5 minute read

Safety Instructions

The Workman 3000/4000 series vehicles are designed and tested to offer safe service when operated and maintained properly. Although hazard control and accident prevention are partially dependent upon the design and configuration of the vehicle, these factors are also dependent upon the awareness, concern, and proper training of the personnel involved in the operation, transport, maintenance, and storage of the vehicle. Improper use or maintenance of the vehicle can result in injury or

Before Operating

Advertisement

1. Read and understand the contents of the Operator’s Manual and Operator’s Video before starting and operating the vehicle. Become familiar with the controls and know how to stop the vehicle and engine quickly. A replacement Operator’s Manual is available on the Internet at www.Toro.com.

2. Keep all shields, safety devices, and decals in place. If a shield, safety device, or decal is defective, illegible or damaged, repair or replace it before operating the vehicle. Also tighten any loose nuts, bolts or screws to ensure vehicle is in safe operating condition.

3. Assure interlock switches are adjusted correctly so engine cannot be started unless clutch pedal is depressed. On TC models, engine should start only when hydraulic lever is in the neutral position. On vehicles equipped with the optional PTO kit, engine should start only when PTO is disengaged.

death.Toreducethepotentialforinjuryordeath,comply with the following safety instructions.

Warning

To reduce the potential for injury or death, comply with the following safety instructions.

4. Since fuel used in Workman vehicles is highly flammable, handle it carefully:

A. Store fuel in containers specifically designed for this purpose.

B. Do not remove vehicle fuel tank cap while engine is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of the top of the tank, not the filler neck. Do not overfill the fuel tank.

E. Wipe up any spilled fuel.

While Operating

1. Sit on the seat when starting and operating the vehicle.

2. Before starting the engine:

A. Sit on operator’s seat and engage the parking brake.

B. Disengage PTO (if so equipped) and return hand throttle lever to OFF position (if so equipped).

C. On TC models, make sure that hydraulic lever is in the neutral position.

D. Move shift lever to NEUTRAL and depress clutch pedal. Keep foot off accelerator pedal.

E. Turn ignition key to START.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and could possibly be deadly.

4. Do not touch engine, radiator, muffler or exhaust pipe while engine is running or soon after it is stopped. These areas could be hot enough to cause burns.

5. Before getting off the seat:

A. Stop movement of the vehicle.

B. Lower bed.

C. Shut engine off and wait for all movement to stop.

D. Set parking brake and remove key from ignition switch.

E. Do not park on slopes unless wheels are chocked or blocked.

Maintenance and Service

1. Before servicing or making adjustments, turn all accessories off, put traction pedal in neutral, stop engine, set parking brake, and remove key from the switch.

2. Make sure vehicle is in safe operating condition by keeping all nuts, bolts and screws tight.

3. Never store the vehicle or fuel container inside where there is an open flame, such as near a water heater or furnace.

4. Make sure all hydraulic line connectors are tight and that all hydraulic hoses and lines are in good condition, before applying pressure to the system.

5. Keep body and hands away from pin hole leaks in hydraulic lines that eject high pressure hydraulic fluid. Use cardboard or paper to find hydraulic leaks. Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid accidentally injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

6. Before disconnecting or performing any work on the hydraulic system, all pressure in hydraulic system must be relieved. To relieve system pressure, push dump lever forward and backward and rotate steering wheel in both directions after the key switch has been turned off.

7. If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

8. To reduce potential fire hazard, keep engine area free of excessive grease, grass, leaves and dirt. Clean protective screen on vehicle frequently.

9. If engine must be running to perform maintenance or an adjustment, keep clothing, hands, feet, and other parts of the body away from moving parts. Keep bystanders away.

10.Do not overspeed the engine by changing governor setting. To assure safety and accuracy, check maximum engine speed.

11.Shut engine off before checking or adding oil to the engine crankcase.

12.Disconnect battery before servicing the vehicle. Disconnect negative (–) battery cable first and positive (+) cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the battery. Reconnect positive (+) cable first and negative (–) cable last.

13.Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes, and clothing. Protect your face, eyes, and clothing when working with a battery.

14.Battery gases can explode. Keep cigarettes, sparks, and flames away from the battery.

15.To assure optimum performance and continued safety of the vehicle, use genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers may result in nonconformance with safety standards, and the warranty may be voided.

16.When raising the vehicle to change tires or to perform other service, use correct blocks, hoists, and jacks. Make sure vehicle is parked on a solid level surface such as a concrete floor. Prior to raising the vehicle, remove any attachments that may interfere with the safe and proper raising of the vehicle. Always chock or block wheels. Use jack stands or solid wood blocks to support the raised vehicle. If the vehicle is not properly supported by blocks or jack stands, the vehicle may move or fall, which may result in personal injury (see Jacking Instructions in Operator’s Manual).

When changing attachments, tires or performing other service, use the correct blocks, hoists and jacks. Always chock or block the wheels and use jack stands or solid wood blocks to support the vehicle. If the vehicle is not properly supported by blocks or jack stands, the vehicle may move or fall resulting in personal injury.

1. Do not start engine while vehicle is on jack, because engine vibration or wheel movement could cause vehicle to slip off jack.

2. Do not work under vehicle without jack stands supporting it. The vehicle could slip off jack, injuring any one beneath it.

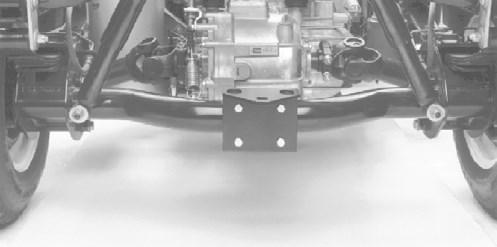

3. The jacking point at the front of the vehicle is under the front center frame support and at the rear it is under the axle tube.

4. When jacking up front of vehicle, always place a wood block (or similar material) between jack and vehicle frame support.

Using Bed Safety Support

Many of the procedures shown in this manual require raising and lowering the bed. The following precautions must be taken or serious injury or death could result.

Before servicing or making adjustments to the vehicle, stop engine, set parking brake and remove key from ignition switch. Any load material must be removed from bed or other attachment before working under raised bed. Never work under a raised bed without positioning bed safety support on a fully installed cylinder rod.

After work is completed, remove bed safety support, insert into storage brackets on back of ROPS panel and lower bed.

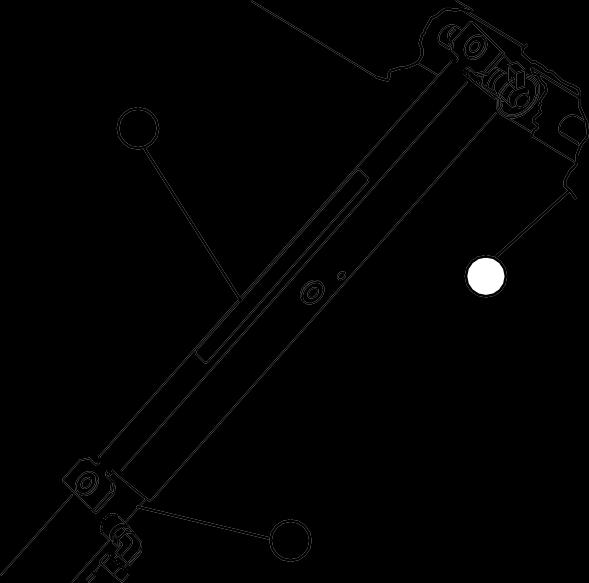

1. Raise bed until lift cylinders are fully extended.

2. Remove bed safety support from storage brackets on back of ROPS panel.

3. Push bed safety support onto cylinder rod, making sure support end tabs rest on end of cylinder barrel and on cylinder rod end (Fig. 3).

4. To store bed safety support, remove support from cylinder and insert into storage brackets on back of ROPS panel.

5. Always install or remove bed safety support from outside of bed.

6. Do not try to lower bed with bed safety support on cylinder: cylinder and bed damage may occur.