Let’s show off the great work you’re doing.

The destination’s the same, but the journey’s different for everyone.

Contact your Smartcane BMP district facilitator to discover what accreditation could look like for you.

75 g/L picloram + 300 g/L 2,4-D

480 g/L fluensulfone 750 g/kg isoxaflutole

330 g/L paraquat

400 g/L fluroxypyr

g/L picloram 132 g/kg hexazinone + 468 g/kg diuron

200 g/L fipronil

g/kg diuron 720 g/L 2,4-D DMA + IPA 750 g/kg metribuzin 625 g/L 2,4-D amine

750 g/kg hexazinone + 150 g/kg imazapic

240 g/L imazapic

g/L MSMA 240 g/L bifenthrin

75 g/kg isoxaflutole +

g/kg terbuthylazine

625 g/L propiconazole

400 g/L asulam

g/L ethephon 800 g/kg ametryn

Editor: Robyn Devine

Advertising and Classifieds: Jane McGregor

Articles appearing in Australian Canegrower do not necessarily represent the policies or views of CANEGROWERS.

Published monthly by: CANEGROWERS, GPO Box 1032, Brisbane, Queensland 4001 Australia. ABN 94 089 992 969

Telephone: 07 3864 6444

Email: editor@canegrowers.com.au

Website: www.canegrowers.com.au

Subscriptions

Yearly subscriptions for 12 hard copies (postage included) Within Australia: $190 inc GST

• Overseas (AUD): $290

12 Month Digital Subscription: $78 inc GST

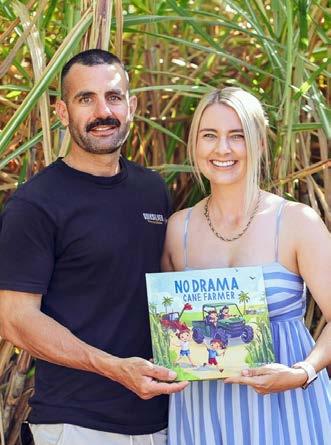

The Camilleri family of Mackay:

Photo credit: Robyn Devine

Read more on page 24

CANEGROWERS Australia Chairman Owen Menkens has been elected President of the World Association of Beet and Cane Growers (WABCG), marking a proud moment for the Australian sugarcane industry on the final day of the WABCG Conference in Cairns.

The appointment was confirmed during official proceedings on the final evening of the conference, with delegates from around the world endorsing Mr Menkens to lead the peak global body representing sugarcane and beet growers from 38 countries.

“It’s a great honour to be elected to this position and to represent growers from around the world,” Mr Menkens said.

“Sugar producers globally are facing many shared challenges – from trade access and climate change to sustainability and pricing. The WABCG plays an important role in ensuring that growers’ voices are heard and that we learn from one another.”

As part of the 2025-26 Budget the Crisafulli Government announced funding to strengthen primary industries sectors.

The Crisafulli Government said the Budget will help boost Queensland’s primary production output to $30 billion by 2030, with a 25-year Primary Industries Prosper 2050 blueprint co-designed, co-delivered and benefitting from co-investment with industry as the centrepiece.

The Blueprint includes five-year action plans to drive investment, create jobs, and unlock opportunities for the sector, supported by a $30 million Sowing the Seeds of Farming Innovation Fund.

One key initiative includes developing a Far North Queensland Cane Expansion Plan with CANEGROWERS Queensland and supporting Mossman growers to transport their crop for 2025 season.

CANEGROWERS has implemented a trial program in partnership with Queensland Agriculture Teachers Association (QATA), CANEGROWERS Isis, Isis Productivity Limited and other industry partners to provide a hands-on learning experience.

This trial will see selected high schools across Queensland take part in growing sugarcane on school grounds. The six schools that are involved in this initiative are located outside of traditional cane growing areas, this is to increase students’ awareness and understanding of our industry.

CANEGROWERS has welcomed the announcement by the Crisafulli Government of a Parliamentary Inquiry into the potential of sugarcane-based bioenergy, calling it a vital step towards building a modern, diversified sugarcane industry in Queensland.

Chief Executive Officer Dan Galligan said the inquiry aligns strongly with CANEGROWERS ' advocacy at the last state election and its ongoing push for a national feedstock strategy to support a homegrown biofuels industry.

“We’re pleased to see the government recognising the enormous opportunity Queensland has to become a world leader in renewable energy and bio-manufacturing built on sugarcane,” Mr Galligan said.

“This is about growing regional jobs, creating new markets, and setting up the industry for long-term success.”

Mr Galligan said the terms of reference reflect issues CANEGROWERS has been raising for years – particularly the shrinking availability of cane land due to urban expansion and large-scale renewable energy projects.

“The industry is ready. We’ve got the feedstock, the expertise, and pilot projects already operating. What’s needed now is strong investment and a clear path forward,” he said.

CANEGROWERS is urging:

Growers to be included as partners in the process and in the future bioenergy industry – not just consulted but actively involved.

The milling sector to step up with large-scale investment in modern, future-ready infrastructure.

The State and Federal governments to back the industry with serious investment in a sugarcane-based bioeconomy – spanning green electricity, biofuels, sustainable aviation fuel, bioplastics and more.

Government support for the development of micro-grids that would enable sugar mills to sell power directly to sugarcane growers.

“This inquiry is the catalyst. But growers need a seat at the table, and momentum must build quickly from here,” Mr Galligan said.

“We’re ready to work with government and millers to turn this opportunity into real outcomes for regional Queensland.

“Let’s not spend nine months re-learning what we already know. Let’s move forward, together – with urgency and purpose.”

Cairns has taken the global spotlight as more than 80 delegates from 18 countries gathered for the World Association of Beet and Cane Growers (WABCG) Conference — hosted in Australia for the first time in nearly two decades.

On the final day of the international conference in Cairns, CANEGROWERS Australia Chair Owen Menkens was elected President of the WABCG, marking a proud moment for the Australian sugarcane industry.

The three-day event hosted by CANEGROWERS from 24–26 June brought together growers and industry experts to address some major topics facing sugar producers worldwide — including trade, sustainability, and the future of farming.

CANEGROWERS Chairman Owen Menkens said the conference was a chance to showcase Australia’s sugarcane industry and contribute to important international discussions.

“This is a moment to put our industry and our region in the global spotlight,” Owen said.

“From trade and climate to bioenergy and innovation, the WABCG Conference is where the world’s sugar producers compare challenges, share solutions, and drive the industry forward. And Australia has a lot to offer to that conversation.”

In addition to formal sessions, delegates experienced local sugarcane growing firsthand through a technical field trip to farms across the Tableland and Gordonvale, along with cultural events celebrating Far North Queensland.

Retiring WABCG President David Thompson, a sugar beets grower from Minnesota in the US, said the conference delivered exactly what

global agriculture needs — connection and collaboration.

“It doesn't matter if it's in Australia, United States, France, Mauritius… everybody’s got something that we can learn from each other,” David said.

“That’s the benefit of these things — it’s an open communication forum where we’re all trying to better our own industries and also better the sugar industry worldwide.”

Topics ranged from geopolitical trade issues and pricing structures to best management practices and the social impact of farming. A key theme throughout was the growing need for farmers to engage more actively with the public.

“We’re not out there destroying the land. If anybody’s going to be caring for the land, it’s us — because that’s our livelihood,” David said.

“Events like this help us educate the consumer and show that farmers are part of the solution, not the problem.”

As consumers, regulators and markets continue to demand more from agriculture, the WABCG Conference offered growers a valuable space to share knowledge, build networks and shape the future of the industry.

Australia’s hosting of the event was not only a chance to contribute but also a statement of leadership — placing Queensland’s cane sector at the centre of global conversations about sustainability, food security, and innovation.

Above: Retiring President David Thompson is congratulated by new WABCG President Owen Menkens

BY RENEE CLUFF

MSF Sugar’s mill reliability has been a silver lining amidst a cloud of climate challenges.

During the 2024 harvest season, MSF Sugar’s South Johnstone, Mulgrave Central and Tableland mills were operating at between 93-per cent and 97-per cent efficiency. All the while, these coastal mills were under a literal cloud. South Johnstone Mill recorded 174 wet days in the first 200 days of 2024, and during the harvest 1,100 hours – or 47 days – were lost to wet weather. Mulgrave Mill wasn’t far behind, losing the equivalent of 20 crushing days because of soggy field conditions.

“For South Johnstone in particular, it has been very disruptive,” said MSF Sugar’s Senior Cane Supply Manager, Mick Ward. “Last year was a record and that beat the previous record, which was the year before, which beat the previous record, which was the year before, which beat the previous record the year before that. So, we’ve had four successive record years of weather loss time. It’s a significant concern and a significant disruption,

not just for our factory but also for the growers getting their cane off and getting their field work done.

“We have the wettest cane supply area of all the mills in Australia here at South Johnstone. There are other areas where, for instance, to the south of us the mill might be in a wet area, but they’ve got dry cane supply areas. At South Johnstone, all our cane supply area averages about 3.8 to 4.2 metres of rainfall a year. We really, really need to make hay while the sun shines.”

South Johnstone Mill Manager

Barry O’Brien said staff work hard to ensure the number of lost days isn’t exacerbated by breakdowns when the weather is clear. “When we are stopped, we need to do all our work then,” he said. “So, we do our evaporator clean, we arc our rollers and any equipment that we’ve got sitting there that we know could be a problem. We get in and try and fix it then so that, when the sun comes out, we are crushing cane.

“All lost time costs the mill money, costs the growers money and it lengthens the season length, so we have a high focus around the cane feeding, milling, boilers, which are the areas that predominantly cause

“Mechanical efficiency is obviously something we pride ourselves on. We lead the industry”

MARK MAGNANINI MSF SUGAR HEAD OF CANE SUPPLY

most of the lost time. We have a very extensive maintenance program, and I guess we’re lucky enough that our owners have supplied enough funding, even when the crops aren’t so big, to be able to still carry out a very large maintenance program.”

Thai owners Mitr Phol purchased MSF Sugar at the end of 2011. Head of Cane Supply, Mark Magnanini, said since then it has invested $700 million into the region.

“It’s a significant amount of money, but it’s not just our sugar factories,” he said. “We have over 800 kilometres of railway track, more than 220 bridges. We’re in the Wet Tropics, so the environment’s harsh and there’s a lot of investment required annually.

“It’s a balance of economics. When you have assets that you need to run as long as possible, you have to have a pre-emptive program that looks at running them to near useful life and then a replacement program. We have good maintenance management systems and we promote changes to equipment, hopefully prior to failure. That’s not always the case, but we’ve been fortunate of late that we’re getting that balance right.

“Another point to note here is that wet weather doesn’t only affect the miller. Wet weather has a huge impact to CCS. The growers unfortunately in the South Johnstone region have the lowest CCS in the whole of Australia and it’s a direct correlation to the amount of wet weather they’re having during the harvest season. So, it’s been unfortunate for the last four years for our growers that they’ve had such a poor yield, but it’s affected their CCS as well.

“Revenue is what’s required to reinvest so it’s difficult when your revenue’s down, your farm input costs are high, and then on top of that is the fact that if it’s too wet to harvest, it’s also too wet to plant. Our planting season has been significantly affected for the last four years, and our district is seeing the challenging results. Data shows

that we have a crop class age that’s blowing out, so we’re really in catch-up mode in our planting regime.

“We have the capacity to crush 4-million tonnes. Today, we’re about half a million tonnes short. But our growing sector is quite resilient in that when we have had adversity with weather they are able to respond quickly if the conditions are right.

“We also have our Canegrower organisations that work with us on how we can incentivise growers to plant. If it’s funding, we can supply short-term funding. If it’s equipment, we try to make sure the equipment’s available at the right time. We’re fortunate that Mitr Phol continues to invest in our region, and we’ve just got to respond by trying to get our cane supply up.”

Barry O’Brien is confident South Johnstone mill would cope well if challenged with optimal throughput, however training and retaining the workforce is an issue he’s trying to address. “South Johnstone has crushed up to 1.7 million tonnes, which is 540 tonnes per hour for two seasons in a row,” he said. “We’re very fortunate that all our engineers, both mechanical and electrical, are locals and they’ve worked at the mill a long time, so they have extensive experience.

“We do have a number of those engineering staff getting towards retirement age and we have a plan in place. Two of our shift supervisors are training for day engineer positions, so we’ve got that area covered. It’s more the trade labour shortages that are a concern.

“We train a lot of tradesmen and we do find a percentage of those head off to the mines, especially the younger ones that don’t have families and don’t have ties to the area. We’ve started a program where we’ve increased our apprentice numbers every year and we’re also training some of the process staff under an eight-year apprenticeship so that in eight years’ time they will be tradesmen in the noncrush and process workers in the crush.”

Hear the full conversation with MSF Sugar via our Mill Performance series on the Around the Paddock podcast.

Find it at canegrowers.com. au/news-media/podcasts or via Spotify or Apple Podcasts.

Moving forward, MSF Sugar’s board has just approved the replacement of a loco bridge over the Barron River in Cairns, which was destroyed during ex TC Jasper. It’s used to transport 45,000-tonnes of cane from north of the river. “It’s a big investment but a commitment our parent company has to ensuring that we have long-term sustainability, because we can’t afford to lose another stick of cane,” Mark said.

“We’re confident that area will continue to grow cane. Because of its locality on the delta it’s not going to be subject to urban sprawl, so it’s important to us and to the region.”

In other positive news for the company, the cogeneration plant at the Tableland Mill is now fully functional. A $20-million damage bill from a fire in the latter stages of commissioning delayed the project, along with the need to navigate changes to the electricity regulations and requirements administered by both Commonwealth and State governments.

Mick Ward said MSF Sugar’s latest challenges will also be overcome. “In the years following Cyclone Yasi, we planted half the area in two years. We planted 25% year-on-year and then we had a couple of 90-tonne per hectare years. Things line up and we can recover. The optimism is still there because we know we can do it. We’ve done it before, and we’ll do it again.”

BY DAN GALLIGAN, CEO, CANEGROWERS

It is hard to believe that where there is enormous diversity and contrasts you can also find tremendous consistency and common ground. Indeed it is the case that both can be true.

We have seen it here in Australia just last month as we at CANEGROWERS had the privilege of hosting the World Association of Beet and Cane Growers.

The many different cultures, farming practices, socioeconomic backgrounds and organisational capacities on show provide a window into just how differently our cane and beet industries are despite the fact that in the end the product we produce is exactly the same. But there are many other things that are exactly the same. The content discussed at that forum was tremendously informative for us to plan ahead and ultimately deliver a better industry for farmers.

Every industry organisation regardless of nationality has a tense relationship with their manufacturer. The friction in the negotiations between growers and processors occurs everywhere and many grower representatives report frustrations with performance and concerns about a lack of investment.

Pressures on farmers across the world to deliver on environmental outcomes, on ESG reporting, emissions reduction, renewable energy projects are everywhere.

Worse still, every country feels farmers are bearing the costs of delivering these environmental outcomes yet they are not getting any benefit or even sufficient recognition of their efforts. In essence it feels like all cost and no benefit. Particularly challenging in an environment where productivity on beet and cane farms is also under threat.

On the opposite of the ledger there are many common opportunities. Case studies on genuine innovation to deliver diversified products from cane and beet pulp as well as emerging and novel food industries and biobased products are particularly clear in the Northern Hemisphere.

The clear potential in providing feedstock to the huge market for sustainable aviation fuel, bio-diesel or other low emission fuels is a beacon on the horizon and clearly having farmers collaborating on how this might happen is the right strategy.

Finally, how we talk to the community, educate our kids and foster new leadership and support succession planning are issues that transcend culture, language and geography.

The issues on the world stage are in fact no different to those we face at home. Collaborating across districts and regions and with our Australian industry stakeholders is where results will be delivered.

Taking the lessons we learn from around the world and applying them to our industry is a tremendous advantage that CANEGROWERS can provide to the industry.

Brazil

India

Thailand

Speculators

Currency

Your Trusted Partner

Current as at 17 June 2025.

By Elliott Apel, QSL Assistant Manager Trading & Risk

After a slow start to harvesting due to wet weather, crushing in Centre South Brazil improved significantly throughout May. The 17 June UNICA report showed that 125 million tonnes of cane had been harvested, and 7 million tonnes of sugar produced by the end of May. The most noteworthy result, however, was the extremely high sugar mix of 51.85% for the second fortnight of May.

The Indian monsoon arrived in the southernmost state of Kerala on 24 May − eight days earlier than the longterm average and the earliest in 16 years. While pre-monsoon and early monsoon was plentiful, meteorological sources are forecasting rainfall for the upcoming four-month period to be “normal” to “above normal.”

Planting in Thailand for the 2025/26 Season is now complete with a consensus view that land under cane may have slightly increased due to a significant drop in cassava prices. The majority of Thailand has seen above-average rainfall year to date, indicating positive conditions for cane growth.

The speculative sector has been actively selling into recent market weakness, feeding into the continued downward momentum and technical signals. As of Tuesday 10 June, the speculators were holding 91,355 lots net short.

The Australian dollar predominantly traded in a 64.50-65.60 US cent range from mid-May to mid-June as markets awaited further clarification over trade negotiations between the US and its trading partners. Flaring tensions in the Middle East also sent a wave of nervousness through financial markets following an Israeli missile strike on Iran.

The outlook ratings above are in relation to AUD/tonne sugar prices. A bullish outlook is considered positive. A bearish outlook is considered negative.

The highest grower-managed pricing levels achieved across all growing regions using QSL products to date (all gross price actual/tonne) are:

• 2025 Target Price = $735 / IFC $735 (Oct25)

• 2026 Target Price = $685 / IFC $690 (Jul26)

• 2027 Target Price = $650 / IFC $610 (Jul27)

• 2028 Target Price = $605

• 22 September 2025 | Any 2025-Season Target Price Contract tonnage not priced by this date will automatically have its pricing window extended and roll costs may apply.

• 22 September 2025 | Any unpriced tonnage allocated to the ICE 11 October 2025 contract through the Individual Futures Contract and/ or Self-Managed Harvest Contract that is not rolled by this date will be priced by QSL at the next market opportunity.

• 31 October 2025 | Last day to nominate QSL as your GEI Sugar marketer for the 2026 Season.

Australian Canegrower caught up with two of the energetic and motivated Next Ratoon participants to hear firsthand how the mentoring experience is shaping their journey.

Tell us about yourself

I grew up on a sugarcane farm in the Wide Bay area, that my dad still lovingly runs. Now, as a mother of two small boys, I feel I’ve come full circle in wanting to be back on the land.

Why did you apply for the Next Ratoon program?

I decided to apply for the Next Ratoon project as I am very passionate about Australian agriculture, and I felt like it could be a really immersive program. I particularly want to bring education and participation in agriculture into the schools.

What have you gained so far?

During this program I have made valuable connections with industry professionals and friendships with other growers from the state. My confidence has grown, and I have learnt a lot about myself during the process.

Who is your mentor?

Michelle Weston the CEO of Caravan Parks Association of Queensland is my mentor, and she is also a Director with Queensland Tourism Industry Council.

What would you say to growers interested in applying for future programs?

The Next Ratoon program has been eye opening in many ways. It’s a great chance to connect with other like-minded people in the sugarcane industry as well as leaders in other industries. CANEGROWERS has created such a positive and supportive environment that gives you the opportunity to explore new ideas and pathways.

Tell us about yourself

Grow your sugarcane business with QRIDA •

HERBERT RIVER

I am a fourth-generation farmer in the Herbert River region growing sugarcane and rotational crops on our family run farm. I also run a small fabrication business and an excavation business.

Why did you apply for the Next Ratoon program?

I applied for the Next Ratoon program to gain more insight and experience about leadership positions from mentors in different roles and industries.

What have you gained so far?

So far, I have gained many things, but a standout point would be perspective. Different ways of interpreting problems to find solutions that aren’t always obvious.

Who is your mentor?

My mentor is Tricia Velthuizen. Former Crown Prosecutor and co-founder of Churchill Education, a business of getting people’s skills recognised through recognised prior learning. (RPL)

What would you say to growers interested in applying for future programs?

Give it a go. I will say it took me out of my comfort zone, but I think it has opened up and added many things into that zone.

You get to meet new people, some with similar experiences and others that have no idea what you are talking about, but everyone was willing to listen and learn from everyone’s experiences. I highly recommend the CANEGROWERS Next Ratoon program.

Wherever you live in Queensland, QRIDA’s team of Regional Area Managers are ready to meet with you, whether it’s in-office or on-farm to discuss your farming business needs and answer your questions about financial assistance available from QRIDA.

From helping you find a loan that meets your needs, to developing your farming business, or walking you through the QRIDA loan and grant application process, our regional team are here to support you.

Contact your local QRIDA Regional Area Manager to find out how QRIDA’s range of concessional loans could help you grow your sugarcane farming business, including*:

Sustainability Loans of up to $1.3 million which help primary producers tap into new and emerging on-farm technologies, improve irrigation systems or purchase or upgrade plant and machinery.

First Start Loans of up to $2 million which help new and next generation producers purchase their first primary production enterprise, including from family members.

BY OWEN MENKENS, Chair, CANEGROWERS

CANEGROWERS recently had the honour of hosting the 2025 World Association of Beet and Cane Growers conference in Cairns.

The WABCG is an organisation that brings together 36 sugarcane and sugar beet grower associations from 34 countries. The purpose of the association is to improve outcomes for growers at their local level by learning about different systems and approaches to the many challenges we face. We have similar challenges with input costs, government regulations, international market pressures and diversification opportunities.

We have much to learn from other countries, whether they produce sugar from beet or cane. The conference offers a valuable opportunity to exchange information and strategies that can lead to better outcomes for our growers.

Sugar is produced in more than 120 countries around the world. We know of the big sugarcane producers like Brazil, India, Thailand and Mexico. There are also many sugar beet producers in temperate regions in most of Europe, Russia, China and the US. The US and China are big sugar producers from cane as well as Beet. Countries from Europe including France, Germany, Ukraine and Russia produce more sugar than we do – all from sugar beet.

Sugar beet is a broad acre crop that is generally grown in rotation with other grain crops as it grows underground and has different agronomy needs. It grows similar to a potato, but the tuber is much larger. It is harvested by large combine machines where it is then sent to a mill for processing.

The beets have a very high sugar content so in some cases they produce similar levels of sugar per hectare that we do. The sugar is usually classified as white sugar, so it is mostly sold on the white market which is priced on the London No. 5 market as opposed to our No 11.

The sugar beet plant can be grown in any climate, but it is best suited to the cooler climates. The milling process is similar to cane at the back end of the mill but the front or crushing part is easier in beet as it is a softer plant.

The European growers face enormous pressures from government regulation which we can learn from in terms of advocacy outcomes. The Brazilians have the size and scale that we can learn from in terms of machinery and agronomy. Africa and India have different issues to deal with but in many ways, they are similar to our issues. The most important thing about WABCG is that it is about putting growers first in all discussions with government, millers and industry. We can learn from these discussions to help our industry going forward.

I hope the crush has started well in your region. We can only hope for a dry period ahead and some good mill performance for the current season.

For over 40 years we’ve has been specialising in providing financial advice throughout Queensland.

Our commitment to clients goes beyond our array of capabilities –we foster lasting relationships by attending to you in your local area and delivering comprehensive and tailored wealth management services that meet the unique needs of each individual. At the heart of Morgans’ philosophy is a dedication to four essential areas that are fundamental to any successful investment strategy: Financial Planning, Tax Planning, Portfolio Management, and Succession including Retirement and Estate Planning.

Financial Planning: Our approach begins with understanding the financial goals of each client. We work closely with individuals to create customised financial plans that are designed to achieve both short-term and long-term objectives. By identifying key goals and prioritising them, we ensure that each plan is actionable and achievable.

Thank you to all our clients, partners and donors.

Together, we raised over $1.6 million for rural and regional Australia on Big Dry Friday 2025.

Tax Planning: Tax efficiency is a critical component of wealth management. Our team of experts provides clients with strategies that minimise tax liability while maximising after-tax returns.

We take a proactive approach to tax planning, ensuring clients stay informed about potential tax changes and opportunities that can enhance their financial outcomes.

Portfolio Management: Morgans’ portfolio management services offer transparency and a personalised investment approach. By building a diverse, well-researched portfolios that align with each client’s risk tolerance and objectives. Our experienced advisers actively monitor market trends and adjust portfolios to keep pace with changing economic and political conditions.

ALISTAIR MILNE

AR: 000259949

Senior Private

Client Adviser/ Partner of Morgans

Milton & SpringfieldIpswich Office

Succession: Planning for retirement is a key concern for many Australians. Morgans offers expert advice to ensure that clients can enjoy financial security throughout their retirement years.

In addition, we guide clients through the complexities of estate planning, ensuring their assets are managed according to their wishes and that their family is well-cared for.

Our core purpose is underpinned by values that prioritise honesty, integrity, and a commitment to act in the best interests of our clients. These values guide everything we do, ensuring we provide trusted, professional advice at every stage of our clients’ financial journeys.

With Morgans, clients in Queensland can trust in a partner that genuinely cares about their financial success, offering services built on a foundation of integrity and excellence.

Get involved in 2026 or find out more

BY LINDSEY PERRY Smartcane BMP Program Manager

This week, my induction into the districts continued with a road trip to the Herbert and the Burdekin.

It has been valuable talking with Smartcane BMP facilitators and growers (including those not accredited) about their thoughts on the program. Several of our facilitators have been with the program for more than 10 years, and they all report there has been a lot of positive change over time in growers’ practices and record keeping.

The Ingham area is one of the larger districts in terms of number of growers. Over 50% of the cane area is now managed by accredited growers –a great result. Their accreditation numbers were further boosted from growers participating in a Reef grant program to upgrade their fertiliser application equipment.

Record keeping remains a topic on growers’ minds, with many saying long days on the farm means finding time to adequately keep records is a challenge.

Smartcane BMP adopts a pragmatic approach to record keeping – it can be a photo of a chalkboard scrawl, voice notes in your phone, notebooks, technology-based record keeping apps or perhaps smoke signals if they capture the necessary information for each block.

James Clear says in his book Atomic Habits: “we don’t rise to the level of our goals, but rather, fall to the level of our systems”. My overdue Linkt notices would agree, and the more we can do as humans to make necessary tasks second nature the easier they are to achieve consistently.

In the Burdekin, I went with Burdekin Productivity Services to visit growers in the Delta and the BRIA. Automated irrigation scheduling in both places was saving money, water and electricity. Pumps can be turned on from a smart phone, enabling irrigation scheduling to fit in with other demands in life and all records are automatically saved, making the collection of relevant records for Smartcane BMP second nature.

Recently I have heard many growers confusing the Smartcane audit process with auditing by government employees to assess compliance with the legislated reef regulations

Smartcane auditors are third party independent auditors contracted by Smartcane BMP to certify that growers are meeting the required practice standards.

This independent evaluation is the core of Smartcane BMP integrity, assuring community, government and supply chain stakeholders that the Queensland sugar industry is responsible and proactive. With 44.5% of Queensland’s cane area now accredited, Smartcane BMP is a whole of industry asset.

Now that my tour of the Wet Tropics is complete, I can now say that Innisfail has my vote for best bakery.

A demonstration of automated irrigation scheduling from a smart phone in the Burdekin Delta

BY RENEE CLUFF

Excitement was in the air as the Burdekin celebrated its 2025 Sweet Days, Hot Nights Festival.

The first fire was ignited, the sweetest schools named, and the champion hand cutter revealed as thousands gathered for the Sweet Days, Hot Nights Festival in Australia’s sugarcane capital in late May.

Held at Home Hill Showgrounds the weekend before the start of the crush, the festival fittingly opened with the season’s first burn, sponsored by CANEGROWERS

Crowds gathered and cameras were pointed as the flames took hold of the sweet stuff, with festival-goers seemingly unconcerned that earlier wet weather meant the fire didn’t break any burning records.

Once the glow faded, a cultural fair complete with everything from Scottish bagpipes to Afro-Cuban tunes entertained the gathering, while visits to food and drink outlets were also flowing. Day two gave rise to another CANEGROWERS -sponsored activity, and the main event for the region’s

children who’d spent the past 12 months tending to sugarcane plots at their schools.

The inaugural Burdekin Sweetest School competition saw 14 schools battle it out for the best sticks of cane, with students cultivating a passion for agriculture and sustainable practices along the way.

Event founder, Burdekin

CANEGROWERS Deputy Chair Rian Swindley, said the initiative has been a sweet success.

“We’ve used it to promote the sugar industry and what we do,” Rian said. “We’re also trying to encourage students to identify available careers in the industry other than the haulout driving, harvesting or farming that might be obvious to them, such as agronomy and engineering. There are so many opportunities. It ties in perfectly with CANEGROWERS ’ One Plant, Many Products student resources.

“The kids seem to love it. But it’s more than that. The fathers are now pulling up to the school, having a chat about the cane. There was one child who was quite disconnected, they couldn’t

get him off his screens, but he’s really interested in the cane and started connecting with other kids because of the cane.

“Those are the benefits we never even imagined”

A $1,000 prize was handed out to the winning school in each variety category, with St Francis Catholic School, Clare State School, Ayr State School and St Colman’s Catholic School taking home trophies.

Mascot Mick the Cane Cutter was on hand to congratulate the children, along with representatives of Sugar Research Australia and Burdekin Productivity Services, who were also involved in the program.

“The teachers also really got onboard, and along with the students they got to learn about the complexities of growing sugarcane,” Rian said. “It really has fostered a sense of community pride and collaboration.”

The other major drawcard on day two was the Australian Hand Cane Cutting Championship, which saw cutters swinging blades across age and gender categories, as well as part of team events.

Mark Vass, who’d grown the cane he was cutting, won the 2025 title after taking just over 14 minutes to fell four drills each 25-metres long. Second prize went to Stuart Gilbert, while Stuart’s uncle Adam secured the final podium spot.

In other results, Wayne Borellini won the over 55 Years category ahead of Enzo Codega and Joe Gallea, Adam Gilbert overcame eventual overall champion Mark Vass and Mark’s brother Karl, who came second and third respectively in the 35-55 Years class, and Keith Gilbert won the under 35 Years age group over his nephews Stuart and Angus in second and third places.

In the women’s events, Lyn McLaughlin took out the Ladies Cup and the best Novice Lady was Nichola Borellini.

The Vass and Gilbert competitiveness was once again on display in the team events, with Vass Engineering winning the Corporate Challenge and Gilbert Group taking out the Cut, Top and Load relay.

The Gilbert family, from cane and banana farms in Tully and Mareeba, have been travelling south to take part in the event for the past 11 years.

Adam, Keith and Scott (three of 10 siblings!) competed in 2025, along with Adam’s wife Laura, niece Julia and nephews Angus and Stuart. Adam has taken out the title four times since 2015, while Stuart was named champion in 2021.

“We as a family enjoy going and seeing how we can battle it out with each other and then catch up with the others as well,” Adam said. “With the Vass family there’s a bit of friendly rivalry, so we have a beer with each other after the events are all done.

“It’s also good to take part in something that is part of cane growing history.

“The event has really grown in the years we have attended.”

No doubt the competition will be fierce once again when Sweet Days, Hot Nights returns to the Burdekin in 2027.

The event is coordinated by Burdekin Shire Council. CANEGROWERS Burdekin Limited staff and board are instrumental in its organisation and implementation, with support from Burdekin Productivity Services and Sugar Research Australia.

Overall

of the

Clare State School students accept their award for winners of the Burdekin Sweetest School competition alongside CANEGROWERS representatives Rian Swindley and Greg Watson.

Call 1800 DRONE1 (1800 376 631) or email info@agdrone.au

As the sugar industry faces increasing pressure from climate variability, labour shortages, and rising input costs, it’s never been more important to embrace smart farming solutions that boost efficiency without compromising sustainability.

At the forefront of this transformation are agricultural drones – tools that are no longer futuristic, but firmly practical and here now.

Drone technology is redefining what’s possible on cane farms. From rapid aerial spraying and spot treatment of weeds, to precision mapping and data capture, drones are giving growers more control over inputs, compliance, and productivity. Whether it’s managing ratoon crops or targeting problematic zones with minimal disruption to the paddock, the flexibility of drone-based operations is changing the game.

At LyonAg Drone Solutions and AgDrone.au, we work with growers across the east coast of Australia –bringing the latest in DJI drone technology to the field, backed by local service, technical support, spare parts, and

CASA-approved training. The feedback from cane growers has been clear: drones aren’t just a novelty – they’re a necessity for modern cane farming.

With dedicated local bases in Mareeba and Ingham, supported by our head office in Tamworth and a network of trusted operators across the region, we’re committed to helping growers unlock more from their land – safely, efficiently, and sustainably.

Whether you're looking to trial drone spraying, integrate mapping into your management plan, or upgrade your operation with the latest tech, now is the time to look skyward.

Let’s grow smarter, together.

AgDrone.au empowers you to soar to new heights. Explore how our innovative DJI-powered solutions can help your business grow.

DRONE1 (1800 376 631) or email info@agdrone.au

Utrisha® N can convert atmospheric nitrogen to a plant-available form inside the leaf.

This ground-breaking foliar-applied technology supplies supplemental nitrogen to the crop throughout the growing season, giving growers more flexibility with their nitrogen management strategies.

Utrisha® N is a biological solution that works with a variety of crops for improved plant health and increased yield potential.

Embrace a balanced future

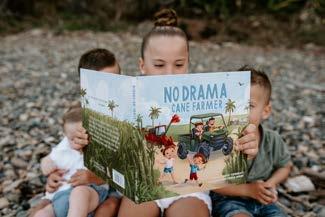

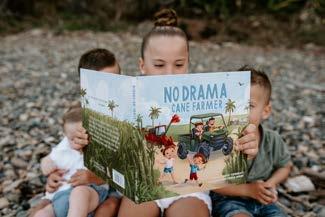

BY ROBYN DEVINE

Nikki Townley never set out to become a children’s author. A mother of four and a former early childhood teacher, she had spent the last eight years at home raising her young family on a cane farm near Mackay, Queensland.

But one quiet night, as her husband was working in the shed and the kids were asleep, inspiration struck.

“I literally just wrote the book in one night and finished it the next night,”

Nikki says. “I obviously was in the mood because I’ve tried since to write another one and it’s just not coming to me!”

Her debut children’s book, No Drama Cane Farmer, is a colourful, engaging story rooted deeply in the reality of her family’s life on the land. Every detail in the book – from the clothes the children wear to the design of the cane planter – is authentic.

“Every single thing in that book mimics our life,” Nikki explains.

“I took photographs of our machinery and sent them to the illustrator.

The planter is exactly the same as ours. The clothes the kids are wearing –that’s what they wear.”

The illustrator Victoria Mikki, a woman living in Ukraine, brought Nikki’s words to life despite facing ongoing power shortages due to the war. Nikki said she had fallen in love with Victoria’s illustrations, having seen her work from previous publications and asked her agency to reach out to her for this project.

“She was so efficient and incredible. I was never waiting on her,” Nikki says.

“Even though she only has electricity for a few hours a day, she always delivered.”

The book was born not only out of personal creativity but also from a desire to educate young readers.

“I wanted to do something for me,” Nikki says. “But I also wanted to write something my kids would be proud of. And I wanted to help other kids understand where their food comes from.”

Although Nikki grew up on a cattle property in Wagoora, near Mackay, she’s spent the past decade immersed in the cane farming world.

Her husband Charlie’s family harvests between 45,000 – 50,000 tonnes annually. She hopes the book will be a springboard for wider agricultural literacy among children.

For Nikki, No Drama Cane Farmer is more than a book – it’s a tribute to family, farming, and the everyday heroes of Australian agriculture.

Above: The Townley children give their mum's book No Drama Cane Farmer a big tick

Left: Charlie and Nikki Townley are committed to sharing life on a sugarcane farm to educate the next generation

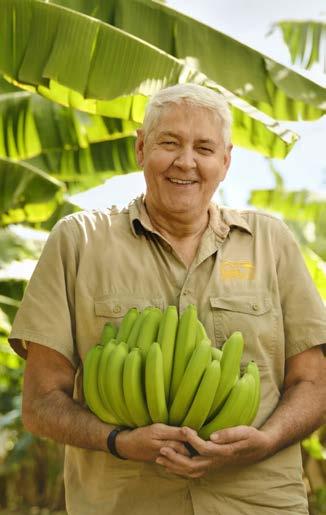

BY CLAUDE SANTUCCI

It is with great sadness that we acknowledge the passing of one of Far North Queensland's true farming legends and innovators after a long battle with lung disease and prostate cancer.

Second generation primary producer Dennis Howe died peacefully on Saturday 7 June 2025, aged 70 years.

Dennis was a visionary industry leader, a pioneer and entrepreneur. He was forward-thinking and innovative and through his hard work demonstrated the ways of expanding agriculture on the Atherton Tableland.

Dennis had tremendous passion for agriculture and more for the technology which allowed to maximise the efficiency and productivity in his farming operations.

He was considered an agribusiness trailblazer and was duly reconised for his achievements in 2016 by being chosen as the inaugural ABC Rural/ Kondinin group "Australian Farming Legend and Innovator of the Year" at a gala ceremony at parliament House in Canberra.

His parents Tom and Yola Howe had started farming on a small soldier settlement block near Mareeba in the 1950s growing tobacco, watermelons and pumpkins, then later in the mid 1970s they were able to purchase a larger farm at Walkamin, with its rich red volcanic soil allowing to grow peanuts, maize and potatoes.

After graduating with Honours from university in 1976, having achieved a Bachelor of Engineering degree, Dennis returned home to help run the home farm. Over the years, Dennis and his siblings have overseen the transformation and growth of the family home into the "Howe Farming Group".

A large agribusiness owning multiple properties throughout the district and now farming approximately 4,500 ha of bananas, avocados, sugarcane, coffee and more recently lemons, mandarins and lychees, employing a workforce of 450 people.

Dennis had a generosity about him and was always willing to share his knowledge with other people. He was a very respected and loved man that had a generous and kind nature.

He was a humble person that treated everyone as an equal. Dennis silently gave and assisted staff and other people in the community who were in need or going through tough times.

Dennis is survived by his two children, four grandchildren and brother and sister.

BY ROBYN DEVINE

Vic Camilleri was just four years old when his family moved from Habana to the current home farm on Sugar Shed road Mackay. It was there that a remarkable farming legacy began – one that now spans more than a century and four generations of dedication, innovation, and resilience.

The story begins with Vic’s father, Andrew Camilleri, who started farming sugarcane in 1916 alongside his brother in Habana. In 1939, Andrew purchased what would become the family’s home farm in Erakala. At the time, Vic was only four years old. Today, more than 86 years later, Vic still works on the farm and still likes to be involved in the discussion making and the daily operations.

“I can’t sit at home and do nothing,” he says. “We were brought up doing hard work, so it was just natural.”

For the Camilleri’s, sugarcane isn’t just a crop, it’s a legacy. It’s the thread that connects four generations, binding the sweat and soil of their Maltese heritage to the hopes and innovations of the future. Vic, his son Andre, and grandson Jacob each embody a different era of cane farming – from horse-drawn sleds and hand-cutting to today’s GPS-guided harvesters and data-driven operations.

Vic left school at the end of 1949 and started on the farm in 1950, working alongside his father with horses, hand tools, and little machinery.

“We had no electricity, no tractors –just gas lamps and a few dairy cows to milk every morning,” he recalls. “Back then, we worked with what we had. There wasn’t much else.”

He remembers loading cane onto sleds drawn by horses, then shifting it onto trucks by hand. “Double handling, back-breaking work. But that’s just how it was. Everyone did it.”

His father had emigrated from Malta and began farming with his brother in the early 20th century. “He came out with nothing,” Vic explains.

“Worked on the railways down south, saved enough, and came up to Habana to start farming. Then he bought this farm in ’39. That was the beginning of it.”

Vic still vividly recalls the steam trains loaded with troops during World War II, the swagmen walking the tracks in search of food and water, and the community spirit that held everything together. “People looked out for each other,” he says. “You never locked the doors. You knew your neighbours.”

Through the years, Vic saw the industry shift dramatically – from manual cutting to mechanised harvesting, and from burning cane to cutting it green.

“Chopper harvesters came in the mid50s, and things changed fast after that,” he says. “We started cutting green cane around 1989. It was a big change – but for the better. The trash blanket helped keep the moisture in. No more burning headaches. It made things easier.”

Yet mechanisation didn’t mean less effort – just different effort. “At least you were riding on a tractor instead of behind a horse,” he chuckles. “Still long days, still sweat and dust.”

While Vic represents the roots, his son Andre is the bridge between generations. He began working on the farm full-time after completing a trade as a fitter and machinist at Mackay Sugar’s Farleigh mill – which provided skills that would prove invaluable not only on the farm, but in building and maintaining much of their equipment.

Andre spent several years juggling contract harvesting with work in the mines during the off-season, but the pull of farming was always stronger.

“I worked in the mines for seven years in the off-season,” he says. “But it didn’t tickle my fancy. The best part about working there was coming home.”

Today, Andre runs a 760-hectare farming business across multiple properties, with a combination of owned and leased farms. They own and operate their own harvester and manage a team of workers.

The business model is built not just on farming, but on resilience, adaptability, and deep local knowledge. Andre is also a director of CANEGROWERS Mackay and is the Chairman of the local harvest management and cane audit committees.

“We’ve had weeks harvesting 15-hour days, then the mill breaks down, and we’re suddenly down to six hours.

That kind of inconsistency wears on your team,” he says. “One of our biggest challenges is mill reliability –and attracting good workers.”

At just 22, Jacob Camilleri represents the fourth generation of Camilleri farmers. Like his father and grandfather, he grew up immersed in the rhythms of the sugarcane seasons. “I’ve pretty much spent my whole life on the farm,” he says. “I knew early on that farming was what I wanted to do.”

From an early age, Jacob was eager to be involved. “Even when I was little, I’d get up at 3am to ride the harvester with Dad. I’d fall asleep on the floor of the cab, then wake up ready to go again.”

Today, Jacob plays a vital role in managing the harvesting operation, as well as assisting his father (Andre) with managing machinery, fieldwork, and planning. He’s part of a generation of farmers who embrace technology as naturally as previous generations wielded a cane knife.

“I just love it,” he says. “There’s definitely opportunity in the industry. You’ve just got to be willing to adapt. It gives you purpose and having someone like Dad and Nunnu to learn from – that gives me a real incentive to keep going.”

From Vic’s days of cutting cane by hand to Jacob’s use of GPS and data tracking, one thing has remained constant: the challenges of change.

“The last few years, the biggest issue has been the mill,” says Andre. “Unreliable performance, extended crush seasons – it throws everything out. It makes it hard to plant break crops like soybeans, do any earthworks, or even just plan ahead.”

Labour shortages compound the issue. “We used to get multiple applicants when we advertised for workers,” Andre says. “Now we’re lucky to get a few quality applicants. A majority are deterred by the sugar industry’s award rates; we cannot compete with the same level of mining wages.”

To keep good workers, the Camilleri’s now offer end-of-season bonuses tied to reliability and care of equipment. As securing and retaining reliable seasonal workers becomes more challenging, the push to expand the search overseas is becoming more urgent. Other local Mackay farmers have already started on this process and have been successful so far.

Innovation is in the Camilleris’ blood. Vic built many of his own implements from scratch, and that inventive spirit lives on.

“We’ve always built what we needed,” says Andre. “Dad didn’t have formal training, but he made it work. I learnt most of my skills from my father, which were enhanced from my trade. We do a lot of our own maintenance and fabrication work.”

Jacob agrees. “Working with Dad and Nunnu, I’ve learned so much. That kind of hands-on knowledge – you can’t buy that. It’s real experience.”

Even as the equipment becomes more complex, the mindset remains: if you can’t find it, build it. If it breaks, fix it.

The Camilleri farm is a family effort in more ways than one. While Andre and Jacob run the farming operations, Andre’s other children contribute their

skills in different ways. His eldest son, Joseph, is a mechanical engineer working in the mining sector for Fortescue in Perth. His daughter recently started work with Deloitte as an auditor and helps with the farm’s accounts.

“It’s a good mix,” says Andre. “We’ve got all the bases covered – engineering, finance, farming. It makes for a good team.”

And, as Vic points out, the farm has always been a place where the whole family pitched in. “You learn a lot growing up on a farm,” he says. “How to fix things, how to solve problems, how to work hard. That’s stayed with us.”

The Camilleri’s are actively planning for the future. Expansion is on their radar, both to grow the business and to support succession planning.

“We’d like to expand more,” says Andre. “It’s about giving Jacob something solid to build on – and hopefully one day, his kids will want to be involved too.”

Jacob echoes the sentiment. “It’s a tradition I want to keep going. It gives me a reason to keep working and pushing forward.”

That drive, passed down from Vic through Andre to Jacob, is what keeps the Camilleri legacy alive. Even amid industry uncertainty – rising input costs, market volatility, regulatory shifts, climate pressures – the family remains focused, resilient, and forward-thinking.

Despite the challenges, the Camilleri’s remain passionate about cane farming – and the broader industry. Andre has witnessed some hard years in his farming career, with the effects of some diseases such as orange rust, smut, and other variety related issues.

More recently, the challenges of facing standover which is the effects of longer season lengths. He also recognises the resilience within the industry.

“There’s always going to be ups and downs,” Vic says. “But cane is pretty tough. And so are the people who grow it.”

Andre believes that strong grower organisations like CANEGROWERS are more important than ever. “We need a strong voice. Grower unity matters.”

As well as his representation and leadership role Andre gets a real sense of satisfaction from being a grower “I get a kick out of seeing new plant cane emerging.

“Sometimes people forget where this industry came from. Our families helped build it – literally. They cleared the land, they cut by hand, they started with nothing,” says Andre.

For Vic, now in his 90s, watching his family carry the torch is a deeply proud moment. “I started with horses and no electricity,” he says, smiling. “Now look at us. It’s a different world. But the values – hard work, family, pride in what you grow – that hasn’t changed.”

Vic is very proud to see what his father, Andrew, started in 1916 and is excited to see where Jacob takes the legacy in the coming years.

The Camilleri’s know there’s no blueprint for the future. But they also know that the same resilience that carried them through the past century will carry them forward.

“You’ve got to challenge yourself,” says Andre. “Take it on. Farming’s not easy –but it’s worth it.”

Jacob nods. “There’s nothing else I’d rather do.”

SUPPLIED BY SUGAR RESEARCH AUSTRALIA

Have you ever noticed the striking flowers produced by different sugarcane varieties?

These blooms are more than just beautiful- they hold the key to unlocking the genetic compatibility (or incompatibility) that determines successful crossbreeding.

Sugar Research Australia (SRA) cytogeneticist Dr Nathalie Piperidis is examining sugarcane flowers as part of a year-long collaborative research exchange with Brazilian

researcher Dr Nina Reis Soares. Their work, funded by the Brazilian research agency Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP), aims to shed light on the genetic mechanisms that influence sugarcane reproduction.

Dr Soares is a Research Associate in the Department of Genetics at the Luiz de Queiroz College of Agriculture, University of São Paulo. Together, she and Dr Piperidis are focusing their efforts on a cellular process known as meiosis – a specialised type of cell division that produces reproductive cells – such as pollen in sugarcane.

“Meiosis occurs within the anthers, the male reproductive structures of the sugarcane flower. What’s fascinating is how dramatically this process can vary from one variety to another,” Dr Piperidis said.

By studying the anthers of flowers from a wide range of Australian and Brazilian sugarcane varieties,

Dr Piperidis (right) is pictured with Dr Soares who won a travel grant at the Plant and Animal Genome Conference in the United States earlier this year

the researchers hope to better understand why certain crosses succeed while others fail.

“This research into sugarcane meiotic chromosomes is critical,” Dr Piperidis said. “Some varieties possess exceptional traits that we’re eager to integrate into new cultivars. However, genetic incompatibility – such as incompatible pollen – can block fertilisation and prevent seedling development altogether.

“Despite having highly desirable characteristics, some sugarcane crosses break down at the genetic level,” she added. “It’s a powerful reminder that successful breeding takes more than just good potential –it requires true compatibility.”

Shield is a highly systemic and effective insecticide registered for the control of Greyback and Childers canegrub in sugarcane

• Highly effective soil applied control

• Rapidly stops canegrubs from feeding

• Improved control versus imidacloprid

• Acts through both ingestion and direct contact

• New more affordable pricing

Today’s sugarcane farms rely on more than experience –they need skilled, safetyconscious workers who are ready for the demands of modern agriculture.

That’s where Civil Safety comes in.

We’re proud to be a training partner of CANEGROWERS Mackay, recently delivering their annual four-day haulout driver course. Participants learned the essentials of cane haulage and gained a solid introduction to sugar processing –fully funded through the Queensland Government’s Skilling Queenslanders for Work program.

As a registered training organisation (RTO 32381), Civil Safety offers nationally recognised, hands-on training tailored for rural and agricultural industries. From High-Risk Work Licences to forklift and earthmoving equipment training, our courses help workers stay compliant and confident on the job. Our Certificate II and III in Rural Operations or Agriculture provide core skills for farming – and transferable qualifications for construction, mining, and more.

We also deliver short courses for indemand skills like chainsaw operation, pest and weed control, chemical handling (ACDC), and vegetation management –boosting safety, productivity, and land care.

Whether you’re new to agricultural operations or an experienced operator, our courses provide you with the skills, knowledge, and confidence to advance your career.

Short Courses

•Plant and Machinery (Earthmoving, Loading, Haul)

•High-Risk Work Licences

•Chainsaw Operation

• Agricultural Chemicals Distribution Control (ACDC)

Qualifications

• Certificate II in Agriculture

Certificate II in Conservation and Ecosystem Management

• Certificate III in Conservation and Ecosystem Management*

• Certificate II in Rural Operations

• Certificate III in Rural Operations*

*Government funding available under the Certificate 3 Guarantee. Eligibility requirements apply.

Build confidence. Gain expertise. Shape your future. Nationally recognised training Multiple funding options available 15+ locations across QLD

Civil Safety is powered by Online Anytime, an Australian digital compliance and training platform streamlining safety, document management, and certification across industries like mining, construction, and agriculture. Its mobile-friendly app digitises onboarding, inductions, VOC certificates, safety checks and more. With real-time analytics, offline access, and automated reminders, it centralises procedures, records, and tasks to boost efficiency and compliance on any worksite. Visit www.online-anytime.com.au to learn more.

Whether you’re onboarding, upskilling, or ensuring compliance, Civil Safety is ready to help grow your team’s capability.

Visit www.civilsafety.edu.au or call 1300 248 457 to learn more.

OVER 100,000 STUDENTS TRAINED TO DATE

It was a drier than average May with 132.7mm falling.

The month was also slightly cooler and although still overcast many days the growing conditions improved. Come early June the cane plants started flowering, and the cooler conditions continued.

The Mulgrave Mill start date shifted later into June due to industrial relations negotiations, so at the time of writing there was still no confirmed start date for the Mossman coastal growers and harvesters.

At the time of writing things were still progressing with the sale of the Mossman Mill assets and it was expected an outcome would become clearer by early July 2025. In the meantime, growers and grower representatives have continued to meet with interested parties and government representatives. There have been meetings around the longer-term future of agriculture, and meetings to prepare for the upcoming harvest and transportation of sugarcane to Mulgrave for

Regional water forum

JCU 27 May 2025

2025. Mid-June growers had another meeting with one of the proponents for utilising Bana Grass for biochar. The Bana Grass planted out earlier in the year is now as tall as some of the sugarcane in adjacent paddocks.

In late May, the Manager attended a Regional Water Forum at JCU in Cairns where speakers talked about the availability of water through the north and how to make it more readily available for use and in some cases for development.

At the Wet Tropics Waterways partnership meeting in early June, the group received a run-down of the data being correlated for the next WTW Report Card to be launched at the end of July. This will be a

2025

milestone for the partnership as it will be the 10th consecutive Report Card on the condition of the river catchments and inlets and inner and outer reef areas and the 5th edition of the Reef and Rivers magazine.

On 13 June, a Primary Producer Disaster Assistance session was held in Mossman. Growers were given the opportunity to finalise applications for the TC Jasper grants, talk with rural Financial Counselling Services

The past month featured a highlight for the region with the FNQ Rotary Field Days held at Kerribee Park, Mareeba.

This year a dedicated “Sugar Tent” was organised.

Representatives from Sugar Research Australia (SRA), Queensland Sugar Limited (QSL), and Tableland CANEGROWERS were on hand for the full three days, engaging with visitors and answering questions about industry developments.

The initiative proved successful, drawing in over 100 attendees with direct involvement in the sugar sector. The tent provided a valuable opportunity for growers, researchers, and industry stakeholders to connect and discuss shared challenges and innovations.

Queensland CANEGROWERS ’ senior leadership also participated in the event. CEO

and to obtain information on other support available.

At the first meeting of the board for the new triennial term, Mr Matthew Watson was elected Chair and Mr Scott Fasano was elected Deputy Chair. It was agreed that the vacancy for the fourth Director’s would be filled by Carmel Raldini.

Once again, with our growers facing the final year of supplying sugarcane to a mill, we wish everyone a successful and safe 2025 crushing.

Smiles

Dan Galligan and Industry Manager Matt Kealley contributed to forums throughout the three days, offering insights into policy, advocacy, and the broader direction of the sugar industry.

Crop Forecast and Grub Impact

There’s been a recent downward revision to the district’s seasonal estimate, dropping from 880,000 to 830,000 tonnes. This reduction is largely due to grub-related damage affecting around 1,000 hectares of crop.

SRA hosted a well-attended workshop focusing on the application of liquid imidacloprid, a key tool in managing grub infestations. The strong grower turnout reflects growing concern

Ground preparation and planting were well underway before some untimely rainfall interrupted progress.

Unfortunately, this also contributed to a delay in the commencement of the crushing season.

Representatives from CANEGROWERS Cairns Region met with the Minister for the Environment and Tourism and Minister for Science and Innovation, Hon Andrew Powell, during his visit to Cairns.

This provided an excellent opportunity for our Environment and Sustainability Officer Joel Tierney and Director Barry Stubbs to raise important matters relating to water quality, regulatory frameworks, and the environmental stewardship demonstrated by growers in our region.

As the season approaches, industry meetings have continued regularly. In partnership with MSF Sugar, CANEGROWERS Cairns Region has established a strategic committee focused on ensuring

across the district about pest pressure and the need for effective, legal application techniques.

As the season progresses, attention remains firmly on pest management and protecting crop yield.

Growers are encouraged to stay informed and utilise the support available from SRA and CANEGROWERS to mitigate ongoing challenges.

The Innisfail District has been busy preparing for the start of the crushing season.

Originally scheduled to begin on June 17, a bout of wet weather postponed the harvest by close to a week.

Overall, the weather in recent months has been favourable, and we have seen a positive start to planting, with more than 130 hectares planted already.

This is very much welcomed, following four successive years of record wet weather conditions that hampered the region’s planting regime.

CANEGROWERS Innisfail Chairman Joseph Marano has been busy in his new role of Senior Vice Chair of CANEGROWERS Queensland (QCGO), attending the World Association of Beet and Cane Growers Council (WABCG) in Cairns alongside regular Board and Policy Council meetings. Our growers are very fortunate to have such high-level advocacy representation at the state level.

Interest in Smartcane BMP continues, with three new accreditations in May and June, along with two reaccreditations. Further audits have been scheduled over the coming months.

the long-term sustainability of the harvesting sector.

Recognising the importance of Mossman cane to the Mulgrave Mill supply, CANEGROWERS Cairns Region Manager Sarah Standen recently met with the Manager of CANEGROWERS Mossman to explore opportunities for enhanced representation and collaboration moving forward.

The organisation’s clean seed plot is performing exceptionally well, with strong grower demand. Most varieties are now fully allocated.

Season 2025 commenced on 3 June, with the first cane tipped at 8.23am, 14 days earlier than season 2024.

As of 17 June, there has been 204,660 tonnes crushed at an average of 686 tonnes per hour.

Seasonal CCS is currently 12.21 with Q252, KQ228 and Q250 the varieties above the average.

Varieties above 80 tonne per hectare are Q240, SRA6, SRA28 and KQ228, with SRA6 coming in at 85 tonnes per hectare.

Initial estimate for the season is 2,379,994 tonnes with the updated estimate at 2,344,184 tonnes after 8.9% harvested. Forecasted rain arrived on 17 June, with a 49mm falling in a 36-hour period, enough to stop the harvest for a day or two.

Planting for the region has had a reasonable start, with a 4-week dry spell allowing farmers to prepare ground and be able to apply lime. Most common varieties planted for this year so far are Q253, Q208, SRA9 and SRA28.

Pre-harvest testing of cane with TSL agronomist Greg Shannon, has been in high demand. Up to 17 June, 254 samples were taken from 32 farms, which represents 11,267 hectares of area. Early testing was conducted on ripened and un-ripened cane.

Older ratoons continue to dominate early harvest, but the percentage of younger ratoons increased during the week. Some concern over early results for 1R, at 71t/ha. Q253 and Q240 account for half the crop at this stage of the season.

There are twelve main varieties of cane supplied to the mill so far this season.

Reports of grub damage in the southern end of the district are a focus for growers with lighter soils. The limited options to control grub is a worry for the industry across Queensland. RSD testing has been taking place, with around 200 blocks of plant source material inspected for growers. To date, RSD has been detected in 13 of the 200 blocks sampled. This is about 7% of the total number sampled and is similar to the results seen in the past three years.

The 2025 cane crushing season officially kicked off in the Herbert on 10 June with Macknade Mill firing up its rollers and processing approximately 42,000 tonnes in its opening week.

Unfortunately, any early momentum was quickly curtailed by widespread rainfall across the district, with between 40 to 50mm falling over a 24-hour period during the second week. This significantly disrupted harvesting operations, as Victoria Mill tipped its first bin on 16 June. The rain brought a halt to cutting across many areas and caused delays in the broader start-up process.

Despite this slow start to the season, the district is still energised from the recent success of the CANEGROWERS Herbert River Link2Country Expo, held on 23–24 May at the Ingham Showgrounds. This two-day event brought together community members, industry professionals, and students from across the

With about 30% of the plant source completed we are seeing an increase in the number of SRA28 blocks with RSD detected followed by Q253. The majority of varieties being sampled this year are Q208, SRA28, SRA37, Q253, Q240 and SRA9.

Many of the seed source blocks have weeds and this has probably come about because of the wet weather and flooding limiting access to some fields. There is also some smut in some of the grower seed source blocks, and this is likely due to the pressure from the high-level smut infections in Q200.

region—including schools from Townsville and Charters Towers.

The Expo drew an impressive crowd of approximately 1,500 attendees, including 872 participants in the free AgriLife Skills program and 119 businesses showcasing their products and services.

The CANEGROWERS Herbert River team engaged with students and attendees through demonstrations on measuring Commercial Cane Sugar (CCS) using a refractometer and

immersive Virtual Reality (VR) experiences simulating life on a sugarcane farm and the process from harvesting the cane through to the milling process.

Interactive exhibits like the children’s tractor pull and the ever-popular excavator challenge captivated visitors, offering both education and entertainment.

It was great to see the crushing commence for the 2025 season on 3 June and for the first time in a very long time all four Burdekin factories commenced on the same day.

The season got off to a solid start and we would like to acknowledge Wilmar’s effort to get all of their factories ready on time with such a short maintenance season after the late finish for the 2024 season. CCS of 12.29 season to date is reflective of standover and wet weather. The jury is still out on the 2025 estimate of 7.97 million tonnes, but time will reveal that outcome in due course.

Forecast rain in mid-June did materialise which was enough to stop the crushing for up to four days and as expected there were some issues with the factories on restart due to mud levels. The wet weather stop provided a break for Wilmar to complete cleans and do some maintenance and repairs to a few issues that were identified when the factories came under cane load.

QCGO representatives came to Ayr to present the Business Essentials course on 5–6

The Expo was a strong demonstration of the region’s innovation, resilience, and community spirit. Congratulations to Nicole Chiesa and the Link 2 Country team on a well thought out and executed event.

CANEGROWERS Herbert River is already looking forward to the next Link2Country Expo.

June which was attended by a number of members with most of the positive feedback around marketing.

The CBL Board met on 11 June and caught up with Wilmar Marketing who provided an update on their pool performance and their outlook on global sugar markets which was timely in view of the global sugar price which has been in a downward trend since early April.

QCGO’s marketing consultant Dougall Lodge also updated the Board on sugar marketing best practice and trends in marketer performance.

In Townsville CBL attended the Department of State Development, Infrastructure and Planning study on biofuels feedstock expansion.

Biofuels has been talked about for a long time without anything tangible coming from it so far, but you can feel the momentum building in this space to meet concerns around fuel security and to diversify and add value to regional communities. Sugarcane is well placed to play a key role in this transition which is exciting, but it is still many years away.

The Burdekin Cane Extension Group (BCEG) met for the first time since April 2023 with participants providing an update on the organisational activities they have underway for the benefit of the Burdekin district.

Canegrubs are coming back with a vengeance and SRA provided a very informative update on Imidacloprid which as we know has been impacted by Nufarm’s decision to discontinue production of the granular product suScon maxi due to concerns around microplastics.

The workshop was well attended with SRA having confidence in some of the liquid Imidacloprid options providing they have been correctly applied. Further on farm trials in the Burdekin are required and SRA asked at the meeting for growers who meet the criteria of having grub damage with no prior application of Imidacloprid to participate in a trial.

Following on from the 2025 Sweet Days Hot Nights Festival Sweetest Schools Competition, CBL also sponsored the Junior Cane Award at the 2025

Burdekin Show which was judged by SRA and it was great to see the interest from the school kids in submitting entries for this event.

Biosecurity Queensland organised an update on the Burdekin Pesticide Project around the work being done, outcomes of the project to date and how to resolve some of the compliance issues with the key message being to read the label, applying the correct rate and good record keeping.

Wilmar finished the month with a Harvest Management Group meeting and processing standover has been problematic due to high fibre and low purity with 50% of the standover still to come in. The season estimate will be reviewed and adjusted by week 10.

With plans to open the mill on 17 June, early week rains unfortunately delayed the harvest by a few more days.

This followed three rounds of steam trials that identified several minor issues that required repair. It is hoped that with improved preparations, the mill would have a far better start to the 2025 season.

The estimate remained at 1.58m tonnes with the opening

interim CCS set at 14.13. With the Burdekin and Plane Creek mills showing poor cane quality results in standover, similar concerns were held for Proserpine. Across the region there remained a mix of both good and poor conditioned cane following long periods of waterlogging after a significantly more wet than normal summer and early autumn.

On 11 June, CANEGROWERS Proserpine organised a grower meeting with the Department of

get unallocated water

to growers under the Whitsunday Resource Plan

Local Government, Water and Volunteers to discuss a way forward for those wishing to access allocation and licenses for unallocated irrigation water under the Whitsunday Resource Plan. The meeting was well received with commitment by the Department to complete a water release by February 2026.

This would follow an EOI process, and all interested growers are encouraged to make submissions (by 31 July 2025). For support in EOI submissions members are encouraged to contact the CANEGROWERS Proserpine office.

There was the first Whitsunday Regional Council Cane Land Working Group meeting held for 2025 on 23 May. The meeting continued its focus on protecting cane supply including the need for controlled development programs and dealing with infrastructure issues such as drainage and roads.

Poorly maintained drainage and culverts following recent wet weather showed to have significant impact on yields

in certain areas and this was highlighted at the meeting. We are thankful that Council remains receptive to input and guidance from industry on the best approach to ensuring the long-term sustainability of the cane sector.