9650 STS and 9750 STS Combines Diagnosis and Tests

For complete service information also see:

Foreword

This manual is written for an experienced technician. Essential tools required in performing certain service work are identified in this manual and are recommended for use.

Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual.

This is the safety-alert symbol. When you see this symbol on the machine or in this manual, be alert to the potential for personal injury.

Technical manuals are divided in two parts: repair and operation and tests. Repair sections tell how to repair the components. Operation and tests sections help you identify the majority of routine failures quickly.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

Technical Manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair.

Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes.

SECTION 210—General SECTION 230—Fuel/Air Operation and Tests

Group 05 Safety

Group 10 Combine and Component Identification

Group 15 General Specifications

Group 20 Diagnostic and Testing Procedures

Group 40 Electrical System Operational Checkout

Group 50 Power Train Operational Checkout

Group 05 General Information

Group 10 Test Procedures and Adjustments

Group 15A Air Intake System Diagnostics

Group 15B Fuel System Diagnostics

Group 20

Component Identification

SECTION 240—Electrical System Operation and Group 60 Parking Brake Operational Checkout Test

Group 55 Four Wheel Drive Operational Checkout

Group 65 Service Brake Operational Checkout

Group 70 Hydraulic System Operational Checkout

Group 75 Main Gearcase Operational Checkout

Group 80 Steering Operational Checkout

Group 90 Heating and Air Conditioning

Operational Checkout

SECTION 211 Diagnostic Trouble Codes

Group A00 A00

Group C00 C00

Group C03 C03

Group E00 E00

Group E02 E02

Group 5 General Information

Group 10 Diagnostic Trouble Codes

Group 15A Active Header Height Control

System Height Sensing Diagnostics

Group 15B Active Header Height Control

System Height Resume Diagnostics

Group 15C 95 Ampere Alternator

Group 15D 185 Ampere Alternator Diagnostics

Group 15E

Armrest Control Unit Overall

Diagnostics

Group 15F Auxiliary Power Strip Outlet

Diagnostics (Power Strip)

Group 15G Backshaft Speed Adjustment

Group E01 E01 Diagnostics

SECTION 212 Observable Symptoms

Group 220 Engine

Group 230 Fuel/Air

Group 240 Electrical

Group 250 Power Train

Group 255

Group 15H CAN Bus Diagnostics

Group 15I

Group 15J

Chopper Raise/Lower Diagnostics

Cleaning Fan Speed Adjust Diagnostics

Group 15K ClimaTrak Diagnostics

Group 15L Comfort Command Seat Diagnostics

Group 15M Contour Master - Automatic Tilt

Four-Wheel Drive Diagnostics

Group 260 Brakes

Group 15N Contour Master Manual Tilt

Group 270 Hydraulics Diagnostics

Group 275 Main Gearcase

Group 15O

Cornerpost Control Unit Overall

Group 280 Steering Diagnostics

Group 290 Heating, Ventilation and Air

Group 15P

Cornerpost - Backshaft Speed

Conditioning - Standard Diagnostics

Group 300 Separator

SECTION 220 Engine Diagnosis And Tests

Group 15Q

Group 15R

Cornerpost - Cleaning Fan Speed Diagnostics

Cornerpost - Contour Master Position

Group 05 General Information Diagnostics

Group 10 Test Procedures

Group 15A Engine Cooling And Rotary Screen

Diagnostics

Group 15B 6081 Engine Operation Bosch

Group 20 Component Identification

Group 15S

Cornerpost - Corn Head Deck Plate

Spacing Diagnostics

Group 15T Cornerpost - Engine Hours Diagnostics

Continued on next page

All information, illustrations and specifications in this manual are based on the latest information available at the time of publication. The right is reserved to make changes at any time without notice.

Group 15U Cornerpost - Engine Speed - 6081

Group 15V Cornerpost - Engine Temperature

Gauge - 6081 Diagnostics

Group 15W Cornerpost - Fuel Gauge Diagnostics

Group 15X Cornerpost - Ground Speed

Group 15Y Cornerpost - Separator Hours

Group 15AA Cornerpost - Threshing Clearance

Group 15AB Cornerpost - Threshing Speed

Group 15AC Deck Plate Adjustment Diagnostics

Group 15BE Lighting System Marker Lamps

Group 15BF

Group 15BG

Group 15BH

Group 15BI

Group 15BJ

Group 15BK

System Panel Lamps

System Rear Discharge

System Road Lamps

System Service Lamps -

System Service Lamps -

System Service Lamps -

Group 15AD DIAL-A-SPEEDDiagnostics Shoe Area Diagnostics

Group 15AE Draper Speed Adjust Diagnostics

Group 15AF Engine Compartment Relay Panel

Group 15AG Four Wheel Drive Type Identification

Group 15AH Four Wheel Drive - Single Speed

Group 15AI Four-Wheel Drive Two-Speed

Group 15BL

Group 15BM

Group 15BN

System Side Finder Lights

System Stubble Lamps

System Unloading Auger

GREENSTAR Mass Flow Sensor Switch Power Diagnostics

Diagnostics

Group 15BU Power Distribution Board 1 - Light

Group 15AP GREENSTAR Mobile Processor Switch Power Diagnostics

Diagnostics

Group 15BV Power Distribution Board 1 Service

Group 15AQ GREENSTAR Moisture Sensor Power Diagnostics

Diagnostics

Group 15AR Header Control Unit Overall

Diagnostics

Group 15AS Header Engage Diagnostics

Group 15AT Header Raise/Lower Diagnostics

Group 15AU Horn Diagnostics

Group 15BW Quick-Stop Diagnostics

Group 15BX Radio System Diagnostics

Group 15CA Reel Fore/Aft Diagnostics

Group 15CB Reel Raise/Lower Diagnostics

Group 15CC Reel/Belt Speed Diagnostics

Group 15CD Right Control Unit Overall

Group 15AV Injection Pump System - 6081 Engine Diagnostics

Diagnostics

Group 15AW Lighting System Diagnostics

Group 15AX Lighting System Daytime Running

Lighting Diagnostics

Group 15BA Lighting System Dome Light

Diagnostics

Group 15BB Lighting System Exit Lighting

Group 15CE Road/Field System Diagnostics

Group 15CF Separator Engage Diagnostics

Group 15CG Spreader Speed Adjust Diagnostics

Group 15CH Start Aid Diagnostics

Group 15CI Starting System Diagnostics

Group 15CJ Tailings Monitor Diagnostics

Group 15CK Threshing Clearance Adjust

Diagnostics Diagnostics

Group 15BC Lighting System Field Light

Diagnostics

Group 15BD Lighting System Hazard/Turn

Group 15CL Threshing Speed Adjust Diagnostics

Continued on next page

Group 15CM Unloading Auger Engage Diagnostics

Group 15CN Unloading Auger Swing Diagnostics

Group 15CO VisionTrak Diagnostics

Group 15CP Warning Display Panel Diagnostics

Group 15CQ Warning Grain Elevator Speed w/

Group 15B

Group 15C

Transmission Diagnostics

Hydrostatic Diagnostics

Group 20 Component Identification

SECTION 255—Four Wheel Drive Diagnosis and GREENSTAR Diag. Tests

Group 15CR Warning - Grain Elevator Speed w/o

GREENSTAR Diag.

Group 15CS Warning Conveyor Auger Speed

Diagnostics

Group 05

General Information

Group 10 Test Procedures and Adjustments

Group 15A Four Wheel Drive Type Identification

Group 15B Four Wheel Drive Single Speed

Group 15CT Warning Discharge Beater Speed Diagnostics

Diagnostics

Group 15CU Warning Engine Air Filter

Diagnostics

Group 15CV Warning Engine Oil Pressure

Diagnostics

Group 15C Four Wheel Drive Two Speed

Group 20

Diagnostics

Component Identification

SECTION 260 Service Brake and Park Brake

Group 15CW Warning Engine Speed Diagnostics System

Group 15DA Warning Engine Temperature

Group 15DB Warning Feed Accelerator Speed

Diagnostics

Group 15DC Warning Grain Tank Full

Diagnostics

Group 15DD Warning Hydraulic Oil Temperature

Diagnostics

Group 15DE Warning Hydrostatic Charge

Pressure Diagnostics

Group 15DF Warning Low Fuel

Group 15DG Warning Main Gearcase Filter

Restricted Diagnostics

Group 15DH Warning Main Gearcase Pressure

Diagnostics

Group 15DI Warning Main Gearcase

Group 05

General Information

Group 10 Test Procedures and Adjustments

Group 15A Service Brakes Diagnostics

Group 15B Park Brake Diagnostics

Group 20 Component Identification

SECTION 270—Hydraulic Operations And Tests

Group 05

Hydraulic System General Information

Group 10 Test Procedures And Adjustments

Group 15A

Hydraulic Basic System Diagnostics

Group 15B BackShaft Speed Diagnostics

Group 15C

Twin-Disk Spreader Diagnostics

Group 15D Corn Head Deck Plate Diagnostics

Group 15E Threshing Speed Diagnostics

Group 15F Draper Belt Speed Diagnostics Temperature Diagnostics

Group 15DJ Warning Parking Brake Diagnostics

Group 15DK Warning Straw Chopper/Straw

Spreader Identification

Group 15DL Warning Straw Chopper Speed

Diagnostics

Group 15DM Warning Straw Spreader Speed

Group 15G Feeder House Gearcase Cooler

Group 15H Header Raise/Lower Diagnostics

Group 15I

Group 15J

Group 15K

Header Tilt Diagnostics

Overheating Diagnostics

Reel Fore/Aft Diagnostics

Group 15L Reel Raise And Lower Diagnostics

Group 15M

Reel And Belt Pick-upSpeed

Diagnostics Diagnostics

Group 15DN Warning Tailings Elevator Speed

Diagnostics

Group 15DO Warning Threshing Speed

Diagnostics

Group 15DP Warning Unloading Auger Engaged

Diagnostics

Group 15DQ Warning Voltage Diagnostics

Group 15DR Wiper System Diagnostics

Group 20 Connector Information (end views,

Group 15N

Group 20

Unloading Auger Swing Diagnostics

Hydraulic Component Identification

SECTION 275—

Group 05

Main Gearcase Systems

General Information

Group 10 Test Procedures and Adjustments

Group 15A

Main Gearcase Pressure Low

Diagnostics

Main Gearcase Temperature High numbers, location photos) Diagnostics

SECTION 250 Power Train Operation and Tests

Group 05 General Information

Group 10 Test Procedures and Adjustments

Group 15A Final Drive Diagnostics

Group 15B

Group 15C

Group 15D

Main Gearcase Filter Restricted

Diagnostics

Separator Engage Diagnostics

Continued on next page

Group 15E Main Gearcase Diagnostics

Group 15F Unloading Auger Engage Diagnostics

Group 20 Component Identification

SECTION 280 Steering System

Group 05 General Information

Group 10 Test Procedures and Adjustments

Group 15 Steering Diagnostics

Group 20 Component Identification

SECTION 290—Heating and Air Conditioning Operation and Tests

Group 05 General Information

Group 10 Test Procedures and Adjustments

Group 15 Heating and Air Conditioning Diagnostics

Group 20 Component Identification

SECTION 300 Separator Diagnostics

Group 05 General Information

Group 15 Separator Vibration Diagnostics

Group 20 Separator Component Identification

Handle Fluids Safely—Avoid Fires

When you work around fuel, do not smoke or work near heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn spontaneously.

Prevent Battery Explosions

Keep sparks, lighted matches, and open flame away from the top of battery. Battery gas can explode.

Never check battery charge by placing a metal object across the posts. Use a volt-meter or hydrometer.

Do not charge a frozen battery; it may explode. Warm battery to 16C (60F).

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

Handle Starting Fluid Safely

Starting fluid is highly flammable.

Keep all sparks and flame away when using it. Keep starting fluid away from batteries and cables.

To prevent accidental discharge when storing the pressurized can, keep the cap on the container, and store in a cool, protected location.

Do not incinerate or puncture a starting fluid container.

Prevent Acid Burns

Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the acid.

3. Flush your eyes with water for 15 30 minutes. Get medical attention immediately.

If acid is swallowed:

1. Do not induce vomiting.

2. Drink large amounts of water or milk, but do not exceed 2 L (2 quarts).

3. Get medical attention immediately.

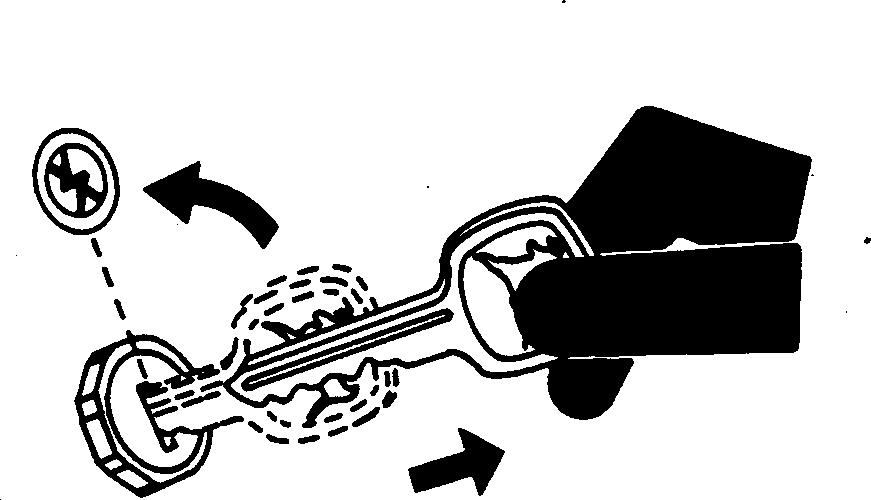

Service Cooling System Safely

Explosive release of fluids from pressurized cooling system can cause serious burns.

Shut off engine. Only remove filler cap when cool enough to touch with bare hands. Slowly loosen cap to first stop to relieve pressure before removing completely.

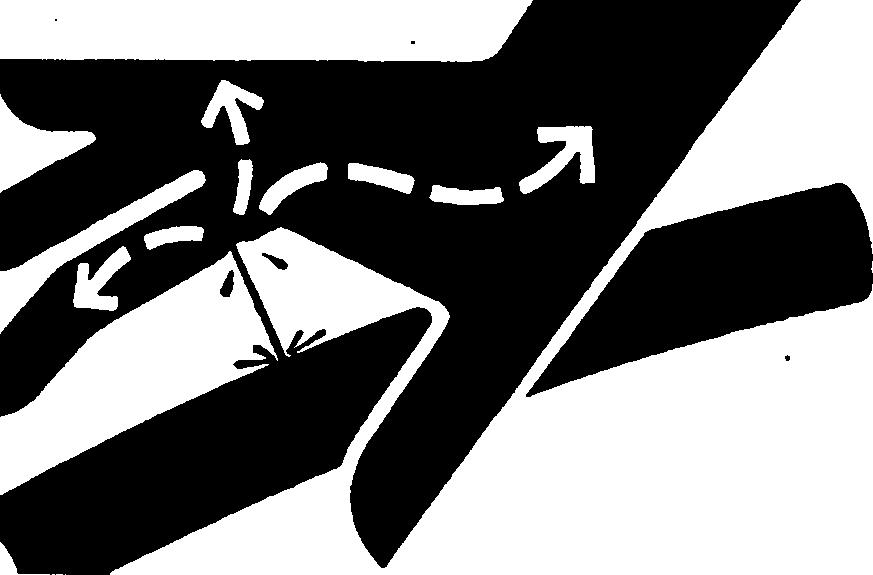

Avoid High-Pressure Fluids

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

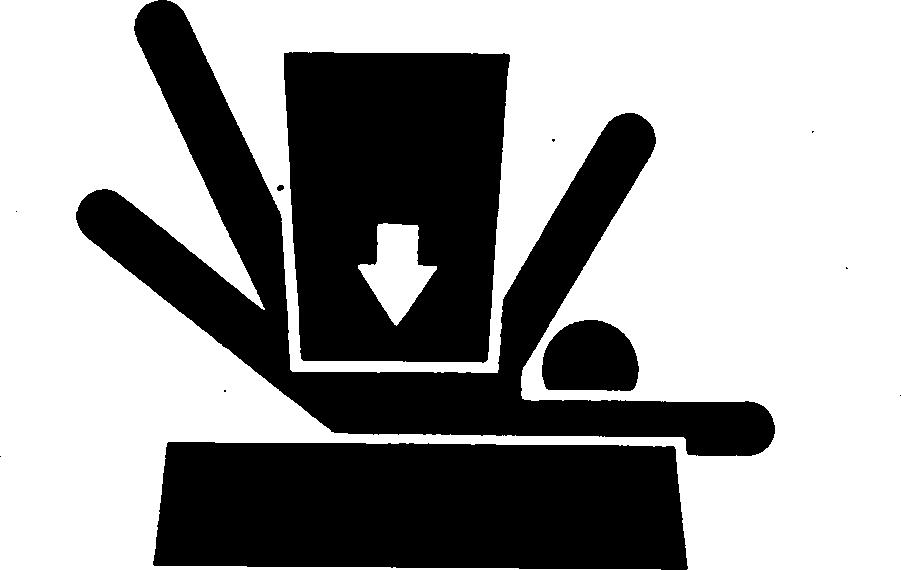

Park Machine Safely

Before working on the machine:

• Lower all equipment to the ground.

• Stop the engine and remove the key.

• Disconnect the battery ground strap.

• Hang a "DO NOT OPERATE" tag in operator station.

Support Machine Properly

Always lower the attachment or implement to the ground before you work on the machine. If you must work on a lifted machine or attachment, securely support the machine or attachment.

Do not support the machine on cinder blocks, hollow tiles, or props that may crumble under continuous load. Do not work under a machine that is supported solely by a jack. Follow recommended procedures in this manual.

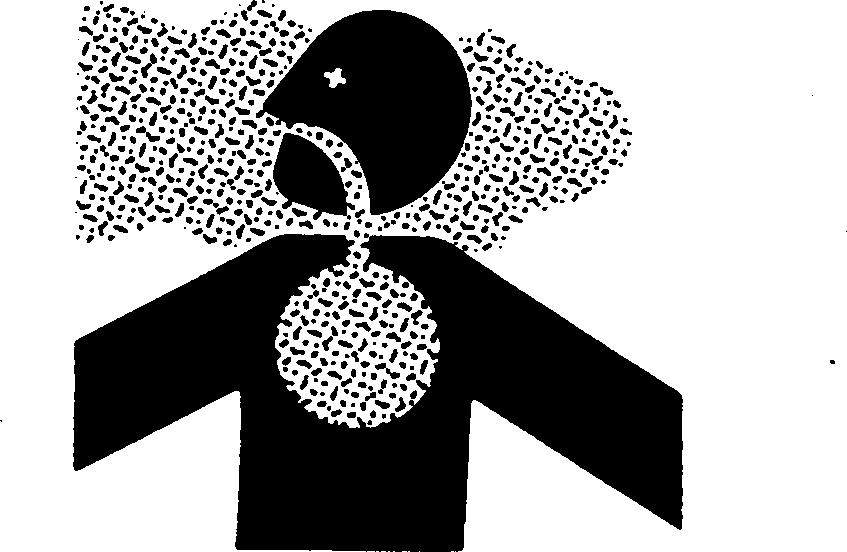

Service Machines Safely

Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items were to get caught, severe injury could result.

Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts.

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension.

If you do not have exhaust pipe extension, open the doors and get outside air into the area

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a portable safety light for working inside or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an accidentally broken bulb can ignite spilled fuel or oil.

Replace Safety Signs

Replace missing or damaged safety signs. See the machine operators manual for correct safety sign placement.

Use Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe injury or machine damage.

Follow recommended procedure for removal and installation of components in the manual.

Protect Against Noise

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

Service Tires Safely

Explosive separation of a tire and rim parts can cause serious injury or death.

Do not attempt to mount a tire unless you have the proper equipment and experience to perform the job.

Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly. Use a safety cage if available.

Check wheels for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

Work in Clean Area

Before starting a job:

• Clean work area and machine.

• Make sure you have all necessary tools to do your job.

• Have the right parts on hand.

• Read all instructions thoroughly; do not attempt shortcuts.

Use Proper Tools

Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards.

Use power tools only to loosen threaded parts and fasteners.

For loosening and tightening hardware, use the correct size tools. DO NOT use U.S. measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches.

Use only service parts meeting John Deere specifications.

Dispose of Waste Properly

Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use food or beverage containers that may mislead someone into drinking from them.

Do not pour waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth’s atmosphere. Government regulations may require a certified air conditioning service center to recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste from your local environmental or recycling center, or from your John Deere dealer.

Live With Safety

Before returning machine to customer, make sure machine is functioning properly, especially the safety systems. Install all guards and shields.

Practice Safe Maintenance

Understand service procedure before doing work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet , and clothing from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower equipment to the ground. Stop the engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be raised for service work.

Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

Disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

Group 10 Combine and Component Identification

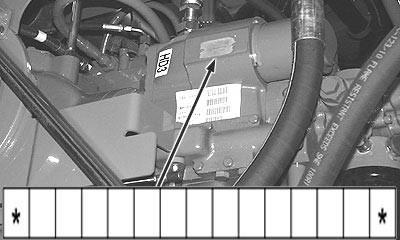

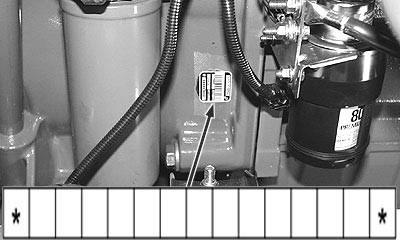

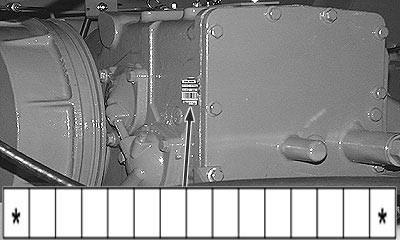

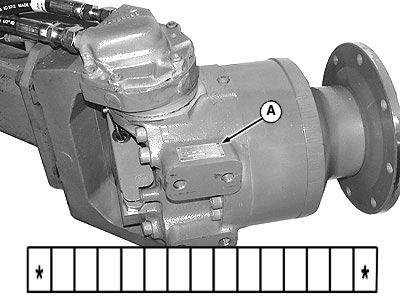

Identification Plates

Each combine has identification plates similar to the one shown. The letters and numbers stamped on these plates identify a component or assembly. ALL of these characters are needed when ordering parts or identifying a combine or component for any John Deere product support program. Also, they are needed for law enforcement to trace your combine if it is ever stolen.

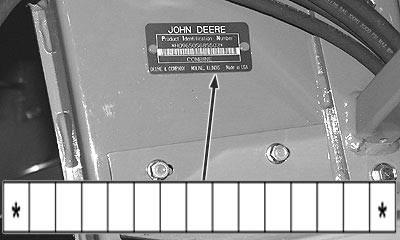

Combine Identification Number

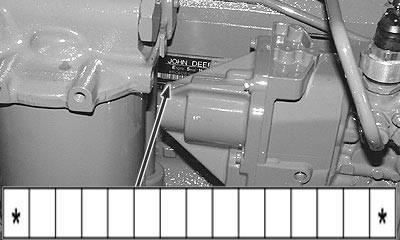

Engine Serial Number

Hydrostatic Drive Unit Pump