Workshop Manual EK10

1Vehicle data

2Travel motor

5Brake

Electromagnetic spring brake..................................................5-01

Checking the rotor...........................................................5-03

Adjusting the brake clearance.........................................5-04 General...................................................................5-04

Adjustment process................................................5-04

Adjusting the braking force..............................................5-05 Maintenance....................................................................5-06

Measuring the brake deceleration...........................................5-07

General...........................................................................5-07

Preparations for measurement........................................5-07

Evaluating the measurement..........................................5-08

6Idling wheels General....................................................................................6-01

7Hydraulic Montagevorschrift....................................................................7-01 Hydraulic circuit plan...............................................................7-01

Block diagram for NO/HO........................................................7-02

Block diagram for NM/HM.......................................................7-03

Pump unit................................................................................7-04

General...........................................................................7-04

Components:...................................................................7-04

Electrically releasable non-return valve..........................7-05

Replacing the carbon brushes (NO, NM)........................7-06

Replacing the carbon brushes (HO, HM)........................7-07

Removal..........................................................................7-08

Removing the pump motor (NO, NM).............................7-09

Removing the pump motor (HO, HM).............................7-10

Adjustment Pressure release valve.................................7-11

Changing the hydraulic oil...............................................7-12

Bleeding the lift cylinders and the hydraulic system................7-13

Procedure........................................................................7-13

Distributor block.......................................................................7-14

Bubble reservoir......................................................................7-15

Hydraulic hoses.......................................................................7-16

13Vehicle

15End-of-aisle

16Speed sensor

17ABÜ - Braking monitor

18Travel control

21Travel control software

General..................................................................................21-01

Making a connection..............................................................21-01

Setting parameters................................................................21-02

Test........................................................................................21-03

Diagnosis...............................................................................21-03

"File" menu............................................................................21-03

Summary of the most important parameters.........................21-05

Battery discharge curves.......................................................21-06

List of parameters..................................................................21-07

Description of parameters.....................................................21-12

Errors displayed with flashing code.......................................21-17

List of error codes..................................................................21-18

Tester Table...........................................................................21-19

22Steering software

General..................................................................................22-01 Making a connection..............................................................22-02 Errors.....................................................................................22-03 Current errors................................................................22-03

Setpoint potentiometer..................................................22-05 Actual value potentiometer............................................22-06 Tester.....................................................................................22-09 Speed measurement.....................................................22-09

Amplifier data................................................................22-10

Digital inputs and outputs..............................................22-11 Travel on curves active.........................................22-11 Deadman..............................................................22-11

Steering wheel/ -knob...........................................22-11

Steering OK..........................................................22-11

Steering motor contactor......................................22-12

Safety relay...........................................................22-12

Potentiometer voltages.................................................22-13

Supply voltage of actual and setpoint values.......22-13

Setpoint voltage at the steering wheel..................22-13

Actual value voltages at the drive wheel..............22-13

Table of errors........................................................................22-14

Table of Contents

23Hand-held programming unit

General..................................................................................23-01

Operating elements...............................................................23-01

Switching on..........................................................................23-02

Switching off..........................................................................23-02

Language selection...............................................................23-03

Setting parameters................................................................23-04 PROGRAM menu.........................................................23-04

Function........................................................................23-05

Special program menu..........................................................23-06

Resetting to initial settings............................................23-07

Loading settings from the control system into the programming unit.............................................23-08

Loading settings from the programming unit into the control system..................................................23-09

Deleting the diagnosis data...........................................23-10

Adjusting the display contrast.......................................23-11 Language selection.......................................................23-12

Displaying information about the programming unit......23-12

Displaying information about the control.......................23-12 Test menu..............................................................................23-13 Displaying current errors.......................................................23-14 Error history...........................................................................23-14

fuels and lubricants.........................................99-02

Functional check of the deadman brake........................99-03

Functional check of the neutral brake............................99-03

Functional check of the reversing brake........................99-03

Maximum wear on the brake lining................................99-03

the lifting chains for damage..........................99-09

the chain elongation.......................................99-13 Main lift..................................................................99-13

the chain elongation.......................................99-14

lift..........................................................99-14

the lifting chains............................................99-15 Repairing the lifting chains.............................................99-15 Lubricating the lifting chains...........................................99-16 Cleaning the chains........................................................99-17

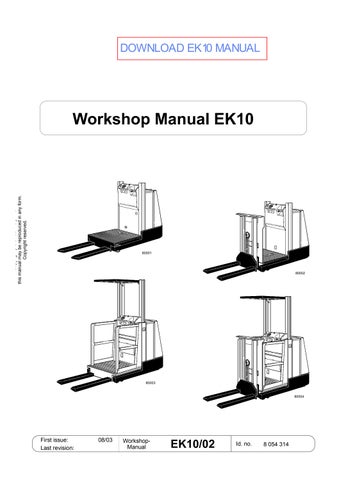

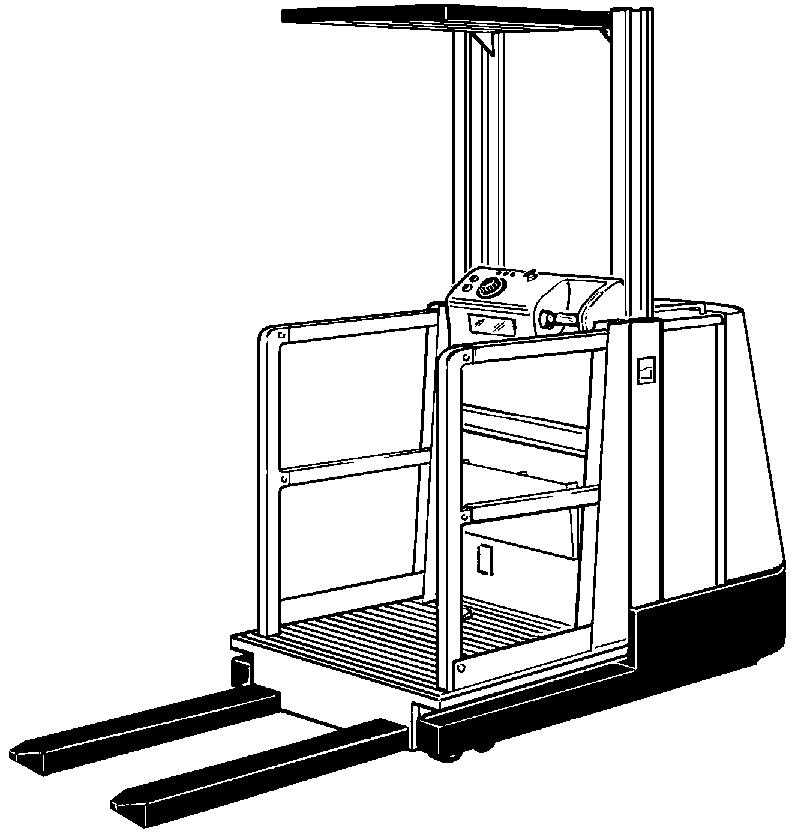

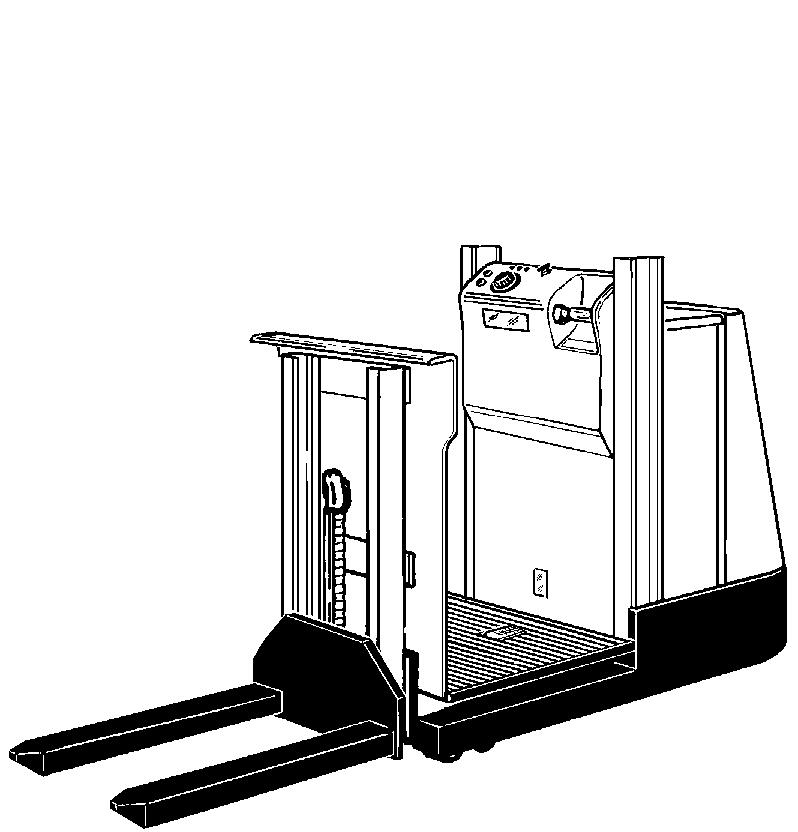

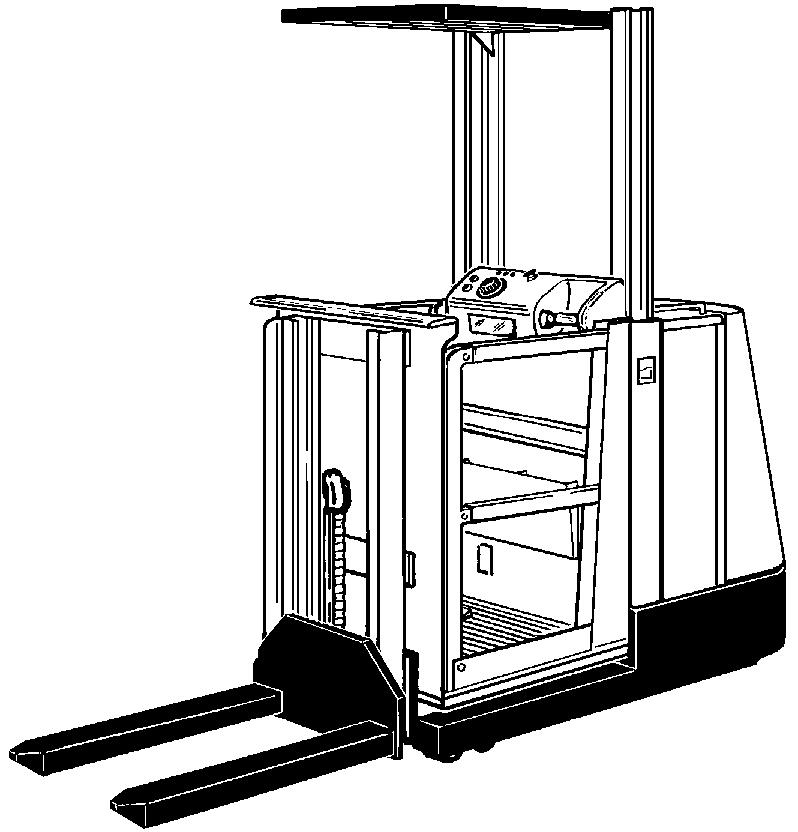

Definition of vehicle model names

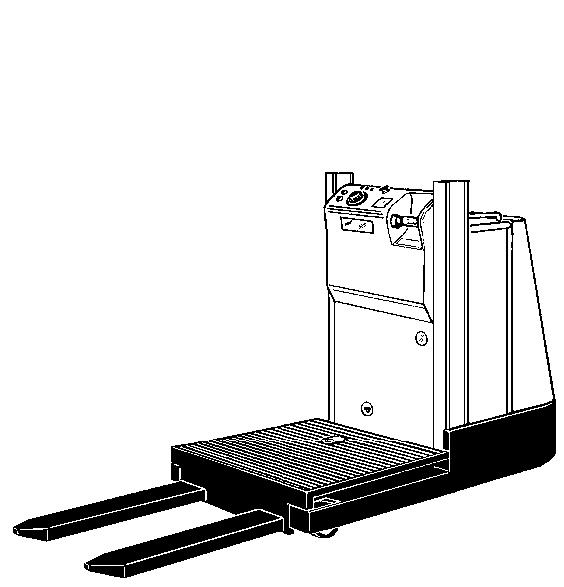

EK10 NO (Niederhub ohne Zusatzhub = low lift without additional lift)

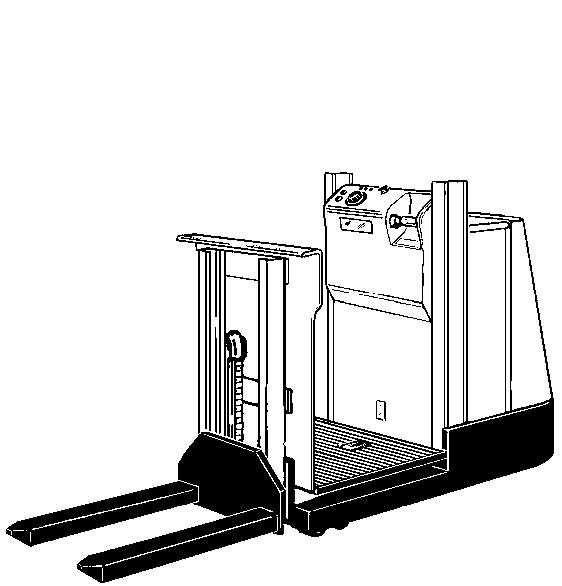

EK10 NM (Niederhub mit Zusatzhub = low lift with additional lift)

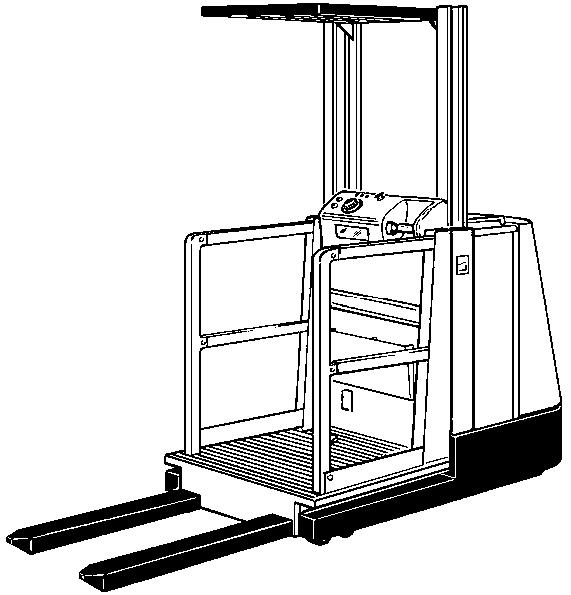

EK10 HO (Hochhub ohne Zusatzhub = high lift without additional lift)

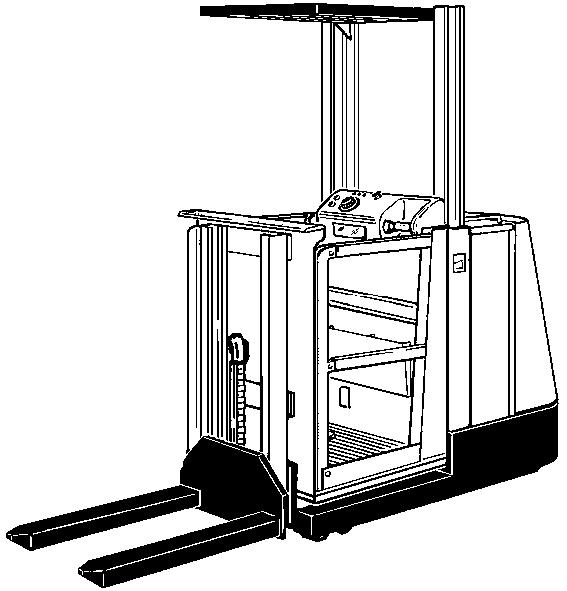

EK10 HM (Hochhub mit Zusatzhub) = high lift with additional lift)

Signs on the vehicle

Nameplate

Travel speed

Outside the aisle

•Type NOalwaysvmax = 9.0km/h

•Type NMPlatform level < 0.5mvmax = 9.0km/h

•Type NMPlatform level > 0.5m & steering straight-onvmax = 4.0km/h

•Type NMPlatform level > 0.5m & steering > ±10°vmax = 2.5km/h

•Type HOPlatform level < 1.2mvmax = 9.0km/h

•Type HOPlatform level > 1.2m & steering straight-onvmax = 4.0km/h

•Type HOPlatform level > 1.2m & steering > ±10°vmax = 2.5km/h

•Type HMPlatform level < 0.5mvmax = 9.0km/h

•Type HMPlatform level > 0.5m & steering straight-onvmax = 4.0km/h

•Type HMPlatform level > 0.5m & steering > ±10°vmax = 2.5km/h

Inside the aisle

Always vmax = 9,0km/h

General

The drive motor used in this vehicle is a 24V shunt motor.

The armature and field coils are controlled separately by the travel controller.

The travel movement is initiated as follows: voltage is applied to the armature and the field is excited. As soon as the armature voltage is equal to the battery voltage, the field current is reduced in order to achieve an increase in speed.

The current speed of the drive motor is determined by a current measurement (measuring shunt) in the travel controller.

Temperature monitor

The drive motor has a temperature monitor (field coil resistor at normal temperature approx. 1.8 ). If the temperature is >90°C, deceleration is initiated by the MOT WRM parameter. If the temperature rises above 105°C, a traction cut-out is initiated by the Mot Hot parameter (see Software travel controle).

Technical data

Model designationGF 114 - F4

Id. no.W8 408 250

Excitation typeshunt wound

Voltage24V

Rated output2000W

Rated speed2700 rpm

Direction of rotationright / left

Protection / insulation classJP 00 / 20

Field excitation6V / 9A

Armature current104A

On-period

Terminals

S2 = 60min

A 1 Armature winding start

A 2 Armature winding end

F1Field winding

F2Field winding

Removing the travel motor

Because the brake (2) is mounted on the travel motor, the vehicle is no longer braked once the brake and the travel motor have been removed. For this reason, always secure the vehicle to prevent it rolling away!

Pull out the battery plug.

Remove power leads (3.

Unplug speed sensor (9).

Remove electro magnetic break (2)

The connection point for the connection cable of the spring brake may be in the cable duct (4)!

Remove the 8 screws (5).

Screw the special eyebolt tool M6 (6), into the armature shaft (min. 20mm).

Pull the rope (7) (special tool: pulley) through the eyebolt (6).

Ensure that the rope is pulled through correctly (8).

Set the length (holding it tight with your hand is sufficient).

Lift the travel motor out with a lever rod.

Never work without the correct aids. A considerable amount of force is required to release the seal (1) between the travel motor and the gear.

Remove the aids.

Lift the travel motor out by hand.

When the travel motor has been removed, the opening left in the gear (2) must be closed off immediately, in order to prevent oil entering the inside of the gear.

Installation

To install the travel motor, follow the instructions for removal in reverse order. It can be installed without the use of any special tools.

Only use screws of the prescribed length, otherwise the four-point bearing may be damaged!

Screw in and tighten the 8 screws (3) diagonally in several passes.