This year marks a truly special milestone – 50 years of Canford. Reaching half a century is not only a moment to celebrate, but also to reflect on the remarkable journey that has brought us here. From our beginnings in 1976 as a small team with a shared passion for audio engineering, to becoming a trusted name recognised across the global broadcast and live events industries, Canford’s story has always been about innovation, collaboration, and a commitment to doing things the right way.

YEARS OF CANFORD

YEARS OF CANFORD

YEARS OF CANFORD

Over the decades, we’ve seen huge changes in technology, customer expectations, and the way our industry works. Yet through it all, one thing has remained constant - our dedication to supporting fellow industry professionals. Whether it’s designing and manufacturing our own products, distributing trusted brands, or offering the

technical expertise that underpins every project, we’ve always aimed to provide solutions that people can rely on.

This special 50th anniversary edition of Source Material celebrates not only our history but also the people behind it – our customers, colleagues, and partners who’ve helped shape Canford into what it is today. It’s also a reminder that our story is far from over.

As we look ahead, we remain focused on the same principles that have guided us since the beginning –listening, adapting, and innovating to meet the needs of a constantly evolving industry.

To everyone who’s been part of our journey so far, thank you. Here’s to the next 50 years of Canford.

Alan Wilson, CEO, Canford Audio

60 Raising the Standard in Commercial Audio: Cloud Electronics CS-S Series Speakers.

Do More with DM3: The Compact Console that Redefines Versatility.

ELC LIGHTING: DMX for the Engineer.

Austrian Audio OC-S10 — A New Reference for Modern Studios. 70 Linearizing Microphones: CORE+ by DPA.

From Spectrum to Sound: The Technologies Powering Wireless Audio.

RØDE: From Audio Innovators to Creator Tech Powerhouse.

Power with Intelligence: HEDBOX Redefines On-Set Energy with the NINA Series.

Andy Dixon Joins Canare to Drive UK Business Growth.

USB-C Cable Solutions from Lindy One Connector. Infinite Possibilities.

Mackie – Thirty Years of Innovation.

Zurich Extreme Sportsman Makes History: First Ever Kitesurf Crossing from China to Taiwan.

SKB Cases: Protection Without Compromise.

Reaching a 50 year milestone is no small achievement, and at Canford Audio it’s a moment we’re all immensely proud of. In 1976, with little more than a vision, a £2,000 bank loan, and a £1,000 overdraft, a young sound engineer named Iain Elliott set out to change the audio industry. What began as a small, independent PA hire company in the North East of England has grown into one of the most respected names globally in professional audio and broadcast equipment. Our journey has been shaped by innovation, resilience, and the dedication of our people. This anniversary isn’t just about looking back at what we’ve built and achieved over the last 50 years, it’s also about recognising the trust of our customers, the talent of our colleagues, and the values that continue to drive us forward as a business. We thought we’d take a look back at how it all started, and all the events that have taken place since then to get us to where we are today.

By Ben Hardy, Marketing Manager at Canford

Early Years: 1974 – 1980s

Fresh out of university in 1974, Iain Elliott worked at Metro Radio for 2 years and he quickly spotted a gap in the market – there was no dedicated supplier for the fast-growing commercial radio industry. Two years later, Canford Audio Limited was born.

The company’s very first job was to supply a sound system for Seaburn Hall on July 1st, 1976. This was the modest start of something much larger, and by 1979, Canford was exhibiting at its first ever trade show at London’s Connaught Room, with a stand borrowed from the radio station and homemade graphics.

Growth soon followed. The team upgraded from a small storage shed in Corbridge to larger office space in Stargate, Ryton. Then in 1981, Canford launched the first edition of its catalogue, which soon became known across the industry as “The Industry Bible”. At its peak, 26,000 copies were printed, with the final edition tipping the scales at an impressive 2kg!

By the company’s 10th anniversary in 1986, turnover had reached £1.5 million. Canford celebrated a decade of operation by acquiring the established Technical Projects intercom range, now known as Tecpro. With continued growth and expansion, space was tight and the move to a new HQ in Washington soon followed in 1987.

Expansion and Innovation: 1990s – 2000s

A landmark moment came in 1992 as Canford won the contract to become a primary supplier to the BBC for broadcast equipment. This was a huge moment for Canford and cemented the company’s reputation as a highly trusted and respected supplier. The partnership not only brought prestige, but also stability as the BBC went on to become Canford’s biggest customer and continues to be to this day.

After continued growth in the years that followed work began on extending the existing building in 1994. By 1995, the building work was complete, effectively doubling the size of the Washington HQ.

In 1996, Canford acquired NEAL, a respected manufacturer of professional audio recording equipment. Used by law enforcement organisations worldwide, NEAL’s specialist expertise in voice recording systems complemented Canford’s growing product portfolio, strengthening its position in the industry and broadening the solutions offered to customers.

1998 became a pivotal moment in Canford’s history, as it marked the launch of the company’s first ever website. In an effort to embrace the digital age, Canford recognised the need to offer what would essentially end up being a digital version of the existing printed catalogue. This move gave customers a new way to order items from Canford, whilst also providing Canford themselves with a new route to market.

The 90s was rounded off by another huge part of Canford’s history –the acquisition of Swift Precision Engineering in April 1999, along with its manufacturing site on the Isle of Portland, Dorset. This move raised a few eyebrows at the time given that Swift’s latest figures suggested it was on a downward trend, however Iain

Elliott saw this as a major opportunity to increase Canford’s manufacturing capability and explore new markets further afield. Today, the Portland site remains an essential part of Canford’s infrastructure handling a vast range of standard custom metalwork.

The 00s also saw the addition of 2 more recognisable Canford brands – EMO in 2000, and Panamic in 2007. The acquisition of both these companies completed the Canford Group as we know it today consisting of Tecpro, NEAL, EMO and Panamic.

The new decade brought with it fresh directions. In 2012, Canford made the difficult decision to retire its iconic catalogue to focus fully on its growing online presence. With the greater reliance from customers on online functionality, the company believed this was the right decision to develop the website further and established itself as a reliable online source. The move also reinforced Canford’s commitment to introduce greener and more sustainable practices.

In 2015, Canford expanded its international function further by opening its Dubai office. This marked a huge step forward for the business in the wake of its 40th anniversary. Canford had been exporting products to the region for over 20 years, and with business growing in the area a decision was made to provide partner support on a local level.

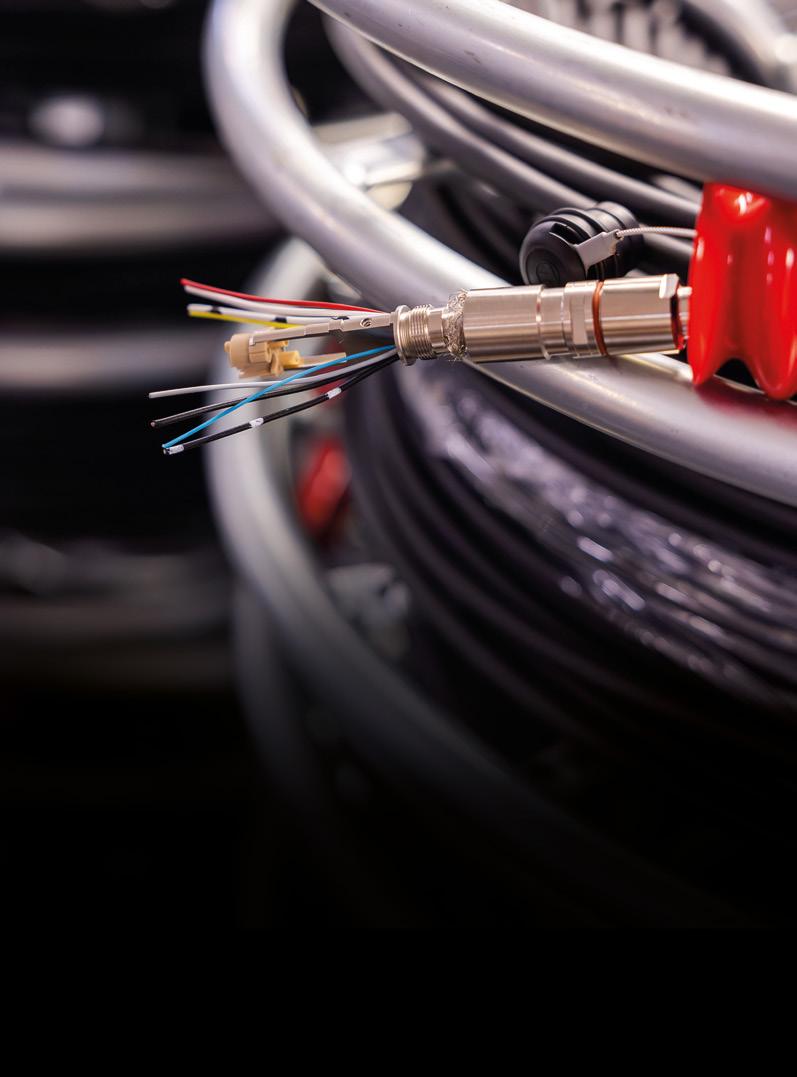

Back in the UK, 2016 marked a double milestone - the launch of a new production workshop, home to the innovative Cable Cell, as well as the 40th anniversary, celebrated with a week of activities, prizes, and celebrations for staff. That same year, Canford also began offering a fibre termination service, setting the stage for the next era of connectivity.

At its peak, 26,000 copies were printed, with the final edition tipping the scales at an impressive 2kg!

New Horizons: 2019-Present

In 2019, Canford transitioned into an Employee Ownership Trust (EOT). This bold step was more than just a change in structure; it was a commitment to the people who had built and sustained the business over decades. By placing the future of the company in the hands of its employees, Canford ensured that decisions would always reflect the values, expertise and dedication of those who know it best. For founder Iain Elliott, this move also carries a personal significance. Iain was determined that Canford should remain in the North East of England, the region where it all began. The shift to employee ownership safeguarded Canford’s independence, reinforced its culture of collaboration and shared responsibility, and empowered its workforce to carry the business confidently into the future. Sadly, in December 2021, Iain Elliott passed away at his Northumberland home following a short battle with cancer. Tributes to Iain and his family rang out across the industry, recognising his achievements at Canford and the contributions he made to the world of broadcast and pro audio.

From a small PA hire in Sunderland to a global name in professional audio, Canford’s journey has always been guided by innovation and a deep commitment to its customers and people. Reaching 50 years is not only a moment to celebrate the past, but also to look ahead with confidence. As new technologies shape the way the world connects and communicates, Canford remains focused on delivering reliable solutions, sustainable practices and unmatched expertise. The tools and markets may evolve, but the spirit of Canford will continue to drive the business into the next half century and beyond.

1976

The company’s very rst job was to supply a sound system on 1st July.

1979

Canford exhibits at its rst trade show.

1987

Canford moves to a new HQ in Washington.

1988

Canford France opens.

1994 - 1995

Extension of the building.

1997

Canford celebrate 21st anniversary.

1999

Acquisition of Swift Precision Engineering.

2006

Canford celebrate 30th Anniversary.

2015

Opening of the Dubai o ce.

2017

Warehouse expansion.

2019

Canford transitioned into an Employee Ownership Trust (EOT).

2022

Canford connect brand launched.

2026

Canford celebrate 50th anniversary. 1 0 s 2 0 s 00 s 8 0 s 9 0 s 7 0 s

1974

Iain Elliott spots a gap in the marketthere was no dedicated supplier for the fast-growing commercial radio industry.

1981

Canford launched the rst edition of its catalogue.

1986

Acquisition of Technical Projects (tecpro) and celebrate the 10th anniversary.

1992

BBC contract.

1996

Acquisition of NEAL.

1998

Canford launch the website.

2000

Acquisition of EMO.

2007

Acquisition of Panamic.

2012

Canford made the di cult decision to retire its iconic catalogue.

2016

Canford celebrate the 40th anniversary with the launch of the new bre department and production workshop, home to the innovative Cable Cell.

2020

Fibre expansion.

2024

2021

Iain Elliott sadly passed away.

Solar Panel project complete.

Neutrik and Canford Audio: two instantly recognisable stalwarts of pro audio and broadcast engineering supply chains. Two companies, that in 50 years have grown in tandem, their fortunes and development often complementary and mutually assured. Yet, after half a century, it is not so widely remembered just how much of a shared experience their origin stories actually are.

As Neutrik moves to the close of its 50th anniversary celebrations and Canford’s are about to begin, we look back to a frenetic and innovative foundational past and forward to an ever more rapidly expanding innovative future, involving levels of technological and engineering development that we could barely have imagined in 1975 - 1976.

At the same time as Iain Elliott, founder of Canford Audio and the man who led the company for some 45 years, was a young broadcast engineer on the launch team for one of the first independent commercial radio stations in the UK in 1974, Bernard Weingartner, was working as a design engineer at AKG Vienna. While working on signature models like the C-414, he noticed a growing preference amongst professional engineers for the XLR type connector, as a more robust solution, far better suited to the every day stresses of production studio applications. He also noted that there were no European based companies making these connectors. The rest, as they say, is Neutrik history. Just a year later, in a farmhouse barn in Liechtenstein with its first

employee, fellow design engineer Werner Bachmann, Weingartner’s newly formed Neutrik AG company began not only manufacturing XLR connectors but innovating patented improvements in their design and manufacturing. Replacing fidgety assembly screws with a threaded rear cover and three-sided stress relief, these rapidly started gaining widespread popularity, making life far easier for cable assemblers and application engineers everywhere. Before long Neutrik had an order from a national European broadcaster for 5,000 of its new XLR connectors, in part to upgrade its significant stock of AKG microphones.

In the UK AKG’s distributor, Eardley Electronics Ltd, took on the UK sales and distribution for Neutrik’s new XLR connector series in 1976. As

AKG distributor, Peter Eardley, had done business with Iain Elliott when he was engineering studio facilities for the nascent Metro Radio back in 1974. Now that same engineer had set up his own broadcast supply company.

Canford Audio arose out of Iain Elliott’s realisation, while working at Metro, that there might be a market in supplying “bits and pieces for radio stations” to people like himself – a broadcast audio one-stop shop; and having set up the shop in the small town of Ryton in Tyne and Wear, that was rapidly proving to be the case. Canford Audio was going to go on to play a major role with Eardley Electronics, in establishing and growing markets for Neutrik AG’s burgeoning product portfolio in the UK. In 1977 the range expanded to include chassis connectors, once more innovating improved design features and reducing engineering complexities to enable far greater ease of use, manufacturing and assembly. By 1984 the new X-Series had eliminated all the screws in the connector design, in another industry first. At the same time the company expanded its portfolio to include measuring equipment with the introduction of the Audio Tracer compact frequency chart recorder in 1977, and later the AudioGraph ink-pen recorder, A1 and A2 analysers, and the pocket-sized Minirator generator and Minilyzer analyser. These developments effectively formed an electro-acoustic division within the company.

applications across a multiplicity of manufacturing, construction, commercial and civic industrial sectors. However, the prospect of Neutrik AG, a Swiss registered entity, buying out a UK business presented a number of legal and regulatory hurdles that would have made the acquisition a protracted affair. So in a gentlemen’s agreement between Bernard Weingartner and Iain Elliott, Canford facilitated the purchase for the board of Neutrik AG. This subsequently resulted in the formation of Neutrik (UK) Ltd., Neutrik AG’s first overseas subsidiary, developing and manufacturing existing and new audio measuring and test systems as Neutrik Test Instruments, and later introducing production lines for Neutrik connector lines on-site.

“Canford has worked closely with Neutrik for almost our entire existence and we will continue to do so. Many Canford products that we manufacture here at Washington use Neutrik connectors”.

Alan Wilson - Canford CEO

In 1986 that line of expansion led to Neutrik being interested in acquiring a UK specialist electronics company based in Cowes on the Isle of Wight. Technical Projects’ business was the manufacturing of audio / noise measuring systems for a range of

Meanwhile Canford introduced what was to be its most famous and widely appreciated marketing strategy with the launch in 1981 of its famous catalogue. Officially titled ‘The Source’ but more affectionately termed the Big Blue Book, it became an indispensable tool throughout the TV and radio broadcast, film and audio and video production industries. Over almost 30 years and 44 editions, the catalogue grew from 24 to 1,500 pages and a major sales and marketing channel for Neutrik products in the UK; its pages a source of promotion for an ever increasing number of Neutrik innovations and industry firsts. These included entirely new product types like the speakON – introduced in 1987 to provide new levels of safety, reliability and performance in the connectivity of power amplification

and loudspeaker systems, required under an EU Low Voltage Directive, not provided by existing banana plug and ¼ inch jack solutions. The design went beyond new specification requirements providing a twist-locking mechanism and solderless terminations within a near-indestructible form factor. Also highly innovative was the introduction, in 1992, of the Combo. Placing a ¼ inch jack insert within a female XLR receptacle, it inaugurated yet another new connectivity standard, enabling the use of older or semi-pro kit within a pro-audio setup. But it was perhaps the introduction, in 1996, of the twist locking AC powerCON connector, with its pre-mating ground before power connectivity feature that represented the most universally significant innovation, representing a hugely significant improvement in single phase mains power supply connectivity for all forms of mobile and event production applications; and many other wide-ranging industry field applications. And in 2001 Neutrik focussed its innovative design and manufacturing skills on the ever expanding requirement for IP connectivity in the field with the introduction of its etherCON product, providing XLR levels of rugged and reliable connectivity of RJ-45 terminated Cat-5 / Cat-6 cabling.

These and many subsequent product innovations – several of them award winning – have grown to become discrete product categories, including in the field of fibre optic transmission where the company’s opticalCON and FIBERFOX product series are breaking new ground in harsh environment AV network applications. Today you won’t find these in the Canford catalogue

but on their hugely expansive website directory. This however is not the only Canford product on which you will find Neutrik products. Canford Audio itself is a Neutrik customer, employing Neutrik connectivity solutions in much of its own extensive manufacturing output of cable and devices; including products often designed by itself to provide industry solutions not available from other manufacturers.

“Canford has worked closely with Neutrik for almost our entire existence and we will continue to do so. Many Canford products that we manufacture here at Washington use Neutrik connectors,” says Alan Wilson, Canford’s CEO, “the reason for this is the quality and reliability that you get with Neutrik. It is a well-known

and respected name in the broadcast market that we both operate in so, it has become a perfect partnership stretching for almost 50 years!”

As the two companies celebrate their respective 50th anniversaries, they remain closely associated. Mark Perrins, Managing Director of Neutrik (UK) Ltd, puts it concisely, “As Neutrik celebrates its first 50 years and Canford Audio looks towards marking their same event, it provides a great opportunity to reflect on the very close and longstanding relationship the two companies have always enjoyed. In particular to recognise their hard work in convincing the market and supporting our early sales success. Neutrik has relied heavily on the strong relationship and continued

efforts of Canford to spread the word and incorporate Neutrik connectors as its ‘go to’ solution for its customers. The continuing relationship of two very strong brands in the professional audio, video and lighting and broadcast markets is a testament to the quality of product and service offered, and a great example of continued cooperation through the best and worst of times. We look forward with great hope to the next 50 years of this great partnership in our industry.”

By Ben Hardy, Marketing Manager at Canford

As Canford celebrates its 50th anniversary, it’s not only a time to look back at the milestones that have defined our journey, but also to recognise one of the most significant steps in our recent history – becoming an Employee Ownership Trust (EOT).

In 2019, Canford Audio joined a growing number of forward-thinking UK businesses choosing to secure their long-term future through employee ownership. The move ensured that the company’s independence, values, and culture would remain firmly in the hands of the people who make it what it is: its employees.

For Canford, employee ownership wasn’t just a financial or structural decision, it was a natural evolution of a philosophy that has always placed people at the heart of the business. From its earliest days, Canford has been defined by a sense of shared purpose. Engineers, designers, warehouse teams, salespeople, and managers are all working together with a common goal – to support the professionals within our industry.

Under the EOT model, every employee is a beneficiary of the trust that owns the company on their

behalf. This means the success of the business directly benefits the people who contribute to it every day.

“The transition to employee ownership was about securing Canford’s independence and ensuring the business continues to be run with the same integrity and commitment to quality that it always has,” explains CEO Alan Wilson. “It reinforces the idea that our people aren’t just working for Canford – they are Canford.”

That sense of collective ownership has only strengthened the company’s culture. It has encouraged even greater collaboration, transparency, and pride across every department. From developing new products and refining customer service, to investing in training and sustainable operations, decisions are shaped by a long-term mindset, and focused on stewardship rather than short-term gain.

Employee ownership has also proven to be a powerful differentiator in attracting and retaining talent. In an industry where expertise and consistency are key, the EOT structure helps ensure that knowledge stays within the company and that everyone is invested in maintaining the highest standards of service and craftsmanship.

As Canford marks 50 years in business, the EOT stands as both a tribute to the company’s founders and a promise to its future. It safeguards the independence that has always defined Canford while empowering a new generation to take the business forward with confidence.

50 years on, Canford remains as committed as ever to its customers, partners and people. Employee ownership simply puts that commitment into the company’s DNA, ensuring that every achievement, every innovation, and every success is shared by those who made it happen.

DMH720-ANC HEADPHONES - PRECISION LISTENING MEETS TOTAL ISOLATION

• Active Noise Cancelling (ANC) - Enjoy immersive sound with ANC automatically enabled when powered on.

• Extended Playtime - Up to 30 hours of ANC listening on a single charge.

• Fast Charging - Fully charges in under 2.5 hours via USB-C.

• Comfort-Fit Design - Lightweight circumneutral (over-ear) earcups and soft padding for long listening sessions.

• Precision Audio Performance - 40mm dynamic drivers delivering a balanced 20Hz–20kHz frequency response.

• Reliable Monitoring Quality - 32Ω impedance and 97dB sensitivity for accurate sound reproduction.

• Long Standby Time - Up to 280 hours when not in use.

• Versatile Connectivity - Includes 3.5mm audio cable, ¼” jack adapter, and USB-C to USB-A charging cable.

• Convenient Portability - Supplied with a protective carry case for storage and transport.

• Lightweight Build - Only 245g for all-day comfort.

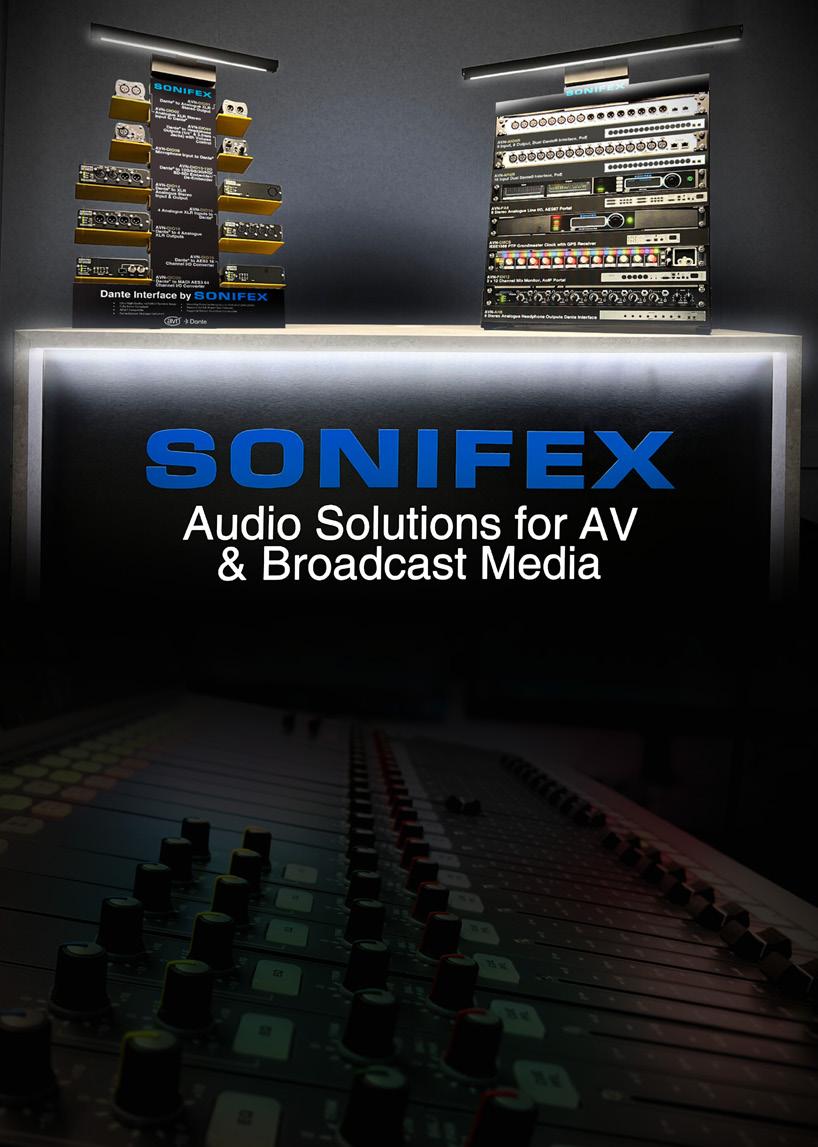

We’re a proud British company with heritage dating back to 1969, specialising in professional audio equipment

Amplifiers

Audio Monitors

Audio Signal Management

Clocks & Synchronisation

Commentary

Mixing

Dante Convertors

Embedders & De-Embedders

GPIO & Control

IP Streamers

Logging

RAVENNA AoIP

Passive Interfaces

Radio & Sound Cards

LED Studio Signs

Silence Detectors

Talkback IFB & Intercom

Telephony

By Gareth Laughton & Eamonn Heffernan at Sonifex

When Canford opened its doors five decades ago, it set out to be more than a supplier - it rapidly became a steady, trusted partner to engineers, installers, and broadcasters across the UK and beyond. As a testament to their success, the Canford catalogue quickly became one of the most popular go-to publications in the industry.

At Sonifex, we’re proud to have stood alongside Canford for most of that journey, supplying products and collaborating closely on projects to bring dependable, practical solutions to customers. That steady presence, responsiveness, and the hard work of their distribution team have made it possible for both companies to deliver products and projects reliably, on time, and to specification.

Shared history, complementary strengths

Sonifex began with a simple brief: to design and build high-quality, ultrareliable, professional audio products to solve real-world problems. Durability, transparent audio performance, and intuitive operation remain at the heart

of our design brief from day one. Canford complements that approach by curating the right solutions, backed by expert advice, consistent stock management, and reliable logistics. Their distribution team deserves special mention for their diligence in proposing the right products, often with tight deadlines, removing the risk for integrators, and keeping installations on time and within budget.

In September, at the IBC show in Amsterdam, UK North Sales Manager, Eamonn Heffernan presented Alan Wilson, CEO of Canford, with the ‘UK Distributor of the Year’ award for 2024/2025 as a token of our gratitude for Canford’s continued sales and support of Sonifex products.

Sonifex past, present & future Innovation runs through Sonifex’s DNA. From NAB cartridge machines with servo-controlled pinch systems in the 1980s to high-tech floppy disk cart players in the 1990s. With a continued focus on radio studios, the lineup included call handling products such as the highly successful HY02 telephone hybrid units (1989), HDX2000 hard-disk automation playout systems (1994), and the Sovereign analogue broadcast consoles (1995). Later milestones include the Courier portable PCMCIA/flashcard recorder (1997), the renowned Redbox audio interface family (from 1999), Net-Log 24/7 audio loggers (2001), S2 mixing desks, and D:Scribe transcription system (2004), and the Reference Monitor range (2008–09). Throughout these developments, Canford has been a valuable ally, helping Sonifex reach studios and users in the UK and in many countries around the world via its huge customer base. The 2010’s saw the rise in demand for AoIP products, with Dante and RAVENNA solutions reshaping the market by bringing broadcast, AV, and related industries closer together - opening new opportunities and increasing competition. New AoIP solutions keep the hardware market evolving. At Sonifex, we remain project-focused and customer-driven, and proud that Canford continues to be a key distribution partner.

Having worked with Canford for many years, Eamonn praised the company, saying, “Dealing with Canford for so long has been a real pleasure. Like Sonifex, Canford has many longserving staff members that we’ve got to know quite well over the years. We sincerely hope the special relationship we enjoy continues to grow for many years to come”.

Navigating new workflows together

The next chapter in Pro AV and broadcast will be defined by cloud workflows, remote production, and tighter IP integration. Sonifex and Canford are already working to make

that transition manageable: products designed for interoperability, and a distribution partner ready to support. By combining Sonifex’s engineering focus with Canford’s steady logistics and practical systems expertise, customers can adopt new workflows with minimal disruption.

To mark Canford’s 50 years, we celebrate a partnership that’s more than commercial - it’s built on shared commitment and everyday reliability. Here’s to the next 50 years of working together: practical engineering, dependable distribution, and the people who make it happen.

“Dealing with Canford for so long has been a real pleasure. Like Sonifex, Canford has many long-serving staff members that we’ve got to know quite well over the years. We sincerely hope the special relationship we enjoy continues to grow for many years to come”.

Eamonn Heffernan - Sonifex UK North Sales Manager

As Radio Design Labs (RDL) joins in celebrating the 50th anniversary of Canford Audio, we reflect not only on the milestones of a trusted partner, but also on the shared journey of innovation, reliability, and service that has defined our relationship. For decades, RDL has proudly contributed to the professional and commercial audio landscape with products that embody the spirit of American engineering and global performance standards.

If you are new to RDL, we are a U.S.-based manufacturer dedicated to high-performance audio products for commercial AV installations. From our headquarters in Prescott, Arizona, we have been designing and building solutions trusted by integrators, consultants, and engineers worldwide for nearly four decades. Our commitment to quality, versatility, and ease of integration has made RDL a preferred brand for projects ranging from corporate boardrooms and educational campuses to broadcast studios and transport infrastructure.

Solutions Engineered for AV Professionals

At RDL, we understand that reliable AV systems begin with dependable building blocks. Our product portfolio is designed to address real-world challenges in system design, offering flexibility, scalability, and intuitive

deployment. Key product lines include:

• Dante® Network Products

The world leader in Dante interfaces for connecting mic-level, linelevel, Bluetooth, and Format-A products to Dante networks - plus Dante-enabled mixers, amplifiers, and volume controls.

• Format-A® Audio Distribution

A streamlined solution for distributing audio and power over standard CATx cable - ideal for decentralised installations and cost-effective system designs.

• Stick-On, TX and Rack-Up Modules

Professional grade compact and rackmount products designed to mix, preamplify, amplify, convert, detect, control and distribute.

• Wall-Mounted Controls, Indicators and Connection Plates

Elegant and functional wall plates for audio I/O, control, and user interaction, designed for seamless integration into modern spaces.

RDL products are trusted in missioncritical systems worldwide and are used in traditional market segments including corporate, education, hospitality, healthcare, entertainment, broadcast, houses of worship, transportation, municipal and the broader public sector.

As AV systems continue to advance, so do the demands for greater

flexibility, seamless interoperability, and remote management capabilities. Alongside our dedication to innovation, we remain deeply committed to supporting our global customer base. To better serve our European partners, RDL is introducing a new line of European format Dante interfaces. These additions reflect our ongoing effort to meet regional needs while maintaining the high standards our customers expect.

We also prioritise installer-friendly design: intuitive connectors, clear labelling, and reliable, robust construction to help reduce installation time and minimise on-site troubleshooting.

• D-NVC2 Dante / AES67 Network Volume Control

Universal rotary encoder volume control that provides volume control and muting on one or two network audio channels. One stereo or one or two mono audio channels may be routed to the D-NVC2, then out to a network destination, such as a power amplifier. This volume control is compatible with any Dante stream, regardless of the manufacturer.

• RU-NMP44 Network Mixing Processor - 4x4

Distributes four Dante channels to six virtual audio mixers for controlling up to six zones. Four mixer outputs feed Dante network channels, two feed

balanced line-level outputs. It features high-pass filtering, individual level adjustment and adjustable ducking per mixer, four system presets for routing, mixing and levels. It’s compatible with optional RDL Network Remote Controls and is configured with RDL’s Console Software.

• D-BTN21 Bluetooth® Audio Dante Network Interface

Single-gang form factor with stereo or mono-summed output to two Dante/AES67 channels. Supports front-panel or remote pairing via RDL Console Software. Networkcontrollable functions include pairing, source selection, and level adjustment. Bluetooth metadata (track title and artist) is multicast over the network.

• EU-BTN21 Bluetooth® Audio Dante Network Interface Offers the same functionality as the

D-BTN21 in a European modular format, designed to fit standard 60mm deep EU junction boxes. Includes a pre-installed white faceplate laminate, white cover plate, and field-replaceable black laminate for flexible aesthetics.

Our longstanding relationship with Canford Audio has been instrumental in bringing RDL products to AV professionals across the UK and beyond. Canford’s technical insight, customer service excellence, and deep market understanding have helped us support integrators with the tools they need to deliver outstanding results.

Together, we’ve empowered countless AV professionals to build systems that sound better, work smarter, and last longer.

As Canford Audio celebrates 50 years of excellence, we honor their legacy and look forward to

continuing our partnership in the years ahead. Their success is a testament to the values we share: integrity, innovation, and a relentless focus on customer satisfaction.

The future of AV is dynamic, and RDL is committed to staying ahead - investing in new technologies, expanding our product lines, and listening closely to the needs of our customers. Whether supporting hybrid workspaces, enhancing public safety communications, or enabling immersive learning environments, RDL is ready to meet tomorrow’s challenges.

To all those who have supported RDL and Canford Audio over the years - thank you. Your trust and collaboration inspire us to keep pushing boundaries and delivering solutions that make a difference.

Here’s to 50 years of excellenceand many more to come.

Lande Rack Cabinets, established in 2012, are the largest manufacturer of 19” rack cabinets in Turkey, producing over 1,000 units per day and exporting globally from their 20,000 sqm state-of-the-art facility.

The partnership with Canford Audio – a UK distributor for Lande – has been going strong for nearly a decade, beginning back in 2013.

Through Canford, Lande offers PROline wall cabinets, SAFEbox IP55-rated cabinets, IP65-rated floor-standing cabinets, DYNAmic floor-standing server cabinets, and

soundproof acoustic cabinets, along with a full range of accessories. These products complement Canford’s extensive range of 19” connector panels, power distribution units, and cables, all manufactured at Canford’s Washington and Portland sites.

The partnership has provided solutions for a wide variety of applications, including broadcast studio installations, sports stadium projects, theatre installations, music festivals, wind farm sites, industrial environments, and standard office IT installations.

A standout product is the SAFEbox

IP55 range – the most sought-after in the lineup – which has been installed in numerous sports stadiums, including Premier League venues. These cabinets are also used in the German Bundesliga for goal-line technology, all supplied by Canford.

Lande Rack Cabinets are recognised throughout the industry for their innovative, high-quality products. Combined with Canford’s industryleading customer service, they provide the ideal solution for thousands of customers worldwide.

By Ben Hardy, Marketing Manager at Canford

2025 has been a landmark year for Canford as we’ve taken to the road meeting customers, partners and future industry professionals across the UK and beyond. From trade shows to career fairs, our team has been out in full force showcasing our latest products, sharing expertise and strengthening relationships throughout the broadcast, audio and AV industries.

Our busy calendar kicked off in February when we attended the Kepier School Careers Fair, engaging with students keen to explore careers in engineering, manufacturing and many more career opportunities Canford has to offer. Inspiring the next generation of talent is something we’re incredibly passionate about, and it was fantastic to see such enthusiasm from young people in the North East. March saw the start of the Broadcast Technology Roadshow, with events in Newcastle and Glasgow. These intimate, regional events gave us a great opportunity to connect with engineers, integrators and technical teams in their local areas, bringing Canford’s expertise directly to them.

The spring period was particularly eventful, as May brought a trio of major exhibitions. We kicked off with PLASA Focus Leeds, where we met with professionals from the live events and AV sectors to discuss the latest trends and innovations. Then, in the same week, we headed down to London for MPTS (Media Production & Technology Show) – one of the UK’s leading broadcast and production gatherings – before jetting off to Broadcast Asia in Singapore to meet international clients and partners. It was an exciting month of global engagement, reinforcing Canford’s role as a trusted supplier worldwide.

In June, we continued the Broadcast Technology Roadshow with a stop in Coventry, as well as attending the Park View School Careers Fair, where we once again had the pleasure of inspiring students to consider

careers in technology and manufacturing.

As autumn arrived, we were back in exhibition mode. September saw us at both PLASA Show London and IBC (International Broadcasting Convention) in Amsterdam – two of the biggest events in our industry calendar. These shows were the perfect platform to demonstrate Canford’s latest product developments – such as the Canford Dante Enabled Diecast Speaker, network with long-time customers, and discover the innovations shaping the future of broadcast and AV technology.

Finally, we wrapped up the Broadcast Technology Roadshow in October, with successful events in Oxford and London, connecting with technical professionals and end users eager to learn more about our expanding product range and bespoke solutions.

From classrooms to international exhibition halls, 2025 has been all about connection – sharing knowledge, building relationships and showcasing the quality and expertise that define Canford. As we look ahead to 2026, we’re excited to continue meeting the people who make our industry so dynamic.

By Ben Hardy, Marketing Manager at Canford

Here at Canford Audio, exhibitions play a vital role in how we engage with our customers, showcase our latest innovations, and strengthen our presence in the pro audio and broadcast industries. With events taking place across the globe, the logistics of transporting equipment, stands and materials can be a complex and time-sensitive challenge. For many years, we have relied heavily on our primary logistics partner Think Expo Logistics to ensure that everything arrives safely, securely and on time. Their support over the years has been instrumental to the success of our exhibition strategy and schedule. Exhibition schedules are rarely straightforward. Tight deadlines, multiple international destinations and last minute changes often mean there is very little room for error. Thanks to Think Expo Logistics’ extensive experience and flexibility, our products are transported quickly and efficiently between shows, whether by road, sea or air. Their ability to work to extremely short timeframes gives us the confidence to focus on what we do best –connecting with our customers and presenting new solutions, knowing that the logistics are in safe hands.

What truly sets Think apart though, is not only their reliability, but their commitment to sustainability. With sustainability targets and aspirations of our own, it’s essential that the companies we partner with share the same ambitions. As an industry, logistics can be quite wasteful, but Think takes proactive steps to reduce environmental impact. They work closely with their partners to reuse stands, equipment, and materials wherever possible, and to recycle at every opportunity. This approach closely aligns with Canford’s own values, where sustainability and responsible business practices remain a key focus for our future.

Importantly, Think Expo Logistics is a carbon-neutral business. They offset all the carbon generated by each and every shipment, and they go one step further by planting a tree for every transport arranged. Their sister company, Think Greener Travel, extends this environmentally conscious approach into business travel, offering group hotel bookings with a “green twist”. Every overnight stay is carbonoffset and matched with another tree planted, helping us all reduce the environmental impact of our exhibition programme even further.

For Canford Audio, working with a logistics partner that not only delivers on efficiency and reliability but also shares our values is essential. The partnership with Think Expo Logistics ensures that our exhibitions run smoothly while contributing positively to the wider goal of reducing our environmental footprint.

For more information about their services, you can contact them on 01243 908 075 or via email at hello@thinkexpologistics.com and hello@thinkgreenertravel.com.

Back in February 2025, Canford Audio was named SME Apprenticeship Employer of the Year, a national recognition of our long-standing commitment to developing young talent and nurturing skills across the business. The award celebrates organisations that demonstrate outstanding support, progression and opportunity for apprentices, and at Canford, apprenticeships have always been at the heart of how we grow our people.

From the earliest days, Canford has recognised the value of investing in new generations of talent. Our CEO, Alan, began his career as an apprentice

By Ben Hardy, Marketing Manager at Canford

– a tradition that continues to shape the business today. Many of our team members started as apprentices and have since progressed into senior and specialist roles across departments.

Throughout Canford’s history, we’ve had more than 50 apprentices through our doors. In recent years, our apprenticeship programme has seen people complete their course and continue in full time employment with Canford in departments like Engineering, Production, Manufacturing, Sales, Warehouse, Site Services and Purchasing. They’re part of a wider community of

apprentices past and present that are all contributing to the business’s ongoing success and innovation.

Anna Roxburgh, Key Accounts Manager in our International Sales department, had the following to say:

“The support provided by Canford whilst completing my apprenticeship was exceptional by opening new and exciting opportunities, as well as offering guidance and feedback to allow me to develop my skills. After completing my apprenticeship, the support from Canford remains as they continue to invest in my growth by setting training plans tailored to improving my skills further, providing regular feedback and encouragement. The support I have around me allows me to build on my confidence and motivation. I am glad I get to work in this sort of environment and being part of a team who provides such support”.

2025 also saw Production Technician Apprentice, Lucas, successfully complete his Level 3 Engineering Apprenticeship, marking a key milestone in his professional development here at Canford. The four-year apprenticeship programme provided Lucas with a mix of practical, hands-on learning and academic study at a level equivalent to A-levels. Throughout this time, he gained experience in designing, building, servicing, and repairing engineering products and systems, gradually developing the skills and confidence required for a career as an Engineering Technician.

The apprenticeship concluded with a rigorous End Point Assessment (EPA), including a portfolio of work, a professional discussion, and an employer reference - all of which Lucas completed to a high standard. Reflecting on his journey, Lucas said: “Canford has supported my journey by always giving me the time to help complete any work and providing support throughout to help me achieve my goals.” We are incredibly proud of his achievement and look forward to seeing his continued growth and

contributions within the engineering team. Congratulations, Lucas! 2025 has also been an incredibly successful one for Caprice, Production Engineer at our Portland facility. Caprice has made an exceptional contribution to Canford through the development of a brand-new product, originally conceived as part of her HNC in Manufacturing Management course. While Canford already offered a modular panel range, its existing frame design provided limited spacing for connections and required a lengthy manufacturing process, resulting in higher labour time and increased cost. Caprice recognised an opportunity to improve both usability and efficiency and designed an alternative solution that offers greater flexibility while being significantly quicker and more cost-effective to produce. Her concept impressed the business so much that Canford has now taken the design into full production and added it to our portfolio.

Alongside this achievement, Caprice completed her HNC at Poole and Bournemouth College with a distinction in June. Her ability to balance academic study with hands-on innovation within the business is a testament to her drive, capability and commitment to continuous improvement. We are incredibly proud to celebrate her success and to see her work already making a tangible impact for our customers.

Founder of Canford, Iain Elliott, once emphasised the crucial role that apprenticeships have played in Canford’s journey:

“The strength of the business – and I know it’s so often said – but it’s the people you have and their abilities.

For me in particular, it’s recognising young talent.”

“The strength of the business – and I know it’s so often said – but it’s the people you have and their abilities. For me in particular, it’s recognising young talent. We’ve had young people since day one with the Youth Opportunities Programme, but now we’ve got proper apprenticeships and placement schemes, and we have done for a long time. When we look at the number of people who have come through Canford, they may have stayed for a two week placement, they may have stayed for longer, or they may have come

Iain Elliott

and stayed for life. We have all sorts, and we work at different levels”.

This approach to nurturing talent ensures that apprentices are not only learning technical skills, but also developing the confidence, creativity and teamwork that define the Canford culture.

The award is a testament to the dedication of both our apprentices and the teams who support them – from managers and mentors to training partners and colleagues who share

Robust: 16A and 32A, 1U or 2U rackmounting panels engineered by Canford to stand up to the rigours of the road.

Safe: Overcurrent protection and locking connectors ensure safe, reliable performance.

Versatile: CEE Form, UK 13A, PowerCON, PowerCON TRUE 1, and IEC Connector Combinations.

their knowledge every day. It recognises the collective effort that goes into creating an environment where people can thrive and build rewarding careers in the audio industry.

As Canford continues to grow, our commitment to developing people at every stage of their career remains stronger than ever. Apprenticeships give us the opportunity to bring in fresh ideas, build vital skills and ensure the long-term success of our business and our industry.

Winning the SME Apprenticeship Employer of the Year Award is a moment of pride, and a reflection of the belief that’s guided Canford since the very beginning: when you invest in people, you invest in the future.

By Beth Routledge, HR Manager at Canford

The Wellbeing Committee has been busy behind the scenes this year, continuing our commitment to supporting the health and wellbeing of everyone at Canford Audio Limited. Here are some of the highlights so far:

In February, we had a fantastic evening at the Better Health at Work Awards ceremony, where we proudly collected our Bronze Award. To our surprise and delight, we were also presented with a special recognition award for “Best Team.” Both trophies now take pride of place in our reception area for all to see. With this success behind us, we’re now aiming for Silver Award status, and we’re hopeful of reaching this milestone by the end of the year.

We were fortunate to welcome Hanan Fischer from Sunderland GP Alliance, who delivered an engaging session on Men’s Health. The session covered signs and symptoms, prevention, screening, and where to access support. Colleagues found the discussion valuable and appreciated

the opportunity to share stories and connect with one another.

We also hosted 50:50, who ran a thought-provoking Lunch and Learn session on Equality, Diversity, and Inclusion. The session explored recent updates to the Equality Act, their practical implications, and how we can continue to build a respectful and inclusive culture at Canford.

Our fundraising efforts have been both meaningful and fun. In support of our nominated charity, Dementia UK, we held a “Guess the Baby” competition, where employees brought in their childhood photos. It sparked plenty of laughter (and some good-natured teasing about retro hairstyles!).

In addition, our teams donated an incredible 64 Easter eggs to Grace House North East, who partnered with the Salvation Army to share them with children who might otherwise have gone without.

Of course, no year at Canford would be complete without our much-loved Fish and Chip Day and Ice Cream Day! These events are a great chance for colleagues to step away from their workstations, enjoy some tasty treats, and catch up with one another.

Looking ahead, the rest of 2025 will remain focused on keeping staff wellbeing at the heart of everything we do, while continuing to give back to our communities, raise awareness of important topics, and of course, have some fun along the way. It’s all about balance!

By Paul Power, Technical Support Engineer at Canford

Headphones are convenient as they can be used in a number of different situations, on the go, in quiet areas where you don’t want to disturb others, to quickly check audio quality, or just for pleasure. Headphone monitoring is very different to monitoring over loudspeakers in a good room, but headphone development has come a long way to improving on this.

Headphones come in two main designs, open back and closed back, however manufacturers vary their headphone designs depending on price point and desired sound signature, varying parts like:

• Earcup design and materials

• Earpad design and materials, which include circumaural earpads which surround the ear, supra-aural which rest on the ear and insert type earbuds which aren’t usually used in pro audio applications.

• Impedance and sensitivity

Driving Seat

The vital part of a headphone is the transducer which turns the electrical signals into sound waves and comes in three main designs:

• Dynamic

• Planar magnetic

• Electrostatic.

Dynamic drivers, or moving coil drivers, first designed in the 1920’s are made up of a small stiff cone connected to a coil of copper wire around a powerful magnet so that when an electrical current moves in the coil it creates a magnetic field causing the cone to move back and forth.

Planar magnetic driver designs were first developed by a startup company, Magnepan, in 1969, initially as a speaker driver, but used in the 1970s by Yamaha in their headphone branded as Orthodynamic. They are like dynamic drivers, the main difference being that the diaphragm has wires embedded in it which are sandwiched between two arrays of magnets. An electrical current going through this generates an electromagnetic field, making the

diaphragm move back and forth. This type of driver uses large magnets so headphones using this type of driver are heavier than those with dynamic drivers.

Electrostatic drivers work on the principle of static energy. The patent for them was first filed in 1953 and then first used in headphones in 1959 by Stax who are still the main player regarding electrostatic headphones. Electrostatic drivers are constructed of a very thin diaphragm suspended between two metal plates which are perforated to allow airflow, one plate being positively charged and the other negatively charged; when an electrical signal is applied to the plates this causes the diaphragm to move back and forth pushing air through the perforations.

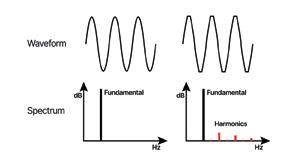

Dynamic drivers are the most commonly used in headphones as they are cheap to manufacture, easy to power and are described as having fast, punchy dynamic bass response. However, since not all parts of the diaphragm move at the same time, this can cause non linearities and distortion. Planar magnetic drivers are similar in design to dynamic drivers and are as capable of producing detailed bass response as the dynamic drivers, but as there is an equal distribution of vibrations across the diaphragm, they are less prone to causing distortion. Electrostatic headphones are known for providing greater detail and top end extension, but these types of headphones require a matching power supply to power the drivers, increasing their cost compared to the dynamic drivers. The enclosure in which the drivers are housed have an impact on the sound they reproduce. There are two main types of headphone enclosure: open back and closed back.

Closed back headphones, when worn correctly, create a seal which provides good isolation from environmental sound and resist transferring sound to the surrounding environment; however, low frequency energy that would usually escape is sealed in and this can lead to listeners experiencing a slight pressure and a fullness in the ear because of bone conducted sound. This is what is called the occlusion effect. Bone conducted sounds entering the ear canal through vibrations can boost frequencies below 1000Hz by up to 40dB; as a result the user’s voice sounds boomy or hollow. There could be more going on than just the occlusion effect, as strong internal reflections in closed back headphones

could be moving the ear away from its natural operating point, ultimately modifying the sound presented by the headphone. This can mean that the headphone becomes uncomfortable to use over long listening sessions; the listeners may then be tempted to increase the volume level to make up for the uneven frequency balance, or the sound image becomes more ‘in head’ because of smearing due to the time delayed reflections interfering with the direct sound.

Optimal bass response requires a good seal between the earpiece and the listener’s ear to avoid leakage. Loss of bass response in headphones can be observed, for example due to small gaps as a result of poor fit of an earpiece because of glasses or hair. On the other hand, to alleviate the occlusion effect a large open area is required to allow some energy to dissipate rather than being reflected back to the eardrum.

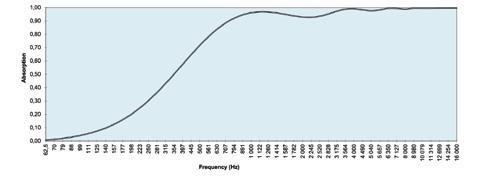

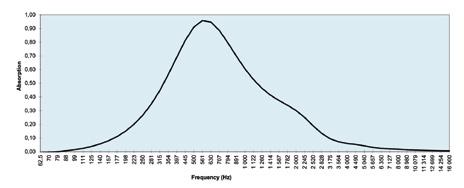

It’s easy to think that open back headphones let all the sound escape, but this is not the case, since the sound leaving the ear canal sees a different acoustic impedance which includes any absorptive material; the size of the gaps in the earpiece mean that some sound will be reflected back into the ear canal, varying with frequency. As a result, designing open back headphones is a balancing act, providing enough open space on the earcup to dissipate energy, but at the same time providing enough resistance to create optimal bass response. The solution to this is to add acoustically resistant material that can convert the sound energy to heat, reducing reflections and allowing some energy to escape, while still providing enough resistance to allow a build-up of pressure to preserve good bass response.

Open back headphones are reported to be more transparent, natural

in sound presentation and are generally preferred when mixing using headphones, as they provide a soundstage closer to using speakers; however open back headphones are also used in applications like virtual reality, augmented reality and spatial audio. Not all open back headphones are created equal and just adding vented earpieces doesn’t automatically alleviate the previous issues. In the same way that there are different sound signatures between closed back headphones, not all open back headphones provide the same degree of openness.

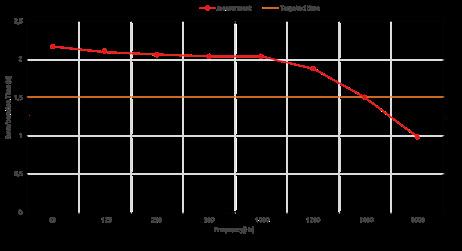

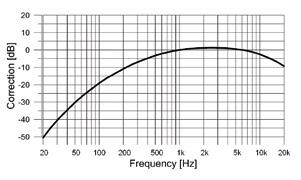

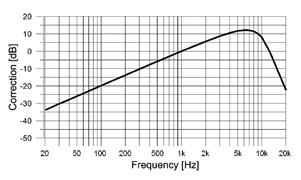

To quantify the performance of headphones during development, measurements are made to BS EN IEC 60268-7: 2025 which include frequency response, total harmonic distortion, sensitivity and impedance. As highlighted above it is necessary to balance the degree of how open a headphone is with the need to preserve some closed aspects to support optimal bass response.

“Openness” is determined by how much energy is reflected back from the headphone to the eardrum, but there is no standard measurement to quantify openness objectively. Research into measurement techniques is evolving and several measurement metrics have been proposed. Execution of these measurements is not straightforward and research continues in order that openness can be quantified and headphones can be optimised and compared.

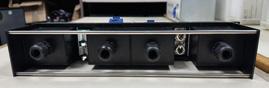

By Marc Hak, CEO and Co-founder GetyourStudio

GetyourStudio develops corporate in-house video studios – systems that can be operated by a single person with no technical background. Designed for webinars, e-learning, talk shows, product demos, and internal communication, whether live or recorded. Equipped with smart, intuitive video control software, these studios can be up and running within days, without complex implementation. With our solutions, we make professional video production accessible to every organisation.

At the heart of GetyourStudio are our Studio-in-a-Box systems: BASIC, PRO and PRO XL. The challenge in developing these systems was to combine standardisation with flexibility and future-readiness. Our goal was to create scalable systems that could be easily expanded and operated by non-technical staff.

For a key part of our Studioin-a-Box, we partnered with Canford. We already knew Canford from previous years, when we occasionally sourced AV components from them. When looking for a reliable partner for

the design and production of our backplates, Canford proved to be the perfect choice. Their flexibility in handling varying production volumes, combined with their complete service – from assembly to screen printing – allowed us to move quickly and achieve a highquality result. The first production runs required some adjustments, but together we refined the design into a robust and professional product that fully meets our vision.

GetyourStudio has now been

successfully rolled out across mainland Europe and is expanding further into the UK, supported by endorsements from Canon UK and Canon Europe. A great example is Jupiter Asset Management in London, which now produces all its corporate video content in-house using our technology, at significantly lower cost. We look forward to the future with confidence and expect to scale up production further in the coming years, continuing our collaboration with Canford as a trusted partner.

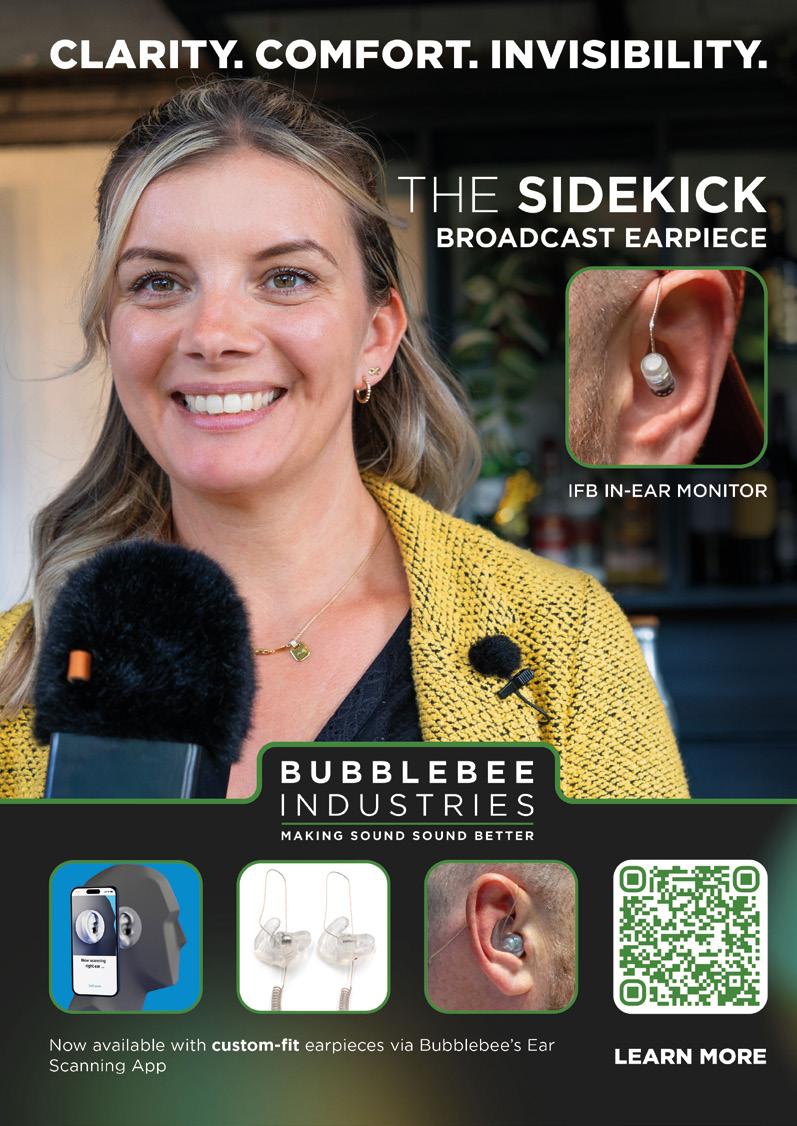

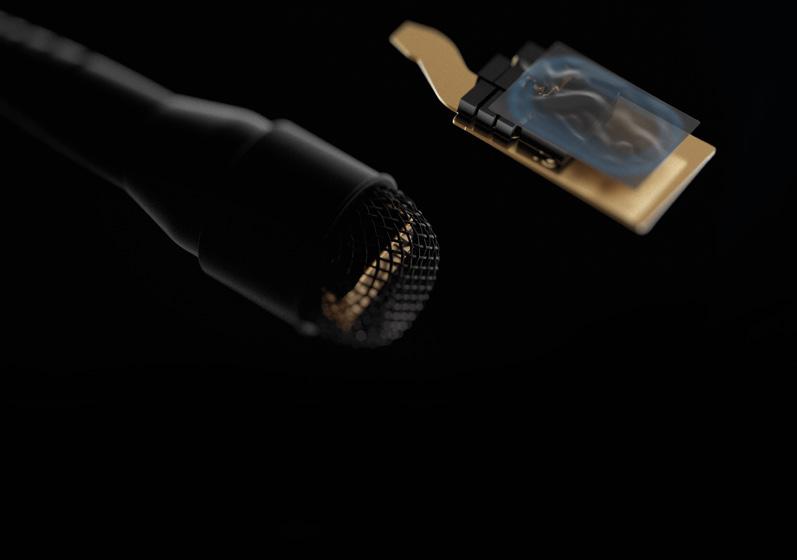

By Aj McQuillan – Commercial Director, Bubblebee Industries

Bubblebee Industries unveils The Sidekick Broadcast Earpiece — the next evolution in discreet, high-clarity communication. Designed for the demands of professional broadcast, and now available with custom-fit earpieces created using Bubblebee’s game-changing Ear Scanning App.

At Bubblebee Industries, our development philosophy is simple: create sound solutions that enhance communication and comfort without compromise. For over a decade, our products have been trusted by sound professionals worldwide — from field recordists and ENG crews to major broadcasters — because we design with one clear goal: to make your job easier and your sound clearer.

Now, we’re proud to introduce our latest innovation: The Sidekick Broadcast Earpiece — a new evolution in discreet communication technology that sets a higher standard for clarity, comfort, and reliability in live production environments.

Purpose-built for Broadcast Professionals

The Sidekick Broadcast Earpiece builds on the proven success of The Sidekick 3, a favourite among sound mixers, camera operators, and live presenters

for its invisible profile, feather-light weight, and crystal-clear delivery. The Broadcast edition takes everything we’ve learned and pushes it further.

reproduction while maintaining our signature ultra-low profile. Its high-definition micro-driver sits comfortably in the ear canal,

“The Bubblebee Ear Scanning App replaces messy impression kits with precision digital scans — redefining comfort and accuracy.”

Designed for demanding broadcast environments, it features a reengineered driver housing that delivers exceptionally natural speech

allowing for hours of wear with minimal fatigue — essential for long days on location or in the studio.

The cable has also been refined to endure daily professional use, remaining flexible and invisible even under stage lighting or camera scrutiny. Every detail — from the connector interface to the strain relief — has been tested and perfected to meet the exacting standards of modern production teams.

To give every user the perfect fit, Bubblebee has developed something truly game-changing: the Bubblebee Ear Scanning App. This technology replaces messy, uncomfortable impression kits and audiologist visits by capturing a precise 3D model of the ear digitally.

The moulds are available in transparent, beige, and a variety of special finishes or colours, allowing users to tailor their earpieces to suit different production environments or personal preferences. Each pair is precision-made to deliver a secure, comfortable fit and consistent acoustic performance — no matter how long the day runs.

-35dB or 85dB Filtered

Comfort and clarity are only part of the story — safety and situational awareness matter too. The standard custom mould attenuates external sound by -35dB, providing strong isolation in noisy environments such as live arenas, OB trucks, or busy event venues.

For those who need to remain aware of their surroundings, the mould can be ordered with a HOCKS filter. This intelligent acoustic filter limits external ambience to 85dB, preserving natural awareness without overexposure to loud environments. It’s the ideal solution for professionals working in dynamic or high-noise settings where both protection and awareness are vital.

Since its introduction, The Sidekick range has been about more than discreet monitoring — it’s about enabling clear communication in the toughest conditions. The Sidekick Broadcast Earpiece continues that legacy, combining cutting-edge micro-acoustics with the comfort and practicality professionals expect from Bubblebee Industries.

From newsroom floors to red carpets, from live sports to highpressure studio productions, Sidekick users trust that their earpiece will deliver consistent, natural sound while remaining virtually invisible on camera. The Broadcast model strengthens that trust with greater robustness, improved intelligibility, and seamless compatibility across the Sidekick ecosystem.

As an authorised agent for Bubblebee products, Canford can now provide broadcast professionals with a complete solution tailored precisely to individual needs. Together, we’re not just improving communication — we’re redefining what it means to hear and be heard in professional environments.

The Sidekick Broadcast Earpiece embodies Bubblebee’s core development values: if a product doesn’t bring something new or make your work better, it doesn’t make it to production. With its innovative engineering, custom-fit options, and the power of Bubblebee’s digital Ear Scanning App now in professional hands, this release marks an exciting step forward in the pursuit of perfect comfort, clarity, and communication.

“The Sidekick Broadcast Earpiece delivers clarity and comfort professionals can rely on, all day, every day.”

The Sidekick Broadcast Earpiece and accessories are available through Canford, an authorised Bubblebee Industries partner. Learn more at bubblebeeindustries.com and canford.co.uk.

By

Tecpro beltpacks have been a familiar sight across theatres, broadcast facilities and live event venues since the early 1980s. The original Series 1 models established a reliable platform, while the later Series 2 units introduced rigid ABS housings that balanced robustness with reduced weight and cost. Both ranges remain in service today, reflecting the durability and practicality of their designs. It is against this backdrop that the BP167 was developed – not as a replacement for the established ranges, but as a specialist evolution. Built around the same proven electronics as the Series 2 beltpacks, the BP167 encloses those circuits in a fully sealed aluminium case with

stainless steel hardware, designed specifically for offshore and wetweather use. Where the ABS housings of the Series 2 focused on durability through practicality, the BP167 focuses on resilience through environmental protection.

Every design decision reflects the demands of challenging conditions. A glove-friendly rotary control and a prominent mic switch - offering both latching and push-to-talk modes - allow operation even when dexterity is limited. Visual and audible confirmations ensure operators know the mic state. The absence of a daisy-chain connector, common in standard beltpacks, helps prevent water ingress, while the belt clip is secured via a stainless-steel mushroom anchor point to withstand physical strain. Although developed for offshore and maritime operations, the

BP167 is equally suited to outdoor events where weather conditions can be unpredictable. IP67 protection ensures that rain, spray, or even brief immersion does not compromise operation, making the unit as reliable at a festival site as it is on an ROV (remotely operated vehicle)

To maintain the IP67 rating throughout the system, the BP167 uses IP-rated Neutrik components. The body of the beltpack features the NC3FXX-HD-D Series XLR connector for system link, providing a secure, weather-resistant connection and ensuring that both the headset and system mating cables preserve the same level of environmental protection. Internally, the BP167 shares the same electronics platform as Series 2 beltpacks, providing compatibility with existing Tecpro systems. Adjustments to sidetone and audio alert levels are accessible internally, preserving the sealed nature of the enclosure while ensuring consistent performance over time.

In this regard, Tecpro continues to hold a unique position. Its products remain a trusted standard in the UK, where generations of technicians have relied on their durability and performance. The same qualities that make Tecpro effective in theatres and studios extend to live event sites across Europe and offshore installations. Systems built decades ago continue to function alongside newer devices such as the BP167, demonstrating Tecpro’s philosophy of cost-effective resilience applied to new environmental challenges. By combining proven electronics, robust environmental protection,

and compatibility with established systems, the BP167 ensures that reliable communication can be maintained in the most demanding conditions, sustaining a legacy that has lasted for over 40 years.

A typical Tecpro deployment relies on a clear logic of power and termination. Each intercom ring requires a system master station and/or power supply to provide both power and the necessary termination for all connected devices, capable of supporting more than 20 beltpacks per ring. System cabling attenuation, based on 0.5mm² (20 AWG) cable, at a threshold of more than half the supply voltage, allows

infrastructure to span kilometres in length, assuming that intermediate nodes or patching points are kept to a minimum. The total number of connected user stations dictates the requirement for additional available current, and in some cases, isolatorcoupled terminations are necessary to preserve signal stability and overall system performance. Additional master stations or power supplies can be added to expand the system, with care taken to avoid double termination by using isolators such as the BA905 to maintain system integrity. Localised 24V DC power supplies can also be incorporated for high-demand units, such as loudspeaker stations, with inline diodes providing protection against short circuits and ensuring reliable overall system operation.

Comfortable: Lightweight design and clear, intelligible audio for fatigue-free communication.

Reliable: Easy to operate, universal power supply (for world-wide use), and renowned for toughness and durability.

Versatile: Connect between two and hundreds of users on up to two independent intercom rings.

By Charles Phelps, Technical Support Engineer

To support Stride deployment requirements, many productions make use of PTPv2-enabled switches from manufacturers such as Netgear, Cisco or Luminex, which offer powerful and flexible solutions. However, these options often require configuration and management expertise that may not always be available on-site. With this in mind, Green-GO introduces the SW6 to provide a streamlined alternative: a compact 6-port PoE+ switch with PowerCON loop-

through, preconfigured for AV and PTPv2 compliance. With no front-end management or user configuration required, the SW6 offers a true plugand-play topology, ensuring compliance and stability even in environments where network setup cannot be accessed or confidently deployed.

When deploying the Stride Antenna, its monitoring mode can be used to visualise the local DECT spectrum, providing insight into potential interference and reflections within the intended coverage area. This allows antenna placement to be verified in advance, helping to mitigate issues caused by reflective surfaces, oxidised paints, or nearby metallic structures. The “doughnut”-shaped radiation pattern of the Stride Antenna should also be considered during placement, as careful orientation can help reject unavoidable localised interference while maximising usable coverage.

https://manual. greengoconnect.com/ en/guides/wireless

In combination, the SW6 and Stride Antenna form a robust deployment framework: the SW6 ensures effortless, compliant backbone connectivity, and the Stride provides visibility and control over RF conditions in the field. Together, they simplify deployment while supporting the stability and reliability required for seamless, production-grade communications.

Since the release of Green-GO version 5, scripting has become a powerful tool, offering users the freedom to create bespoke functionality without waiting on firmware revisions or direct developer intervention. Built as a streamlined, event-driven language – a derivative of Python – Green-GO scripting allows users to react to system events, modify device properties, and redefine the user experience in real time. Scripts can monitor and manipulate up to 64 simultaneous events, with a built-in safety mechanism that gracefully reverts to normal operation if a low-priority script fails, ensuring creative flexibility without compromising reliability.

Interface control is equally versatile. Calling ui.clear(i) within a ui.draw(i) event wipes the indexed display, ready for repopulation with new elements such as lines, rectangles, or text. Each ui.draw# command is typically followed by defined parameters and payload. Objects such as device, group, channel, and ui serve as exposed interfaces into the Green-GO ecosystem, each capable of being read or rewritten during runtime, enabling adjustments to routing and system behaviour.

Functions, variables, and constants give further structure to scripting logic. Functions can be defined using the function #() syntax, allowing repeated

or conditional behaviour to be encapsulated cleanly for reuse across multiple events. Variables – both local and global – can be declared freely, storing numerical or text data for tracking states or intermediate calculations, while constants provide stable, non-rewritable reference values to ensure clarity and consistency throughout a script.

Channel modes form another crucial part of interactive behaviour. Within scripting, each channel can be addressed directly to manage talk, listen, and call states. For example, setting channel.talk(i) engages talk mode on a specific channel, while listening for channel.listen(i) or channel.call(i) events allows precise control over monitoring and signalling behaviours. These modes can be combined with UI feedback to give operators clear visual and tactile cues, reinforcing communication status across complex networked systems.

Ultimately, Green-GO scripting bridges the gap between user creativity and system capability. It allows operators to build adaptive workflows that reflect their environment – from subtle interface tweaks to fully responsive intercom logic – all without touching firmware. If you want it, script it.

https://manual. greengoconnect.com/en/

Green-GO is a cost-effective, multi-award-winning digital intercom system that transmits audio over an existing Ethernet network; no special wiring needed! Its proprietary design allows for scalability from a small, deployable application up to incredibly complex communication systems ideal for major live events, multifunction performance venues, and broadcast operations, but can be used almost anywhere.

• Reliable: No central matrix, which eliminates a potential single point of failure (whilst also providing a substantial cost saving.)

• Scalable: Start simple and build your way toward an incredibly complex system of up to 400 groups and 3000 users.

• Versatile: Wired and wireless, powered over Ethernet, and packaged with highly configurable, proprietary software which allows for an almost limitless range of possibilities.

Canford has been the sole UK and Ireland distributor of Green-GO since 2016

By Márcio Leiria, Marketing and Creative Manager at Ampetronic | Listen Technologies

As someone who works at the intersection of creativity and technology, I’ve always believed that good design should be invisible. It should simply work, quietly improving lives without demanding attention. That’s exactly what accessibility should feel like. Seamless. Empowering. Uncomplicated.

At Ampetronic | Listen Technologies, we’ve spent years helping people hear better in public spaces. But with the launch of Auri™, we’re entering a new era. One where accessibility is not just about compliance, but about experience. One where AI and Auracast™ come together to make sound more personal, more flexible and more inclusive than ever before.

Listening Shouldn’t Be a Luxury

Whether you’re in a theatre, a classroom or an airport, being able to hear clearly is essential. Yet for

millions of people, background noise, poor acoustics or hearing loss make that difficult, with over 430 million people worldwide currently requiring rehabilitation for disabling hearing loss. That number is projected to rise to more than 700 million by 2050, according to the World Health Organization. Traditional solutions have helped, but they often rely on specialist equipment, complex installations or limited compatibility.

Auri™ changes that. It’s a complete system that allows venues to broadcast high-quality audio to both dedicated

receivers and personal devices. That means people can use their own smartphones, hearing aids or earbuds to tune in. No need to borrow equipment. No need to feel singled out. Just clear sound, delivered directly. This is what Auracast™ enables. It’s a new Bluetooth® technology that lets users choose audio streams in public spaces, much like selecting a Wi-Fi network. And Auri™ is built to support it fully. It’s designed to work today, and to grow with the technology tomorrow.

AI Makes It Smarter. And More Human.

What excites me most is how artificial intelligence is starting to shape the future of accessibility. AI isn’t just about automation or data. It’s about understanding people better.

Imagine a system that learns your preferences. That knows which announcements you want to hear, and which ones you don’t. That adjusts volume based on your environment, or helps you find the right audio stream in a busy space. These are the kinds of experiences AI can help create.

In our work, AI also helps us design better. It allows us to test how people interact with our materials, understand what they need, and make sure our messaging is clear and inclusive. It’s not replacing creativity. It’s enhancing it.

When we talk about accessibility, we’re not just talking about technology. We’re talking about people. About making sure everyone feels welcome, informed and included.