DOWNLOAD SERVICE

Covers All Models & All Repairs A-Z

This Is Not Generic Repair Information! It Is Vehicle Specific. This Is The Exact Same Manual Used By Technicians At The Dealerships To Maintain, Service, Diagnose And Repair Your Vehicle.

Complete Step-By-Step Instructions, Diagrams, Illustrations, Wiring Schematics, And Specifications To Completely Repair Your Vehicle With Ease!

You Get Everything You Will Ever Need On One Easy-To-Use Pdf-Manual. No More Flipping Through Books To Find What You Need. Print Only The Pages And Diagrams You Require. No More Greasy Pages Or Torn Lost Paper Manuals Again.

All Pages Are Printable, So Print Off What You Need & Take It With You To Your Vehicle Or Workshop. You Can Blow-Up Images And Then Print Off Enlarged Copies!

John deere 710d backhoe loader Technical Manual

Factory Highly Detailed Repair Manuals, With Complete Instructions And Illustrations, Wiring Schematics And Diagrams To Completely Service And Repair Your Vehicle.

All Manuals Are Windows Vista32 And 64, Xp, Me, 98, Nt, 2000 Compatible And Work With Mac!

* Maintenance

* Engine

* Control System

* Mechanical

* Fuel Service Specifications

* Emission Control

* Intake Exhaust Cooling

* Lube

* Ignition Starting Charging

* Auto Transmission Clutch

* Manual Transmission

* Transfer Propeller Shaft

* Drive Shaft

* Differential

* Axle Suspension

* Tire & Wheel

* Brake Control

* Brake

* Parking Brake

* Steering Column

* Power Steering

* Air Condition

* Suppl Restraint System

* Seat Belt

* Engine Immobilizer

* Cruise Control

* Wiper & Washer

* Door Lock

* Meter Audio/Visual

John deere 710d backhoe loader Technical Manual

710DBackhoeLoader OperationandTest

OperationandTest

TECHNICALMANUAL TM153726FEB02(ENGLISH)

Forcompleteserviceinformationalsosee:

Foreword

Thismanualiswrittenforanexperiencedtechnician. Essentialtoolsrequiredinperformingcertainservice workareidentifiedinthismanualandare recommendedforuse.

Livewithsafety:Readthesafetymessagesinthe introductionofthismanualandthecautionspresented throughoutthetextofthemanual.

Thisisthesafety-alertsymbol.Whenyouseethis symbolonthemachineorinthismanual,bealertto thepotentialforpersonalinjury.

Technicalmanualsaredividedintwoparts:repairand operationandtests.Repairsectionstellhowtorepair thecomponents.Operationandtestssectionshelpyou identifythemajorityofroutinefailuresquickly.

Informationisorganizedingroupsforthevarious componentsrequiringserviceinstruction.Atthe beginningofeachgrouparesummarylistingsofall applicableessentialtools,serviceequipmentandtools, othermaterialsneededtodothejob,servicepartskits, specifications,weartolerances,andtorquevalues.

TechnicalManualsareconciseguidesforspecific machines.Theyareon-the-jobguidescontainingonly thevitalinformationneededfordiagnosis,analysis, testing,andrepair.

Fundamentalserviceinformationisavailablefrom othersourcescoveringbasictheoryofoperation, fundamentalsoftroubleshooting,generalmaintenance, andbasictypeoffailuresandtheircauses.

SeeDB1990ServicePublicationsCatalogtoordera completeTechnicalManual(TM)oraTechnical ManualSection(TMS).AcompleteOperationandTest manualincludesthefollowingsections:

JohnDeereDealers

IMPORTANT:Pleaseremovethispageandroute throughyourservicedepartment.

Listedbelowisabriefexplanationof“WHAT”waschange and“WHY”itwaschanged.

1.Section9000:

Toincludeanyspecifications,oilcapacityandsafety concernsfornewrearaxle,transmission,charge pump,parkbrake,andservicebrakevalve.

2.Section9005:

Toaddoperationalchecksfornewtransmission,park brake,differentiallock,andservicebrakevalve.

3.Section9010:

Toincludemiscellaneousupdatesandupdateserial numbers.

4.Section9015:

Toincludeinformationfornewengine,frontconsole, andsideconsoleharnesses.Toaddnewtachometer andlowbrakepressurewarningsystem.

5.Section9020:

Toaddinformationfornewtransmissionandrearaxle. Formachines(S.N.872257—),informationonthe parkbrakeanddifferentiallockwillnowbeprovidedin thissection.

6.Section9025:

Tomakerequiredchangesbecauseofnewcharge pumplocatedontherearofthetransmission.To changeplumbingandschematicsrequiredbythe removaloftheparkbrake/differentiallockvalve.To addinformationonthenewservicebrakevalve.

7.Section9031:

Toimproveformatandaddinformationonnewside consoleharness. 8...

Weneedyourhelptocontinuallyimproveourtechnical publications.PleaseFAXormailyourcomments,ideas andimprovementsonthiscommentsheet.

SENDTO: JohnDeereDubuqueWorks

P.O.Box538 Dubuque,Iowa52004-0538 Dept.304

Attn:PublicationsSupervisor

FAXNUMBER:319-589-5800

TM1537710DBackhoeLoaderOperationandTestManual Ideas,Comments,(PleasestatePageNumber):

OVERALL,howwouldyouratethequalityof"ALL"InstallationInstructionsprovidedtoyou?(Checkone)

CompanyName Address Phone FAXNo. DealerAcct.No.

THANKYOU!

SECTION9000—GeneralInformation Group20—Adjustments

Group01—SafetyInformation Group02—GeneralSpecifications Group03—TorqueValues Group04—FuelsandLubricants

SECTION9005—OperationalCheckoutProcedure Group10—OperationalCheckoutProcedure

SECTION9010—Engine Group05—TheoryofOperation Group15—SystemDiagnosticInformation Group20—Adjustments Group25—Tests

SECTION9015—ElectricalSystem

Group05—SystemInformation Group10A—SystemDiagrams(S.N.—872256) Group10B—SystemDiagrams(S.N.872257—) Group15A—Sub-SystemDiagnostics(S.N.— 872256)

Group15B—Sub-SystemDiagnostics(S.N. 872257—) Group20—References

SECTION9020—PowerTrain Group05A—TheoryofOperation(S.N.—872256)

Group05B—TheoryofOperation(S.N.872257—) Group15A—SystemDiagnosticInformation(S.N.— 872256)

Group15B—SystemDiagnosticInformation(S.N. 872257—)

Group20—Adjustments Group25A—Tests(S.N.—872256) Group25B—Tests(S.N.872257—)

SECTION9025—HydraulicSystem Group05—TheoryofOperation

Group15—DiagnosticInformation Group20—Adjustments Group25—Tests

SECTION9031—HeatingandAirConditioning Group05—TheoryofOperation Group15—DiagnosticInformation

Allinformation,illustrationsandspecificationsinthismanualarebasedon thelatestinformationavailableatthetimeofpublication.Therightis reservedtomakechangesatanytimewithoutnotice.

HandleFluidsSafely—AvoidFires

Whenyouworkaroundfuel,donotsmokeorworknear heatersorotherfirehazards.

Storeflammablefluidsawayfromfirehazards.Donot incinerateorpuncturepressurizedcontainers.

Makesuremachineiscleanoftrash,grease,anddebris. Donotstoreoilyrags;theycanigniteandburn spontaneously.

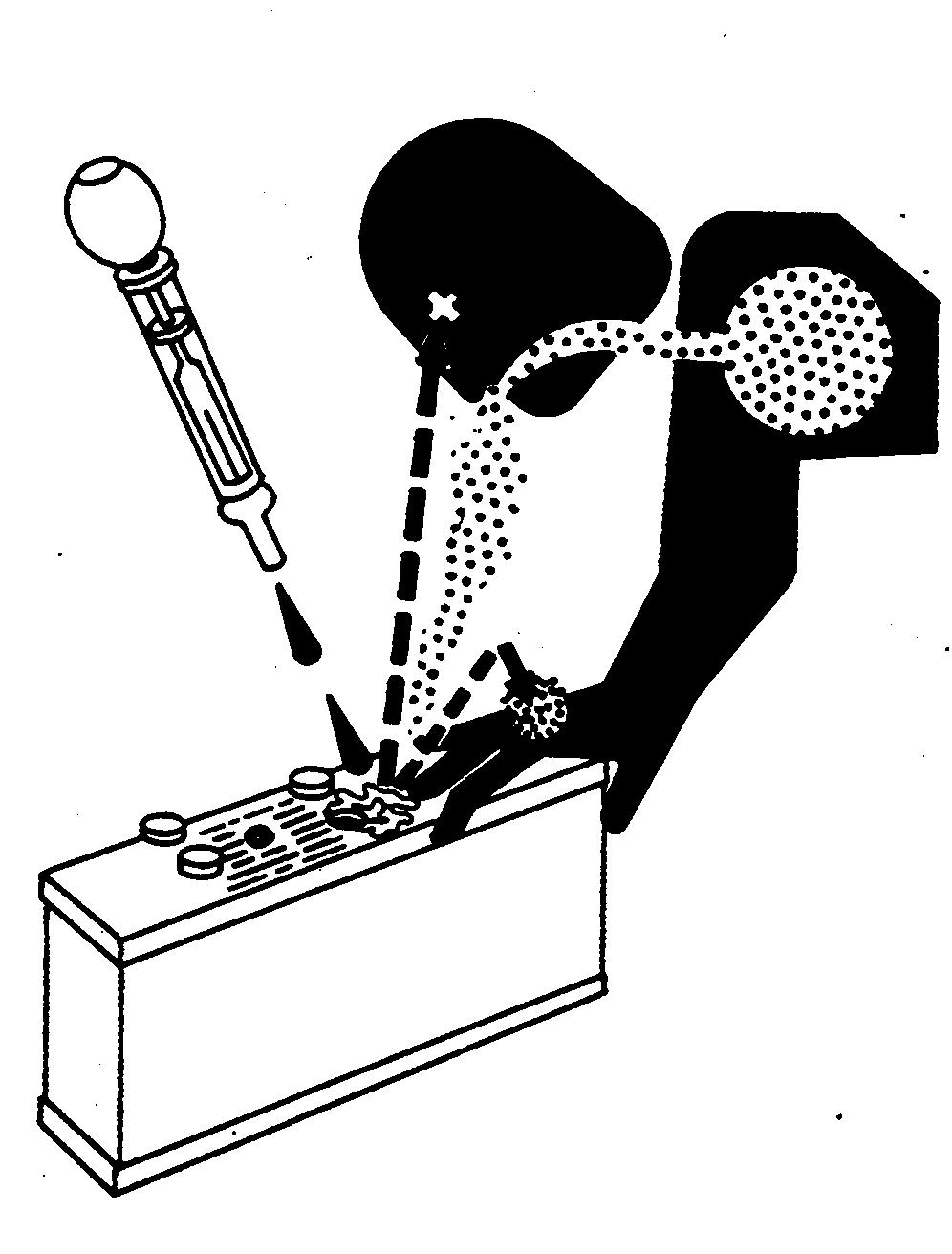

PreventBatteryExplosions

Keepsparks,lightedmatches,andopenflameawayfrom thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavolt-meterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

PrepareforEmergencies

Bepreparedifafirestarts.

Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice, hospital,andfiredepartmentnearyourtelephone.

PreventAcidBurns

Sulfuricacidinbatteryelectrolyteispoisonous.Itisstrong enoughtoburnskin,eatholesinclothing,andcause blindnessifsplashedintoeyes.

Avoidthehazardby:

1.Fillingbatteriesinawell-ventilatedarea.

2.Wearingeyeprotectionandrubbergloves.

3.Avoidingbreathingfumeswhenelectrolyteisadded.

4.Avoidingspillingordrippingelectrolyte.

5.Useproperjumpstartprocedure.

Ifyouspillacidonyourself:

1.Flushyourskinwithwater.

2.Applybakingsodaorlimetohelpneutralizetheacid.

3.Flushyoureyeswithwaterfor15—30minutes.Get medicalattentionimmediately.

Ifacidisswallowed:

1.Donotinducevomiting.

2.Drinklargeamountsofwaterormilk,butdonot exceed2L(2 quarts).

3.Getmedicalattentionimmediately.

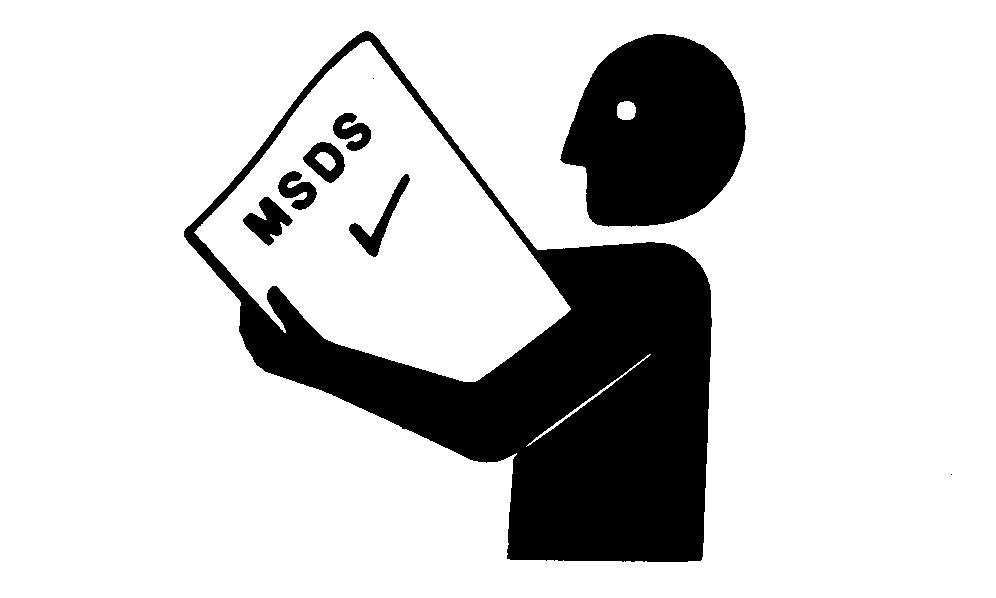

HandleChemicalProductsSafely

Directexposuretohazardouschemicalscancause seriousinjury.Potentiallyhazardouschemicalsusedwith JohnDeereequipmentincludesuchitemsaslubricants, coolants,paints,andadhesives.

AMaterialSafetyDataSheet(MSDS)providesspecific detailsonchemicalproducts:physicalandhealthhazards, safetyprocedures,andemergencyresponsetechniques.

ChecktheMSDSbeforeyoustartanyjobusinga hazardouschemical.Thatwayyouwillknowexactlywhat therisksareandhowtodothejobsafely.Thenfollow proceduresandrecommendedequipment.

(SeeyourJohnDeeredealerforMSDS’sonchemical productsusedwithJohnDeereequipment.)

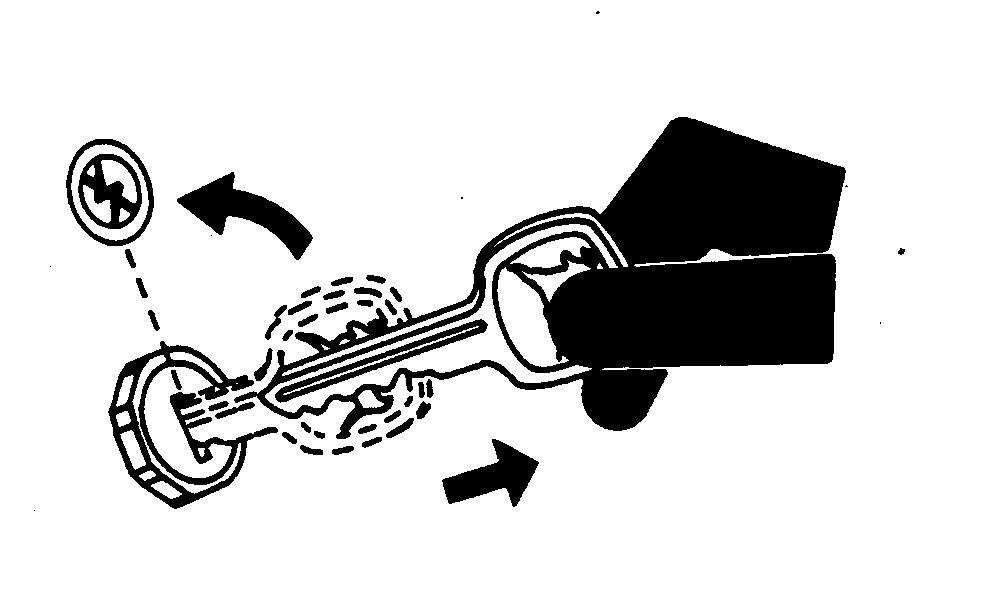

AvoidHigh-PressureFluids

Escapingfluidunderpressurecanpenetratetheskin causingseriousinjury.

Avoidthehazardbyrelievingpressurebefore disconnectinghydraulicorotherlines.Tightenall connectionsbeforeapplyingpressure.

Searchforleakswithapieceofcardboard.Protecthands andbodyfromhighpressurefluids.

Ifanaccidentoccurs,seeadoctorimmediately.Anyfluid injectedintotheskinmustbesurgicallyremovedwithina fewhoursorgangrenemayresult.Doctorsunfamiliarwith thistypeofinjuryshouldreferenceaknowledgeable medicalsource.SuchinformationisavailablefromDeere &CompanyMedicalDepartmentinMoline,Illinois,U.S.A.

ParkMachineSafely

Beforeworkingonthemachine:

• Lowerallequipmenttotheground.

• Stoptheengineandremovethekey.

• Disconnectthebatterygroundstrap.

• Hanga"DONOTOPERATE"taginoperatorstation.

SupportMachineProperly

Alwayslowertheattachmentorimplementtotheground beforeyouworkonthemachine.Ifyoumustworkona liftedmachineorattachment,securelysupportthe machineorattachment.Ifleftinaraisedposition, hydraulicallysupporteddevicescansettleorleakdown.

Donotsupportthemachineoncinderblocks,hollowtiles, orpropsthatmaycrumbleundercontinuousload.Donot workunderamachinethatissupportedsolelybyajack. Followrecommendedproceduresinthismanual.

Whenimplementsorattachmentsareusedwithatractor, alwaysfollowsafetyprecautionslistedintheimplement operator’smanual.

WearProtectiveClothing

Wearclosefittingclothingandsafetyequipment appropriatetothejob.

Operatingequipmentsafelyrequiresthefullattentionof theoperator.Donotwearradioormusicheadphones whileoperatingmachine.

WorkinCleanArea

Beforestartingajob:

• Cleanworkareaandmachine.

• Makesureyouhaveallnecessarytoolstodoyourjob.

• Havetherightpartsonhand.

• Readallinstructionsthoroughly;donotattempt shortcuts.

ServiceMachinesSafely

Tielonghairbehindyourhead.Donotwearanecktie, scarf,looseclothing,ornecklacewhenyouworknear machinetoolsormovingparts.Iftheseitemsweretoget caught,severeinjurycouldresult.

Removeringsandotherjewelrytopreventelectrical shortsandentanglementinmovingparts.

WorkInVentilatedArea

Engineexhaustfumescancausesicknessordeath.Ifitis necessarytorunanengineinanenclosedarea,remove theexhaustfumesfromtheareawithanexhaustpipe extension.

Ifyoudonothaveanexhaustpipeextension,openthe doorsandgetoutsideairintothearea

IlluminateWorkAreaSafely

Illuminateyourworkareaadequatelybutsafely.Usea portablesafetylightforworkinginsideorunderthe machine.Makesurethebulbisenclosedbyawirecage. Thehotfilamentofanaccidentallybrokenbulbcanignite spilledfueloroil.

ReplaceSafetySigns

Replacemissingordamagedsafetysigns.Seethe machineoperator’smanualforcorrectsafetysign placement.

UseProperLiftingEquipment

Liftingheavycomponentsincorrectlycancausesevere injuryormachinedamage.

Followrecommendedprocedureforremovaland installationofcomponentsinthemanual.

RemovePaintBeforeWeldingorHeating

Avoidpotentiallytoxicfumesanddust.

Hazardousfumescanbegeneratedwhenpaintisheated bywelding,soldering,orusingatorch.

Doallworkoutsideorinawellventilatedarea.Disposeof paintandsolventproperly.

Removepaintbeforeweldingorheating:

• Ifyousandorgrindpaint,avoidbreathingthedust. Wearanapprovedrespirator.

• Ifyouusesolventorpaintstripper,removestripperwith soapandwaterbeforewelding.Removesolventor paintstrippercontainersandotherflammablematerial fromarea.Allowfumestodisperseatleast15minutes beforeweldingorheating.

AvoidHeatingNearPressurizedFluidLines

Flammablespraycanbegeneratedbyheatingnear pressurizedfluidlines,resultinginsevereburnsto yourselfandbystanders.Donotheatbywelding, soldering,orusingatorchnearpressurizedfluidlinesor otherflammablematerials.Pressurizedlinescanbe accidentallycutwhenheatgoesbeyondtheimmediate flamearea.

KeepROPSInstalledProperly

Makecertainallpartsarereinstalledcorrectlyifthe roll-overprotectivestructure(ROPS)isloosenedor removedforanyreason.Tightenmountingboltstoproper torque.

TheprotectionofferedbyROPSwillbeimpairedifROPS issubjectedtostructuraldamage,isinvolvedinan overturnincident,orisinanywayalteredbywelding, bending,drilling,orcutting.AdamagedROPSshouldbe replaced,notreused.

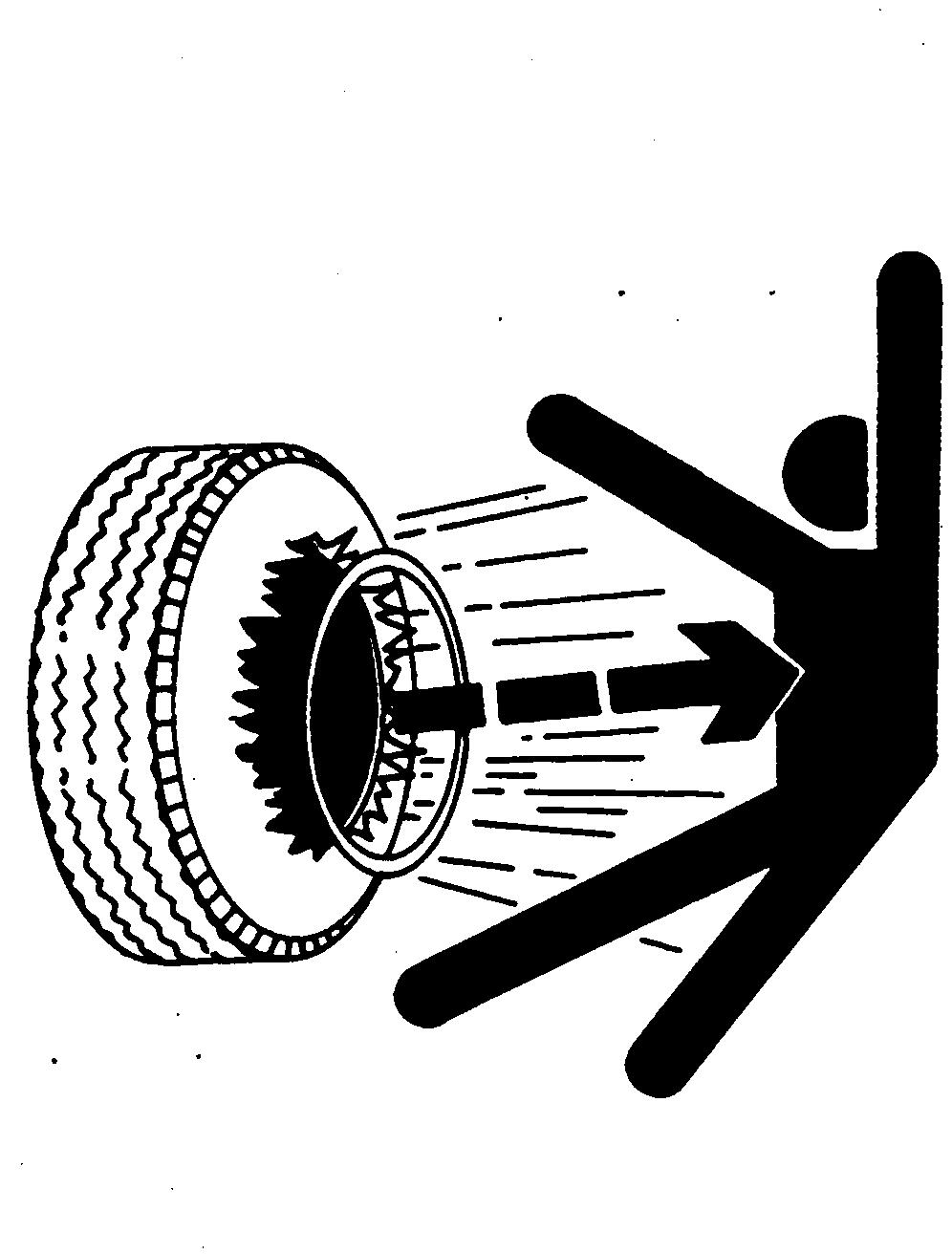

ServiceTiresSafely

Explosiveseparationofatireandrimpartscancause seriousinjuryordeath.

Donotattempttomountatireunlessyouhavetheproper equipmentandexperiencetoperformthejob.

Alwaysmaintainthecorrecttirepressure.Donotinflate thetiresabovetherecommendedpressure.Neverweldor heatawheelandtireassembly.Theheatcancausean increaseinairpressureresultinginatireexplosion. Weldingcanstructurallyweakenordeformthewheel.

Wheninflatingtires,useaclip-onchuckandextension hoselongenoughtoallowyoutostandtoonesideand NOTinfrontoforoverthetireassembly.Useasafety cageifavailable.

Checkwheelsforlowpressure,cuts,bubbles,damaged rimsormissinglugboltsandnuts.

AvoidHarmfulAsbestosDust

Avoidbreathingdustthatmaybegeneratedwhen handlingcomponentscontainingasbestosfibers.Inhaled asbestosfibersmaycauselungcancer.

Componentsinproductsthatmaycontainasbestosfibers arebrakepads,brakebandandliningassemblies,clutch plates,andsomegaskets.Theasbestosusedinthese componentsisusuallyfoundinaresinorsealedinsome way.Normalhandlingisnothazardousaslongas airbornedustcontainingasbestosisnotgenerated.

Avoidcreatingdust.Neverusecompressedairfor cleaning.Avoidbrushingorgrindingmaterialcontaining asbestos.Whenservicing,wearanapprovedrespirator.A specialvacuumcleanerisrecommendedtoclean asbestos.Ifnotavailable,applyamistofoilorwateron thematerialcontainingasbestos.

Keepbystandersawayfromthearea.

PracticeSafeMaintenance

Understandserviceprocedurebeforedoingwork.Keep areacleananddry.

Neverlubricate,service,oradjustmachinewhileitis moving.Keephands,feet,andclothingfrom power-drivenparts.Disengageallpowerandoperate controlstorelievepressure.Lowerequipmenttothe ground.Stoptheengine.Removethekey.Allowmachine tocool.

Securelysupportanymachineelementsthatmustbe raisedforservicework.

Keepallpartsingoodconditionandproperlyinstalled.Fix damageimmediately.Replacewornorbrokenparts. Removeanybuildupofgrease,oil,ordebris.

Onself-propelledequipment,disconnectbatteryground cable(-)beforemakingadjustmentsonelectricalsystems orweldingonmachine.

Ontowedimplements,disconnectwiringharnessesfrom tractorbeforeservicingelectricalsystemcomponentsor weldingonmachine.

UseProperTools

Usetoolsappropriatetothework.Makeshifttoolsand procedurescancreatesafetyhazards.

Usepowertoolsonlytoloosenthreadedpartsand fasteners.

Forlooseningandtighteninghardware,usethecorrect sizetools.DONOTuseU.S.measurementtoolson metricfasteners.Avoidbodilyinjurycausedbyslipping wrenches.

UseonlyservicepartsmeetingJohnDeerespecifications.

DisposeofWasteProperly

Improperlydisposingofwastecanthreatenthe environmentandecology.Potentiallyharmfulwasteused withJohnDeereequipmentincludesuchitemsasoil,fuel, coolant,brakefluid,filters,andbatteries.

Useleakproofcontainerswhendrainingfluids.Donotuse foodorbeveragecontainersthatmaymisleadsomeone intodrinkingfromthem.

Donotpourwasteontotheground,downadrain,orinto anywatersource.

Airconditioningrefrigerantsescapingintotheaircan damagetheEarth’satmosphere.Governmentregulations mayrequireacertifiedairconditioningservicecenterto recoverandrecycleusedairconditioningrefrigerants.

Inquireontheproperwaytorecycleordisposeofwaste fromyourlocalenvironmentalorrecyclingcenter,orfrom yourJohnDeeredealer.

LiveWithSafety

Beforereturningmachinetocustomer,makesure machineisfunctioningproperly,especiallythesafety systems.Installallguardsandshields.

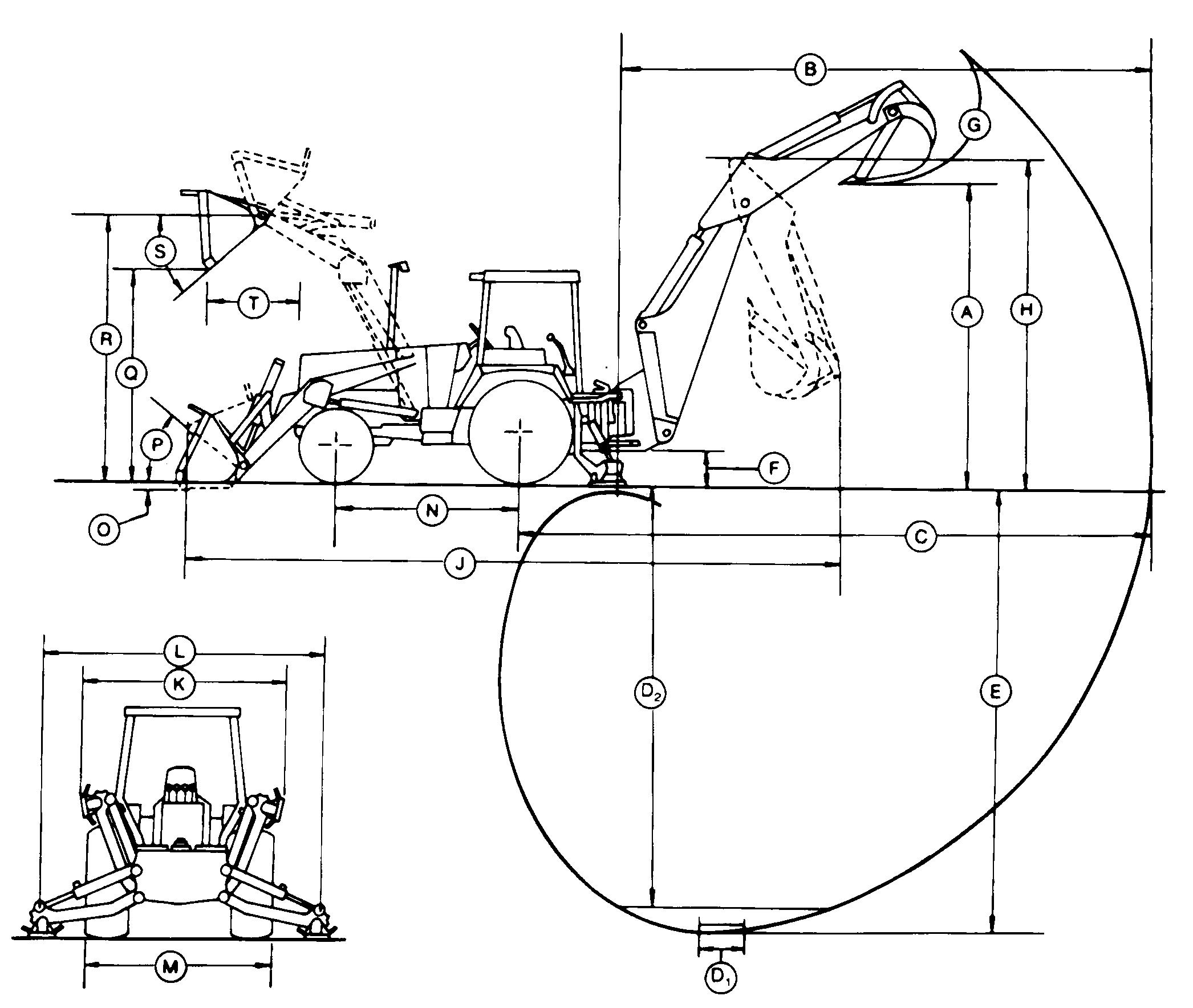

NOTE:Specificationsanddesignsubjecttochange withoutnotice.Whereverapplicable, specificationsareinaccordancewithICED andSAEStandards.Exceptwhereotherwise noted,thesespecificationsarebasedona standardmachinewith21L-24,16PR,R4rear

tires;14.5/75—16.1,10PR,F3fronttireswith 75percentCaCl2 fill;1.15m3(1.5cuyd)loader bucket;610mm(24in.)backhoebucket; ROPS/FOPS;fullfueltankand79kg(175lb) operator.

710DBackhoeLoaderDimensions

ExtendibleDipperstick

BackhoeStandardRetractedExtended

A—Loadingheight,truckloadingposition4.03m(13ft3in.)3.98m(13ft1in.)4.65m(15ft3in.)

B—Reachfromcenterofswingmast6.90m(22ft8in.)6.90m(22ft8in.)8.31m(27ft3in.)

C—Reachfromcenterofrearaxle8.15m(26ft9in.)8.15m(26ft9in.)9.56m(31ft4in.)

D—Diggingdepth(SAE):

(1)610mm(2ft)flatbottom5.53m(18ft2in.)5.51m(18ft1in.)7.03m(23ft1in.)

(2)2440mm(8ft)flatbottom5.26m(17ft3in.)5.24m(17ft2in.)6.82m(22ft4in.)

E—Maximumdiggingdepth5.55m(18ft2in.)5.52m(18ft1in.)7.04m(23ft1in.)

F—Groundclearance,minimum356mm(14in.)356mm(14in.)356mm(14in.)

G—Bucketrotation152°/162° 152°/162° 152°/162°

H—Transportheight4.21m(13ft10in.)4.31m(13ft11in.)4.31m(13ft11in.)

J—Overalllength,transport8.13m(26ft8in.)8.13m(26ft8in.)8.13m(26ft8in.)

K—Stabilizerwidth—transport2.44m(8ft0in.)2.44m(8ft0in.)2.44m(8ft0in.)

L—Stabilizerspread—operating3.48m(11ft5in.)3.48m(11ft5in.)3.48m(11ft5in.)

M—Overallwidth(lessloaderbucket)2235mm(88in.)2235mm(88in.)2235mm(88in.)

Diggingforce,bucketcylinder(powerdigposition)57.5kN(12,940lbforce)57.5kN(12,940lbforce)57.5kN(12,940lbforce)

Diggingforce,crowdcylinder42.7kN(9600lbforce)42.7kN(9600lbforce)29.8kN(6700lbforce)

Loaderwith1.24m3 (1.62yd3 )Loaderwith1.0m3 (1.375yd3 )Bucket BucketandMFWD

N—Wheelbase2.29m(90.5in.)2.29m(90.5in.)

O—Digbelowground—bucketlevel147mm(5.8in.)152mm(6.0in.)

P—Rollbackatgroundlevel40° 40°

Q—Dumpclearance,bucketat40°

2.80m(9ft6in.)2.80m(9ft6in.)

R—Maximumheighttobuckethingepin3.57m(11ft8in.)3.61m(11ft10in.)

S—Maximumbucketdumpangle40° 40°

T—Reachatfullheight,bucketat40° 851mm(33.5in.)836mm(32.9in.)

GeneralSpecifications

710DBackhoeLoaderEngineSpecifications (S.N.—830204)

ItemMeasurementSpecification

Engine:JohnDeere6059T turbochargeddiesel,4-strokecycle

NetPower@2200PowerSAE86kW(115hp)

GrossPower@2200PowerSAE90kW(120hp)

CylindersQuantity6

BoreandStrokeDistance106.5x110mm(4.19x4.33in.)

DisplacementVolume5.884L(359cuin.)

FuelConsumption,TypicalConsumption7.6to12.5L/h(2.0—3.3gal/hr)

CompressionRatioCompression17.8to1

MaximumTorque@25%at1400TorqueRise465N•m(343lb-ft) rpm

MainBearingsQuantity7

ElectricalSystemVoltage12volts

AlternatorAmperage65amps

LubricationPressuresystemw/full-flowfilterand cooler

Fan Suction

AirCleanerDry

710DBackhoeLoaderEngineSpecifications (S.N.830205—)

ItemMeasurementSpecification

Engine:JohnDeere6068Tand PowerTech 6068Tturbocharged diesel,4-strokecycle,Model# 6068TT050

NetPower@2200PowerSAE87kW(116hp)

GrossPower@2200PowerSAE93kW(125hp)

CylindersQuantity6

BoreandStrokeDistance106.5x127mm(4.19x5.00in.)

DisplacementVolume6.8L(414cuin.)

FuelConsumption,TypicalConsumption9.5to14.3L/h(2.5—3.8gal/hr)

CompressionRatioCompression17.0to1

MaximumTorque@27%at1400TorqueRise515.5N•m(380lb-ft) rpm

MainBearingsQuantity7

ElectricalSystemVoltage12volts

AlternatorAmperage95ampsw/AC 65ampsw/oAC

PowerTechisaregisteredtrademarkofDeere&Company

710DBackhoeLoaderSpecifications(S.N.—872328)

ItemMeasurementSpecification

TravelSpeeds:ForwardTravelwith standard21Lx24rearand14.5/75x 16.1fronttires

Forward1Speed5.1km/h(3.1mph)

Forward2Speed8.7km/h(5.4mph)

Forward3Speed17.9km/h(11.1mph)

Forward4Speed30.6km/h(19.0mph)

TravelSpeeds:ReverseTravelwith standard21Lx24rearand14.5/75x 16.1fronttires

Reverse1Speed5.4km/h(3.4mph)

Reverse2Speed9.6km/h(6.0mph)

TravelSpeeds:ForwardTravelwith MFWDand21Lx28(required)rear and15x19.5fronttires

Forward1Speed5.5km/h(3.4mph)

Forward2Speed9.6km/h(6.0mph)

Forward3Speed19.8km/h(12.3mph)

Forward4Speed33.9km/h(21.0mph)

TravelSpeeds:ReverseTravelwith MFWDand21Lx28(required)rear and15x19.5fronttires

Reverse1Speed6.0km/h(3.7mph)

Reverse2Speed10.6km/h(6.6mph)

General Specifications

ItemMeasurementSpecification

Steering

Non-PoweredAxleTurningradiuswithbrakes4.37m(14ft4in.)

Turningradiuswithoutbrakes4.63m(15ft2in.)

Clearancecirclewithbrakes11.02m(36ft2in.)

Clearancecirclewithoutbrakes11.54m(37ft10in.)

Axleoscillationstop-to-stop20°

MechanicalFront-Wheel-DriveTurningradiuswithbrakes4.39m(14ft5in.)

Turningradiuswithoutbrakes4.76m(15ft7in.)

Clearancecirclewithbrakes11.06m(36ft3in.)

Clearancecirclewithoutbrakes11.80m(38ft9in.)

Axleoscillationstop-to-stop18°

Steeringwheelturnsstop-to-stop,3.0to3.8 bothaxles

HydraulicSystem:Closedcenter (variableflow,constantpressure)

MainReliefPressure17500kPa(175bar)(2550psi)

MainPumpRadialPistonsQuantity16radialpistons,variableflow

Flow@15170kPa(151bar)FlowRate201L/min(53gpm) (2200psi)

ChargePumpFlow@FastIdleFlowRate64L/min(17gpm) (Minimum)

Filter,ReturnOil10micronsteelenclosed, replaceablepaperelement

Screen,PressureOil20/cm(50/in.)mesh

TX,9000,BG785–19–19AUG99–2/2

710DBackhoeLoaderSpecifications(S.N.872329—)

ItemMeasurementSpecification

TravelSpeeds:ForwardTravelwith standard21Lx24rearand14.5/75x 16.1fronttires

Forward1Speed5.3km/h(3.3mph)

Forward2Speed8.8km/h(5.5mph)

Forward3Speed21.9km/h(13.6mph)

Forward4Speed35.4km/h(22.0mph)

TravelSpeeds:ReverseTravelwith standard21Lx24rearand14.5/75x 16.1fronttires

Reverse1Speed6.1km/h(3.8mph)

Reverse2Speed9.8km/h(6.1mph)

Reverse3Speed24.5km/h(15.2mph)

TravelSpeeds:ForwardTravelwith MFWDand21Lx28rearand15x 19.5fronttires

Forward1Speed5.6km/h(3.5mph)

Forward2Speed9.5km/h(5.9mph)

Forward3Speed23.5km/h(14.6mph)

Forward4Speed38.1km/h(23.7mph)

TravelSpeeds:ReverseTravelwith MFWDand21Lx28rearand15x 19.5fronttires

Reverse1Speed6.4km/h(4.0mph)

Reverse2Speed10.6km/h(6.6mph)

ItemMeasurementSpecification

Reverse3Speed26.2km/h(16.3mph)

TravelSpeeds:ForwardTravelwith MFWDand20.5Lx25rearand15x 19.5fronttires

Forward1Speed5.8km/h(3.6mph)

Forward2Speed9.7km/h(6.0mph)

Forward3Speed24.0km/h(14.9mph)

Forward4Speed38.7km/h(24.1(mph)

TravelSpeeds:ReverseTravelwith MFWDand21.5Lx25rearand15x 19.5fronttires

Reverse1Speed6.4km/h(4.0mph)

Reverse2Speed10.8km/h(6.7mph)

Reverse3Speed26.7km/h(16.6mph)

Steering

Non-PoweredAxleTurningradiuswithbrakes4.37m(14ft4in.)

Turningradiuswithoutbrakes4.63m(15ft2in.)

Clearancecirclewithbrakes11.02m(36ft2in.)

Clearancecirclewithoutbrakes11.54m(37ft10in.)

Axleoscillationstop-to-stop20°

MechanicalFront-Wheel-DriveTurningradiuswithbrakes4.39m(14ft5in.)

Turningradiuswithoutbrakes4.76m(15ft7in.)

Clearancecirclewithbrakes11.06m(36ft3in.)

Clearancecirclewithoutbrakes11.80m(38ft9in.)

Axleoscillationstop-to-stop18°

Steeringwheelturnsstop-to-stop,3.0to3.8 bothaxles

CED,TX03679,3599–19–19AUG99–2/3

GeneralSpecifications

ItemMeasurementSpecification

HydraulicSystem:Closedcenter (variableflow,constantpressure)

MainReliefPressure17500kPa(175bar)(2550psi)

MainPumpRadialPistons,Quantity16 VariableFlow

Flow@15170kPa(151bar)FlowRate201L/min(53gpm) (2200psi)

ChargePumpFlow@FastIdleFlowRate90L/min(24gpm) (Minimum)

CED,TX03679,3599–19–19AUG99–3/3

710DBackhoeLoader—OtherInformation

Transmission(S.N.—872328):

JohnDeeredesignedandbuiltplanetarypowershiftwith torqueconverter,fourspeedsforwardandtwospeeds reverse.The310mm(12.2in.)singlestage,dualphase torqueconverterhas1.99:1stalltorqueratio.

Transmission(S.N.872329—):

Asinglestagetorqueconverterdrivesahydraulically engaged,fourspeedsforwardandthreespeedsreverse, countershafttypepowershifttransmission.

MFWDAxle—IfEquipped:

Formachines(S.N.—872328),limitedslipdifferentialwith 19.64:1ratio.

Formachines(S.N.872329—),limitedslipdifferential andoppositeinputrotationwith14.00:1ratio.

FinalDrives:

Heavy-duty,inboardmountedplanetarytype.Evenly distributesaxleshockloadsoverthreegearsthatrunina coolingoilbath.

Brakes:

Hydraulicwetdiskservicebrakesaremountedinboard andarepressurecooledandlubricated.Theyare self-adjusting,self-equalizing,andrequirenoperiodic service.Individualpedalsallowthemtobeapplied togetherorseparately.Theparkingbrakeisan independentsystemthatisspring-applied,hydraulically releasedandcontrolledbyanelectricswitchonthe controlconsole.AllbrakesconformtoSAEJ1473.

Tires:

Regular

• Front:14.5/75x16.1,10PR,F3

• Rear:21Lx24,16PR,R4

Axle

GeneralSpecifications

• Front:14.5/75x16.1,10PR,F3

• Rear:21Lx28,14PR,R4

• Front:16.5Lx16.1,10PR,I-1

• Rear:21Lx28,14PR,R4

MFWD

• Front:15x19.5,8PR,lugthread

• Rear:21Lx28,14PR,R4

OperatingWeights:

ItemMeasurementSpecification

710DBasicMachineWeight10450kg(23000lb)

AddOptionalWeights:

CabWeight227kg(500lb)

MFWDWeight590kg(1300lb)

ExtendibleDipperstickwithWeight618kg(1362lb)

RequiredCounterweights

OptionalFrontCounterweightWeight318kg(700lb)

ReversibleStabilizerPadsWeight41kg(90lb)

Loaderbuckets:

710DBackhoeBuckets

Widthmm(in.)HeapedCapacitym3 (cuyd)

Loader2337(92)1.24(1.62)

710DDrainandRefillCapacities

ItemMeasurementSpecification

EngineCoolantCapacity26L(28qt)

EngineOil(IncludingFilter)Capacity19L(20qt)

TransmissionwithMFWD(S.N.—Capacity13.2L(3.5gal) 872328)

TransmissionwithoutMFWDCapacity9.5L(2.5gal) (S.N.—872328)

Transmission(S.N.872329—)Capacity15L(4gal)

HydraulicReservoirCapacity40L(10.5gal)

FuelTankCapacity166L(44gal)

FrontAxle(MFWD)Capacity12.3L(3.25gal)

FrontWheelPlanetary(MFWD)Capacity1L(1.1qt)

RearAxleDifferential(S.N.—Capacity18L(4.75gal) 872328)

RearAxle(S.N.872329—)Capacity16L(4.25gal)

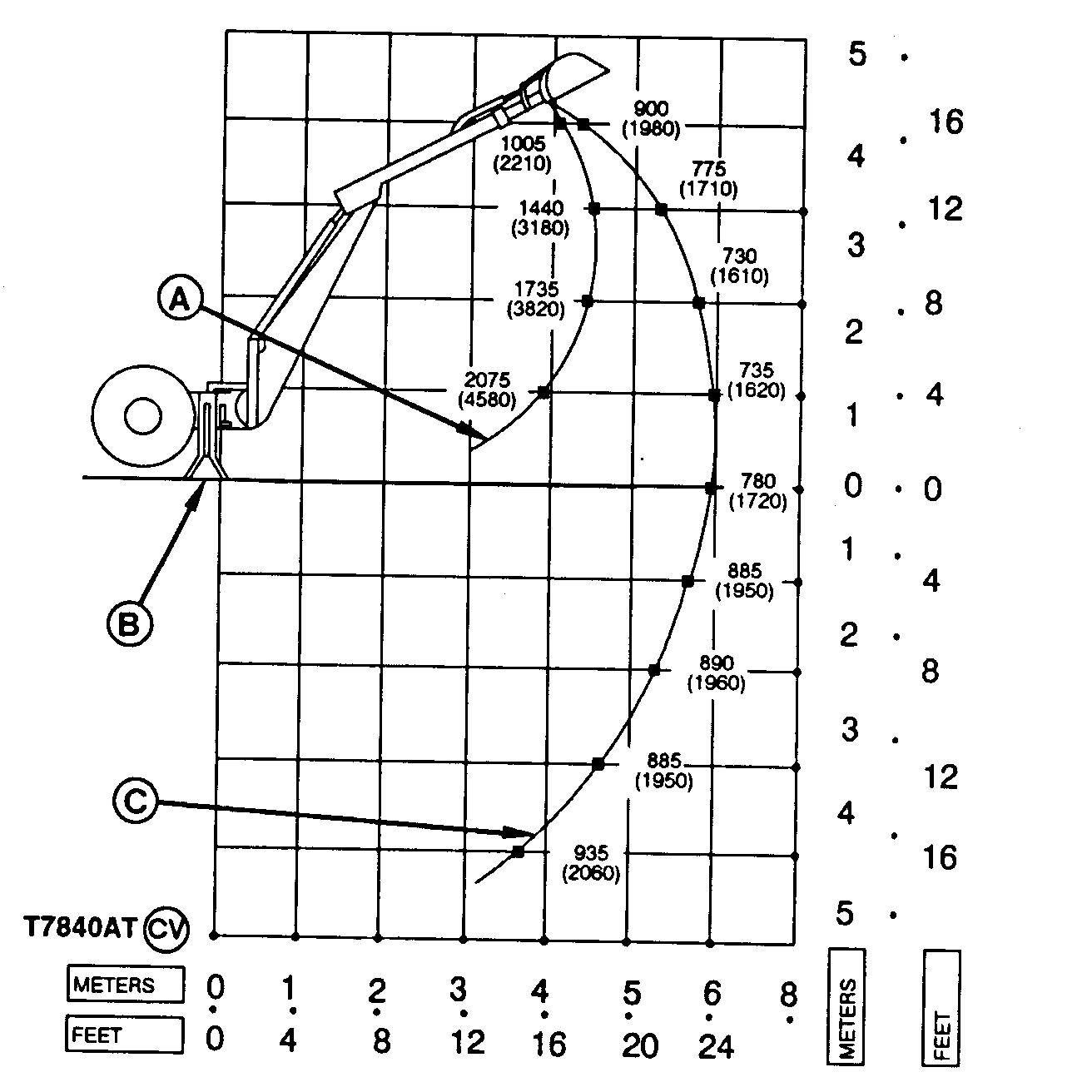

710DBackhoeLoaderLiftingCapacities

LiftCapacity,BackhoewithStandardDipperstick.BasedonSAEJ31.Ratedliftcapacitiesareinkg(lb).Lift capacitiesarehydraulicallylimited.

A—DipperLiftat65° B—SwingPivotC—BoomLift

Liftingcapacityratingsaremadewithbuckethingepin, loaderbucketandstabilizersonfirm,levelground.Lift capacitiesarehydraulicallylimited.Liftingcapacities are87%ofthemaximumliftoveranypointonthe swingarcanddonotexceed75%ofthetippingload.

Anglebetweenboomandgroundis65°.Machineis equippedwith610mm(24in.)standardbucket, standardorextendibledipperstickandstandard equipment.

Continuedonnextpage

LiftCapacity,Backhoewith1.52m(5ft)ExtendibleDipperstick,Retracted.BasedonSAEJ31.Ratedliftcapacities areinkg(lb).Liftcapacitiesarehydraulicallylimited.

A—DipperLiftat65° B—SwingPivotC—BoomLift

NOTE:Loaderbucketongroundsignificantlyimproves sidestability,thereforeimprovingliftcapacity totheside.Liftcapacityovertherearisnot affected.

Continuedonnextpage

TX,115,RR2660–19–19AUG99–2/3

LiftCapacity,Backhoewith1.52m(5ft)ExtendibleDipperstick,Extended.BasedonSAEJ31.Ratedliftcapacities areinkg(lb).Liftcapacitiesarehydraulicallylimited.

A—DipperLiftat65° B—SwingPivotC—BoomLift

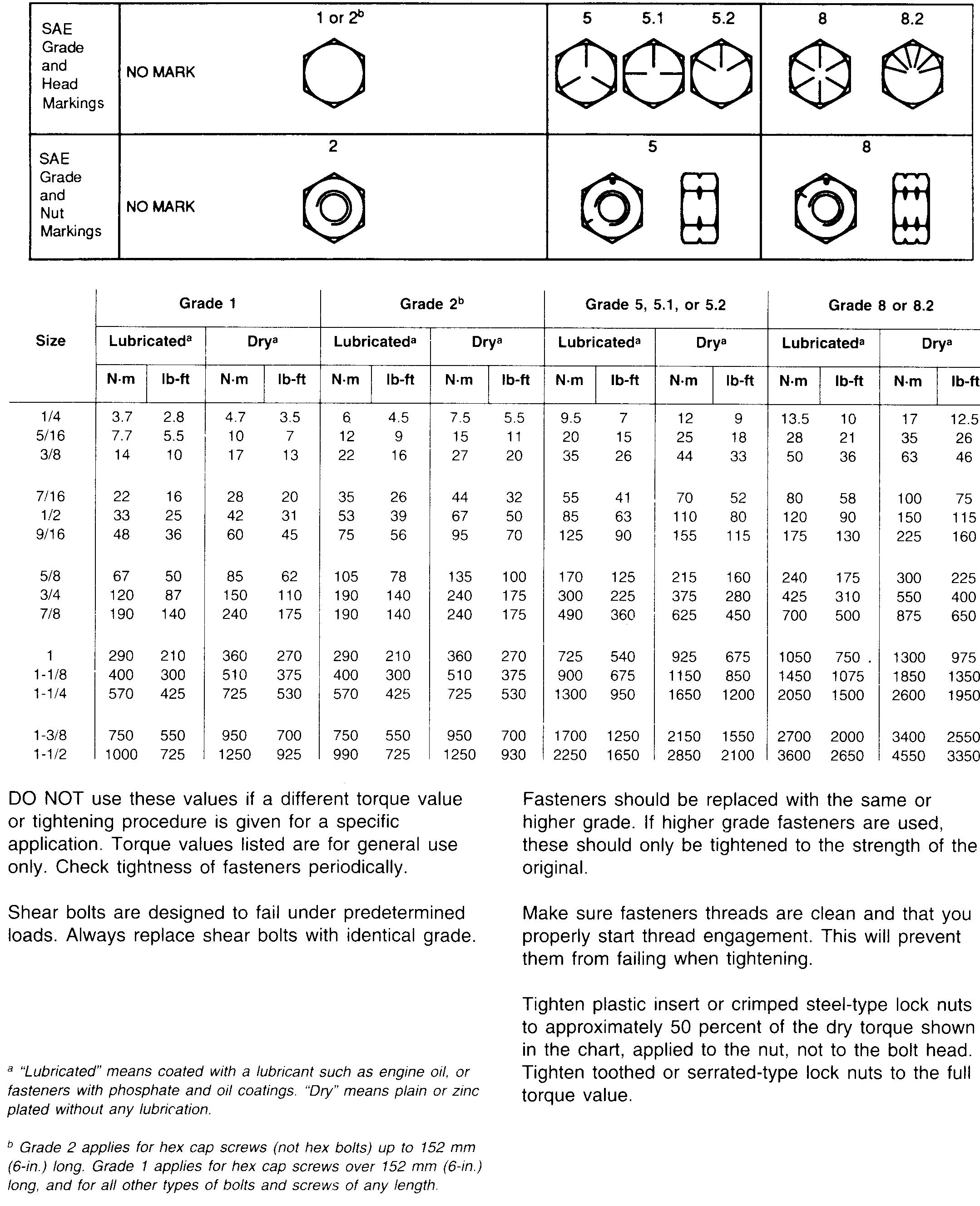

HardwareTorqueSpecifications

Checkcapscrewsandnutstobesuretheyaretight.If hardwareisloose,tightentotorqueshownonthe followingchartsunlessaspecialtorqueisspecified.

710DTirePressure

NOTE:Tireshippingpressuremaynotbethesameas tireoperatingpressure.Youmaychangetire pressurestosuitworkingconditionsaccordingto tiremanufacturer’srecommendations.

ItemMeasurementSpecification

TireSize(Front)

14.5/75x16.1,10PR,F3Pressure276kPa(2.8bar)(40psi)

15x19.5,8PR(w/MFWDonly)Pressure276kPa(2.8bar)(40psi)

16.5Lx16.1,10PR,I-1Pressure276kPa(2.8bar)(40psi)

TireSize(Rear)

20.5x25,12PR,R4Pressure241kPa(2.4bar)(35psi)

21Lx24,16PR,R4Pressure276kPa(2.7bar)(40psi)

21Lx28,14PR,R4Pressure248kPa(2.5bar)(36psi)

ROPSTorqueSpecifications

CAUTION:Makecertainallpartsarereinstalled correctlyiftheroll-overprotectivestructure (ROPS)isloosenedorremovedforanyreason. Tightenmountingboltstopropertorque.

TheprotectionofferedbyROPSwillbe impairedifROPSissubjectedtostructural damage,isinvolvedinanoverturnincident,or isinanywayaltered.AdamagedROPSshould bereplaced,notreused.

Wheninstallationofequipmentonamachinenecessitates looseningorremovingROPS,mountingboltsmustbe tightenedto420 ± 84N•m(310 ± 62ft-lb).

ItemMeasurementSpecification

ROPSMountingBoltsTorque420 ± 84N•m310 ± 62lb-ft)

CheckingWheelFastenerTorque

Tightenwheelcapscrews.

Specification

FrontStandardAxle—Torque230+35-46N•m(170+26-34 ft-lb)

FrontMFWDAxle—Torque407+60-80N•m(300+45-60 ft-lb) ....................

RearAxle—Torque575+170-115N•m(425+125 -85ft-lb)

John deere 710d backhoe loader Technical Manual

DOWNLOAD SERVICE

Covers All Models & All Repairs A-Z

This Is Not Generic Repair Information! It Is Vehicle Specific. This Is The Exact Same Manual Used By Technicians At The Dealerships To Maintain, Service, Diagnose And Repair Your Vehicle.

Complete Step-By-Step Instructions, Diagrams, Illustrations, Wiring Schematics, And Specifications To Completely Repair Your Vehicle With Ease!

You Get Everything You Will Ever Need On One Easy-To-Use Pdf-Manual. No More Flipping Through Books To Find What You Need. Print Only The Pages And Diagrams You Require. No More Greasy Pages Or Torn Lost Paper Manuals Again.

All Pages Are Printable, So Print Off What You Need & Take It With You To Your Vehicle Or Workshop. You Can Blow-Up Images And Then Print Off Enlarged Copies!

John deere 710d backhoe loader Technical Manual

Factory Highly Detailed Repair Manuals, With Complete Instructions And Illustrations, Wiring Schematics And Diagrams To Completely Service And Repair Your Vehicle.

All Manuals Are Windows Vista32 And 64, Xp, Me, 98, Nt, 2000 Compatible And Work With Mac!

* Maintenance

* Engine

* Control System

* Mechanical

* Fuel Service Specifications

* Emission Control

* Intake Exhaust Cooling

* Lube

* Ignition Starting Charging

* Auto Transmission Clutch

* Manual Transmission

* Transfer Propeller Shaft

* Drive Shaft

* Differential

* Axle Suspension

* Tire & Wheel

* Brake Control

* Brake

* Parking Brake

* Steering Column

* Power Steering

* Air Condition

* Suppl Restraint System

* Seat Belt

* Engine Immobilizer

* Cruise Control

* Wiper & Washer

* Door Lock

* Meter Audio/Visual