RFID REVOLUTION:

Transforming Textiles for Tomorrow

2024 PREPARED BY CALDERON TEXTILES JUNE 2024

Article | RFID in Textiles: Exploring Inventory Conversion

The article by Ammar Khan highlights the significant benefits and complexities of converting laundry operations to RFID technology, emphasizing the need for strategic planning to balance cost and efficiency gains.

Blog | RFID in Textiles: Exploring Inventory Conversion

This summary blog post discusses strategies for cost-effective implementation of RFID technology in laundry operations, focusing on in-house chipping, outsourcing, purchasing new, and a hybrid approach to enhance operational efficiency and ROI.

Explore the benefits of partnering with Calderon Textiles for your RFID product needs.

View our current RFID enabled product offerings and download our digital catalog.

Quick Facts: Inventory Conversion

Explore recent statistics on RFID conversion from our industrial laundry partners and access Ammar’s AlliantCon presentation on inventory conversion.

Jack Morgan’s article discusses the growing adoption of RFID technology in the linen and uniform service industry, highlighting its benefits for inventory control and service quality, despite the high costs and implementation challenges.

Unlocking Efficiency and Precision: The Advantages of RFID Chips in Commercial Laundry

Christy Perdue’s article highlights the transformative impact of RFID technology in the commercial laundry industry, emphasizing its role in enhancing operational efficiency, improving inventory management, and boosting customer satisfaction, with Calderon Textiles leading the transition to RFID-enabled textiles.

About Calderon Textiles

Learn a little more about what sets Calderon apart and dive into our RFID Journey over the past five years.

CONTENT

03

07 Flagwork Tagging

‘True Financial Analytics vs. Assumptions’

Comes of Age—

11

15 Calderon RFIDReady® Catalog

10 RFIDReady®

Calderon

with

9

14, 16

17

03

RFID in Textiles: Exploring Inventory Conversion

“In the evolving world of laundry operations, it’s clear that RFID technology is the driver that will allow businesses to streamline operations, ensure accuracy, more effectively bill and collect revenue transparently, and ultimately propel stronger and more viable companies.”

9

RFIDReady® with Calderon

Explore the benefits of partnering with Calderon & view our catalog of current RFID products.

15 Unlocking Efficiency and Precision

“At the heart of RFID technology lies its ability to automate and track.”

RFID In Textiles: Exploring Inventory Conversion

by Ammar Khan, CEO of Calderon Textiles | March 2024

As referenced by Jack Morgan in his August 2023 TRSA article “Flatwork Tagging Coming of Age,” the first wave of laundry operators to implement RFID-enabled operations have experienced significant cost reductions and efficiencies, specifically “significant savings on textile ordering, recovery of missing rental goods, fewer return trips by route service reps (RSRs), and reduced staff work related to shortages.”

However, converting a laundry to RFID-enabled operations is a tremendous undertaking. Strategies must be developed for addressing new processes within software/route accounting systems and laundry operations, sourcing of hardware chips, and inventory conversion. Assigning inventory to clients and billing the critical mass of products needed means a majority percentage of your stock must have RFID capability. If your goal is to have your inventory RFID-enabled ASAP,

the change will be expensive; the most cost-effective means will take both time and attrition. So, what are the considerations to developing your inventory conversion strategy?

Benefits of Converting Inventory to RFID-Enabled

The benefits of converting a laundry operation’s inventory to an RFID-enabled system are clear. RFID-enabled technology:

• ensures a dedicated inventory,

• efficiently details the correct quantity of product for weekly routes,

• enables the tracking of products and customers with the highest losses,

• supports transparency in product availability, thus enhancing customer satisfaction, and

• has the potential to streamline billing and revenue processes.

Converting Existing Products into RFID-Enabled Inventory

If you are planning to use RFID technology for one or more of the above reasons, you will need to transition your entire inventory to RFID-enable. There are three main approaches to consider. 1) You can self-install the necessary tags on products in-house. 2) You can outsource the installation of the tags of your current inventory. 3) You can replace current inventory as they age out with products that are already RFID-enabled. Each method has its pros and cons. Let’s take a deeper look at each of the three options.

Self-installing the tags in-house involves using your staff to complete the task. Typically, laundry operations start by tagging garments, mats, and then inventory items from most to least expensive (e.g., table linen to sheets).

On the plus side, self-installation offers flexibility, convenience, speed, and is

3 | RFID REVOLUTION Calderon Textiles

As you embark on the RFID journey, it is essential to have a strategy - to weigh the pros and cons of each approach, and to choose a path that best aligns with your operational goals and financial considerations.

RFID REVOLUTION Calderon Textiles | 4

more cost-effective than immediately replacing your entire inventory with RFID-pre-tagged items. In terms of flexibility and convenience, staff could be assigned tagging duties during downtime, working on available items and not disrupting rotating operational needs. Once you purchase the sewing equipment and train your staff, you can utilize them to begin tagging. This training helps to build competency for when product maintenance is required and ensures all circulating inventory is tagged and retagged as and when needed.

There is a downside to self-installing the tags that touch on management issues, labor concerns, the need for up-front capital, and floor space. For extensive inventories, this can be an overwhelming project requiring skill, training, a learning curve for staff. Purchasing the necessary equipment can be expensive. Tagging each linen piece demands rigorous organization. Each RFID tag must be sewed into the product and assigned within the software program. Moreover, the maintenance and potential up-

grades of the system can be a continuing cost. Another major disadvantage to self-installation is that a dedicated space will be needed to accommodate the tagging process, especially if you are dealing with a large inventory. This can take up valuable real estate on your wash floor.

The second option, outsourcing the tag installation of your existing inventory, can get the job done quickly—generally within two to four weeks depending on the scope of the project and size of the inventory. Outsourcing can be more cost-effective in comparison to self-installation in that equipment investment is minimal; although freight costs should be factored in and will change the equation. As far as convenience goes, outsourcing can be a turnkey operation with no need to involve laundry staff or management.

A major downside to outsourcing tag installation is the complex planning needed to schedule available inventory for tagging without disrupting stock requirements.

The third option is to purchase products already RFID-enabled. Replacing inventory can be executed wholesale by obsoleting existing circulating items and changing over to new RFID-enabled products all at once. Or the process can be completed over time as items are discarded and replaced with RFID-enabled equivalent products.

Purchasing RFID-enabled inventory replacements over time is manageable and spreads the cost out incrementally. This makes it more cost-effective as compared to other tagging strategies. However, replacing inventory over time on an as-needed basis can be a longterm proposition. Given the seasonal nature of large table linen rentals, as well as product durability, restocking table linens on an as-needed basis could potentially take years to convert your entire existing inventory to the RFID management system.

If you are considering a wholesale replacement of existing inventory with RFID-enabled products, there is one method that will accelerate the process

5 | RFID REVOLUTION Calderon Textiles

and reduce the expensive venture—a Container Program. Using a container program to get your inventory RFIDtagged is more economical, but requires forecasting, based on anticipated replacements of inventory. Disadvantages include leadtimes for the inventory to arrive, forecasting accuracy, and large investment chunks; but it is a clever strategy when considering changing out large amounts of inventory.

A Hybrid Solution to Converting to RFID Inventory Management

The ideal solution to converting your laundry’s inventory management to an RFID-enabled system will naturally be one that aligns with your laundry’s objectives. What is your priority? Is it speed of conversion? Or cost considerations when initiating the RFID technology? Or a combination of startup speed and cost-effectiveness?

For a hybrid solution to converting to an RFID inventory management system, consider combining elements of the

three options. Here is one example:

• Quick table linen conversion, outsourced.

• In-house inventory modification for smaller items.

• New acquisitions for terry products.

Note that replacing current inventory with the more expensive RFID-enabled products can actually save you money. It can be more costly in the long run to have stock go untagged, even compared to the initial investment needed to tag existing inventory in-house or to outsource the project.

In Summary

In the evolving world of laundry operations, it is becoming clear that RFID technology is the driver that will allow businesses to streamline operations, ensure accuracy, and more effectively bill and collect revenue transparently, thus propelling a stronger and more viable company.

RFID conversions will require a strategy as it pertains to software/route accounting systems, laundry operations, sourcing of hardware chips and inventory. The investigation into inventory conversion approaches outlined above offer considerations based on individual needs, on inventory sizes, and on investment capability. Whether opting for self-installation, outsourcing, or considering a hybrid model, the goal is to achieve operational efficiency and maximize RFID investment.

As you embark on the RFID journey, weighing the pros and cons of each conversion approach will help you develop your strategy and choose the path that best aligns with your operational goals and financial considerations. The future of laundry operations is undeniably entwined with RFID technology, and making informed decisions now will set the stage for success in the years to come.

RFID REVOLUTION Calderon Textiles | 6

RFID In Textiles: Exploring Inventory Conversion BLOG

Investing in RFID Technology

You’ve seen the advantages of RFID in laundry operations and decided to invest in hardware, software, tags and more. The sooner the capabilities and benefits of RFID in laundry are harnessed, the sooner you’ll see a return on that investment. Today, we’ll discuss strategies to potentially mitigate costs and expedite the conversion of inventory to RFID.

Hardware: readers, antennas, portals

Software: Alliant (or other systems)

Tags: and other related equipment

Benefits of Converting Inventory

• Ensuring dedicated inventory

• Producing the right quantity of product for weekly routes efficiently

• Tracking products/customers with the highest loss

• Maintaining transparency in product availability and enhancing customer satisfaction

• Streamlining billing and revenue processes

Whether you’re considering using RFID technology for any of these reasons, you’ll need to transition your non-RFID inventory to RFID-enabled inventory. Typically, laundry operations start by tagging garments, mats, and then inventory items from most to least expensive (table linen to sheets).

Converting existing products into RFID-Enabled inventory offers several approaches:

1. In-House Chipping

PROS

• Convenience: You can utilize current inventory.

• Flexibility: Flexibility in labor availability – staff can chip during downtime.

• Speed: It’s faster than waiting for the lifecycle of current inventory to conclude and then replacing.

• Cost: More cost-effective than replacing the entire inventory.

CONS

• Management: Chipping each linen piece demands rigorous organization. Each RFID tag must be accurately cataloged against the specific item it’s fixed to. For extensive inventories, this can be overwhelming.

• Labor: The method demands dedicated personnel trained in the technical and practical aspects of RFID chipping. This can be labor-intensive depending on inventory size.

• Capital: Purchasing the necessary equipment, including the RFID tags and the readers, can be expensive. Moreover, the maintenance and potential upgrades of the system can be a continuing cost.

• Floor Space: A dedicated space is required to carry out the chipping process, especially if you’re dealing with a large inventory. This can take up valuable real estate within your establishment.

7 | RFID REVOLUTION Calderon Textiles

2. Outsourcing PROS

• Speed: It’s a quick process, with a 2-4 week lead time.

• Cost: It’s cost-effective in comparison to selfinstallation.

• Convenience: It’s a turnkey operation. There’s no need for additional laundry staff or management.

CONS

• Cost: While this method is cost effective in comparison to self-installation, freight costs should be factored in.

• Management: Complex planning is essential to utilize the “available inventory” without disrupting stock requirements.

3. Purchasing New PROS

• Cost: The incremental cost is manageable.

• Management: Easier to oversee.

CONS

• Speed: It’s time-consuming to convert existing inventory. Given the cyclic nature of large table linen rentals and product durability, purchasing new table linen might mean it takes years to convert all existing inventory.

There is one method to accelerate RFID implementation in this case:

4. Container Programs

PROS

• Flexibility: Flexibility in labor availability – staff can chip during downtime.

• Convenience: You can utilize current inventory.

• Speed: It’s faster than waiting for the lifecycle of current inventory to conclude and then replacing.

• Cost: More cost-effective than replacing the entire inventory.

CONS

• Seasonal: Primarily beneficial when executed seasonally.

Hybrid Solution

The ideal solution aligns with your laundry objectives. What’s your priority?

• Speed

• Cost-effectiveness

Consider these combined options:

• Quick table linen conversion, outsourced.

• In-house inventory modification for smaller items.

• New acquisitions for terry products.

When considering the more expensive RFID-enabled products, it becomes more costly not to have items chipped than it would for the initial investment.

In the evolving world of laundry operations, it’s becoming clear that RFID-enabled textiles are the future of the industry. This technology allows businesses to streamline operations, ensure accuracy, and ultimately drive a stronger ROI.

The approaches I’ve outlined offer solutions based on individual needs based on inventory sizes and investment capability. Whether opting for self-installation, outsourcing, or considering a hybrid model, the goal is achieving operational efficiency and maximizing your investment.

RFID REVOLUTION Calderon Textiles | 8

WE MAKE IT SIMPLE.

We’re excited to offer RFIDReady™ products with pre-installed, incognito tags.

How is RFID technology changing the industry?

LAUNDER EFFICIENTLY

Reduce manual sorting with software that directs laundry to the appropriate area or machine.

OPTIMIZE INVENTORY

Streamline operations, maintain stock availability, and eliminate excess with accurate inventory counts.

PREDICT SERVICE LIFE

Find out how long your textiles last and improve forecasting with reliable wash count data.

PREVENT LOSS

Reduce the number of lost or stolen textiles by quickly pinpointing the source of discrepancy.

Our Loyal Customers

Mark Rawlinson New System

Mark Rawlinson New System

Andrew Thornbury Miller’s Textile Services

Frank Gagne Crown Linen Service

Andrew Thornbury Miller’s Textile Services

Frank Gagne Crown Linen Service

GENERATE REPORTS

Analyze reports to learn more about your products and how customers interact with them.

SCAN TO LEARN MORE & VIEW OUR DIGITAL RFIDREADY ™ CATALOG.

9 | RFID REVOLUTION Calderon Textiles

Our RFIDReady™ Products

Prisma® Self-Tie Apron

Prisma® Pencil Pocket Apron

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

Prisma® Table Cloth

100% Spun Polyester 30x34” White, Black, Navy

100% Spun Polyester 30x34” White, Black, Navy, Red, Royal Blue, Forest Green

100% Spun Polyester 90” Round White, Black, Ivory

100% Spun Polyester 120” Round White, Black, Ivory

100% Spun Polyester 132” Round White, Black, Ivory

100% Spun Polyester 42” Square White

100% Spun Polyester 52” Square White, Ivory

100% Spun Polyester 62” Square White, Black, Ivory

100% Spun Polyester 72” Square White, Ivory

100% Spun Polyester 85” Square White, Black, Ivory

100% Spun Polyester 90” Square White, Black, Ivory

100% Spun Polyester 52x96” White, Black, Ivory

100% Spun Polyester

Prisma® Table Cloth 100% Spun Polyester

White, Black, Ivory

White, Black, Ivory

Prisma® Table Cloth 100% Spun Polyester 90x132” White, Black, Ivory

Prisma® Table Cloth 100% Spun Polyester

White, Black, Ivory

RFID REVOLUTION Calderon Textiles | 10

Product Fiber Content Size Color

52x72”

52x114”

90x156”

Product Fiber Content Size Hem Color Item # ComfortWeave™ T-180 Pillowcase 55/45 Cotton/Polyester Standard White 20PRF-PC ComfortWeave™ T-180 Flat Sheet 60/40 Cotton/Polyester 54x81” Green 20PRF-5481-GH ComfortWeave™ T-180 Flat Sheet 60/40 Cotton/Polyester 66x115” Blue 20PRF-66115-BH ComfortWeave™ T-180 Flat Sheet 60/40 Cotton/Polyester 81x115” Red 20PRF-81115-RH ComfortWeave™ T-180 Flat Sheet 60/40 Cotton/Polyester 90x115” Yellow 20PRF-90115-YH ComfortWeave™ T-180 Flat Sheet 60/40 Cotton/Polyester 108x115” Brown 20PRF-108115-CH Product Fiber Content Size Color Item # Bariatric Patient Gown 55/45 Cotton/Polyester 84" Sweep Burgundy 702-PGBARIBURGRFID Endurance Robe 100% Spun Polyester 59" Sweep Blue 702ES-ROBEBLUERFID Patient Gown 55/45 Cotton/Polyester 60" Sweep Navy Blue Floral 702-PGTWLRFID Bath Blanket 80/20 Cotton/Polyester 70x90” Bleached 301-YUKONRFID Thermal Blanket 55/45 Cotton/Polyester 66x90” White 301W-THERRFID Product Fiber Content Size Color Item # Avalon Bath Towel 100% Cotton 27x54” White 1004-15AVALONRFID Avalon Hand Towel 100% Cotton 16x30” White 1013-4AVALONRFID Avalon Bath Mat 100% Cotton 22x34” White 1032-95AVALONRFID Everest Bath Towel 86/14 Cotton/Polyester 24x48” White 1002-8EVERRFID Everest Hand Towel 86/14 Cotton/Polyester 16x27” White 1012-3EVERRFID APRONS SHEETS TOWELS PATIENT GOWNS BATH BLANKETS TABLE LINENS

Flatwork Tagging Comes of Age— ‘True Financial Analytics vs. Assumptions’

by Jack Morgan, Textile Services | August 2023

As the linen, uniform and facility services industry grows ever-more competitive—especially with the national chains that can apply massive marketing muscle and economies of scale—deciding wheth- er or not to refit flatwork with radio frequency identification (RFID) tags is getting easier for laundry operators— particularly independents.

Tagging technology is hardly new. Datamars introduced its LaundryChipsTM in 1990. Textile Rental (renamed Textile Services in 2012) and Industrial Launder (IL) began featuring ads and articles on this garment-tracking technology in the early ’90s. Like any innovation, RF tracking has evolved. Today’s sys- tems are far more accurate than those of its infancy. Still, even though costs have fallen in relative terms, the tag- ging of either garments—or as is now increasingly popular, linens—is not a low-cost proposition.

Regardless, for operators such as Miller’s Textile Services Wapakoneta, OH, the debate over implementing RFID in flatwork is now settled. When asked if he’d consider ordering pre-tagged flatwork from vendors vs. installing them in-house, Miller’s COO Andrew Thornbury says such questions are inconsequential when compared with the

opportunity that RF technology offers to improve inventory control. “Affordable is a subjective term,” he says. “But ultimately I don’t believe that laundry operators can afford not to invest in RFID tagging.”

Savings & Service Gains

Several operators we contacted that have implemented RFID tracking cited significant savings on textile ordering, recovery of missing rental goods, fewer return trips by route service reps (RSRs) and reduced staff work related to shortages. However, the improvements in service, including the routine fulfillment of 100% of every order, were also important to winning over laundry operators to RF technology.

As with any tech initiative, RSRs, plant staff and clients encounter a learning curve with RFID at first. “As far as challenges, training of our route service team and then our customer base was by far the biggest obstacle we faced,” says Operations Manager Riley Hill Taylor, Taylor Linen Services, Andalusia, AL. “We had to prove ourselves, and by that, I mean that we had to prove that the system does work and will improve our service and reduce undue expenses for our customers. Our RSRs couldn’t believe the amount of linen being re-

turned—they were so used to trying to deliver 100% of par, that when the RFID counts were only recording 80% of that par, the RSR couldn’t believe that we had been trying to fill needs that weren’t there. I will say, after they started getting 100% of what was need- ed and were no longer bringing unused linen back with them—and no longer having to make ‘run-backs’ to get the remainder of the order delivered—the RSRs and service managers couldn’t help but embrace this new way of life!”

For Taylor and other laundry executives we interviewed, the savings alluded to above make tagging flatwork a win-win both financially and in terms of service improvements. When we asked Taylor about the impact on both revenue and service of RFID tag- ging of flatwork he answers, “Huge!” adding that “Comparing YTD 2023 to the same period prior to having all flatwork RFID tagged—a 15% increase in revenue— our cost of new linen has been reduced from 11.2% to 6.7% and the overall cost of new products has been reduced from 14% to 9.9%! And while (textile) loss seemed to pose a challenge—in fact it was unused and ‘uninvoiced’ linen recovery that Taylor Linen needed to correct,” he says.

Most of the laundry operators that have

11 | RFID REVOLUTION Calderon Textiles

applied RFID to flatwork are scanning goods in the soil area as well as outgoing clean goods. The technology gives plant and route staff a clearer picture of where their textiles are and which ones haven’t come back from customer locations. In essence, adding RFID to flatwork has enhanced these laundries’ credibility, as well as customer confidence that they won’t run out of linens.

This, in turn, has helped reduce the hoarding of textiles, while at the same time improving customer satisfaction, says General Manager Rick Snyder of U.S. Linen & Uniform, Richland, WA. “RFID has had a huge impact on reducing losses and managing inventory,” he says. “We now know exactly how many items a customer has. When they don’t return the inventory on time, they get billed rent until the inventory is returned.” Snyder emphasizes that the point of the RF tagging isn’t to punish customers, but rather to add transparency to the linen-supply process. “We make all our decisions based on how it is going to benefit the customer,” he says. “In the long run, (RF tagging) will help customer satisfaction, as we will have more product available. Now that customers are ordering in line with their usage and not hoarding our prod- uct, we have more product available.”

Customers are also now more inclined to accept the RSR’s assurances that they’ll have enough linen to meet their needs. “The RFID has also given us a lot of credibility with our customers,” Snyder says. “We have had many customers call us up after getting charged rent for unreturned products. Practically every customer said they returned everything. When we would ask them to look for our product, they would always find the unreturned items.” While billing customers for missing linen en- tailed some risk of client pushback, the added transparency of RF tagging helped customers understand the process. “In the past, I think customers took our product for granted,” Snyder says. “Now that they are charged when they don’t return the product, they have more respect for it.”

Next Up, Napkins

Until recently, most operators who have adopted RF systems have done so with garments or mats, rather than flatwork. The reasons they cite is that it’s harder to get ROI on an RF tag that’s inserted into an item that’s of limited value, such as a washcloth. Other flatwork, such as bar mops aren’t expected to last more than about 20 washes, and you may or may not be able to recover

the tag before the item is lost or ragged out. The rationale is different for highend tabletops or sheets that are expected to deliver more rental value, along with a longer service life.

Somewhere in this thought process came the idea of tagging reusable napkins. Few companies have taken this step, noting that most napkins are a rel- atively low-cost item that may not de- liver ROI through tagging. However, this resistance appears to be waning, as several operators we spoke with are ei- ther considering tagging napkins or are already doing so. Brad Dudley, CEO/ President Servall Linen Supply, Rapid City, SD, is now in the process of up- grading his rental garments and mats from high-frequency tags to faster, more accurate ultra-high-frequency tags. Once that project is complete, the next goal is to tag virtually all his flatwork items, including napkins. Supply-chain issues with the tagging-upgrade process has slowed the move to tag flatwork, but that’s only a temporary delay, he says. “Servall does have plans to move forward with UHF chips on linen, but due to supply issues with scanners, we have not been able to move forward as originally planned,” says Dudley, “We are currently working on converting our HF RFID chipped garments and mats with the new UHF

RFID REVOLUTION Calderon Textiles | 12

chips. Once we have completed that, we will re-fo- cus on chipping linens. All new linen and dust-control purchases are being ordered with chips installed, which in- clude napkins, tablecloths, aprons, bath & hand towels, sheets & pillowcases, mats and dust mops.”

Dudley believes that the principle of enhanced accountability to rental customers that comes with tagging garments and especially mats, will apply equally well to the rental flatwork that Servall provides to its customers. “The ROI on linens should be very similar to mats,” he says. “When linen is delivered, the UHF ID is assigned to the customer. If the customer has inventory in excess of needs, they will be advised that charges for the inventory will be made; however, they have the option to return the excess linen to avoid inventory charges.” Dudley thinks it’s a matter of time before RF tagging becomes a standard for most laundries.

Somewhere in this thought process came the idea of tagging reusable napkins. Few companies have taken this step, noting that most napkins are a rel- atively low-cost item that may not de- liver ROI through tagging. However, this resistance appears to be waning, as several operators we spoke with are ei- ther considering tagging napkins or are already doing so. Brad Dudley, CEO/ President Servall Linen Supply, Rapid City, SD, is now in the process of up- grading his rental garments and

mats from high-frequency tags to faster, more accurate ultra-high-frequency tags. Once that project is complete, the next goal is to tag virtually all his flatwork items, including napkins. Supply-chain issues with the tagging-upgrade process has slowed the move to tag flatwork, but that’s only a temporary delay, he says. “Servall does have plans to move forward with UHF chips on linen, but due to supply issues with scanners, we have not been able to move forward as originally planned,” says Dudley, “We are currently working on converting our HF RFID chipped garments and mats with the new UHF chips. Once we have completed that, we will re-fo- cus on chipping linens. All new linen and dust-control purchases are being ordered with chips installed, which in- clude napkins, tablecloths, aprons, bath & hand towels, sheets & pillowcases, mats and dust mops.”

Dudley believes that the principle of enhanced accountability to rental customers that comes with tagging garments and especially mats, will apply equally well to the rental flatwork that Servall provides to its customers. “The ROI on linens should be very similar to mats,” he says. “When linen is delivered, the UHF ID is assigned to the customer. If the customer has inventory in excess of needs, they will be advised that charges for the inventory will be made; however, they have the option to return the excess linen to avoid inven-

tory charges.” Dudley thinks it’s a matter of time before RF tagging becomes a standard for most laundries.

Another operator, Preston McElheney, president, Halifax Linen Service, Roanoke Rapids, NC, was among the early adopters of RF technology for aprons and other food and beverage (F&B), healthcare and hospitality items. The company is currently testing a tagged napkin stockkeeping unit (SKU) to determine the feasibility of tagging these items. “We placed 125,000 napkins in rotation with RF (tags) embedded,” he says. “We are six months into eval- uating and a breakeven will not occur until 2024 on this SKU. I have always heard a napkin is a loss leader. I think we are simply validating this statement, but we will fully vet this test before re- verting back to non-RFID. To date, we have no SKU where we embedded RF and then reversed that decision, and we are in our 19th year of this adventure!”

Meanwhile, Halifax has gone two full years and 152-plus days with no shortages to customers. McElheney credits his staff for getting behind RFID as a way to deliver a better linen-rental program for both the company and its customers. He adds that the company’s first 17 years of working with RF tagging mainly were dedicated to “dialing in the programs,” Now the focus of the past 24 months has shifted to extracting and analyzing linen-use data. We currently have 3,496,586 RF chips in total rotation,” he says. “Of these, 756,652 have been ‘lost’ and not returned (no longer generating revenue).” He adds that Halifax has 1.4 million RF tags currently distributed to various customers. “I say this as we are very close to understanding the true consumption of textiles by customer/SKU. Given this, we also know the cost to produce and deliver, so we can create scenarios of win/win for our customer base and company by using true financial analytics vs. assumptions.”

To Tag or Not to Tag...

For operators considering a move to inserting RFID tags in flatwork, in- cluding napkins, you should weigh the issues associated with taking this step.

A primary concern is the cost of tags.

13 | RFID REVOLUTION Calderon Textiles

Starting the process gradually can help. Taylor says his company started with tagging mats and expanded to linens. “The initial investment has paid for it- self time and time again.”

Another concern is that if you get untagged linens from a competitor, this can throw off the tracking effort. Snyder says that with a high-volume item like napkins, you could easily end up with 100-200 untagged napkins each week. He says technology should provide a fix at some point. “The only real solution I see is to have an RFID reader somewhere on the flatwork ironer or towel-bagging machine that would check for an RFID chip, and if it didn’t find one then it diverts the item.”

Beyond any ROI based on fewer linen losses and added revenue from textiles that customers previously had hoarded, is implementing RFID a worthwhile investment? One area that’s hard to quantify is the improved customer sat- isfaction that comes from better ser- vice. That said, operators should ana- lyze the costs. “Adding an RFID tag to a napkin would increase the cost by about 50%” Snyder says. “Since napkins last a long time, if it was feasible, I would make that investment. I think the accountability outweighs the cost in the long run.” Thornbury compares the emergence of RFID tracking to other groundbreaking developments in the linen-supply industry. “Just like the transition from 100% cotton to 100% polyester items, RFID tags are a step in continuous improvement,” he says. “One of Miller’s core values is innova- tion, which often means looking for opportunities to work smarter, not harder. For those who share this desire, tagging linens will become the stan- dard. However, this takes a lot of effort, money, time, patience and communi- cation. For those reasons, I think it will take most companies longer to get there successfully.” TS

JACK MORGAN is senior editor of Textile Services. Contact him at 877.770.9274 or jmorgan@trsa.org.

Morgan, J. (2023, August). Flatwork Tagging Comes of Age— ‘True Financial Analytics vs. Assumptions’. Textile Services.

INCREASED nearly 50% REDUCED Labor by 22% DECREASED Purchases nearly 50% RFID In Textile s ADDITIONAL SAVINGS DEPARTMEN T LABOR Soilroom Loading Shuttle Delivery WEAR & TEAR Equipment Merchandise WASHROOM COSTS Chemicals Water Energy

RFID REVOLUTION Calderon Textiles | 14

Unlocking Efficiency and Precision: The Advantages of RFID Chips in Commercial Laundry

By Christy Perdue, Calderon Textiles | March 2024

In the ever evolving commercial laundry industry, efficiency and precision are paramount. The integration of Radio Frequency Identification (RFID) technology has emerged as a transformative solution, revolutionizing operations and enhancing customer satisfaction. With RFID chips, commercial laundries have unlocked a plethora of benefits, propelling them into a new era of streamlined processes and optimized workflows.

At the heart of RFID technology lies its ability to automate and track. Unlike traditional barcode systems, RFID chips do not require line-of-sight scanning, enabling seamless identification and monitoring throughout the laundering process. This eliminates the need for manual handling, reducing labor costs and minimizing the risk of errors or misplacement, a win-win for laundries and their customers.

One of the primary advantages of RFID chips in commercial laundry is enhanced inventory management. Each piece of linen or textile item embedded with an RFID chip becomes a unique, identifiable asset within the system. This enables precise tracking of items from intake to distribution, mitigating the risk of loss. Laundry facilities can effortlessly monitor stock levels, track usage patterns, and optimize replen-

ishment cycles, ensuring that they maintain sufficient inventory without overstocking.

RFID technology also facilitates real-time visibility and transparency across the laundry chain. Laundry managers can monitor the status and location of each item as it progresses through various stages, including sorting, washing, drying, and folding. This insight allows for proactive decision-making, enabling operators to allocate resources efficiently, prioritize urgent orders, and minimize bottlenecks.

In addition to operational efficiency, RFID chips also contribute to quality control and customer satisfaction. By embedding RFID tags into textiles, laundries can capture crucial data points such as wash cycles, temperatures, and handling instructions. This information ensures compliance with industry standards and customer preferences, guaranteeing consistent quality and prolonging the lifespan of textiles.

The adoption of RFID chips in the commercial laundry industry represents a paradigm shift towards efficiency, accuracy, and customer-centricity. By harnessing the power of RFID technology, laundry businesses can optimize their operations, minimize costs, and deliver

exceptional service. As the industry continues to evolve, RFID remains a cornerstone technology, driving innovation and differentiation in the competitive landscape.

Calderon Textiles, understanding the value of RFID technology and the increasing need for more efficient linen management, has taken the charge in this space. Calderon has facilitated the transition to RFID enabled inventory and lowered the barriers of entry by manufactured and inventoried textiles products to include RFID chips . If your company is interested in an RFID program, you can contact Calderon for additional information on how your facility will benefit from this technology, how to get started, and what we have to offer.

CHRISTY PERDUE is Director of Corporate Accounts at Calderon Textiles. Contact her at 513.267.6201 or cperdue@ calderontextiles.com.

15 | RFID REVOLUTION Calderon Textiles

RFID IN TEXTILES

VIEW

Learn about:

PURCHASING NEW INVENTORY

IN-HOUSE CHIPPING

OUTSOURCED CHIPPING

THE PRESENTATION EXPLORING INVENTORY CONVERSION

RFID REVOLUTION Calderon Textiles | 16

Founded in 1983 and headquartered in Indianapolis, IN, Calderon Textiles has established itself as a leader in the textile manufacturing industry. Over the past 40 years, we have dedicated ourselves to being a vital, profitable component of our customers’ supply chains through global sourcing, technological advancements, and customer-driven solutions.

Calderon is committed to sourcing the highest quality materials from our partner manufacturing facilities in Pakistan, China, Bangladesh, and India, while upholding our core values of Quality, Ethics, Safety, and Security throughout every stage of our operations. Our products undergo multiple checks during the supply chain process to ensure that our benchmarks, which exceed industry standards, are consistently met.

Our expertise in supply chain management is unparalleled. We manage the transportation of products from global manufacturing units to the U.S. market in an efficient and cost-effective manner. Our extensive distribution network covers the continental United

States with facilities in Indianapolis, Harrisburg, Houston, Jacksonville, and San Jose, enabling delivery within just two days.

Our inventory management system is robust, with over 400 individual items managed across 250,000 sq. ft. of space. We offer real-time tracking and reporting on key metrics such as stock availability, on-time shipping, and order accuracy, maintaining transparency with our customers at every step.

At Calderon, we see ourselves as more than just a supplier; we are a partner. Our team is deeply knowledgeable about our products and the industry, and is always ready to provide support, share valuable market insights, and deliver product application education. Our consultative sales approach and textile expertise are geared towards fostering long-term, mutually beneficial relationships.

As a responsible global citizen and fair employer, Calderon is committed to ethical practices and continuous improvement. Our unique selling propo-

sitions—Cost Effectiveness, Quickness, and Reliability—ensure that we not only meet but exceed the expectations of our clients and stakeholders.

Looking ahead, Calderon Textiles will continue to focus on building long-term partnerships by earning trust, guaranteeing satisfaction with our high-quality products and services, and proactively offering value-added services. Our commitment to providing the best service and products at competitive prices ensures that Calderon remains a leader in the textile industry.

We create longterm partnerships with our customers and supplier base.

17 | RFID REVOLUTION Calderon Textiles

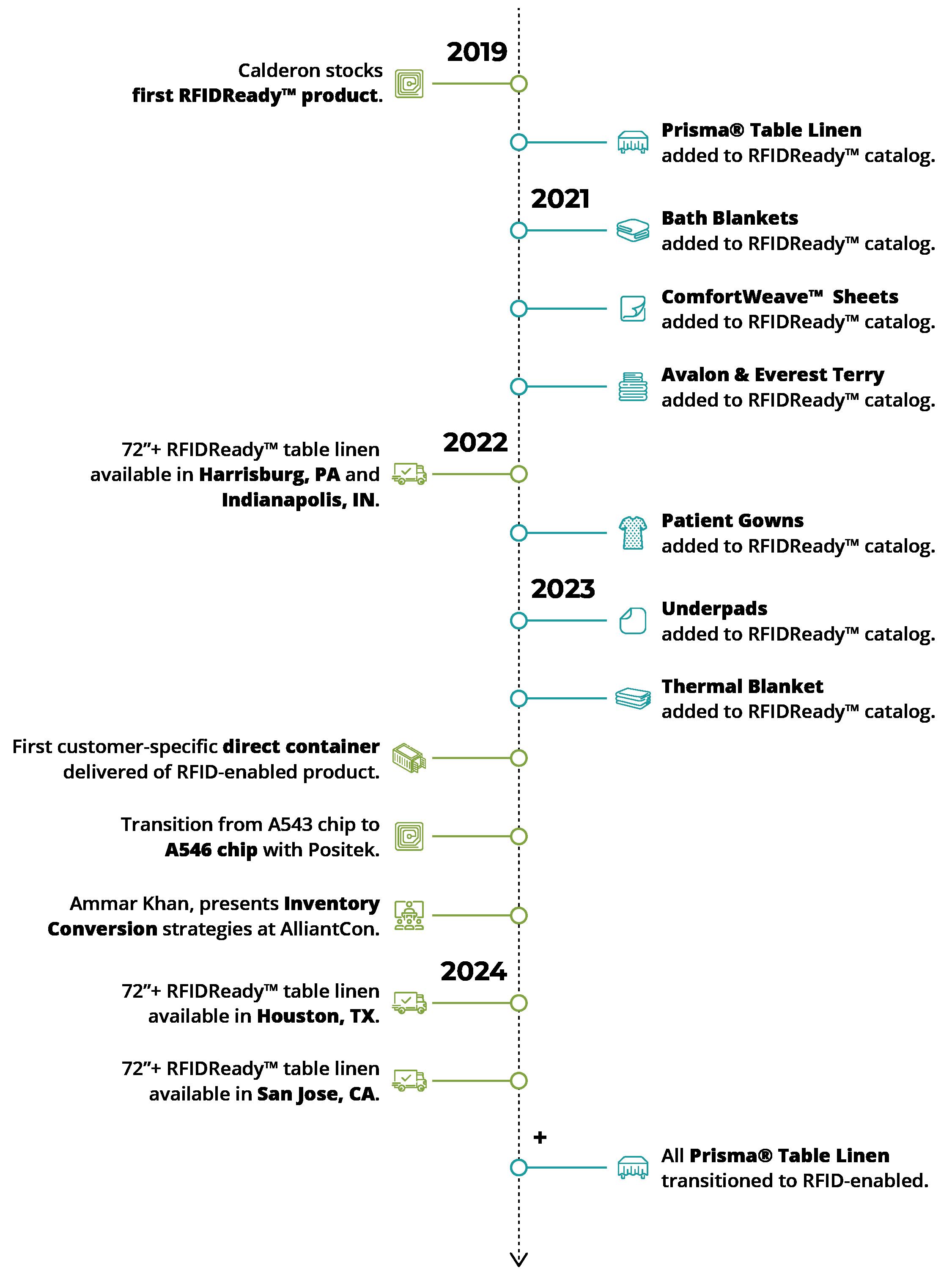

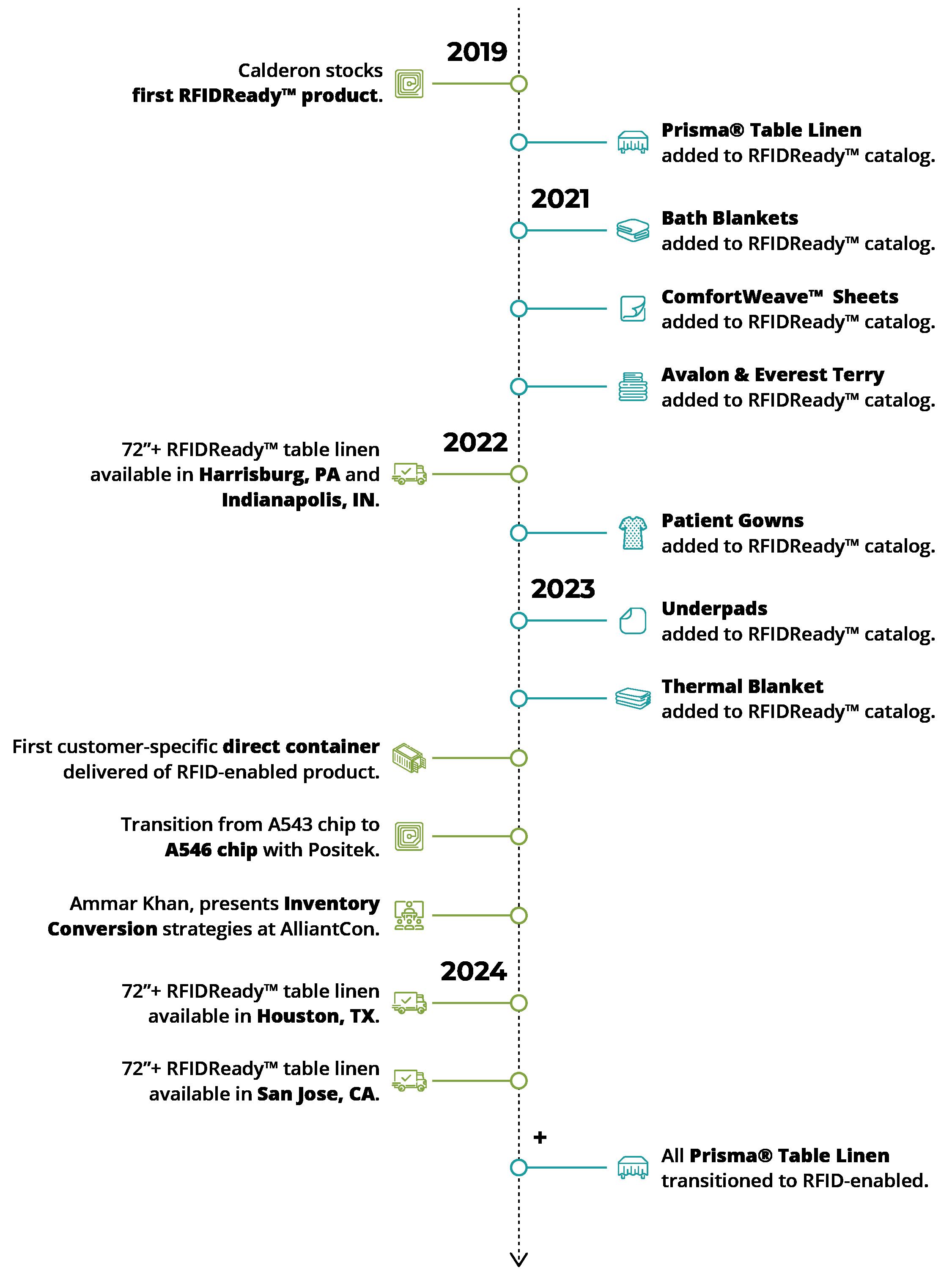

Our RFID Journey

Want to learn more about Calderon?

Reach out to us today to find out how Calderon can assist you with transition to RFID-enabled textiles.

RFID REVOLUTION Calderon Textiles | 18

COAST-TO-COAST DISTRIBUTION NETWORK 6131 W 80 th Street Indianapolis, IN 46278 800.252.1986 www.calderontextiles.com PREPARED BY CALDERON TEXTILES JUNE 2024

the digital version of RFID Revolution: Transforming Textiles for Tomorrow

Scan, Download, & Share

Mark Rawlinson New System

Mark Rawlinson New System

Andrew Thornbury Miller’s Textile Services

Frank Gagne Crown Linen Service

Andrew Thornbury Miller’s Textile Services

Frank Gagne Crown Linen Service