The concept of family is at the heart of Cal Poly’s Materials Engineering Department.

Students are welcomed into a tight-knit community as they begin their journey of learning and self-discovery, supported by other students, faculty and staff. When they graduate, MATE students stay connected to their “family,” nurturing friendships they’ve built, visiting as alumni and giving back to the department that shaped them.

A prime example can be found in the story of Cindy Shurtleff, the first female to graduate from the Metallurgical Engineering Department — now called Materials Engineering — in 1980. She forged lifelong friendships with faculty members and classmates during a chapter that was foundational to her success.

“Cal Poly Engineering was there at a formative time of my life and helped me become the adult that I am — an independent woman,” she said. “I could go back to campus any time and be welcomed back. It feels like home.”

Cindy recently donated $1 million to our department’s discretionary fund to ensure the MATE family grows. We could not be more grateful for her generous gift that will impact students and faculty for years to come.

You can also read about the community-

building efforts of lecturer Nicole JohnsonGlauch, who organizes a range of events during the school year, including board game nights, book clubs and holiday-themed activities. Her work, funded by Cindy’s gift, has strengthened MATE’s culture of togetherness.

Our students are excelling both inside and outside the classroom, with many winning awards, scholarships and recognition.

Senior Sydney Fultz-Waters earned a $3,000 scholarship from ASM International, the world’s largest association of materials-centric engineers and scientists, to continue her work in the field of materials engineering. Her senior project this year is focused on streamlining the electric vehicle testing process and contributing to sustainability in an industry she is passionate about.

Research is a key part of how we Learn by Doing, and there’s no shortage of that within our department.

Materials Engineering Professor Mohsen Kivy is guiding students Ryan Thompson, Juan Palominos Jr., Matthew Kestenbaum and Lucy Hunter as they test the crystallization of highentropy alloys at different temperatures in the search for a new, stronger alloy. The group presented their findings at an exhibition and contributed a journal article detailing

their discoveries.

Members of the Association for Materials Protection and Performance club — one of the oldest student chapters in the worldwide organization — continue to study corrosion, as companies clamor for more information about the process that drives up maintenance and repair costs.

Students gather weekly, host experts and are undertaking research projects that will help inform corrosion control efforts.

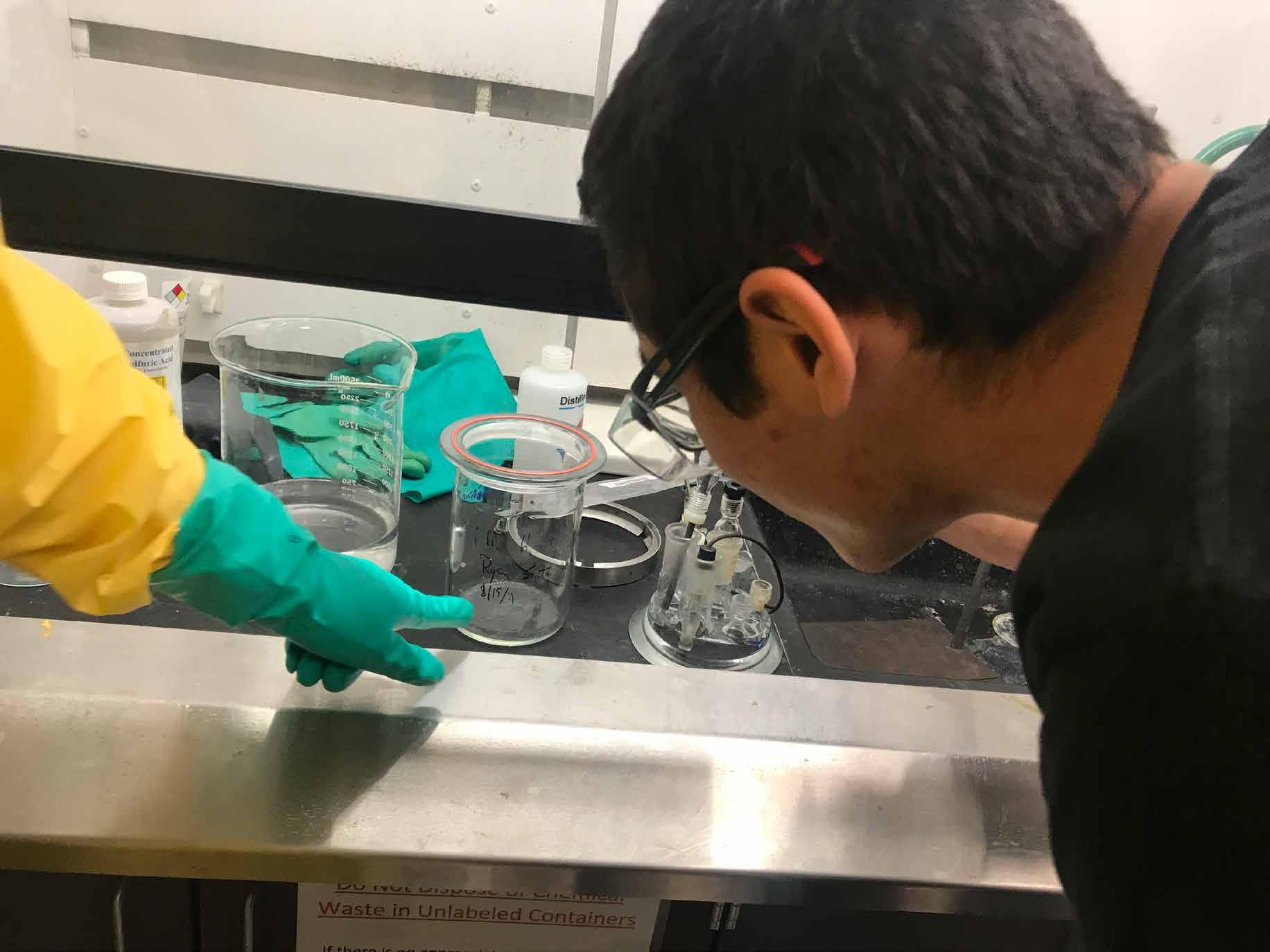

Lastly, as our students and faculty members conduct their work, often with dangerous chemicals, our student safety technician Jacob Reed is making sure everyone proceeds with caution. You can read about his critical responsibilities, which are key to the success of our department.

The MATE Department continues its legacy of transforming young people into some of the finest materials engineers in the world. We hope you will join Cindy in supporting the next generation of students who join our family. You can give HERE. n

Materials engineering senior Sydney Fultz-Waters was recognized for her academic excellence by ASM International, the world’s largest association of materials-centric engineers and scientists. Organization representatives awarded her a $3,000 scholarship in fall 2022 to continue her work in the field of materials engineering.

“The application process consisted of writing a short essay and submitting letters of recommendation,” she said.

Fultz-Waters attributed the scholarship to what she learned in her Cal Poly classes, specifically the ceramics and glasses materials engineering course and the solid state physics course, two of her favorites throughout her undergraduate education.

More recently, Fultz-Waters conducted research with Sandia National Laboratories during a five-month internship from March to August 2022 where she worked closely with a team of scientists and engineers to design a process for an inductor out of a composite material. The coop focused on a combination of design and lab work.

“Usually, traditional inductors are made of metals, so the work we were doing would allow for a cheaper and more sustainable material for inductors and other power system components,” she explained.

During her time there, she developed a working computer simulation model to validate real-life results for electric vehicle inductors.

“This model helped the team at Sandia speed up their prototyping

process because they we able to perform fewer iterations of the inductors,” she explained.

Fultz-Waters continued her work developing novel inductors for her Cal Poly senior project to help streamline the electric vehicle testing process and contribute to sustainability in the industry, one of the main reasons she decided to pursue materials engineering. She plans to present her work at the CENG Project Expo in the spring and at the Materials Engineering Department Technical Conference later this year.

“I first chose materials engineering because I was interested in problem-solving,” she said. “I first learned about the engineering path at my college career at a different university. When I saw it was an option at Cal Poly, I jumped on it because it seemed like a good combination of math, science and engineering.”

The Cal Poly senior’s research and hands-on experience investigating the way materials change at the atomic level is what pushes her in her continued pursuit of materials engineering education.

“It’s incredible how atomic structures can affect the properties we see every day,” she said.

Fultz-Waters is active in clubs and organizations across campus. She is a lead for the Cal Poly Racing Baja team, the president of Alpha Sigma Mu and an officer for the Microsystems Technology Group. She plans to attend graduate school after completing her Cal Poly education in the spring. n

Student technician helps keep Materials Engineering Department running smoothly

Materials engineering major Jacob Reed plays a critical role as the department’s student safety technician, managing chemicals and making sure standard operating procedures are followed.

Students in the Materials Engineering Department learn about the various materials that make up everything from rockets and computer chips to electric vehicles and biomedical devices. They also design and test new materials, which involves significant lab time and much more chemistry than other engineering majors.

As a result, MATE students regularly handle a variety of chemicals.

“Chemicals are a means to an end,” said Reed, a third-year student who was hired as a safety technician in 2021. “As materials engineers, we can use them as a tool to get the effect that we need.”

One of the effects, he said, is etching metal — the department’s most common use of chemicals — to look at the microstructure of the material.

He added that the general goal is to get MATE students into the lab as soon as possible, because so much of their learning will happen in that space.

As safety technician, Reed spends even more time in MATE labs.

“I am more comfortable with all the lab equipment than most people I know,” he said with a grin.

Outside the lab, he coordinates with students, faculty and Environmental Health and Safety to make sure regulations are met and safety plans are followed.

“I make sure that everyone is on the same page,” he said.

Much of Reed’s energy is spent following protocol to safely dispose of chemicals.

“A big chunk of my time is spent taking care of hazardous waste for the department,” he explained.

Reed also organizes chemicals for disposal and storage, labeling containers and positioning them so that oxidizers are not near flammables, for example.

He aids students who must fill out safety documents for projects, including one that involved taking samples to the Cal Poly Pier to see how the materials corroded in seawater.

Because he is a student, Reed said his peers feel comfortable texting or calling him with their questions. He welcomes those queries because they may prevent someone from taking an unsafe action.

The more responsibility Reed has taken on, the more faculty have come to rely on him, which he also appreciates.

“I’ve had the chance to build relationships with faculty and, also, build my own confidence coordinating people,” he added.

Reed is on track to graduate in 2024 to pursue a career in corrosion, but not before he passes down his hard-earned knowledge to a new safety technician as is the practice in the MATE Department. n

When Cindy Shurtleff started studying metallurgical engineering at Cal Poly, she joined a tight-knit group of aspiring engineers and supportive professors who have stayed connected for close to 50 years.

Shurtleff was admitted to Cal Poly in 1975, transferred from chemistry to engineering and became the first female to graduate from the Metallurgical Engineering Department — now called Materials Engineering — in 1980.

The Washington state resident looks back at the years she was cheered by faculty members invested in her success and classmates with whom she forged lifelong friendships as a critical juncture on her road to a life of adventure.

“Cal Poly Engineering was there at a formative time of my life and helped me become the adult that I am — an independent woman,” she said. “I could go back to campus any time and be welcomed back. It feels like home.”

To ensure the concept of “family” stays at the heart of the Materials Engineering Department, Shurtleff recently donated $1 million to the department’s discretionary fund for projects and people that can positively shape students the way she was.

“The impact of Cindy’s gift is profound,” said department Chair Trevor Harding. “It provides the resources needed to sustain the family-like atmosphere in MATE through social events, the R.C. Wiley Plaza and book clubs. It also helps us to keep our laboratories up to date, which impacts all MATE students, current and future.”

Shurtleff, then Garretson, paints a picture of her time in the fledgling Metallurgical Engineering Department, where a small number of students took classes in an old weld shop – a building and experience they claimed as their own.

“We were together the whole time. We went to the same classes, socialized together and all bought motorcycles,” said Shurtleff, adding she cruised around campus on her own 50cc motorcycle. “It was like joining a fraternity.”

Professors were committed to helping students learn the science of metals and become well-balanced engineers, Shurtleff said, with one even giving his senior-level spelling tests to teach them the terminology of their industry.

“When you have professors watching you and showing they care about you, that makes you want to do your best,” Shurtleff said.

Shurtleff had nine job offers upon graduating, ultimately accepting a position as a metallurgical engineer at Raychem Corp., one of the world’s largest producers of industrial electronics components, serving industries including aerospace, automotive, consumer electronics and medical.

Along the way, Shurtleff obtained a master’s degree at Stanford University and moved into product marketing, continuing her work in the field after moving to Seattle with husband Rob, who had a long career with Microsoft Corp.

Shurtleff left the workforce to raise her two children, Kyle and Katie, and dove into volunteer work in her community, schools and nonprofit organizations including the Washington Women’s Foundation.

She also traveled the world, visiting 96 U.N. countries to gain a better understanding of global issues and taking her children on many trips and adventures.

“It’s important for them to understand their place in the world,” she explained.

To support MATE: Your donation to the Materials Engineering Department can make a big difference, too. Please consider making a gift HERE.

Shurtleff rejoined her classmates on campus last year for the department’s 60th anniversary celebration and dedication of a sculpture designed and constructed by Steve Patterson (‘80) with help from Bob Adams (‘81) to honor the department’s first chair – Richard C. Wiley.

The sculpture, “Atom Shifter,” was installed in the R.C. Wiley Memorial Plaza, outside the Brown Engineering Building, with new tables and chairs funded by Shurtleff and other alumni to give students a place to gather and build their own community.

Shurtleff’s $1 million donation, payable over 10 years, also has financed three book clubs for MATE students to discuss issues at the intersection of materials science and society; social events including a pumpkin carving for Halloween and MATEsgiving; an advanced 3D printer for composite materials; and renovations of the electron microscopy facility.

Additionally, the donation has covered travel expenses for Harding’s trip to the University of Birmingham, where he discussed possibilities for a study abroad program specific to materials engineering students so they wouldn’t have to spend extra time at Cal Poly before graduating.

“I wanted to make a large and meaningful gift to Cal Poly that allows the department to enhance the student experience both inside and outside the classroom,” Shurtleff said. “This gift can help students have a similar experience to the one I had.”

Harding said the discretionary nature of the donation gives the department flexibility to best use the funds.

Bolstering the department’s core was critical for Shurtleff, who said, “It’s easy to make grants or gifts to a project, but all departments need funding for their core business, and it’s hard to ask for that.”

Shurtleff has retired from full-time philanthropy but fills her days with myriad activities — hiking, helping a youth ski team near her home, advocating for land preservation, playing competitive squash,

learning Italian and, of course, traveling.

The self-professed speed demon still has a motorcycle – a Yamaha TW200 — but after a rib-breaking crash, she decided to stick to her electric mountain bike.

“I have a full, wonderful life,” she said. “I am where I am because Cal Poly gave me the confidence to be independent, and an engineering degree was the ticket to that independence. I did not waste my technical degree; I just used it in different ways.” n

“I have a full, wonderful life. I am where I am because Cal Poly gave me the confidence to be independent, and an engineering degree was the ticket to that independence.”

In the push for more sustainable, efficient ways to advance science and technology, materials engineering holds the key to creating new materials that can push development forward. Creating a new material starts with a problem and a question: How can we fix an existing issue, or how can we improve a solution that is already in place?

In Materials Engineering Professor Mohsen Kivy’s case, he decided to study high-entropy alloys, a class of multicomponent metallic alloys that are relatively new and have attracted interest due to their unique properties.

“I had a project that a few of our students were working on,” Kivy shared. “It was computational and experimental. They were doing simulations to predict results, then conducted the experiment to confirm their simulation results.”

Under the guidance and curiosity of Kivy, materials engineering students Ryan Thompson, Juan Palominos Jr., Matthew Kestenbaum and Lucy Hunter tested the crystallization of high-entropy alloys at different temperatures. Their goal was to discover a new alloy that would be stronger than traditional alloys.

The group used density functional theory (a quantum mechanical modeling) and the software package CALculation of PHAse Diagrams, or CALPHAD, to examine the crystal structure of the material.

“We wanted to see what kind of crystal structure the materials would form if we wanted to cast this alloy,” Kivy said. “Then we took it a step further — What if we changed the temperature? What kind of crystal structures would form at different temperatures?”

Thompson, Palominos Jr., Kestenbaum and Hunter comprised their research into a poster and presented the findings at the Materials Science & Technology (MS&T) Technical Meeting and Exhibition in Pittsburgh, Pennsylvania, last October.

The former second- and third-year undergraduate students shared their research among their peers of graduate students and Ph.D. candidates.

“The students did a great job presenting their poster,” Kivy shared. “It resulted in a lot of consultation and collaborations, some of which are ongoing.”

But the work didn’t stop there.

“We continued that project with the same students and published in a journal explaining our discoveries,” Kivy said.

The article, Experimental and Computational Study of Microstructure of Al2FeCoNiCu High-Entropy Alloy, was published this year in the Journal of Phase Equilibria and Diffusion.

In addition to his research on alloys, Kivy is also focusing on a way to prolong the shelf life of food products and reduce the amount of carbon dioxide put into the atmosphere. The process involves encapsulation of different compounds in metal-organic frameworks. Kivy and his colleagues have published three papers on the research. n

by Taylor Villanueva

by Taylor Villanueva

Building strong relationships among peers can be difficult, especially while balancing a heavy courseload, clubs and extracurriculars. To combat these potential challenges, lecturer Nicole JohnsonGlauch incorporates a range of events throughout the school year so materials engineering students can feel connected to their classmates.

“I have hosted board game nights, a book club every quarter, pumpkin carving for Halloween, MATEsgiving (Thanksgiving for the MATE Department) and even a game of “Dungeons and Dragons” for the students,” she shared. “I’m also doing professional development events, like resume and cover letter workshops.”

The events provide ample opportunities for students to connect with their classmates who are going through, or have completed, the same coursework.

Senior Joselyn Hurtado is the president of Cal Poly’s Materials Engineering Student Society (MESS) and helps put on department events alongside the club’s officers.

“The event where I believe we bond the most and always have the most turnout is definitely MATEsgiving,” Hurtado said. “We bring food and eat together, hang out and have a movie playing in the background. It’s nice to connect with younger MATE students and see how they are doing, as well as share advice.”

The department events help foster a community environment for materials engineering students.

“We have really close relationships with our instructors,” said junior Marcus Hawley. “It’s easy to feel seen when your professors know who you are and have an understanding of your skillset and interests and can point you in the right direction.”

Johnson-Glauch attributes the camaraderie in the Materials Engineering Department as part of the reason she joined the department.

“I had a similar community feel when I was an undergraduate student and wanted to have that when I became a faculty member,” she explained.

Besides hosting a range of events, the Materials Engineering Department also provides designated gathering spaces.

“We have two department spaces open to students,” Hawley shared. “One is a classroom and the other is our student lounge.”

The dedicated spaces provide a place for students to study or socialize with their peers.

“Encouraging a sense of belonging has been shown to help students thrive academically, but I like to think that empowering students to form relationships with their peers will have benefits throughout their lives,” Johnson-Glauch said. n

One club in the College of Engineering is all about corrosion, and industry professionals couldn’t be happier.

“There are a lot of jobs in corrosion, and companies have a vested interest in making sure materials engineering students at Cal Poly graduate with a knowledge of corrosion,” said Kiran Lochun, president of the college’s Association for Materials Protection and Performance.

Cal Poly’s student chapter is one of the oldest in the worldwide organization, formerly known as the National Association of Corrosion Engineers. Members gather weekly, host experts in the field and undertake research projects, with a healthy budget that’s been bolstered by companies eager for data on corrosion control.

“Nearly all metals and some composites — including reinforced concrete, one of the most widely used materials in the world — undergo corrosion,” said Lochun, a fourth-year materials engineering major, noting companies spend colossal sums on maintenance and repair due to corrosion.

For the club, resources or faculty expertise is not the issue but, rather, the need for more students to pitch — and join — research projects.

“If you have a passion project having to do with corrosion or coatings, come see us,” Lochun said. “We are happy to have you.”

When Lochun took over as club president, the club had three members including him.

He said most members graduated last year and recruiting was complicated by the fact that the NACE chapter became AMPP after NACE International merged with the Society for Protective Coatings.

Once word started spreading in the MATE Department — and word

travels fast in a department where everyone knows your name — students started showing up and pitching their research projects. AMPP now has about two dozen members.

“We were definitely drifting toward the shore, but we are turning the ship around,” Lochun said.

The projects serve as an intermediate step between a MATE lab class and senior project, he added, and they offer students a chance to ask and explore open-ended questions.

“We start with a problem we need to investigate or solve, then research the literature and set up an experiment using MATE knowledge,” Lochun said. “We may not get the results we want on the first try, but as long as we learn from the process, it’s totally fine.

“Then we repeat, repeat, repeat … and hopefully we make a discovery in the end.”

The club’s three main projects focus on the impact of corrosion on stainless steel, aluminum and titanium, and nickel.

The first project, led by Joshua Venz, a fourth-year teaching assistant, looks at the long-term stress corrosion cracking of stainless steel.

The group of mainly first-year students is immersing the material in acid to watch the interaction.

“Stainless steel is a common material, and we want to see how long it will last without cracking,” said Lochun, who noted corroded steel pipes abound across the country, including one transporting hydrofluoric acid at a Philadelphia refinery that led to an explosion and fire in 2019.

Lochun hopes the team will publish a paper based on their findings as he believes the subject is insufficiently researched.

“There are not a lot of opportunities for MATE students to perform research, and I wanted this club to give space for people to do that work,” he added. “Regardless of what you do in materials engineering, you should have a basic understanding of corrosion.”

The second project, led by third-year student Jacob Reed, is supported by a California-based robotics company that specializes in building remotely operated underwater vehicles. The team of mainly second- and third-year students will test aluminum and titanium — metals used in the robots — in seawater to analyze the long-term effects.

Members hope to run the project over the summer at the Cal Poly Pier after machining a tank for the metals, but data won’t be available until at least six months.

The third endeavor — a passion project of third-year student Marcus Hawley — studies the corrosion of nickel-plated contacts in batteries. Lochun believes the team’s research will fill another gap that could come into play as batteries improve and last longer.

“I was surprised to learn during my education that there are large holes in knowledge that you would expect to be filled but aren’t,” said Lochun, who added AMPP aims to supply just those opportunities.

As Lochun prepares to leave Cal Poly and head for graduate school at Georgia Tech, he’s hopeful for the future of the club. He noted there are plenty of third-year students to keep the projects and momentum going, and he said the addition of Chemistry Professor Erik Sapper as a club adviser could pave the way for more chemistry majors to join.

“It’s been great to see the club grow this year,” said Lochun, adding he’ll check in on the club’s group chat from Georgia. n

“If you have a passion project having to do with corrosion or coatings, come see us. We are happy to have you.”Materials engineering senior Kiran Lochun is the president of the Association for Materials Protection and Performance. During his term, he has helped the club grow exponentially.