DOWNLOAD SERVICE MANUAL ! ”!

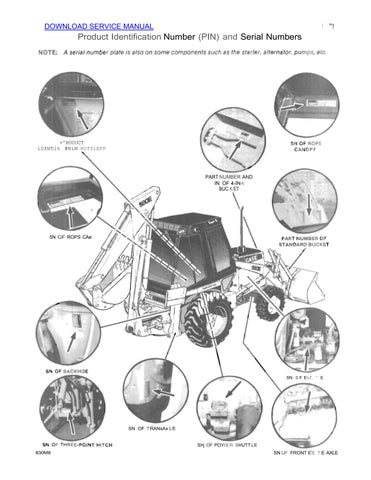

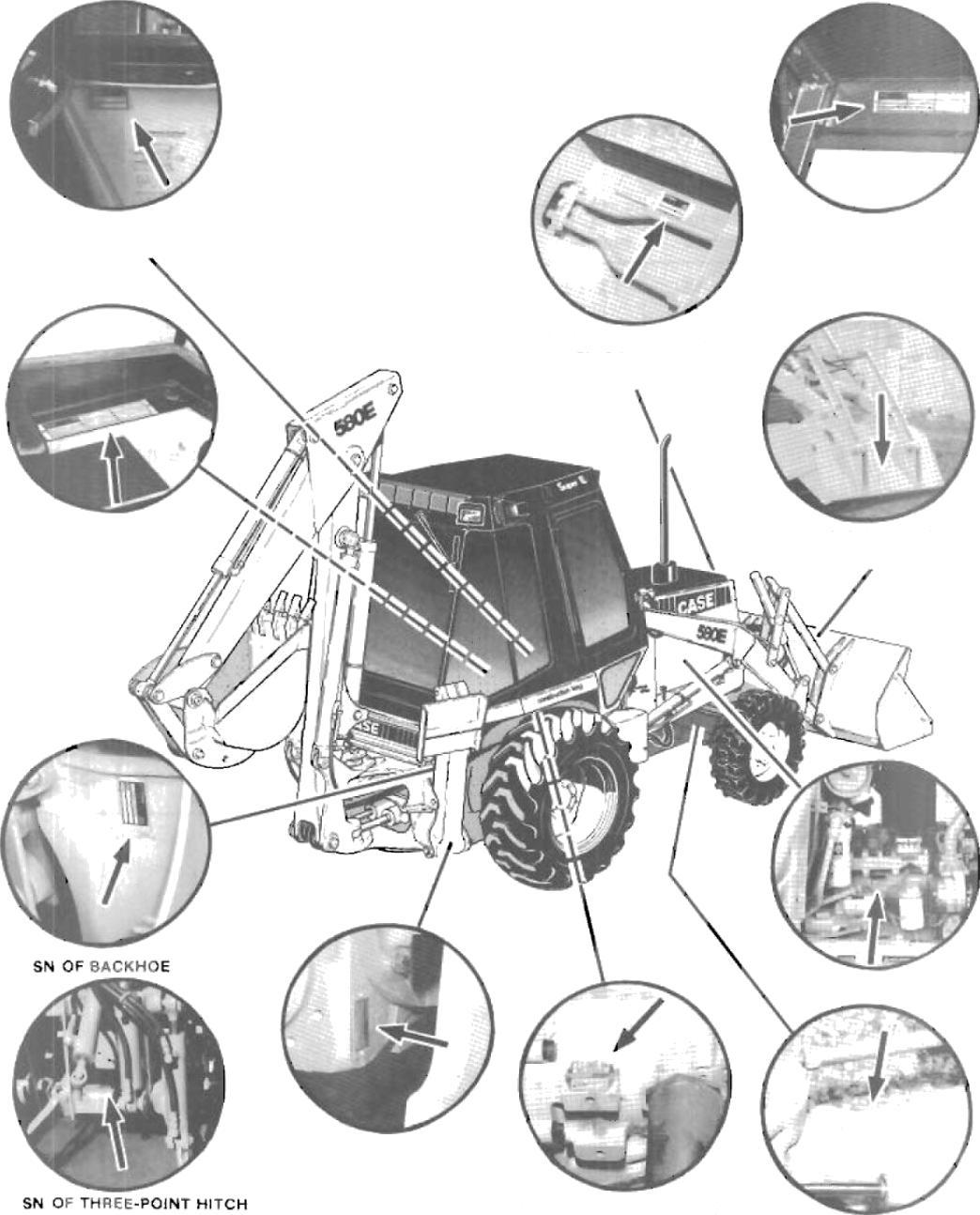

Product Identification Number (PIN) and Serial Numbers

+'HOOUCT

l0fNTl% #NiM HUfflEFP

PART NUMBER AND IN OF 4-IN-\ BUC K ET

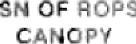

TOROUE 9PECIFICATION8 - U.8. HARDWARE

Use tha torques in this Chart when special torquss are not given. These torques apply to fasteners with both UNC and UNF threads aa received from suppliers.dry,orwhen lubricated with en9ine oil. Not applicable lfspecial graphites, moly-disulfide greases, or othar extreme pressure lubricants are used.

Gmde 5 Bol@, Nutc, and 6tu&

1/J In 6.4 mm

5/16 In

8/6In 8.6 mm

7/16 Izt 11.1 mm

1/2 ki 12.7 mm

9/16 In 14.3 mm

6/6!n 15.g mm

9/4 In 19.0 mm

7/8 In 22.2 mm

1.0ln 25.1mm

I

Grade 8 Bol@, Null, and 9tudc

1/4In

8.4 mm S/16 In 7.0 mm S/6 In 8.5 mm 7/16In 11.1 mm 1/9 In 12.7 mm 9/16In 14.3 mm 6/8ks 15.9 mm 8/4ks 18.0 mm 7/gbs S2.2mm IN tzt 25.4 mm IN in 2fl.6 mm 1•'$/'4 ks 1-8/s in 34.9 mm 1-UZ In 38.1 mm

TOROUE SPEGIFICATIONS - STEEL HYDRAULIC FITTINGS

Spill Flange Mounting Bolt9

MAINTENANCE AND LUBRICATION

Fiuidsand Lubrtcants

MalntenanceChart

CoolanI Recovery System . .

TABLEOF CONTENTS

Written In C/ear And Simple English

COMPONENT

Fuel tank

Engine crankcase

Witn filler chan.ge

Cooling sysìem

Wom neater

Wi hout heater

ł•1ÿdraulİC rØBØ'rVOir

System capacity with 1nader/backboø

Power shut\Ie

'Tiansax/e

FLUIDS AND LUBRICANTS

SPECiFlPATIONS

Saø Operators ManuBl

Fronf orive axla

Center bowl

Pțane1ary in¢fS (eaCh)

Transfer case

}Four wheøI drived

Brakømaster c xu ‹ter(

11 quartc 10.4 iitras

Parksng Øf8ke cable

Grease lilłings

16.9 quarts 17.B fltras 18.2 quØrEa 17.2 litres 12.5 gaI1ons 47.3 litres 23.75 gallons 89.9 Iltres

Recommended Engine Oił’ Aoore30ºF Ï-ï C) SAE 3o‘•’7eß CC. CD oCve IO°F :-12 C/ SAE fsW-TO CC. CD Be oa 90ᵉF f32’Ci SAE n 0F-T0 CC.CD fi \ernaie Engine ‹3i1-

Above 5û* F 110° C ł SAE 4O CC, CO

Above 39“F (4”C) SAEIU CC,CO

23ᵉ to68”n- ‹-5" tO 20”Cl saE żavzzß CC. CD

3e'o v 3 F IO° Cl .... . SAE 10vv GC, CD

Mix ethylene glycol with wator for the lowesi ambient ten peratuæ expected, ThB mixï\ire must be half ethylene glycol and half water.

Case TC J Fluid

Case TCH Fluid

CasaFDLFıuîd Alłerneie n'i: Gear Lubricant IAPI-GL-4j

Above 0”F {-16"C) - SAE 90

Belo< 0ºF 18*C) SAE BO

7quaj•țs 6.6 !‹1re9 I.5 qt›ar1s 1.4 l'ire

1 pinl 0.5 lime

NOTE: cafe prooucfion machines have masier cylinders tnai ara cnnneclBd to Ihe ny• orøc/ic øy/fam. 6ae Secńon

as required as reüu i red as *equ›reğ a5 required

Case *3L F”iaid

Case FDL Fluid

Case TCI-I Flu d

Lubriplate 1Πgrease.

Add drinking water or distillùd waie›

mo. 2 Molyoisulfide greases