATION AR-AUTOMATIC–HIGH LIFT 1052 1054

MANIFOLD

MANIFOLD GP-CONTROL–AXLE OIL FLOW DIVIDER................................................................... 1209

MANIFOLD

MANIFOLD GP-HYDRAULIC 1410 1411 1413

MANIFOLD GP-INLET..................................................172

MIRROR GP ............................................................... 1755

MIRROR GP-REAR VIEW 1756 1758

MIRROR GP-REAR

PROTECTION GP-WIRING

PROTECTOR GP-EDGE

PROTECTOR GP-LINKAGE .....................................

PULLEY GP-CRANKSHAFT .........................................

PUMP & MTG GP-BRAKE & HYD FAN 1417

PUMP & MTG GP-HYDRAULIC 1418 1419 1420

PUMP & MTG GP-HYDRAULIC FAN....................1421

PUMP & MTG GP-LUBRICATION..........................1087

PUMP & MTG GP-LUBRICATION–AUTOLUBE 1088

PUMP & MTG GP-SECONDARY STEER 1576

PUMP GP-ELECTRIC DRIVE 1577

PUMP GP-ENGINE OIL.................................................

PUMP

(2-PIN) (FRONT

(2-PIN) (REAR

SENSOR GP-POSITION (STEERING)

SENSOR

(3-PIN) (ENGINE

INDEX

SWITCH AS-PUSH BUTTON (LUBRICATION PUMP) .......................................................................1090

SWITCH AS-PUSH BUTTON (PAYLOAD STORE). 416

SWITCH AS-PUSH BUTTON (THROTTLE LOCK ON, OFF) 515

SWITCH AS-ROCKER (24-VOLT) 431 436 443

SWITCH AS-ROCKER (24-VOLT) (AIR CONDITIONER CONTROL) 450

SWITCH AS-ROCKER (24-VOLT) (AIR CONDITIONER ON, OFF)......................................457

SWITCH AS-ROCKER (24-VOLT) (AIR CONDITIONER, HEATER)......................................442

SWITCH AS-ROCKER (24-VOLT) (HAZARD LIGHT).........................................................................419

SWITCH AS-ROCKER (24-VOLT) (HYDRAULIC LOCKOUT)..................................................................513 515

SWITCH AS-ROCKER (24-VOLT) (IMPLEMENT LOCKOUT) 503 505 509 511

SWITCH AS-ROCKER (24-VOLT) (QUICK COUPLER) 418

SWITCH AS-ROCKER (24-VOLT) (WINDOW WASHER) 449 457

SWITCH AS-ROCKER (AIR CONDITIONER, HEATER).....................................................................435

SWITCH AS-ROCKER (FORWARD, NEUTRAL, REVERSE) 433 1661 1663 1669 1671 1677

SWITCH AS-ROCKER (HEATED MIRRORS)..... 1757

SWITCH AS-ROCKER (PARKING BRAKE) 433

SWITCH AS-ROCKER (POWER) 433

SWITCH AS-THERMOSTAT (HVAC) 1645

SWITCH AS-TOGGLE (BOTTOM GUARD) 426

SWITCH AS-TOGGLE (HOOD TILT ACTUATOR)...............................................................

SWITCH AS-TURN SIGNAL

SWITCH GP-DISCONNECT

SWITCH GP-MAGNETIC (24-VOLT) (START RELAY)

VALVE & LINES GP 1441

VALVE & LINES GP-LUBRICATION........................1128 1129 1132 1137

VALVE & LINES GP-LUBRICATION–FRONT 1126 1135

VALVE & LINES GP-LUBRICATION–REAR 1125

VALVE & LINES GP–REAR......................................1447

VALVE & LINES GP–WITH HEAT INSULATION 1443 1445

VALVE & MTG GP-CONTROL–2-VALVE 1449 1454

VALVE & MTG GP-CONTROL–2-VALVE, RIDE CONTROL.................................................................1456

VALVE & MTG GP-CONTROL–3-VALVE 1459

VALVE & MTG GP-CONTROL–WITH RIDE CONTROL 1451

VALVE & MTG GP-COUPLER................................1462

VALVE & MTG GP-MAIN CONTROL–3VALVE 1464

VALVE & MTG GP-RIDE CONTROL 1468

VALVE AS-PRESSURE RELIEF (REFRIGERANT COMPRESSOR) 1659

VALVE AS-RELIEF 218

VALVE AS-RELIEF (LUBRICATION)........................1091 1097

VALVE GP 1474

VALVE GP-ACCUMULATOR CHARGING 1161 1162

VALVE GP-ACCUMULATOR CHARGING (BRAKE)....................................................................1156 VALVE GP-CHECK

VALVE GP-CHECK (AUTOMATIC LUBRICATION LINE)............................................................................988

VALVE GP-CHECK (AXLE OIL COOLER BYPASS)...................................................................

VALVE GP-CHECK (PARKING BRAKE