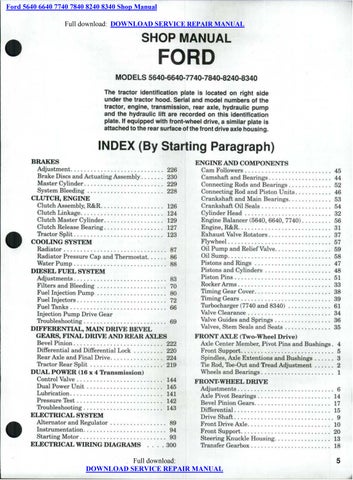

FRONT AXLE SYSTEM (TWO-WHEEL DRIVE)

FRONT AXLE ASSEMBLY AND reversing diaaasezably procedure. Grease retaioer(8) STEERING MNKAGE

Two•WheeI Drive Models

1. W££EELB AND BEARINGS. lb remove front wbeél hub and bearings, firat raiee and support the front axle eztenaion, then unbolt and remove the tire and wheel aBaembly. Remove the cap (1 Fig. 1), cotter pin (3), Blotted nut (Z), waaher (4) and outér bearing cone (5). 81ide the hub a8aembly (6) from spindle axle ahaft (10). Remove greaBe retainer :(8) and inner bearing cone (7). Hub ia slotted to facilitate removal of bearing cups.

Pack wheel bearings libeéally with Förd.MlC137A, M1C7fi-B or equivalent greaae. Reaaaomble by

and inner bearing cone (7) should be pöBitioned on spindle, thea install wheel hub (G). Tighten slotted nut (2) to a torque of 27-40 N•m 120-30 ft.-lbs.), than rotate hub aevetal turns. Tighten nut(2) to 61-74 N•m (45-50 IN-lbs.), thén back nut off less than one dat and lflBI&11 cotter pin (3). Be Bure to install cap (1) se-

B.TIE ROD,TÖE-OUT ACD TREAD ADJU8T-

MRNT. All modela are equipped with one tie rod extending between left and right ateering arms. The hydroatatic atasring cilinder (lWFig. 2) is attached between the front axle and the center of the tie rod. Left end (18) of tie rod and both enda of steering cylinder are automotive type aDd Bhould be renewed if wear iB £ixces8ive. The procedure for removing and instelling the enda is aelf evident. Automotive end of right tie rod ia renewable only as an assembly with the right tie rod.

All two-wheel drive models are equipped with adjustable tread axle. Tie rod is equipped with locating acrews (16) for quick adjuatment of tie rod length when changing tread width. 'Ib adjuat tread width, raise sid support front axle. Remove tie rod loeating BCP8Wfl(IS)andclBoljlBCTBWB(9)fromaxleexteneions (5 and 12), then alide axle extenaions in or out of axle center member(8). Tighten the track adjusting clamp screws (9) which attaeh axle extenaions inaide the axle center aection to 400 N•m (300 f£.-lbs.) torque. Tighten tie rod locating serewa (16) to 150 N•m (110 ft.-lbs.) torque and lotknuta to 75 N•zn t65 f£.-lba.) torque. After reeetting axle tread width, check ’and a‹}juet front wheel toe-out aB dBacribed below, Recommended front wheel toe-ottt fa 0-15 mm (OK in.) for two-whee1 drive modem. 2b check toa-ont, tuPR Bteering wheel Bo that front whsela are tp straight ahead position. Measure distance (A Fig. 3) between wheel rims on centerline of axle, parallel to groun6. Rotate wheels R turn, then measure be• tween wheels at front of wheele in position (B). Dimenaion (A) should be 0-13 mm (0-R in.) smaller than dimension (B). Tb adjuut.toe-out, remove locating bolt I lWFig. 2) from left end of tie rod tube (16). LmBen clamp bolt in left tie rod end (18). Turn threaded Section of tie rod (17) in or out to obtain desired toe-out. Tighten tie rod locating .bolt to 150 N•m (110 If,-lbs) torque.and clamp bolt to!7fi N•m (55 IN-lbs.) torque.

8. 8PINDLEB, AKLE EKT£iNHIO2'fB BU8HINGA. 'l'ö remove Bpindle (l Fig. 2), remove the wheel and hub, then diBCOnflect tie md end from:steering arm f7 or 13). Check threaded end

of spindle and steering arm for alignment marka (M Fig. 4) before removing steering arm. Note that it may be necessary to use a thread file to clean the threads of spindle since they are deformed during asBembly at the factory in order to lock the spindle nut in place. Remove nut retaining steering arm (7 or 18 Fig. 2), then pull steering arm fPoin Bplines of spindle. Lower spindle (1) from axie extension (5 or 12). Remove thrust bearing(3) and chambered waaher (2) from spindle. Clean and in8pect parta for wear or other damage and renew aa neceBaary.

When reassembling, lubricate bushings (4) and pack thrust bearing (31 with Ford MIC 137-A,

FIg. 2 Exploded vle ' al adjustahle axle typlcal of ta'o-vvfieel drlve może/s.

1. Spindlr

Z. h'asher

3. Thrust bearing

4. Bushings

5. Left axłe excenuion

6. Felt sealing waaher

7. Left steering arm

8. Axle center member

9. Tratk clamp holt

10. Bu8hingB

11. Washers

12. Axle right extension

l3. Righ t steering arm

J

l4. Righ t tie rod

5. Locking screws

j6. że rad tube

l7. Left tie rod

18. że rod end

19. Power sŁeering eytinder

MIC75-B or equivalent grease. Install waaher (2) with chamfered edge down toward bO8B Of spindle, then install thrust bearing (3) on spindle so that numbered aide of bearing ia facing upward. Insert spindle through axle extension. Install new felt waaher(6), then locate steering arm on top of gpindle. Align marks on threaded end of spindle and steering arm as shown (M Fig. 4). Tighten steering arm retaining nut to 488-597 N•m (360-440 ft.-lbB.)

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

torque, then atake threads to prevent loosening. Referto pamgraph 2 for tread width and toe-out adjustment. Balance of reaaaembly is the reverse of diaaaseiobly. Tighten the. track adjusting clamp screws tMPig. Z) which attach axle extenaiona inside the axle center Section .to 400 N•ai (300 It.-Iba.) torque. Tighten tie rod locating bolta,(16) to 1fi0 N•m (110 ft.-lba.) torque and locknuto to 75 N•m (55 ft.-lbB.) torque. Tighten ieft tie rod end clamp bolt to 100 N•m (76 ft.-lbs.) torque after toe-out is correctly set,

4.AgEE CENTER MEMBER, PIVOTPINAND

BUflHING8. Tb remove front axle aaBembly, raiae front of tractor in such a way that it will not interfere with the removal ofthe axle. A hoist may be attached to front support or special standa can be attached to sideB. Removal Oftheaxlecenter member ( Fig..3)

ParagraphsG7

Check axle pivot buahinga (10) and renew if necessary. Reverse removal procedure when asBembling. Lubricate pivot bushings with Ford M IC137-A, M1C75-B or equivalent greaBe. Tighten screwa retaining the nxle pivot pin to 70-90 N•m (52-66 ft,-lbB.) torque, then bend locking tabs around screws to prevent loosening.

fi. FROST SUPPORT: 3b remove the front suppow,the1uüeitatbezewoved,tdeidba wu&tbe removed from the support and the front support muat be unbolted from the front of engine. The front axle, the front support and the remainder of the tractor must each be supported separately while removing, while separated and while assembling. Be sure that sufficient equipment is available before beginning.

may be easier if the axle extension and B@indlâ un, Refer to paragraph 67 and remove the main fuel sembly is firat removed from each side;, howiiñeé, the tank, then refer to paragraph 87 and remove the complete asaembly can be removed as a unit.1Íomove radiador. SupJ›ort front of tractor in such a way that front wheela and weights, tben support the axle with it will not interfere with removal of either the front a suitable jack or special safety stand to ¡iréveñt support or the front axle. Remove axle as outlined in tipping while permitting the axle to be lowered acid paragraph 4. Attach a hoiat or other supporting demoved safely. Disconnect hoaes from the steering: vice to the front support, then unbolt and separate cylinder and cover openings to prevent the entry. of the front support from the front of the engine. Be dirt. Unbolt and remove the front axle pint pin. careful not to lose or dafnagG B 2TtB loC8ted between Ix›wer axle until axle is free from front suppprt, .tiien front support and engine. Keep ahims separate and carefully roll axle away from under tractor. label for installation in aame location.

FRONT•WHEEL DRIVE

Mechanical front-wheel drive ia available .whiéfi uaes a front drive axle manufactured by Gñrraro. Modela 5640, 6640, '?740 and 7840 are equipped with Bt&ndard type 709 axle; Models 8240 an‹i 8340 âre equipped with heavy duty type 709 axle. g•«e:aneences in the front-wheel drive ayatema will he noted in the following service inatructionB.

The transfer gearbox engagement ia cofit%1lad Jim an electric Bolenoid/hydraiilic valve which directs oil pT8Bsure to move a dog clutch and engage :thé front wheel drive. The tranafer gearbox is attache.d:tp:the bottom of the rear axle center housing of:.all tnpdelu: A drive ahaft conneeta the transfer gearbon ito trent

ADJUSTMENTS

All Four-Wheel Drive Models

& FRONT WHEEL TREAD WIDJD• Frontwheel drive axle ia a fixed aaBembly. However; track width can be aé{juated by changing the wheel rim relative to the center disc, the rim and/or diac rstqtive to axle hub or by interehanging the front whe8lB. ThB drawings ahown in Fig. 5 illustrate different wheel

rim and diac poaitiona relative to the hub and the P8Btllting trask width settinga.

NOTE: When lnterchanglrsg front whaels from alde to side, make aure that “V” of tire. tread le polntlng Inthe dlrection of forward travel.

Tighten diac to hub mounting nuts to,476 N•m í8S0 it.-lba.) torque and disc to rim mounting nuta to 24O N•ai (177 ft.-lbs.) torque. Recheck the diac and ripi mounting nut torque afYer driving the tractor about 200 meterB (200 yardsl, after one hóur of operation, alter eight houra of operatioñ and at 60 hotir intervalo.

AAer reBetting trach width, check toe-in setting as outliüed in paragraph 7 and stesring stap setting as outlined in paragraph 8.

7. TIE RODC AND TOE-IN. Tie rod enda are not adjustable for wear and faulty unita must be renewed. To check toe-in, fir8t turn, steering wheel ao that front wheels are in straight .ahead position. Measure distance between fronfi wheol«,at:i’ront and rear of wheels from rim flange to rim flange at hub height. Distance neasursd at frogt of wheela should be 06 mos f0-V4 ira) \esB (toed to) t?ian ’distaace measured at rear of wheela. 'lb adjuat, looaen clamp

Disc/Rim Position Trsrh Setiinp 24in. 28in. wheets wheels

bolt (2 Fig. 6), then turn tie rod ( 1) in or out of tie rod end (3) as required. Adjust both sides evenly. When adjustment is correct, tighten clamp bolt IZ1 to 56 N•m (41 ff.-lbs.i torque.

8. STEERIGSTOPSANDARTíCULATION.

The front axle is provided with adjustable steering and articulation stops to prevent the front tires from contacting the tractor. Adjusted setting should not change during operation, but different tire sizes or tread and changes in track width may make adjustment necessary. The steering stop screwa ( MFig. 7) should be adjusted to provide a minimum clearance of 20 mm (°24 in.) between tire and frame. Tighten

Flg. front-wheeI drlva axle traah wldth is ad)usted by changlng posltlon at vvheel rlm and dice.

lockout to 150 N•m (110 ft.-Ibn:) torque when a‹}jusb ment ia correct.

Articulation atopa (1 Fig. 8J should prevent the tires from contacting the tractor when the front axle ia tipped against atopa. When atop ia attached to the rear two acrewa (2) aa ahown, the axle ahould be limited to approximately 8° of movement. Whefi the stop is attached to the center and front hole 3), articulation is limited to about 12° from horizontal. Stops (1) ahould be positioned at same loeâtioñ fin both aidea.

DRIVE SHAFT

All Four-Wheel Drive Models

8. REMOVR AND a£'•IHSTAI•£• Two different drive ahafte have been used as ahown in Fig. 8, depending upon transmission used.

'lb remove drive ahaft (5), iirst unbolt and remove the ahield assembly (1). 2b remove drive shaft.ahown in the lower view, remove acrew (4) and sli‹le .touplinga (2 and 3) until drive shaR Clamps (7) muat be removed before fzont' uñiâe?oa1 joint can be separated from yoke (6) of modeia with 8 x 2 and 16 x 4 transmissions.

When inat»lling driva ahaft on modela with l2 x 12 and 16 x 16 speed tr&ri8miaaionBi greaae coupling splinea, alide couplings onto drive shaft, i:›oaition drive ahaft, then alide couplings into poaitioñ mid inBtall screws (4).

On models with 8 x S and 16 x 4 speed tranamiaarena, grease rear coupling splines before installing drive shaft. Tighten clamp bolta of front universal joint to 67 N•m (42 ft.-lbs.) terque.

FRONT DRIVE AXLE

All Four-Wheel Drive uodels

10.R&RA88RMBLY. First remove the drive ahaft azid Bhield aB Outlined in paragraph ii. If differential unit ie to be serviced, it ia rooommended that the bével pinion shaft nut be loosened at tbia time. Pry out pinion ahaft oil aeal, then looaen not using special pinion nut wrench I’T31fi8 or equivalent. Remove frnntweighta. Raiaefrontoitr8.ctoE iH BTtCX away it will not interfere with the removal .of the axle. A hoist may be attached to front support or special standa can be attached to aidea. Remove front wheeiB, then support the axle with a suitable jack or special safety stand to prevent tipping while permitting the axle to be lowered and moved safely. Disconnect hoB8B from the steering cylinder and cover openings to prevent the entry of dirt. Unbolt and ramove iix›nt and rear pivot brackets (1 and 17 Fig..10), lower .axla until flee, then carefully mll axld away.

IBM front drive axle by reversing the removal procedure. Tighten screws attaching front and' rear pivot brackets t1 and 17) to 317-388 N•m (284-286

ff.-1ba.) torque. Tighten ateering hoae connectiono to 34 N•ni (Z5 ft.-Ibe.1 torque ifremoved or diaconneeted.

WHEEL HUB AND PLANETARY

Models 5640-6640-7740

11.R&R AND OVERHAUL. Either front wheel hub and planetary can be Berviced without removing the steering knuckle housing from ax)e. Support front aale housing and remove front wheel, Remove drain plug (l Fig. 11) from planet carrier and drain oil from hub aBaembly. Remove the two Allen acrewa from planet carrier(2-Fig. 12) and lift planet carrier from knuckle housing 130).

Remove anap ringe (7) and retainer plate (8). Mark shaRs (4) and planet gears (6), then keep bearings (5) and thrust washerB (3) separate TO that they can be reinatalled aa a aet in the aame location.

Before removing the ring gear (14), mark relative position of ring gear (14) and steering knuckle housing (30) to facilitate installation in Bame location. Remove snap ring 110), Bun gear 111), apacer (12) and washer (13). Unscrew retaining screwa (16), then use fouroftheremovedscrewBaajaekscreWB inthreaded holes of the ring gear carrier (18) tu push carrier (18) and ring gear (14) from hub (21).

fly. f0=-riew of fronf and rear p/rot brecketa(I a f ') InataIIed• Fourscia ' e ozsusedroo/iscfteachdzac8etto fiant

Bump hub (21) from steering knuckle (30). Remove cupa for bearings (20 and Z2) and aeal (231 from hub. If necessary, remove inner bearing cone front knuckle housing.

Clean and inspect all parta for exce8aive wear or other damage and renew as neceaaary.

When reassembling, drive eupa for bearings 120 and 22) and oil aeal t23) into hub (21). If removed, install cone for inner bearing(22) on knuckle housing (30). Install hub 121) and cone for outer bearing (20) ontn knuckle housing. Assemble ring gear (14) to carrier (18) and secure with retaining ring 119). Install ring gear (14) and gear carrier (181 and tighten IDOtllltJRg C BßF8WB (16) to 220 N•m ( l6ß tt.-1ba.) torque. Install waBher (13), apacer (12), aun gear (11) and Bnap ring (101. Stick thruat waaher (9) in place on carrier (2) with “Loctite 638” or equivalent and install new “O” ring (15) in groove of hub (2). Install thruBt washers (3), bearings (6), planet geara (6) and retainer plate f8l, then Becure with snap ringß (7). Install planetary carrier assembly. Install the two Allen screwa. Fill hub and planetary to the level of opening for drain/fill plug (l Fig. 11) in carrier with “OIL LEVEL” mark (L) on Carrier horizontal, Fill with Ford ESN-M2CI34-D or equivalent. Install front wheel and tighten diac to hub nuts to 270 N•m (200 ft.-1ba.) torque. Diac to wheel rim nuts should be tightened to 240 N•m (177 ft.-lba.) torque.

Models 7840-8240-8340

lS. R&R AND OYERf2AUL• Either front wheel hub and planetary csv be serviced without removing the Bteering knuckle housing (30 Fig. 13). Support front aale housing and remove front wheel. Remove drain plug t1 Fig. 111 from planet carrier and drairi pit from hub assembly. Remove the two Allen acrewa from planet carrier(2 Fig. 13) and lift planet carrier from knuckle housing (301.

Remove planet gear retaining screwa and waahera ( Fig. 13). Mark planet gears 16) and ahaAa (4), then remove planet gears, bearings f8) and thrust washers (3). Keep bearingB (6) and thrust washers (3) separate with their respective planet gearu ao that they can be reinatalled as a aet in the same location.

1. Magnetic drain plug

Z. Planet cartier

3. Thruet waaher

4. Planet shaft

5. Needle zo]Ieze (30/geam

B. Planet gear

7. finsp ring

8. Planet cartier plate

9, Thrust pad

t2. 9pacer

lfi. °O” ring

16. Swews fM10 x801

17. Buahing

lC. Ring gear earrier

Before removing the ring gear (14), mark relative position of ring gear (14) and steering knuckle housing (30) to facilitate installation in same location. Remove snap ring (10) from drive shaR aun gear. Unscrew retaining screws (16), then use four of the removed ecrewa as jackacrews in threaded holea of the ring gear carrier (18) to push carrier (18) and ring gear (14) from hub (21).

Bump hub (21) from steering knuckle (30). Remove ctlpB for bearingB t20 and 22) and Beal (23) from hub.

2l. Huh

22. Bearing

2fi. Oilseal

0d. Grease fitting

2fi. Lower retainer

26. fihims l0.10,0.19, 0.05 mm1

27. 8eal

29. Belleville waaher

31. Upper retainer

32. Bnh;»g 83.AM

36. Eeal

If necesBary, remove inner bearing cone from knuckle housing.

Clean and inapect all parts for exceaaive wear or other damage and renew as neeeaaary.

When reaaaembling. drive cups (or bearings (20 and 22) and oil aeal (231 into hub (21). If removed, install cone for inner bearing (221 on kniirir!e houBing (30). Install hub (21) and cone for outer bearing (20) onto knuckle housing. Assemble ring gear (14) to carrier (181 and secure with retaining ring (19). Install ring gear tl4) and gear carrier t18l and tighten

28.B«ving

mounting cap Bcrews (lti) to 220 N•m (162 ff.-1ba.) torque. Install wuther (12) and snap ring (10). Stick thrust washer (9) in place on carrier (3) with Pte 638” or equivalent and install new “O” ring (16) in groove ofhub(2). Install thrust waahera (3), bearings (5), plamet gears (fi) and thruat waahera (8), then BOCufp with retaining acrewa. Install planetary carrier.a8aembly and secure with the two Allen streWB. Fill hub and planetary to the level of opening for drain/fill plug (1 Fig. 11) in carrier with “OIL LEVEL” mark (L) on carrier horizontal. Fill with Ford ESN-M2CI34-D or equivalent. Install front wheel and tighten disc to hub nuts to 270 N.m (200 ft.-Ibn.) torque. Di8e to wheel rim nuts should be tigbteoed to 240 N•za (17’7 ft.-lbs.) torque.

STEERING KNUCKLE HOUSING

All Four-Wheel Drive Models

IC. R&R AND .OVRR£IAUL. 3b remove either steering knuckle housing (3WFig. 12 or Pig. 13), firat remove planetary and wheel hub an outlined in

paragraph 11 or 12. Disconnect tie rod from steering knuckle arm, Unbolt and remove Bteering knuckle retainers (2S and 31). Note that early axles use ahims t26) to adiuet vertical play of steering knuckle (30) and thickness of ahima (26) located under each retainer should be recorded when dissasembling to aid in reasaembly. Later modela are equipped with Belleville washers (29) that automatically adjuat vertical play. The upper Belleville waaher ia the thicker of the two washers.

Carefully remove steering knuckle housing (30) from all modela. Axle shaft and double W" joint aaoembly (34) may be withdrawn with knuckle housing. Lower bearing cone (28) may fall from lower retainer (26). Remove upper bearing cone (28), cap (31) and Beal (27). Bearing eupa can be removed if necesBary.

If desired, axle shaft and “U"joint aaaembly can be withdrawn for inBpeetion or repair. lf renewal ia required, oil seal (35) and bushing (36) can be removed frown knuckle housing (30). Oil seal f33) and bushing (32J can be removed frnm ax.ie hounizig. Bua.Write f32 and 36)should be pressed into position with external

groove txiward top andinternal arrow-ahapeddrooveu pointing toward inaide of oil-filled höuaing (away fmai seal). Be careful not to damage sealB (83 and36) whën inatalling axle and knuckle houaing.

Reassemble by reveraing the disasaembly tiroiædure. On early axle originally equipped with aliimn (26), aufficient thicknesa of ahims muat be installeà to provide kíng pin with 0-0.1 mm (0-0-0lfi in.) tret play. Tó determine ohim pack thickneBa required !to. aet free play within specified limita, first pOBitiOn knuckle housing on uxle housing and install,upper retainer (311 without shima. Install lower retains (26) with enough shims (26) to provide some end'play and tighten upper and lower retainer mounting acrews to 190 N.m 1140 ft.-lba.) torque. Position a dial indicator aa shown in Fig. 14 and check vertical play

of king pin bearings. Por exémple, íf meaaured end p1ay is 0.15 mm (0.006 ic.). reïmo*è 0.10 ouzi (0.004 m.TsWmbobmizendplayithinthedeeüedhxüts. Divide ehims (2€›-Fig. 13) equally at top and bottom, to center the asaembly. Shima are available in 0.10, 0.19 and 0.35 rnra (0.0ò39, ò.0075 and 0.0138 In.) tbickzieasea.

Vertical play of steering knuckles on later models is controlled by Belleville washers f29) located between axle center housing and cup of bearings (28J and no adjustment is necessary. The thicker of the two Belleville washers is installed on top knuckle

Refer to paragraph IL or paragraph 12 when reauèembling hub and planetary.

AXLE PIVOT BEARINGS

AII Four-Wheel Drlva Models

14. REMOVE AND REINSTALL. R remove the axle pivot bearings, refer to paragraph 9 and remove the drive start, then refer to paragraph 10 and lower the front axle aaaembly. The front pivot bracket (l Fig. 15) and rear pivot bracket (17) can be withdrawn from the axle.

Clean all parts, complete disassembly, if required, and inspect all parta fur wear or damage. Use new“O" ringe and aeala when aBsembling. Tighten acrews attaching:front and rear pivot brackets (1 and l7) to. 317-388 N•m (234-286 ft.-lba.) torque, Tighten steering hoae connections to fI4 N•in (25 IN.-lba.) .t6rque.

Flg. Jfi••••PaeIIaIIy axpladad viar of

1. Front pivot bracket 7. "O* zïag

2. Bushing 8. Bushing

8. Sleeve 9. Oil.seal

4. Thrust washer 10. Locating dowel

5. Thruet wa•ber 17. Bear pivot G. i51eeve bracket

DIFFERENTIAL

All Four-Wheat Drive I\Models

16. REMOVE AND REINS'PALL. lb remove the differential assembly, refer to paragraph 9 and remove the drive shaft. Refer to paragraph 10 and remove the fmnt axle assembly. Refer to paragraph 13 and remove steering knuclde (3 I‹‘ig. 12 or Fig. 13) azid ante shsft assembly (34) froza both sides. Sooza mechanics prefer to remove the steering kauc]cles and axle ahafte before removing the axle fron the tractor, to reduce the weight of the unit. The differential housing contains the hydrostatic steering cylinder whichmustberemoved as outlined in paragraph 27. Unbolt and remove the differential carrier housing(l Fig. 17) from the axle center housing.

When inBtalling, apply Loctite 610 or equivalent aealer to mating Burface of differential carrier housing and axle housing. Tighten the ten retaining acPeWB 169 N•m (125 ft.-1ba.)torque. Remainder of aaaembly and inatallation ia reverse of disaaaembly procedure.

IB. OVERHAUL. Before disasBembling, mark both bearing eapa and housing asahown at (M Fig. 16) to facilitate alignment when reassembling. Straighten tabs of both lock plates 113 Fig. 17), then remove both cap acrews (12), washers and lock platea. Leo8en, but do not remove, the four screwa attaching capa (C=-Fig. 16), then unscrew adjusting rings (14). Remove both bearing capa and lift differential, bearing cupa and adjusting rin8B from housing.

Mark halvea of differential caae (16) before disasBembling tofacilitate alignment when reassembling.

Remove screws (17) and remove ring gear (11). Case halves can be separated after removing acrews (17). Assembly of original parta iB eaBier if side gears (22) aad clutch parts (23, 24 and 2ii) are kept together for each aide and not mixed.

Clean and inspect all parta for wear or other damage. Lubricate all 8rte while aBaeIRbling. Alternate the five eatemal splined plates (fl4) and four internal splined diaca (25). The internally Bplined thruat disc (23) ia thicker (2.8 mm) than other diaca and Bhould be assembled next to side gear (22). InBtall thrust washers (18), piniona (19) and ahaft (20). Drive pin (21) iR from ring gear Bide of differential caae on two pinion differential. When aaaembling all modelB, align any previously affixed marks. Install ring gear (11),applying Loctite 270 or equivalent to acrewa (17) and tightening to 78 N•m (68 ft.-lbs.) torque. Preaa bearing conea (15) onto ease (16) until seated.

When installing the differential and King gear aBaembly, it iB necessary toCheck and adjust both backlaBh and carrier bearing preload aB follows: FifBt measure rotating dragofbevel pinion ahaft(10) using a spring scale with a string wrapped around the pinion BhaR aa ahown in Pig. 18. Do not measure starting torque (force necessary to atart pinion shaft turning), only measure the force necessary to keep pinion turning. Record the rotating drag measurement for later uae, then install differential aaaembly in carrier housing and tighten bearing cap ( Fig. 16) bolt8 tight enough to hold capa in place but allow adjuster rings (14) to be rotated. Turn adjuster ringn to remove all free play between ring gear and bevel proton gear. Preload of differential carrier bearings and gear backlash are both adjusted by turning ad)ttB Q PiRga (14L and l4R). Backlash between bevel ring gP&I Bhould 0.18-0.25 mm (0.0070.010 in.) ana can be measured at face of ring gear with a dialindicator( Fig.19). TurnadjuBterring8 (14) by amounts to move ring gear (111 away f/ompinion ear until desired backlash ia obtained. Atijuster ringa (14L and 14 Fig. 17) should be tight and differential should rotate freely in carrier bearings (151 when checking backlash. Carrier bearing preload ia correct when 3.2-4.7 Kg. (7-10 lba.) more rotational force is necessary to turn the pinion shaft than waa neceaaary to turn only the pinion ahaft when previously measured. Turn adjuster ring (14L) opposite ring gear to increase or decrease bearing preload. It is important to check both rotational drag (a« shown in F'ig. l8) and bevel pinion to ring gear backlash (Fig. 19) after changing the position of either adjusting ring (14L or l Fig. 17).

Tighten bearing cap ( Fig. 16) bolta to 266 N.m (196 ft.-lba.) torque. Install adjuster ring lock pl8teB (lWFig. 17 or Fig. 18) and tighten locking plate retaining screwa to 12 N•m (9ft.-lba.) torque.

I. HO\Psi ng 2.Nt

fl. Lock washer

4. Bearing cup & cone {Same na 8J

5. Washer (Name as 7;

6. Spacer

7. Washer I Same as 5i

8. Bearing cup& tone fsame an 4i

9. Shim12.5-3.4 mmi

10. Bovel pinion

11. Ringgear lii. Screws IN. Locking clipe 14L. Adjusting ring

BEVEL PINiON GEARS

All Four-Wheel Drive Models

17. REMOVE AND PINSTALL. 'Tb remove the bevel pinion gears (10 and 11 Fig. 17}, refer to paragraph 9 and remove the drive ahaft. Pry out pinion shaft oil seal ( Fig. 15J, then looaen pinion shaft nut (2 Fig. 17) using pinion nut wrench FT3I68 or equivalent. Refer to paragraph 15 and remove the differential aBsembly. Refer to paragraph 16 and remove ring gear from differential.

'lb remove the bevel pinion (1 Fig. 171, remove nut (2) and washer (3), then push pinion out toward inside. Cone of bearing (4) drill slide from shaft as p'nirin is removed. The bevel pinion must be renewed as a set. and ring gear

Thickness of shims t9i should be selected to adjust mesh position of bevel pinion ( 10 I if gear set t10 and 11),pinion bearings(4 and8)and/ordifferential houB-

14it. Adjusting ring 1ft. Hearing cup &cone lfi. Differential cnse I I ur 2 piecea/ 17. Screws Id. Thruut washers l9. Pinion geats 20. Rnionshaft

i? 1. no11 pin

22. Side gears

23. Spacer I I each side)

34. External spl ine plates i i each nide i

25. Iiitnrnal uplinc disrs i 4 ench side i

26. flclleville wusher

'Ig. 20-•••fizose section of dltterentlel hauling efiow'trtg meaauee enta roqo/led foaccci/ofeJy aefp/nfon pos/f/on. Reler to text lor measuring dlstenae (C) fiom bearing inner lace to aenter ofrerrh leering Oars.

G. Depth gauge

R. Bearing retainer

S. Bar gauge

1. Differential housing

4. Pinion bearings

8. Pinion bearing

ing (1) ia renewed or if previous meBh position is questioned. Install cups for bearings (4 and 8) in housing (1), then position bearing coneB in cups as ahown in Fig. 20. Use a retainer as shown at (R) to hold conea tight in cups while measuring. Install both carrier bearing capa and tighten the retaining nuts securely. Measure the diameter ofthe bearing bores (A). Both bearing borea ahould be the same diameter. Position bar gauge (S), part of tool No. 3135, in bearing bores. Note that bar gauge can be fabricated using a metal or wooden dowel with a hole drilled through it ao that depth gauge (G) can be inserted

through the gauge as ahown in Fig. 20. Meaaure the distance from the bar gauge to the inner ilanae of bearing (8) aa ahown at (B). Determine distance (C) from the center of the bearing bore to the bearing flange using formule B - D + (A < 2) = C.

The following ia an example of the Bhim thieknesa calculation: Divide bearing bore (A) diameter by 2, aubtract diameter of gauge bar (D) from meaaurement (B), then add the reaultB of theae two calciiiations to obtain dimenaion (C). If measurement (A) ie 90.00 mm, measurement (B) ia 90.35 mm and measurement (D) ia 25 mm; 90.35 mm - 25 mm + 4b mm = 110.35 mm (C).

Tb determine the thicknesa of ahims to be installed at (9 Fig. 17), subtract the value (1 Fig. 21) atamped on pinion face frDm the calculated diatance ( Fig. 20). The reBtllt IB the correct thickneas of shim (WFig. 17). Example: 110.35 mm (Cl - 107.25 mm (value on pinion gear) = 3.10 mm(ahim thiekneas required).

If2Btall aelected ahim (WFig. 171 On piniOfl Bhaft (10) with chamfer toward pinion gear. Remove carrier bearing caps and bearing ooneB (4 and 8) from carrier houaing (1). Install inner bearing cone f8) on pinion (10) against aelected Bhim.

Inatall washer (7), new (not yet collapBed) apacer f6) and waaher (5) on pinion shaft (10) and insert into housing through the installed bearing cups. InstaI1 eone for bearing (4), lockwaBher (3) and nut (2). Tighten nut (2) until all play in bearinga is just taken up, then oieaaure rotating drug with a apring seale and atring wrapped around the pinion shaft 8S Bhown in Fig. 18. Do not meaaure storting torque (force necessary to start pinion shaft turning), only meauure force necessary to keep pinion tuming. Correct amount of rotational force measiired by the Bpring

Fig. 2 V'lew ol front-w'heeI drIva tzenefer flees Installed.

acale should be within the range of 10.1-16.2 Kg. t22-33 lba.). Tighten nut (2 Pig. l7) to tighten bearings and increase rotational force. Note that bearing adjuBtment is accomplished by crushing apacer (6),

and nut (21 Bhould not be loosened unless a new spacer is installed.

TRANSFER GEARBOX

All Feur-Wheel D›1ve Models

18. On SL and SLE model tractors, drive from the 12 x 12 OP 16 x 16 tranBmiusion to power front wheel drive axle iB incorporated in the transmio»ion. Refer to appropriate transmission paragraphs for service.

Drive from transmission for front drive axle ie from a transfer gearbox attached to bottom oftranami8aion housing nfmodels with 8 x 2and 16»4 transmissions {S model tractors). Refer to the following paragraphs for service to the trana£er gearbox.

Models Wlth 8 x 2 And 16 x 4

Transmissions

1&. R&RAND OVERHAUL.’lb remove the transfer gearbox, remove drain plug l3MFig. 22) and allow or) to drain. Remove drive shaft as described in paragraph 9. Remove cover, disconnect wire (1) frozn the solenoid and disconnect wiring tube froth Bide of hottBing. Detach hydraulic linea(6),positionfloorjack

Ffg. 2 p/oded v/ew of'door-wA drtve tzBnsfar gearbox used on models w/tJ6x2artdflux 4frenem/ss/one.

2. Control aolenoid

4. Covcr

8. Exter-nal oil line

9. Retainer 10. i3him

l1. Bearing 12 Idler gear

14. Spacer 15. Bearing 16. 8him

17. Shaft

IB. Screw l9. Oil seal

20. End plate

22. Shim 23.b wd rolet beanug

24. Saap ring

26. Springs l4 usedI z7. Dep cltrtch coupler

28. "O" ring

28. ”O‘rin8

31. Gear and clutch

82. Pilot vaive aaaembly

33. Ter' at waaher

34. Tapered roller bem•tng

35. "O" riztg

87. £;nd plate fl8. Drain plug

FORD

uoüer the traoBfer gearbox, zemove retatnlag ecrews and lower transfer gear caae from the tractor.

Vb diaaaB8mble the unit, remove the external oil line (WFig. 23), remove the nut from the Bölenoid and remove solenoid ooit (Zl. AAer the aolenoid ooii is removed, the core and valve aaBembly can be removed from the houding. Remove socket head aerew (18). It may bo neee«aary to heet net and (81 of»crew to eoftotz tkzwad 1ockïog eozapouzzzt. 5tarÏrfront aide of idler gear (12) to aaBist reinstallation with aame side toward front, then bump ahaft (17) out. ARer shaft is removed, idler gear and shall aaaembly (9-17) can be liRed out. Unbolt and remove output ahaA end plate (20), being eareM to oollact and identify shima (22a to assist assembly Unbolt and remove end plate (37) and oil transfer tube (36). Gently bump the output ahait (30) toward front, then toward rear to remove outer races of tapered rnller bearings (23 and .341. Uae aocketa ( Fig. 24) of a suitable size and levers (L) to depreaa apring keeper (25) far enough to remove snap ring (S4). Remove the four springs (2€›-Pig. 23) after snap ring ia removed from groove. Support gear (31) with spatera located between front of gear and front of houaing (39), then preek shaft (30) toward frost out nl bearing (34). Remove bearing, tbruat waoher (33) and gear (31). With ahaft eziending from front, uae a suitable puller to remove bearing (23). Slide snap ring (24) forward on ahaft ttntil it IB P8moved. Move ahaft (fl0) out toward rear, while removing spring keeper (25) and clutch coupler (27). Be careful not to loae or damage pilot valve (32).

Clean and inapect all pt and renew any showing excesaive wear orother damage. Pilot valve aaBembIy (32) can beremoved by blowing into the eroes passage

with eompresaed air. Springt (26) should be 48 mm (1.889 in.) long and must not be distorted.

When reaaaembling, renew all ‘O" ringa, aeal8 and gaaketB. Be Bure that pilot valve aaaembly (32) ia installed in end of output shaft (30) so that oil will pasa through valve from transfer tube in end cover (37) into the shaft toward dag elutch (27), but will not flow the other direttion. Reasaemble by reveraing diaaseembly prooedure. Uae oil on Beala a22d make sure that “O” ringa are not damaged while asBembling. AaBemble using shima (22) which were originally used, but without oil seal (19) and *O" ring(21). Inatall and tighten cap screws retaining end plates (20 and 37a tn 51 N•pi (38 ft.-lbs.) torque. Add or remove sufficient shims (22) to provide 0.1 mm(0.004 in.) preload. Check for correct bearing adjuatment by ll81IlQ £t Btfillg gray:i d around ahaft and apring Bcale to meaaure rolling torque ofahaft as shown in Fig. 25. When properly aaaembled uaing the correct tbickn£iB8 OË Bhims (22 Fig. 23), meaaured rolling torque without seal (191 will be 1.9-4.5 Kg. (4.2-9.9 lbB.). When correct shimB have been selected, remove plate (20), install and lubricate new aeal (19) and “O” ring (21), then reassemble. Tighten retaining screws to 5l N.m (38 ft.-lbs.) torque.

Install transfer tube and Bolenoid (2), Special tool FT 3169 (available froze Ford) pr equivalent ia neceaBJ to check and adjuBt idler gear bearings. Thickness of ahimB (13) adjuat bearings tll and 15) and thickness of ahima (10 and 16) adjusts for fit between luga of housing (39). Make aure that outer ranea of bearings (11 and IS) are pressed tightly againfit shoulders ofgear(12). Assemble bearings (11 and 15), apaeer (14) and approximately 0.3 mhm (0.012 in.) thickness ofahima(13) on special tool. Make 8ure that screw of tool ie tightened to 68 N•m (50 ft.-lbs.) clamping bearing inner raceB, spacer and ahims

using the correct ahims and shaft (17). Tighten serew (18) to 80 N.m (59 If.-lbs.) tarque.

Reinstall transfer gearbox by reversing the removal procedure. Uae only approved gaaket between transfer gearbox and rear axle center housing, because ita thickness aete the meBh position ofidler gear (12) an6 mating gear. Tighten transfer gearbox retaining aerews to 66 N•ai (49 ft.-lba.) torque. Apply Loctite 542 or equivalent thread locking compound to threads ofdrive ahaft retaining aerewo and tighten to 57 N•m (49 ft,-lbs.) torque. Fill rear axle center housing to level of dipstick with Pord ESN-M2C134-D or equivalent.

FROftT SUPPORT

All Four-Wheel Drive Models

tightly together; then clamp the tool in a .viae::and check rolling torque as ahown in Fig. 26., GoGreet rolling resistance is 0.4b-l Kg (1.0-2.2 lbs.) ând is changed by varying the thickness of ahims (lMFig. 23). AAer the measured rolling resistance hi& beén correctly eet be inatalling the proper thickfieBB! of ahims, measure distance between inner rdées aa ahovrn in Fig. 27. Measure distance between oiounting luga of housing as shown in Fig. 28. Subtéact the thiekneua of bearings from the distance between lo », tlsen add shima (10 .and 1€›-Fig. 231 equal to the result. Shima should be evenly divided (10 and 16) to oenter the gear.

Afi;er aelecting ahims 110, 13 and 16), rsmove gear aad beaz?og aBBeotbly fzoa special tool aad ioatatl

20. REMOVED AND REINSTALL. Tb remove the front support, the axle must be removed, the radiator muat be removed i'rom the auppnrt and the front support must be unbolted from the front of engine. The front axle, the front support and the remainder of the tractor mat each be supported separately while removing, while separated and while assembling. Be sure that sufficient equipment ia available before beginning.

Reier to paragraph 67 and ramove the main fuel tank, then refer to paragraph 87 and remove the radiator. Support front of tractor in such a way that it will not interfere with removal of either the frnnt support or the front axle. Refer to paragraph 9 and remove the drive shaft, then refer to paragraph 10 and remove the front axle aaaembly. Attach a hoist or