DOWNLOAD SERVICE MANUAL

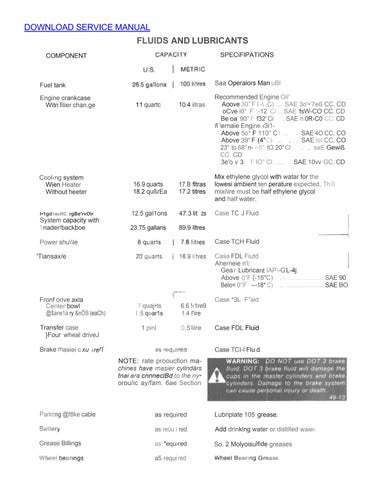

FLUIDS AND LUBRICANTS

COMPONENT

Fuel tank

Engine crankcase

Witn filier chan.ge

Cool‹ng system Wien Heater Without heeter

I•1gdraulIC rgBe'rvOir System capacity with 1nader/backboe

Power shu\\le

'Tiansax/e

Fronf orive axla

Center bowl

@$ane1a ry &nÖS (eaCh)

Transfer case }Four wheal driveJ

Brakemasiei c xu ‹rer(

11 quartc 10.4 iitras

SPECiFlPATIONS

Saa Operalors Man uBl

Recommended Engine Oil’

Aoove 30°F I-\ C) SAE 3o‘•’7eß CC. CD oCve i0° F :-12 C/ SAE fsW-CO CC.CD Be oa 90°F f32’Ci SAE n0R-C0 CC.CD fi \ernaie Engine ‹3i1-

Above 5o* F 110° C t SAE 4O CC, CO

Above 39“F (4”C) SAE tel CC, CO 23° to68”n- ‹-5" tO 20”Cl saE Gewiß CC. CD 3e'o v 3 F IO° Cl .... . SAE 10vv GC, CD

Parktng@f8ke cable

Grease Billings

16.9 quarts 17.B fltras 18.2 qußrEa 17.2 titres

12.5 gaI1ons 47.3 lit zs 23.75 gallans 89.9 Iltres

7quaj•ts 6.6 !‹1re9 I.5 q‹›ar1s 1.4 l'ire

1 pinl 0.5liire

NOTE: rate prooucfion machines have masier cyllndärs tnai ara cnnneclBd to Ihe ny• orou/ic ay/fam. 6ae Section as required as reüu i red as *equ›red

a5 required

Mix ethylene glycol with watar for the lowesi ambient ten perature expected, ThB mixi\ire must be half ethylene glycol and half water.

Case TC J Fluid

Case TCH Fluid

Casa FDL Fiutd Aherneie n'i: Gear Lubricant IAPI-GL-4j

Above 0”F {-16"C) - SAE 90 Belo< 0°F 18*C) .. ......................SAE BO

Case *3L F”aid

Case FDL Fluid

Case TCI-I Flu d

Lubriplate 105 grease.

Add drinklng water or distilled waie›

So. 2 Molyoisulfide greases

DOWNLOAD SERVICE MANUAL

MAINTENANCE CHART

Thisch6•T showsmaximum service intervals for the.correctmaintenance ofthemachine. Someoperating condiliona MII make it necessary IO OftBFl tha 9BfViC6 i0tBf”VBI9.

INTERVAL SERVICE

Arte the ft 9i 2 hours machine only

50, 1IXl. and 2 hours of operation new machlne onlx

Altar tha first 20 hours of opgration, newmaGhIne only

Evgry 10 hours of opsration or each oay, whichever

Every50 hours of operation

@ygry 1gggauls of OperéltfOD

TighEgn thg tYheel bolts.

*ighten1f›e Ie-rision rodnuts for tha backhoe.

iqhteo the tour e vin9pivot nut low the backime.

Oo the Aflgr Del'very Check.

Lubncate the loader andbackhoe givo points.

Lubricate the dipper extension. i‹ e0uioqea.

Check the level of the engina oil

Luorica e he ihre¥i poin• hircft pivot palms, if gQtjipped.

INSTRUCTIONS

Section 9TDD.

Section 9100.

Operators Manual

Opera\ rs Manual

Ope atom Manual.

OP8ratOr& Manual

Check the t/rsl stage fun! filler f r water gr sediment. Ooerators Manual.

Check the level of the oil in the power snuffle.

Check tha levol of the coolant in ihe

CheCk the level of tne pil lp trjg' rggg'rygirr

LubrlCatg the lront Axle king plns

Lubri0ate the Ironr axle pivot.

L.ubric4te tho parking brake cross shaft.

Lunrlcaie the tie rgo anus.

L bri 6te the rear axIe bearings.

Chack the alr pressure and condition Of the lires

Check ihe level ef the oi'f in thetransoxle.

Operators Manual.

Operators Manual.

Operators Manual.

Opgratorg Manual. Section 6212.

INTERVAL SERVJCE

Evary100hoursof Check lha level of theoil ln the transfer

INST9JCTIONS

Op8r8lO 8 MediaI. operation(Con'i.) CaaB, If equipped

Glean thespark arrestedmuffler. ileqrilpped

Every N0 tioursof Lubricate lhe seat post-

Lubrlcaie mecablefortha parking brake.

Lubricate iheplvoisforthebrake pedals-

Lubflcate weIontan4rear pivotsfor the(rantdrivaay!e, ilequipped-

Cneck thelevalof theoil in thecancer yylandplanetariesotthefr0ntdriva acle. II equipped.

Glean ihebreathe-forthefront driy6axlg. ifequipc›ed

Cleanmabreathesforthetransfer case,

Clean the battery.

inch me iovelClf the fluid in lh4t JOw mainiananca oaMery.

Cneck trie tensionof ‹nedriveomit lor theairconotionercompressor.

Check tneoperg1ion of tn9apr c,ondiItoning system.

Tighten ihe nutsonthebackhoe mansion reds.

Change the engine oil.

Laplacetha flit+rfOf lie engiri6eiI

Gheck thelevalof theIIuId In Ihe brake maslercylinoers. {Not nscessary lor master CylinderswiihclaMprefgirJer8,

Cn0ck Erie I6VBIOf thecoolant in lhe

EverySIXIhoursof operation

Lugncatetheuniversal¡olnlsandtheslio jointonthelronrnnof+ardive Amir.

Lubrtcate theo••ot lormie transfercasecontrol lever.ilequipped.

Operators Manual.

Opera!o•s Manual.

Operaior¥ Manual.

Op6r6lOI'S MAñual.

OgeratorS Manual.

Op6ratora Menual

Operalor9 nual.

Section 4005

5ecrons00-

OperatorsManual

Operalers Manual

Sae WARNIMGon page1002-2.

Pggg 100Z-0.

DOWNLOAD SERVICE MANUAL

tNTERVAL 5|F#VlCE

Evory 30 hours of operation (¢On I .)

Lugricale ihe EouplJ/g for tna pump drive shaft.

I.r bric8ip the pivcjts for the IoaÖer control inver.

LLÎbrlcnto the pivols lo Ihe back hoe control feve•rs

LuDrica‹e il frsnt wheeT bearings.

Lubricaie the king pin5 (4\ for the frpnt o‹i e ax1a, if equ‹ppad

Peplacc tha fuel f|Iters.

Every 1ŒKI son rs o\ operation

Chuck1he leve cf the fiuio ir 1he mainierance fred oattery.

Service 1ha ROPS cab ,girfiI ler

Drain wa zr anc sedimcn i from the fuel tank

Change the oil ›r :ne powe• shut•le.

Glear› lha screeri in chu oowar shul!lo

Chef ge the h ygrac |io €/||.

Change the gear luoriEanT in ‹ne Iransaxle

Evary 2000 ho.ms of gparation or aah›* Y “!^ whichgvgr uCcurs firS1

E'•ery 4DOD hours of opera lion

Change thu genr Iuorir:ant in ff\q transfer casn, if equippeo.

FIuSLI Ihe cool ng syctem.

Replace tre drive belt for the Inn and tna aitorneiar.

Impact the fuel injection purrip.

Serviœ me air cleaner wner lne warning lam p for ihe air eleanor stays ill u i innien du ring operation.

Replaae !rio fllter for the riyoraulic sysrem when Ihe warn›ng lamp ’or ‹Aa killer s!ays i lum nated du‹Tng pperat on.

INSTRUCTIONS

Oporgtorg lnm mal.

0 ÇarRtOFs Manual.

Ope atora Manual0 peFNtOr5 k1.zn ual.

Section 34 TO.

seation aO0.a

sectlon 906 I

Operaiors Ma••ual

9CiiOP Û2O2

SgcHon 80DZ.

Op0ra1ors Manual

Operators r•Janr›aI

FluiÖ6 and L ub rioaa[S Char-

Section 34t,1

Sec!!on 800û.

lNTER\ł A}

SERViCE

j i@hien łFe neet acits •v+ry I›vt hsu•s 'Jfłt I tne wneel ho lx sfąy tigh‹ ‹›i wćeneuer a vyhaal I s removed and insiallen.

Tighten Ile nuls on Ihe tension rogs fCtr the lee o»everpiwo fiouWual'l lfiencnssiay hghf. gnO when i^sJIrg !he haCnhce Or new mounting prs.

Adjus1 łhe parking hraśe- SecWon 7lO6

COOLANT RECOVERY SYSTEM

50 Hour Check

C neck the level ‹›I tha coolant in lhe reservoir whan tea pngine is cold. I! iria cooIan1 Is Delow tha ADD mark, 8dd a m xt¿re wat is Sai* ethylene glycol anti LtgJf waler. If gi oteCtijgr' yg$ rs• f•eezir›g below-34•F (-37”C) i»rcquf•ed. usemoreethylene

ISO Nour Check

Cneck ihe level of ins cooian I In me r a aior xwhgn the gnging is cold- i| thB cOoI1nt is not even w‹tn the opening | n the radiator. add a Mixture of coolant accordir g io rs• uc•ions fo• he SO Hat r Checx.

II Ihe level of thn coolant In lhe r adiałor iS Jow. 'herocervoir nas now beenkept huh. thare idaIeak in