Cat Caterpillar 966h Wheel Loader Parts DOWNLOAD

Parts Manual

966H Wheel Loader

A6D1-UP (Machine)

RSX1-UP (Engine)

TXE1-UP (Engine)

AYW1-UP (Transmission)

AYY1-UP (Transmission)

DKG1-UP (Transmission)

FAF1-UP (Transmission)

HAX1-UP (Transmission)

HAY1-UP (Transmission)

W2Y1-UP (Transmission)

HAN1-UP (Torque Converter)

TKF1-UP (Torque Converter)

Product and Dealer Information

Note: For product identification plate locations, see the section “Product Identification Information” in the Operation and Maintenance Manual.

Delivery Date:

Product Information

Model:

Product Identification Number:

Engine Serial Number:

Transmission Serial Number:

Generator Serial Number:

Attachment Serial Numbers:

Attachment Information:

Customer Equipment Number:

Dealer Equipment Number:

Dealer Information

Name: Branch:

Address:

Sales:

Parts:

Service:

Dealer Contact Phone Number Hours

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS

BUCKET AS-HEAVY DUTY..................................2488

BUCKET AS-MATERIAL HANDLING............................................................2490

BUCKET AS-MULTIPURPOSE 2494

BUCKET AS-ROCK 2495

BUCKET GP-COAL 2512

BUCKET GP-GENERAL PURPOSE 2513

BUCKET GP-HEAVY DUTY 2527

BUCKET GP-MATERIAL HANDLING 2528

BUCKET GP-MULTIPURPOSE 2532

BUCKET GP-ROCK 2536

CONTROL AR-QUICK COUPLER 2545

COUPLER AR-QUICK............................................2546

COUPLER GP-QUICK............................................2549

EDGE AS-CUTTING...............................................2563

EDGE GP-BIT & CUTTING 2564

EDGE GP-CUTTING 2566

EDGE GP-SEGMENT 2570

EDGE-CUTTING 2575

EDGE-END 2587

EDGE-SEGMENT 2590

FORK AR-LOG & LUMBER 2597

FORK GP-LOG & LUMBER.................................2599

FRAME GP-QUICK COUPLER............................2621

GUARD-BUCKET CORNER..................................2623

HOOK GP-COUPLER ............................................2625

PLATE AS-WEAR 2627

PLATE GP-WEAR 2629

PLATE-WEAR 2630

PROTECTOR GP-EDGE 2637

TIP AS-ABRASION 2639

TIP AS-GENERAL PURPOSE 2641

TIP AS-HEAVY PENETRATION 2644

TIP AS-PENETRATION 2646

TIP GP-ABRASION 2647

TIP GP-EXTRA-DUTY............................................2648

1. MACHINE IDENTIFICATION

GENERAL INFORMATION

Components such as engines, transmissions, axles, etc.

Cat machines are identified by Product Identification and work tools will continue to use an 8 character Serial Numbers (PIN). Some components included in a Number (S/N). machine may be identified by Serial Numbers (S/N).

Typical components that will be serialized include engines, transmissions, bulldozers, and rippers. The machine and engine are further identified by arrangement numbers and in some cases modification numbers. These numbers are shown on the product identification plate(s) and on the master plate in the operator's compartment.

Cat dealers need all of these numbers to determine accurate parts identification.

2.

ORDERING PARTS

Effective First Quarter 2001 the Cat Product Identification Number (PIN) changed from 8 to 17 characters. In an effort to provide uniform equipment identification, Caterpillar and other construction Quality Cat replacement parts are available from Cat equipment manufacturers are moving to comply with the dealers throughout the world. Their parts inventories are latest version of the product identification numbering up to date and include all parts normally required to standard. Non-road machine PINs are defined by ISO protect your investment in Cat machines. Dealers may 10261. The new PIN format will apply to all Cat offer repair kits or remanufactured parts to allow machines and generator sets. The PIN plates and frame selection of the most effective repair alternative for a marking will display the 17 character PIN. The new particular situation. When ordering parts, your order format will look like the following: should specify the quantity, part number, part name, and the serial number/product identification number of the machine for which the parts are needed.

Where:

3. PARTS MANUAL ORGANIZATION

Product information in this manual is presented as "information elements" that represent all of the components for the specific model. Engine Arrangement and Seat Group are examples of information elements. The information elements are organized alphabetically by part name and secondarily by part number within each major section of the manual.

4. TABLE OF CONTENTS

1. Caterpillar's World Manufacturing Code (characters 1- A table of contents (TOC) is found at the beginning of the 3) manual. The TOC lists each section of the manual with a

2. Machine Descriptor (characters 4-8) complete list of all information elements organized as they appear in the manual. Page numbers are provided

3. Check Character (character 9) for quick reference to detailed parts identification illustrations and serviceable consist lists.

4. Machine Indicator Section (MIS) or Product Sequence Number (characters 10-17). These were previously

5. MAINTENANCE PARTS INDEX referred to as the Serial Number.

Machines and generator sets produced before First The Maintenance Parts Index, located near the Quarter 2001 will maintain their 8 character PIN format. beginning of the manual, references most frequently used maintenance part numbers, providing description, quantity, usage and page number. This information is organized alphabetically by part description.

6. INDEX

GENERAL INFORMATION

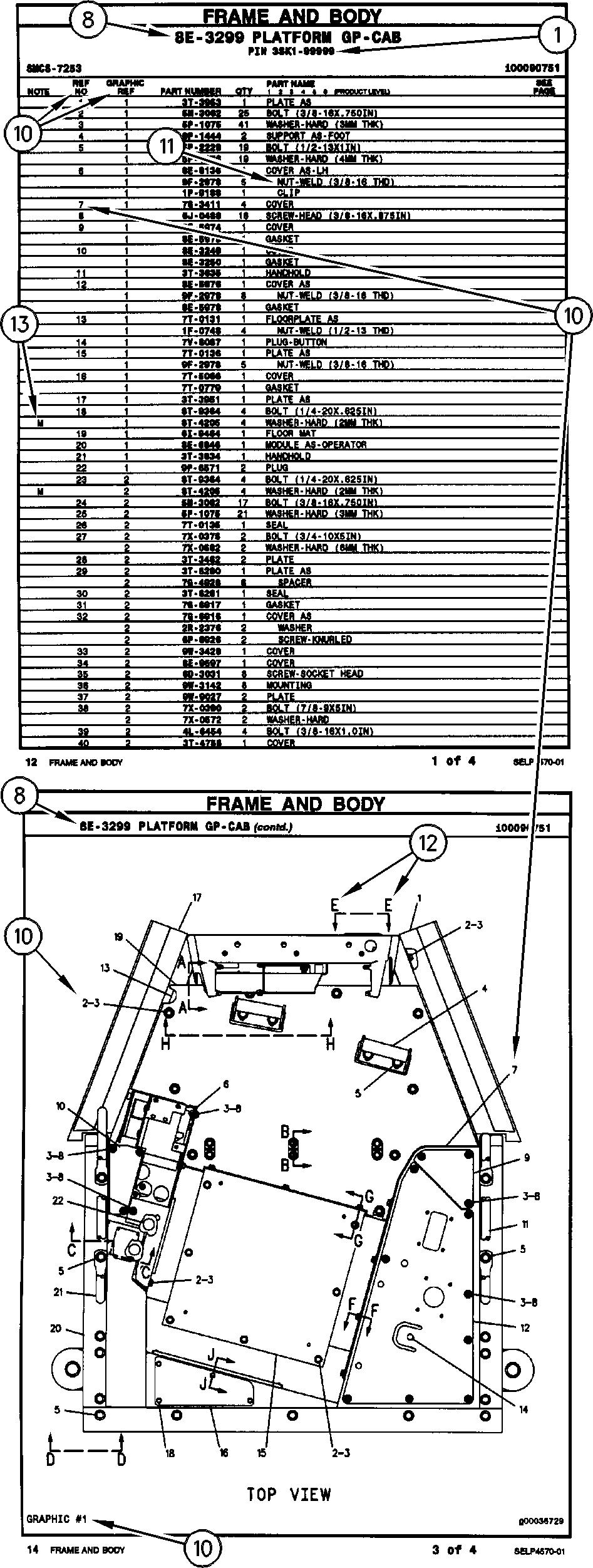

12. ILLUSTRATION REFERENCE LETTERS

The index located near the front of the manual is an When necessary, illustrations contain reference letters alphabetical listing of all information elements included in (A, B, C etc.) that are intended to track lines and the manual. Page numbers are provided for quick harnesses from one point to another. They are also used reference to detailed parts identification illustrations and to show where to reconnect illustrations that have been serviceable consist lists. separated.

7. PART NUMBER INDEX

13. ABBREVIATIONS AND SYMBOLS

A numerical index listing all part numbers and the O.D. – Outside Diameter corresponding page number(s) appears at the back of I.D. – Inside Diameter the manual. A – Not Part Of This Group B – Use As Required

8. CAPTIONS C – Change From Previous Type D – Order By The Meter

Captions located at the beginning of each information E – Order By The Centimeter element identify the part number and part name along F – Not Shown with additional descriptive information. PIN and S/N G – Order By The Inch information found in each caption should be used to I – Refer To Hydraulic Information System select correct information for a specific machine. Field M – Metric Part replacement options, identification of optional R – Remfg Part May Be Available attachment components, and where used ("part of") Y – Separate Illustration information is also provided.

Z – Not Serviced Separately

The first line of a caption is shown in larger type font to 14. DESCRIPTION OF TYPE CHANGES indicate the beginning of an information element. Captions for additional pages that may be required to Type - A type is defined as any configuration change that illustrate an information element will be shown in requires an additional Information Element for an standard type font and will include the term (contd.). Arrangement, Group, or Assembly. If serial number breaks for types are not available, a type # ( Type 1, 9. NON-SERVICED PARTS Type 2, etc.) will be displayed in the caption. These

In some instances it is necessary to display non-serviced "type" changes are identified with a "C" note (change

parts that are a link to a lower level serviceable consist from previous type) in the Parts List. Only the "types" that lists. These non-serviced part numbers are shown in apply to this Parts Manual will be included. Additional italic type indicating that they are not available. types may exist causing "C" notes to appear on an Information Element when no other types are shown.

10. PARTS LIST REFERENCE NUMBERS

15.<END>

Numbers shown in the Ref No column correspond to This symbol indicates the end of an information element. numbers used in the associated graphic(s). An alphabetic suffix may be added to a reference number to

NOTE: identify lower level consist items. Numbers shown in the Graphic Ref column refer to the graphic number identifier

Continuing improvement and advancement of product displayed in the lower left corner of each illustration. The design may cause changes to your machine which may Graphic Ref number may be used in combination with not be included in this publication. Whenever a question the item Ref No to determine the correct part number. arises regarding your Cat product or this publication, There may be intentional omission of a Ref No in a please consult your Cat dealer for the latest available consist list as information is updated to reflect the latest information. serviceable part numbers.

11. INDENTED PART NAMES

When a part name is indented in a parts list, it is part of (included in) the group or assembly under which it is indented.

REPAIR ALTERNATIVES

REMANUFACTURED COMPONENTS

As an option when making repairs consider Cat Remanufactured Components. Components that are available through the Cat Remanufactured Program are identified three ways in the parts book:

• with the letter R in the note field of the parts list

• with an R* at the beginning of the first line of the caption

• with an *R at the end of the first line of the caption

Typical components included in the Remanufacturing Program include:

ALTERNATORS

CONNECTING RODS

CRANKSHAFTS - UNDERSIZE

CRANKSHAFTS - UPGRADE TO NEW

CYLINDER HEADS

ELECTRONIC CONTROL MODULES (ECM)

ELECTRONIC SENSORS

FUEL INJECTORS

FUEL NOZZLES

FUEL PUMPS

GOVERNORS

OIL PUMPS

PISTONS

SHORT BLOCKS

STARTERS

TURBOCHARGERS - COMPLETE

TURBOCHARGER CARTRIDGES

WATER PUMPS

Cat Remanufactured engines for many engine arrangements are also available.

SUPPLEMENTAL COOLANT ADDITIVES

CUSTOMER BENEFITS:

Protects against cavitation, foam, erosion, corrosion, and scale buildup in cooling systems.

• Provides measured coolant conditioner.

DESCRIPTION:

Additives deplete from the coolant with normal operation. For this reason, Supplemental Coolant Additives (SCA) must be added to all heavy duty coolants at regular intervals. In addition, when not using a fully formulated, pre-charged antifreeze, like Cat DEAC, an initial charge of SCA must be added to the cooling system. The amount of SCA added to the system is dependent on the capacity of the system.

The SCA for initial fill is provided as a liquid. SCA's for maintenance intervals are available in liquid form and as a spinon element. (No Spin-on available for 3600 Family of Engines)

NOTE:

The amount of SCA added at initial fill is not the same as the amount added at maintenance intervals.

The coolant additive elements can be used with any ethylene or propylene glycol type antifreeze which meets ASTM D4985 or ASTM D5345 Specifications.

NOTE:

For use with standard heavy duty coolant only, not for use with Extended Life Coolant.

PARTS NEEDED:

(6-8)

(1)

(1) 30-38 (8-10) 3P-2044 (1) 6V-3542 (1)

(1)

(1) 38-49 (10-13)

3P-2044 (1) 8T-1589 (1)

(1)

(1) 49-64 (13-17) 3P-2044 (2)

(1)

(1) 64-83 (17-22)

83-114 (22-30)

3P-2044 (2) 8T-1589 (1) 111-2372 (1) 6V-3542 (1)

3P-2044 (3) 8T-1589 (1) 3P-2044 (1)

(1)

(1) 114-163 (30-43) 3P-2044 (5)

(1) 6V-3542 (1)

(2) 163-242 (43-64)

3P-2044 (8)

3P-2044 (2) 9N-3718 (2)

* Normal maintenance period is 250 hrs. See your Operation and Maintenance Manual for complete coolant maintenance instructions.

( ) Indicates quantity required.

INLET AND EXHAUST SYSTEM

MAINTENANCE PARTS

SYSTEM

(92-DEG C) (COOLANT)

(ALTERNATOR)

AUTOMATIC RESET) (POWER GUARD ACTUATOR)

AUTOMATIC RESET) (RUNNING LIGHTS)

(HOOD

(UNSWITCHED BAT POWER TO CAB)

(ENGINE START)

MAINTENANCE PARTS

MAINTENANCE PARTS

WATT) (TURN SIGNAL)

SYSTEM

SYSTEM

MAINTENANCE PARTS

MAINTENANCE PARTS

(LIFT, TILT, FNR,

ELECTRONIC

(INDICATOR PANEL, CENTER)

(INDICATOR PANEL, RH, LH).

–2-

–LIFT, TILT, DOWNSHIFT FUNCTION.

(3-FUNCTION, WITH

WITH 2067 DOWNSHIFT ...........................................................

2076

2077

GP-JOYSTICK–3-FUNCTION, WITH 2089 FNR, DOWNSHIFT 2108 2091

GP-MONITOR–BACKLIGHT

(DUMP, TILT

(FUSE

(HYDRAULIC OIL

(HYDRAULIC OIL)

(LIFT EYE

(INPUT/OUTPUT)

(JOYSTICK

(PRODUCT LINK, READ FILM-IDENTIFICATION (LIFT EYE, TIE-DOWN OMM).

LOCATION)

FILM-IDENTIFICATION (LIFT, FLOAT, FILM-INSTRUCTION (ENGINE START)

LOWER)

(FUEL, READ OMM)

(GREASE PRESSURE

FILM-WARNING (HIGH PRESSURE, READ OMM,

U.S.).

FILM-WARNING (HOT FLUID UNDER

PRESS).

& FUEL FILM-WARNING (HOT FLUID UNDER PRESSURE, (PRIMARY)..................................................................

U.S.).

VERTICAL).

(HOT SURFACE-

(PRIMARY)

(SECONDARY)

GUARD

GUARD

GUARD

PANEL

(2-PIN) (AXLE

SENSOR AS-TEMPERATURE (2-PIN) (FRONT

SENSOR

(2-PIN) (HYDRAULIC

SENSOR

(AXLE OIL COOLER

BYPASS)

VALVE GP-CHECK (HIGH PRESSURE, RIDE

WIRING

MACHINE ARRANGEMENT

236-9000 CHASSIS AR

S/N: A6D1-UP PART OF 246-1388 COMMON AR, 236-8957 GENERAL AR SMCS-7000

S/N: A6D1-2536

S/N: A6D2537-UP

S/N: A6D2478-UP

S/N: A6D2478-UP

S/N: A6D1-2214

MACHINE ARRANGEMENT

MACHINE ARRANGEMENT

MACHINE ARRANGEMENT

246-1388 COMMON AR

369-7105 COMMON AR

i04991569

MACHINE ARRANGEMENT

121-1340 1 ANGLE AS

8T-3490 1 NUT-WELD (M10X1.5-THD)

332-7262 1 BOX AS-BATTERY 124-3019 2 BRACKET AS (EACH INCLUDES) M 8T-3490 1 NUT-WELD (M10X1.5-THD)

127-9323 1 BRACKET AS M 8T-3490 1 NUT-WELD (M10X1.5-THD) 148-3495 1 BRACKET AS M 8T-3490 1 NUT-WELD (M10X1.5-THD)

243-5821 1 BRACKET AS 328-4419 3 BRACKET AS 311-7036 1 CABLE AS

E

8C-0596 CABLE (2-GA) (40-CM)

E 6V-9023 TUBE-HEAT SHRINK (12.7-MM DIA) (3-CM)

030-1712 1 TERMINAL-RING (2-GA, 1/4-IN SCREW)

E 125-7876 TUBE-HEAT SHRINK (17.78-MM DIA) (4-CM)

324-0680 1 CABLE AS 324-0682 1 CABLE AS 8C-5917 1 TERMINAL AS-BATTERY (POSITIVE)

9X-4519 1 BOOT (RED)

9X-5632 1 COVER-TERMINAL (RED, RH POS)

E 159-8049 CABLE (00-GA, RED) (58-CM)

B 1P-0810 1 TAPE-ELECTRICAL

1S-7251 1 TERMINAL-CABLE (00-GA, 1/2-IN SCREW)

E 351-9309 TUBE-HEAT SHRINK (32-MM DIA) (4-CM)

328-4407 1 CABLE AS 9X-4519 2 BOOT (RED)

E 159-8049 CABLE (00-GA, RED) (178-CM)

B 1P-0810 1 TAPE-ELECTRICAL

1S-7251 2 TERMINAL-CABLE (00-GA, 1/2-IN SCREW) E 351-9309 TUBE-HEAT SHRINK (32-MM DIA) (8-CM)

328-4408 1 CABLE AS E 159-8050 CABLE (00-GA, BLACK) (55-CM) B 1P-0810 1 TAPE-ELECTRICAL

1S-7251 2 TERMINAL-CABLE (00-GA, 1/2-IN SCREW) E 351-9309 TUBE-HEAT SHRINK (32-MM DIA) (8-CM)

328-4409 1 CABLE AS E 159-8050 CABLE (00-GA, BLACK) (33-CM)

B 1P-0810 1 TAPE-ELECTRICAL

1S-7251 1 TERMINAL-CABLE (00-GA, 1/2-IN SCREW) E 351-9309 TUBE-HEAT SHRINK (32-MM DIA) (7-CM)

315-0180 1 TERMINAL-RING (00-GA, 3/8-IN SCREW)

MACHINE ARRANGEMENT

331-2384 CONFIGURATION AR (contd.) i03632173

NOTE PART NUMBER QTY PART NAME SEE 1 2 3 4 5 6 (PRODUCT LEVEL) PAGE

328-4417 1 CABLE AS 3L-6513 1

E 6V-9023

TERMINAL-RING (1-GA TO 2-GA, 1/2-IN SCREW)

TUBE-HEAT SHRINK (12.7-MM DIA) (3-CM)

E 8C-3056 CABLE (2-GA, RED) (235-CM)

8T-8827 1 BOOT (RED)

B 1P-0810 1 TAPE-ELECTRICAL

E 125-7876

E 311-4859

TUBE-HEAT SHRINK (17.78-MM DIA) (4-CM)

TUBE-HEAT SHRINK (48-MM DIA) (35-CM)

325-9438 2 GROMMET AS

328-4400 1 HARNESS AS-CHASSIS (SERVICE CENTER) 155-2255 1

KIT-CONNECTING PLUG (12-PIN)

155-2260 1 KIT-CONNECTING PLUG (3-PIN) 155-2270 4

8T-8737 3

E 114-8843

E 114-8844

KIT-CONNECTING PLUG (2-PIN)

(EACH PLUG KIT INCLUDES PLUG AS, WEDGE, & INTERFACE SEAL)

PLUG-SEAL

SLEEVE-PLASTIC (100-CM)

SLEEVE-PLASTIC (20-CM)

20 SOCKET-CONNECTOR (16-GA TO 18-GA) –OR–

20 SOCKET-CONNECTOR (14-GA TO 16-GA)

E 125-7874

TUBE-HEAT SHRINK (5.72-MM DIA) (10-CM) 328-4412 1 HARNESS AS-ENGINE

1 CAP-SEAL 126-1774 1 COVER-CONNECTOR

3

KIT-CONNECTING PLUG (3-PIN) 155-2270 6

KIT-CONNECTING PLUG (2-PIN)

(EACH PLUG KIT INCLUDES PLUG AS, WEDGE, & INTERFACE SEAL) 102-8803 2

126-1767 2

9X-3401 3

126-1767 3

KIT-RECEPTACLE (3-PIN)

(EACH INCLUDES RECEPTACLE AS & WEDGE)

PIN-CONNECTOR (14-GA TO 16-GA)

PIN-CONNECTOR (16-GA TO 18-GA) –OR–

PIN-CONNECTOR (14-GA TO 16-GA)

8T-8737 47 PLUG-SEAL

300-9462 1 PLUG AS 160-7689 1 PLUG AS-CONNECTOR (70-PIN) 240-7874 2 PLUG AS-CONNECTOR (2-PIN)

E 317-1204

SLEEVE (69-CM) 9X-3402 74

126-1768 74

SOCKET-CONNECTOR (16-GA TO 18-GA) –OR–

SOCKET-CONNECTOR (14-GA TO 16-GA) 9X-4998 1 SOCKET (14-GA TO 16-GA) 3S-2093 2 STRAP-CABLE B 1P-0810 1 TAPE-ELECTRICAL

E 119-3662

E 125-7874

TUBE-HEAT SHRINK (10.85-MM DIA) (13-CM)

TUBE-HEAT SHRINK (5.72-MM DIA) (25-CM) 328-4403 1 HARNESS AS-FRONT 274-3774 6 CAP-CONNECTOR 155-2260 4

KIT-CONNECTING PLUG (3-PIN)

MACHINE ARRANGEMENT

331-2384 CONFIGURATION AR (contd.) i03632173

NOTE PART NUMBER QTY PART NAME 1 2 3 4 5 6 (PRODUCT LEVEL)

155-2270 16

KIT-CONNECTING PLUG (2-PIN) (EACH PLUG KIT INCLUDES PLUG AS, WEDGE, & INTERFACE SEAL)

102-8803 2 KIT-RECEPTACLE (3-PIN)

102-8801 2 KIT-RECEPTACLE (12-PIN) (EACH RECEPTACLE KIT INCLUDES RECEPTACLE AS & WEDGE)

E 5P-1506 HOSE (65-CM)

9X-3401 42 PIN-CONNECTOR (16-GA TO 18-GA) –OR–

126-1767 42 PIN-CONNECTOR (14-GA TO 16-GA)

126-1767 13

PIN-CONNECTOR (14-GA TO 16-GA)

8T-8737 21 PLUG-SEAL 113-0580 1 RECEPTACLE AS-CONNECTOR (40-PIN)

E 114-8843

E 114-8844

E 114-8845

SLEEVE-PLASTIC (400-CM)

SLEEVE-PLASTIC (40-CM)

SLEEVE-PLASTIC (20-CM) 9X-3402 38 SOCKET-CONNECTOR (16-GA TO 18-GA)

OR–

38 SOCKET-CONNECTOR (14-GA TO 16-GA)

TUBE-HEAT SHRINK (10.85-MM DIA) (13-CM)

E 125-7874

TUBE-HEAT SHRINK (5.72-MM DIA) (30-CM)

278-5259 1 HARNESS AS-SENSOR (AXLE TEMPERATURE)

1 KIT-CONNECTING PLUG (2-PIN) (INCLUDES PLUG AS, WEDGE & INTERFACE SEAL) 102-8802 1 KIT-RECEPTACLE (2-PIN) (INCLUDES RECEPTACLE AS & WEDGE)

SEE PAGE

G

9X-2383 HOSE (19.3-IN)

9X-3401 2 PIN-CONNECTOR (16-GA TO 18-GA) –OR–

126-1767 2

PIN-CONNECTOR (14-GA TO 16-GA) E 114-8843 SLEEVE-PLASTIC (40-CM) 9X-3402 2 SOCKET-CONNECTOR (16-GA TO 18-GA) –OR–126-1768 2 SOCKET-CONNECTOR (14-GA TO 16-GA)

6V-2722 TUBE-HEAT SHRINK (25.4-MM DIA) (0.1-M)

328-4421 1 HARNESS AS-SENSOR 155-2270 1 KIT-CONNECTING PLUG (2-PIN) (INCLUDES PLUG AS & WEDGE)

(2-PIN) (INCLUDES RECEPTACLE AS & WEDGE)

(16-GA TO 18-GA) –OR–

(14-GA TO 16-GA)

(16-GA TO 18-GA)

(14-GA TO 16-GA)

SHRINK (25.4-MM DIA) (0.1-M)

(2-PIN)

MACHINE ARRANGEMENT

331-2384 CONFIGURATION AR (contd.)

NOTE PART NUMBER QTY PART NAME 1 2 3 4 5 6 (PRODUCT LEVEL)

(EACH INCLUDES PLUG AS, WEDGE, & INTERFACE SEAL)

7X-6222 1

3E-4367 1

PLUG AS-CONNECTOR (24-PIN)

RING-RETAINING

M 3E-8558 1 BOLT (M5X0.8X39.37-MM)

9X-3265 2

SEAL-CONNECTOR (24-PIN)

8T-8737 7 PLUG-SEAL

E 114-8843

E 114-8845

9X-3402 37

126-1768 37

E 125-7874

SLEEVE-PLASTIC (200-CM)

SLEEVE-PLASTIC (20-CM)

SOCKET-CONNECTOR (16-GA TO 18-GA) –OR–

SOCKET-CONNECTOR (14-GA TO 16-GA)

TUBE-HEAT SHRINK (5.72-MM DIA) (10-CM)

323-8354 1 PANEL AS 244-8780 1 PLATE AS 9F-2978 2 NUT-WELD (3/8-16-THD)

328-4418 1 RECEPTACLE AS 9X-4519 1 BOOT (RED)

E 159-8049 CABLE (00-GA, RED) (53-CM)

E 159-8050 CABLE (00-GA, BLACK) (30-CM)

1S-7251 2

E 351-9309

TERMINAL-CABLE (00-GA, 1/2-IN SCREW)

TUBE-HEAT SHRINK (32-MM DIA) (8-CM) 314-2405 1 SWITCH AS-PRESSURE (SERVICE BRAKE OIL) 102-8803 1

8T-8729 3

KIT-RECEPTACLE (3-PIN) (INCLUDES RECEPTACLE AS & WEDGE)

PIN-CONNECTOR (16-GA TO 20-GA)

E 9X-1813 SLEEVE (28-CM)

301-2980 1 SWITCH AS-TOGGLE (ROTOR TURNING) (HOOD TILT ACTUATOR)

102-8803 1

KIT-RECEPTACLE (3-PIN) (INCLUDES RECEPTACLE AS & WEDGE)

8T-8729 3 PIN-CONNECTOR (16-GA TO 20-GA) 336-2911 1 TUBE AS

8R-9186 1 ANGLE 329-1428 2 BRACKET

4D-7794 2 CLIP

6K-8178 4 CLIP (LOOP)

7I-3722 6 CLIP

067-2551 1 CLIP

096-2626 1 CLIP 156-6175 1 CLIP (LADDER)

323-8362 1 GUARD

204-8000 10 MOUNTING-CABLE TIE

M 315-5390 2 NUT (M40X1.5-THD)

119-6200 1 PLATE 133-3260 1 SPACER (11X19X10-MM THK)

193-3973 10 STRAP-CABLE 7X-3393 2 WASHER-HARD (8.3X19X1.83-MM THK)

SEE PAGE

B - USE AS REQUIRED

D - ORDER BY THE METER

E - ORDER BY THE CENTIMETER

G - ORDER BY THE INCH

M - METRIC PART

Y - SEPARATE ILLUSTRATION

MACHINE ARRANGEMENT

334-0434

MACHINE ARRANGEMENT

CONFIGURATION AR–HEATED AIR SEAT, MIRRORS

S/N: A6D2438-UP

CANNOT BE USED WITH 260-4872–PAGE: 2321

SMCS-7000 i06059716

PART NAME

NOTE PART NUMBER QTY 1 2 3 4 5 6 (PRODUCT LEVEL)

Y 259-1999 1 MIRROR GP-REAR VIEW (EXTERIOR, HEATED) 2243

Y 440-9357 1 SEAT GP-SUSPENSION (HEATED, 24-VOLT)

Y - SEPARATE ILLUSTRATION <END>

339-5932 CONFIGURATION AR–2-V, RIDE CONT, QCPLR, LMT SLP

S/N: A6D2478-UP

CANNOT BE USED WITH 243-1946–PAGE: 2069, 319-8253–PAGE: 2080, 236-9099–PAGE: 833, 326-2754–PAGE: 1419, 342-4991–PAGE: 1420, 276-7252–PAGE: 867, 236-9092–PAGE: 1418

(PRODUCT

(FRONT,

DIFFERENTIAL) Y 236-9094 1 CONTROL AR-RIDE

Y - SEPARATE ILLUSTRATION <END>

339-5933 CONFIGURATION AR–2-V,

S/N: A6D2478-UP

RIDE CONT, LIMITED SLIP

CANNOT BE USED WITH 243-1946–PAGE: 2069, 319-8253–PAGE: 2080, 236-9099–PAGE: 833, 326-2754–PAGE: 1419, 342-4991–PAGE: 1420

SMCS-7000 i03852610

Y 129-4282 1 AXLE

(FRONT, LIMITED SLIP DIFF)

Y 129-4283 1 AXLE AR-OSCILLATING (REAR, LIMITED SLIP DIFF) 845

Y 236-9094 1 CONTROL AR-RIDE (2-VALVE) 1421

Y - SEPARATE ILLUSTRATION

339-5934 CONFIGURATION

<END>

AR–2-V, RIDE CONT, QCPLR, LMT SLP

S/N: A6D2478-UP

CANNOT BE USED WITH 243-1946–PAGE: 2069, 319-8253–PAGE: 2080, 236-9099–PAGE: 833, 326-2754–PAGE: 1419, 342-4991–PAGE: 1420, 236-9092–PAGE: 1418

Y 129-4282 1 AXLE AR-FIXED (FRONT, LIMITED SLIP DIFF)

Y 129-4283 1 AXLE AR-OSCILLATING (REAR, LIMITED SLIP DIFF)

Y 236-9094 1

(2-VALVE)

Y 325-2741 1 COUPLER AR-QUICK 2547

Y - SEPARATE ILLUSTRATION

<END>

339-5936

MACHINE ARRANGEMENT

CONFIGURATION AR–3-V, RIDE CONT, STD AXLES

S/N: A6D2478-UP

CANNOT BE USED WITH 243-1941–PAGE: 2063, 236-9092–PAGE: 1418, 319-8254–PAGE: 2089, 326-2754–PAGE: 1419, 276-7252–PAGE: 867, 342-4991–PAGE: 1420

Y 283-2587 1 ARM AS-LIFT

Y 129-4280 1 AXLE AR-FIXED (FRONT, STANDARD DIFFERENTIAL)

Y 129-4281 1 AXLE AR-OSCILLATING (REAR, STANDARD 845 DIFFERENTIAL) Y 342-1569 1

Y - SEPARATE ILLUSTRATION

339-5939

S/N: A6D2478-UP

CANNOT BE USED WITH 243-1941–PAGE: 2063, 236-9092–PAGE: 1418, 319-8254–PAGE: 2089, 276-7252–PAGE: 867, 276-7254–PAGE: 867, 236-9099–PAGE: 833

SMCS-7000

NAME

DIFFERENTIAL)

Y 342-1569 1 CONTROL AR-RIDE (3-VALVE) 1421

Y 325-2741 1 COUPLER AR-QUICK 2547

Y 323-9292 1 LINES GP-COUPLER 1477

Y - SEPARATE ILLUSTRATION <END>

360-5884

S/N: A6D2478-UP

CANNOT BE USED WITH 243-1941–PAGE: 2063, 319-8254–PAGE: 2089, 236-9092–PAGE: 1418, 326-2754–PAGE: 1419, 342-4990–PAGE: 1420, 342-4991–PAGE: 1420, 236-9099–PAGE: 833, 276-7252–PAGE: 867 PART OF 360-5883 DISTRIBUTION AR

SMCS-7000

PART NAME

i05121817

(PRODUCT LEVEL)

Y 129-4282 1 AXLE AR-FIXED (FRONT, LIMITED SLIP DIFF) 835

Y 129-4281 1 AXLE AR-OSCILLATING (REAR, STANDARD 845 DIFFERENTIAL)

Y 342-1569 1 CONTROL AR-RIDE (3-VALVE) 1421

Y 326-2752 1 COUPLER AR-QUICK 2547

Y - SEPARATE ILLUSTRATION <END>

MACHINE ARRANGEMENT

339-5918

CONVERSION AR-MACHINE

S/N: A6D2478-UP

CANNOT BE USED WITH 263-3322–PAGE: 407, 240-4542–PAGE: 2165 PART OF 352-0298, 360-5883 DISTRIBUTION AR

R - REMANUFACTURED PART MAY BE AVAILABLE Y - SEPARATE ILLUSTRATION

356-3061

CONVERSION AR-MACHINE

S/N: A6D1-UP

352-0298

DISTRIBUTION AR

Y - SEPARATE ILLUSTRATION

MACHINE ARRANGEMENT

360-5883 DISTRIBUTION AR

236-8957 GENERAL AR

543-1963 INSTALLATION AR-FIELD

MACHINE ARRANGEMENT

275-4049 MACHINE AR–VALUE PACKAGE

275-4050 MACHINE AR–VALUE PACKAGE

275-4051

MACHINE AR–VALUE PACKAGE

MACHINE ARRANGEMENT

275-4052

MACHINE AR–VALUE PACKAGE

275-4053

MACHINE AR–VALUE PACKAGE

275-5235 MACHINE AR–VALUE PACKAGE

MACHINE ARRANGEMENT

297-4842 MACHINE AR–VALUE PACKAGE

S/N: A6D1-UP FOR USE WITH 244-2736–PAGE: 2236, 245-6184–PAGE: 1148, 259-1999–PAGE: 2243, 2604870–PAGE: 2321

Y - SEPARATE ILLUSTRATION

297-4843 MACHINE AR–VALUE PACKAGE

S/N: A6D1-UP

–

Y

Y - SEPARATE ILLUSTRATION

297-4844

<END>

MACHINE AR–VALUE PACKAGE

Y

Y - SEPARATE ILLUSTRATION

MACHINE ARRANGEMENT

297-4845

MACHINE AR–VALUE PACKAGE

S/N: A6D1-UP FOR USE WITH 244-2736–PAGE: 2236, 245-6184–PAGE: 1148, 259-1999–PAGE: 2243, 2604870–PAGE: 2321 SMCS-7000

Y - SEPARATE ILLUSTRATION

305-0006

MACHINE AR–VALUE PACKAGE

MACHINE ARRANGEMENT

MACHINE

MACHINE ARRANGEMENT

Y - SEPARATE ILLUSTRATION

328-9884 OPTION

AR-CAB–AM/FM RADIO, CD PLAYER, CB RADIO READY

S/N: A6D2478-UP

CANNOT BE USED WITH 320-9998–PAGE: 2180, 284-4739–PAGE: 2332 PART OF 352-0298, 360-5883 DISTRIBUTION AR

SMCS-7000,

Y - SEPARATE ILLUSTRATION <END>

339-5946

OPTION AR-COLD WEATHER

S/N: A6D2478-UP

CANNOT BE USED WITH 339-5929–PAGE: 840

352-0298, 360-5883 DISTRIBUTION AR

Y - SEPARATE ILLUSTRATION <END>

Y - SEPARATE ILLUSTRATION

MACHINE ARRANGEMENT

339-5948 OPTION AR-PRECLEANER

S/N: A6D2478-UP

CANNOT BE USED WITH 198-7248–PAGE: 881

276-2384 SCRAP HANDLING AR

S/N: A6D1-UP

245-2032

WASTE HANDLING AR

ENGINE ARRANGEMENT

234-7848

ENGINE AR-COMPLETE*R

S/N: TXE1001-UP; RSX15223-UP 213 BRAKE KW (286 BHP) AT 1800 RPM FIELD REPLACEMENT FOR 349-4468–PAGE: 27 PART OF 246-1388, 369-7105 COMMON AR

ENGINE ARRANGEMENT

S/N: RSX15243-17037

S/N: RSX17038-UP

PLEASE USE THE GASKET KIT LINK IN SIS OR CONTACT YOUR LOCAL DEALER FOR THE LATEST GASKET KIT INFORMATION

Y - SEPARATE ILLUSTRATION <END>

ENGINE ARRANGEMENT

234-7850 ENGINE AR-COMPLETE*R

S/N: RSX1038-UP 211 BRAKE KW (283 BHP) AT 2100 RPM

ENGINE ARRANGEMENT

S/N: RSX1038-2137

RSX17047-UP

S/N: RSX17047-UP 235-7509 1 ELECTRONICS GP-ENGINE RATINGS

S/N: RSX1063-UP

PLEASE USE THE GASKET KIT LINK IN SIS OR CONTACT YOUR LOCAL DEALER FOR THE LATEST GASKET KIT INFORMATION

Y - SEPARATE ILLUSTRATION <END>

ENGINE ARRANGEMENT

291-6601

ENGINE AR-COMPLETE*R

S/N:

Y - SEPARATE ILLUSTRATION

ENGINE ARRANGEMENT

PLEASE USE THE GASKET KIT LINK IN SIS OR CONTACT YOUR LOCAL DEALER FOR THE LATEST GASKET KIT INFORMATION

ENGINE ARRANGEMENT

349-4468

AR-COMPLETE*R

ENGINE ARRANGEMENT

234-7845

ENGINE AR-CORE

ENGINE ARRANGEMENT

263-6681 ENGINE AR-CORE

SEPARATE ILLUSTRATION

ENGINE ARRANGEMENT

286-5803 ENGINE AR-CORE

S/N: TXE1-UP; RSX1-UP

353-5788 ENGINE AR-CORE

S/N: TXE1-UP

Y - SEPARATE ILLUSTRATION

ENGINE ARRANGEMENT

353-5794 ENGINE AR-CORE

S/N: TXE103-UP PART OF 291-6601 ENGINE AR-COMPLETE

353-6115 ENGINE AR-CORE

S/N: TXE1-UP PART OF 353-5788, 353-5794, 366-8502, 394-0447 ENGINE AR-CORE

366-8502 ENGINE AR-CORE

S/N:

ENGINE ARRANGEMENT

394-0447

ENGINE AR-CORE

S/N: TXE1-UP

Y - SEPARATE ILLUSTRATION

236-7231

INSTALLATION AR-ENGINE

343-7250

INSTALLATION AR-ENGINE

S/N:

BASIC ENGINE

BASIC ENGINE 229-2611 BASE GP-VALVE COVER

BASIC ENGINE

–ENGINE

BASIC ENGINE