1st edition English September 2012

DOWNLOAD MANUAL

INTRODUCTION

Power Shuttle transmission

Power Shuttle transmission external controls

Power

Powered front axle

Front bevel gear set and dif ferential

Final drive steering and shafts front axle

Rear axle system

Powered rear axle

Rear bevel gear set and dif ferential

Planetary and final drives

Brakes and controls

Parking brake / Parking lock

Hydraulic service brakes

Pump control valves

Fixed displacement pump

hitch control valve

hitch cylinder

Remote control valves

Reservoir , cooler , and filters

Safety and main relief valves

Front loader bucket hydraulic system

T ool quick coupler hydraulic system

Rear hitch external controls

Frames and ballasting

Frame

Ballasts and supports

Steering

Steering control

Hydraulic control components

Cylinders

Wheels

Front wheels 1

Rear wheels

Cab climate control

Air conditioning

Electrical systems

Cab/Platform harnesses and connectors

Cab engine controls

F AUL T CODES

Front loader and bucket

Arm Bucket cab, and decals

Machine shields and guards

Protections - ROPS and FOPS

Cab

Safety rules DANGER

Improper operation service this machine can result accident. not operate this machine perform any lubrication, maintenance, repair until you have read and understood the operation, lubrication, maintenance, and repair information. Failure comply will result death serious injury

D0010A

W ARNING

Maintenance hazard!

Always perform all service procedures punctually the intervals stated this This ensures optimum performance levels and maximum safety during machine operation.

Failure comply could result death serious injury .

W ARNING

Pressurized system!

W0132A

Before attempting any service procedure, your responsibility know the number accumulators the and the correct procedure for releasing the pressure each accumulator

Failure comply could result death serious injury .

NOTICE: Extreme working and environmental conditions require shortened service

W0136A

Use Case fluids, lubricants, and filters for the best protection and performance your machine. All fluids, lubricants, and filters must disposed compliance with environmental standards and Contact your dealer with any questions regarding the service and maintenance this

Read the safety decals and information decals the Read the Operator ’ s Manual and safety Understand the operation the machine before you start any

Before you service the put a Not tag the steering wheel over the key Ensure the tag a location where everyone who might operate service the machine may see clearly One tag included with your new machine. Additional tags are available from your dealer .

Plastic and resin parts

• A void using gasoline, paint thinner , etc. when cleaning plastic parts, console, instrument cluster , etc.

• Use only water , mild and a soft cloth when you clean these

• Using gasoline, thinners, etc. can cause discoloration, cracking, deformation the part being cleaned.

Safety rules Ductile iron

DANGER

Improper operation service this machine can result accident. Any unauthorized modifications made this machine can have serious consequences. Consult authorized dealer modifications that may required for this not make any unauthorized modifications. Failure comply will result death serious injury .

Before you drill holes any part this make sure the part not cast ductile See your dealer you not know a part cast ductile The following are cast ductile iron parts:

• two wheel drive steering link

• dump links

• front axle

• Air Conditioning / compressor mounting bracket

Unauthorized modifications cast ductile iron parts can cause injury W drilling can cause cast ductile iron break. not weld, cut, drill repair attach items cast ductile iron parts this machine.

Safety rules

Before welding the machine you must the following. you have any questions about welding the machine contact your dealer

• Disconnect the

• Disconnect the alternator terminal

• Disconnect the instrument cluster

• Disconnect the engine control Disconnect all connectors from the engine harness the

• Disconnect the controller for the loader 4 1 bucket auxiliary hydraulics, equipped (one connector , located under the loader valve the rear , left derside the

DOWNLOAD MANUAL

Safety rules

Unless otherwise instructed, always perform these steps before you service the machine: Park the machine a level

Place the loader bucket the ground, with the bottom the loader bucket parallel the surface.

Place the direction control lever and the transmission you need open the hood perform raise the loader arms and install the support Shut down the

Place a Not tag the key switch that visible other workers remove the key

SER VICE MANUAL

Engine - General specification

Engine - Speeds stall test check sheet

Engine - Prepare for stall tests

Perform the stall test find the cause poor

The main relief valve must set within specifications achieve accurate readings when performing the following stall

The engine run full throttle and the transmission and hydraulic systems are engaged separately , and then gether .

Comparing the engine speeds from the stall test with the check sheets this section will help find the cause the problem. can necessary check a separate system find the exact cause the problem.

Use a photo tachometer other tachometer equal accuracy get accurate results from the stall

The transmission and hydraulic system must operating temperature before doing the stall Heat the oil according instructions this

Machines with standard transmission

NOTE: Check the throttle linkage

Apply the parking

Move the transmission gear selector into fourth gear

Lock the brake pedals together Put your foot the service brakes and hold the machine with service

Release the parking

With the engine running low move the tion control lever

Slowly increase the engine speed full the machine begins move any decrease the engine speed low idle and stop the

Procedure heat torque converter and hydraulic oil

Apply the parking

Start and run the engine low

Run the engine full hold the loader control lever the rollback position for

Return the loader control lever neutral for

Repeat steps 3 and 4 until the temperature the oil ( 126 ) The side the reservoir will very warm this

With the engine running low move the mission control fourth gear and the direction trol lever

Run the engine full throttle for seconds.

Decrease the engine speed low idle and move the direction control lever neutral for

Repeat steps 6 through 8 until the pointer the gauge for transmission oil temperature the ter the green zone the gauge for transmission oil

Stall test procedure

Prepare the machine for the stall test according instructions this

Heat the oil according instructions this

Apply the parking brake and start the

With the engine running full hold the loader control lever the lift position and read the ter Record the reading line 1 the check

Decrease the engine speed low

Move the transmission control lever fourth gear

Lock the brake pedals together Put your foot the service brakes and hold the machine with service

Release the parking

Move the direction control lever

Slowly increase the engine speed full throttle and read the tachometer Record the reading line 3 the check sheet.

1 With the transmission control lever fourth gear , the direction control lever forward, and the engine ning full hold the loader control lever the lift position and read the tachometer Record the reading line 4 the check

Decrease the engine speed low move the directional control lever

Run the engine low idle for two minutes and then stop the

See the check sheet understand the results the stall test.

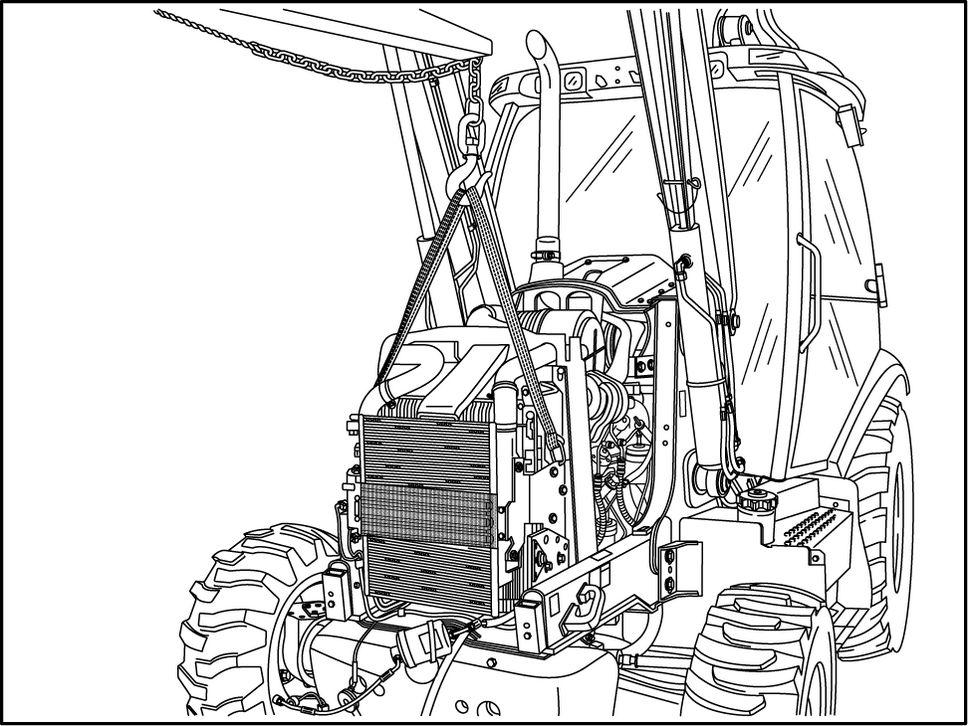

Engine - Remove

Prior operation:

Drain the hydraulic

Prior operation:

Disconnect the

Prior operation: Remove the engine

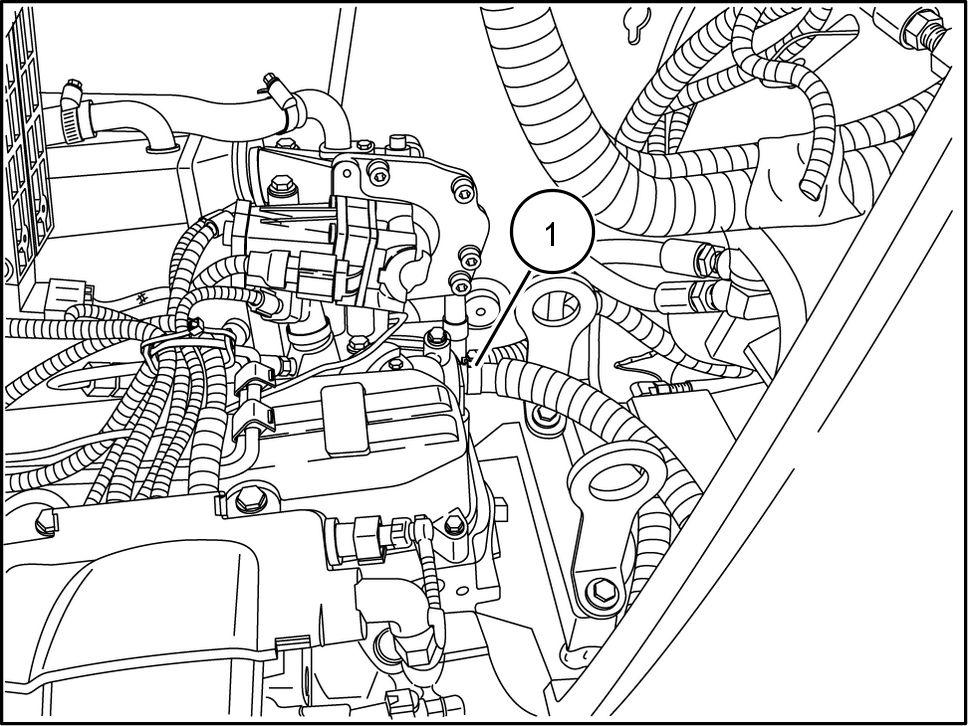

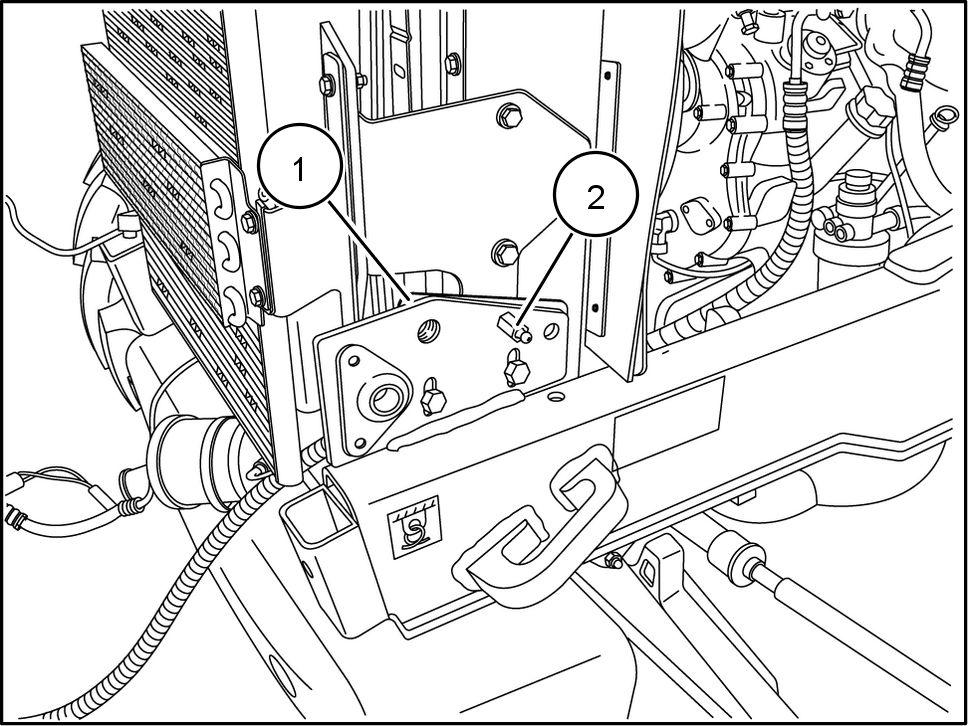

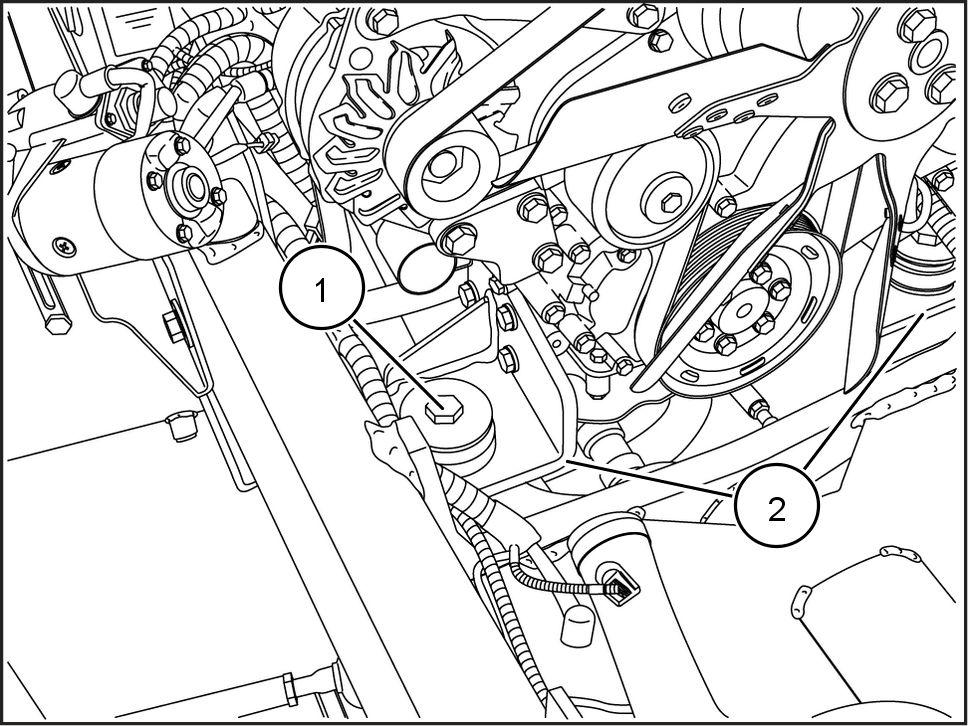

Remove the air intake tube support bracket bolts (1) and bracket (2)

Disconnect the A / C condenser inlet line (1) .

Disconnect the inlet fuel cooler line (2)

Disconnect the outlet fuel cooler line (3)

Disconnect the A / C condenser outlet line (4)

Remove the horn bracket nut (1) Place the horn and horn bracket away from the cooling

Loosen and remove the receiver / dryer hold - down clamps (1) Place the receiver / dryer away from the cooling package.

Support the cooling package housing wrapper

Remove the cooling package housing wrapper bolts (1) , (2)

10. Carefully lift and remove the cooling package ing wrapper

1 Label and disconnect the hydraulic oil hoses (1) ing the hydraulic oil cooler

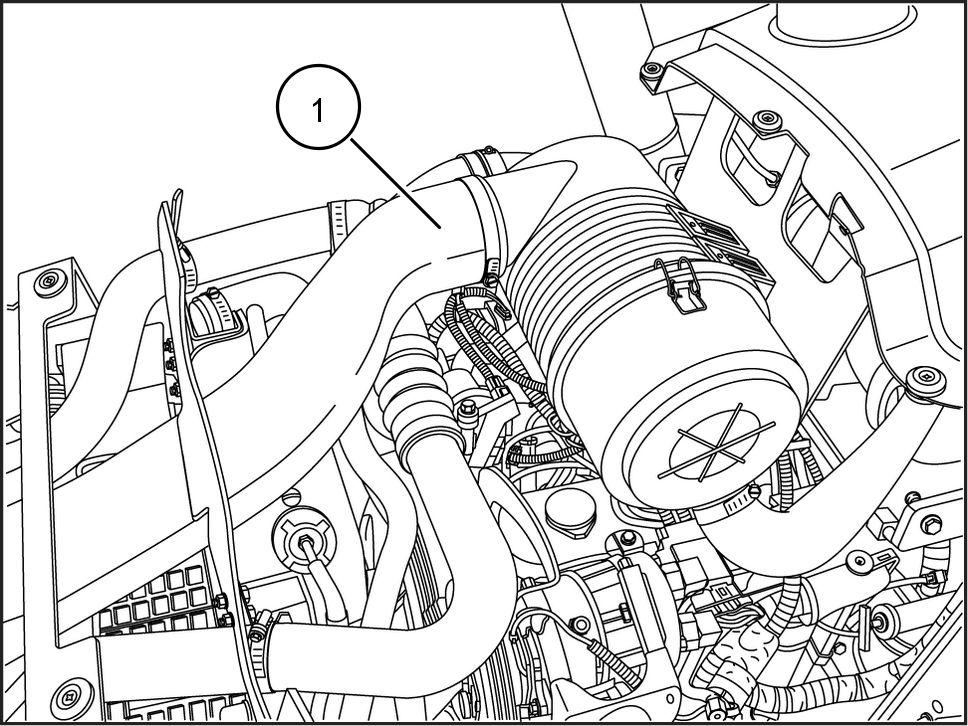

Disconnect the air intake tube (1) from the air cleaner

13. Disconnect the lower radiator hose (1) from the ator

Label and disconnect the transmission oil cooler hoses (2) leading the transmission oil cooler .

Disconnect the turbo outlet tube (1) the

16. Disconnect the upper radiator hose (2) from the diator

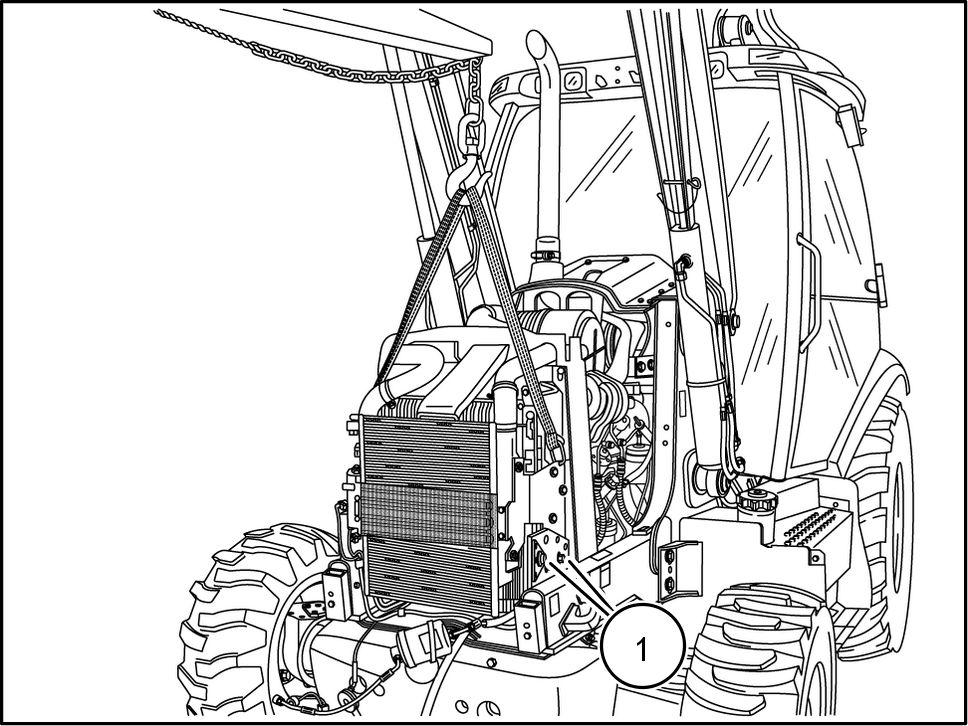

Support the cooling package using lifting

18. Remove the hood strut post (2) and retainer (1) .

Remove the cooling package retaining bolts (1)

Carefully lift and remove the cooling

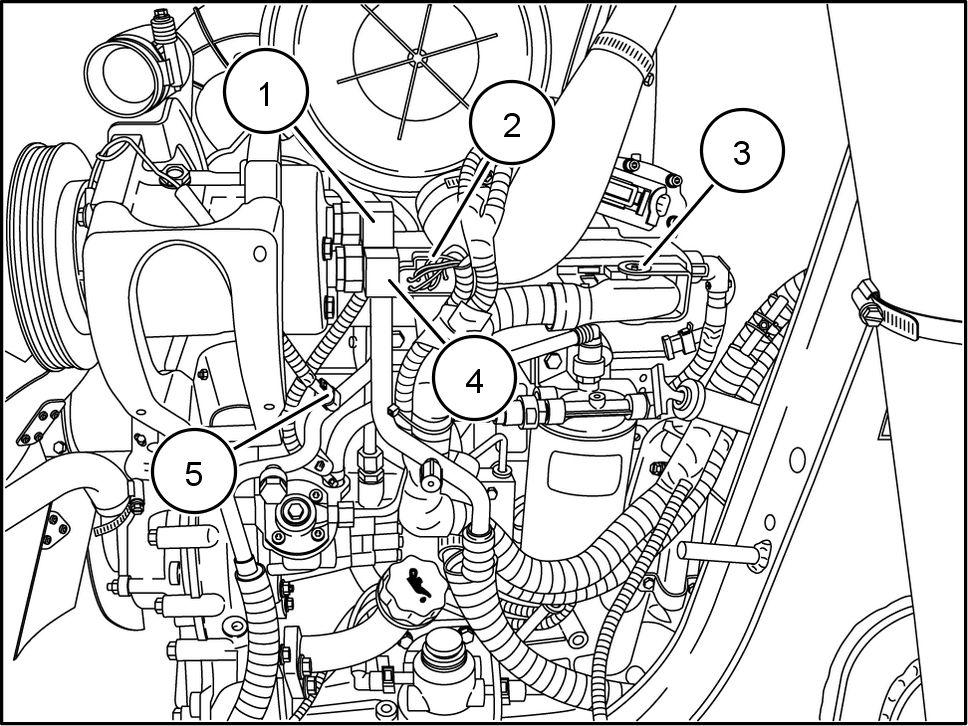

Disconnect the A / C high pressure line (1)

Disconnect electrical connectors (2) and (3)

22. Disconnect the A / C low pressure line (4) .

23. Disconnect the A / C condenser voltage wire (5) .

24. Disconnect fuel lines (1) and (2) .

Disconnect the water sensor electrical connector (not

NOTE: W ater sensor located the bottom the primary fuel filter

Remove the diesel particulate filter (DPF)

See Particulate filters - Remove (10.501)

Remove the DPF tray (1)

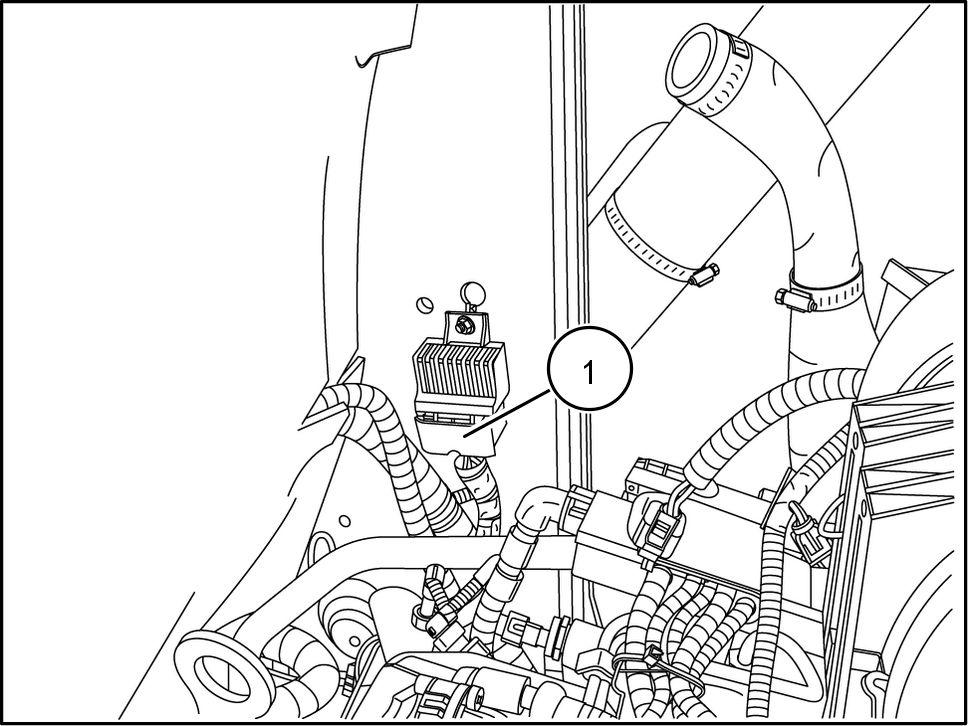

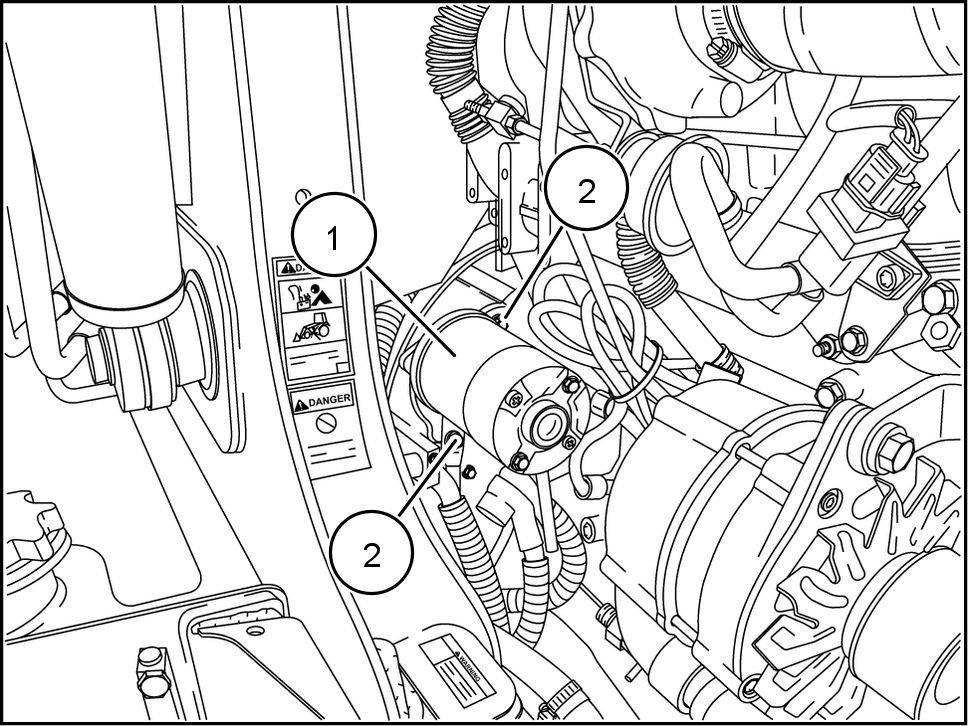

Disconnect the glow plug control unit electrical nector (1) .

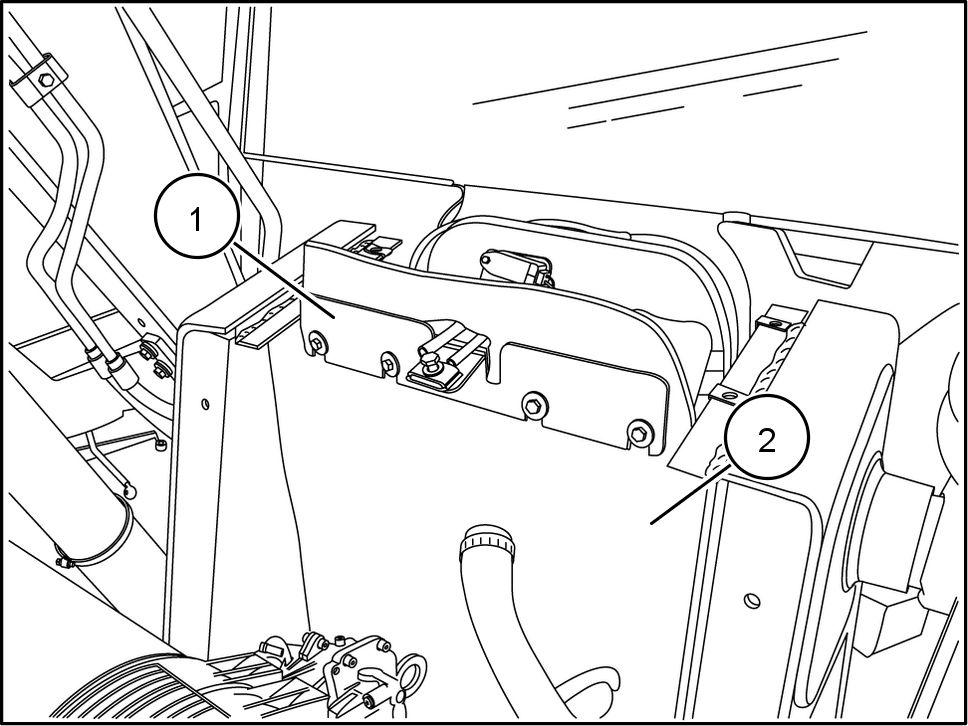

29. Remove the supporting bracket (1) and hanging rier curtain (2)

Disconnect the heater hose (1)

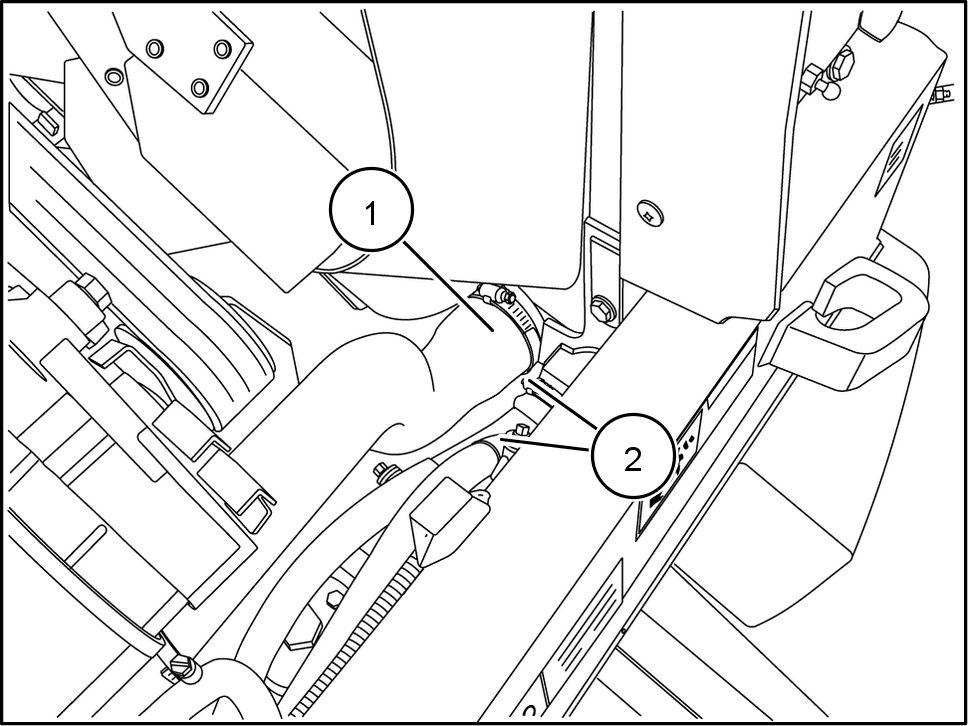

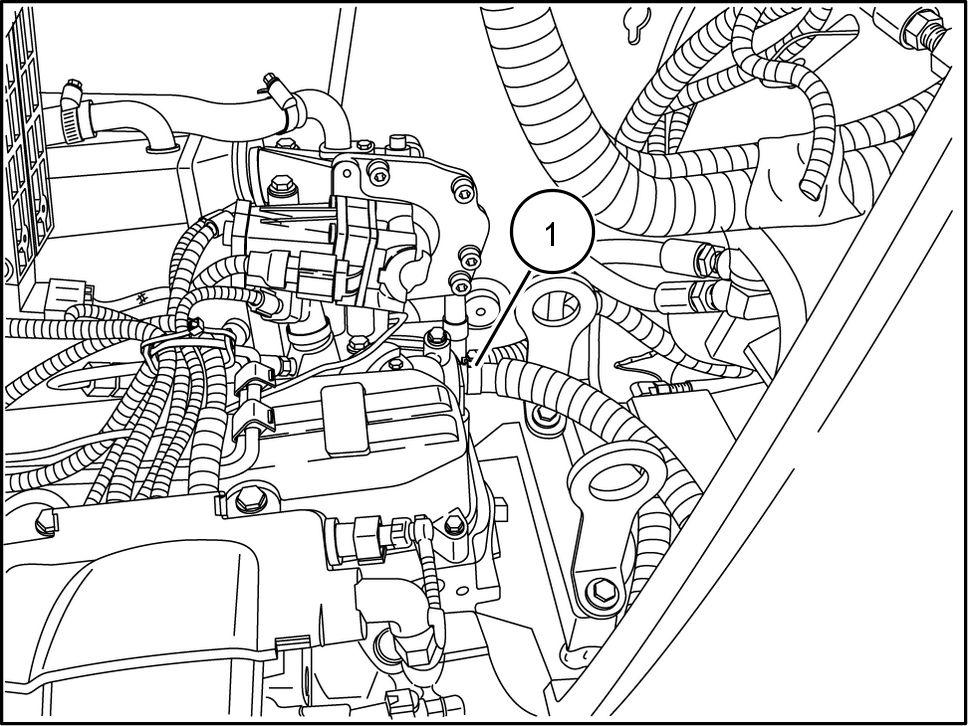

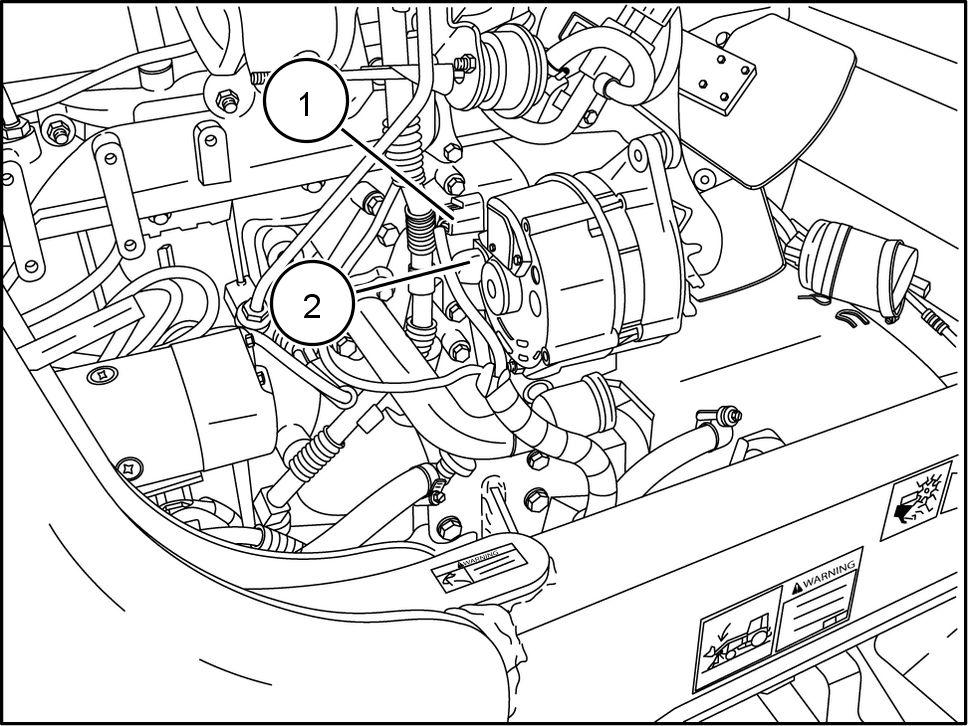

Label and disconnect the air sensor wires (1)

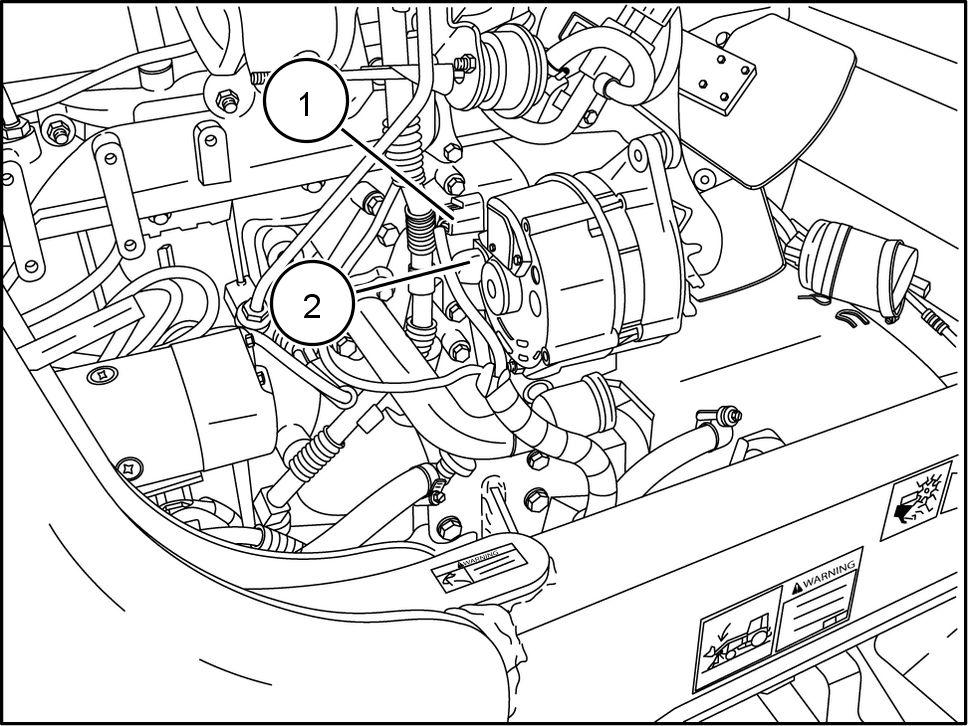

Label and disconnect the alternator electrical nector (1) and the alternator battery wire (2)

Remove the starter (1)

Remove the button plug and the insert flywheel ing part number 380000988

35. Remove the cover . T urn the flywheel using the wheel turning tool expose the flywheel bolts (1)

Remove the flywheel bolts (1)

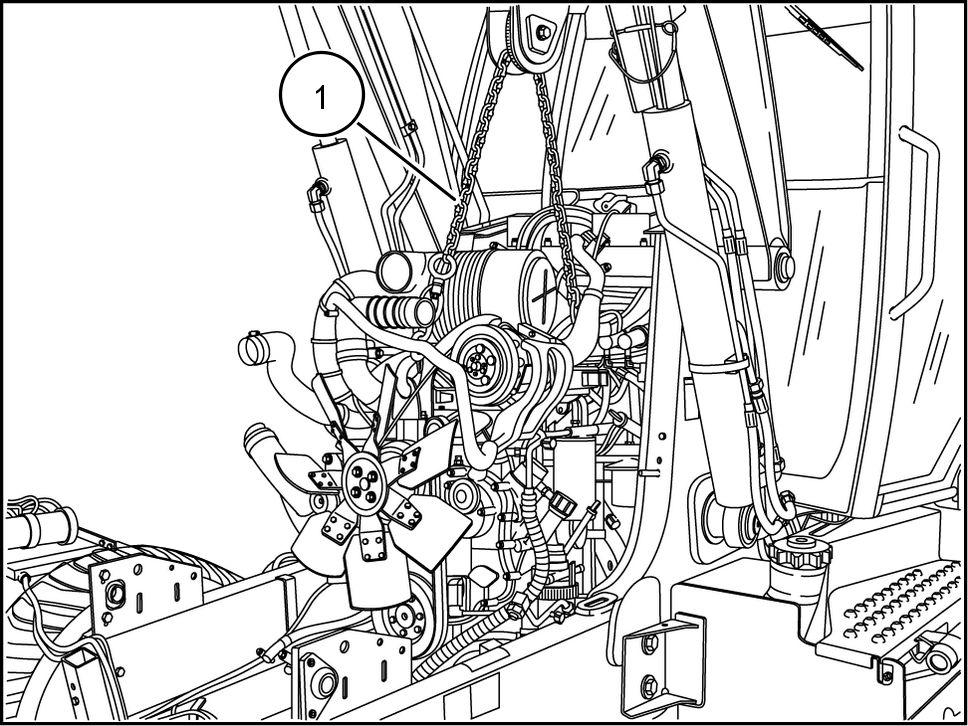

Support the engine using lifting

Removing the engine mounts (1)

NOTE: Lower radiator hose removed for picture clarity

38. Remove the bell housing bolts (1) .

Carefully lift and remove the engine from the

Engine - Install

Carefully lower the engine into the

1

Install the bell housing bolts (1) T ighten the bell housing bolts (1) a torque - ()

Install the engine mounts (2) T ighten the mounting bolts (1) 212 - 241 N·m ( 156 - 178 )

NOTE: Lower radiator hose removed for picture clarity

Remove the lifting equipment (1) .

Install the flywheel bolts (1) . T ighten the flywheel bolts N·m ( )

Install the bell housing flywheel bolt cover and button

Install the starter (1) T ighten starter bolts (2) a torque N·m ( )

Connect the alternator electrical connector (1) and the alternator battery wire (2)

Connect the air sensor wires (1)

Connect the heater hose (1)